Employees of the Institute of Window Technology in Rosenheim (Germany) believe that all wood used for the manufacture of window frames can be assessed only according to two criteria: resistance to external factors and resistance to warping.

But in fact, there are many more of these parameters and they all affect the service life of wooden windows.

How to choose the right wood for window frames so that it does not lose its properties over time?

Features of modern wooden structures

The great popularity of wooden window blocks is due not only to the aesthetic properties of the material, but also to better performance properties compared to metal-plastic profiles.

Wood, as is known, has been a valuable building material since ancient times. Its strength and relative ease of processing made it possible to create window structures of any complexity - from simple fixed windows to multi-casement and rotary systems. Today, wood processing technology makes it possible to make window frames from both solid wood and laminated timber.

Windows made from natural solid wood are more highly valued because all frames are made from solid wood. But products made from laminated veneer lumber are cheaper - all structures are a set of boards glued together into one array.

In both cases, the source material undergoes multi-level processing from drying to stabilization under pressure, which is why the service life of such windows is 45-50 years.

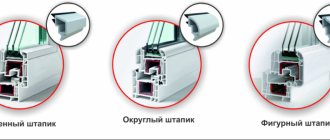

As for glass, just like in plastic structures, they are a sealed glass unit with a set of seals. They are mounted in the frame in the same way as in a plastic profile - using a sealing rubber band and then secured with a clamping strip.

The only significant nuance of wooden frames is the technology of their installation. The greater mass of wood compared to plastic windows requires a different technology for fixing the structure in the opening, and also, unlike plastic, solid wood requires the installation of a waterproofing barrier.

Window performance by wood species

There are a lot of wood species intended for making window frames. Their cost and quality depend on the area and delivery price.

Interesting. For wooden frames, you can use any type of wood, and for wood-aluminum frames - only those that have special physical and chemical properties.

In Russia, the most common species are larch, pine and oak (white, red) . Firstly, because there is a lot of this material, and secondly, its cost is quite reasonable and many can afford to buy it.

There are other high-quality wood species, for example, Siberian cedar, ash, merbau, spruce, afzelia, but the price for them is affordable for only a few.

Therefore, this article will only discuss the three most popular wood species and their characteristics.

Larch

This is a coniferous tree that has a more presentable appearance (especially a late tree) than pine , and in terms of characteristics it is not inferior to oak or ash.

It has a very rich dark or brown color.

Larch tolerates temperature changes and prolonged exposure to water well due to the presence of tannins and resins in it.

Its wood is elastic, strong and hard, and its strength is 30% greater than that of pine.

Its other features:

- Lifetime.

In nature, larch can live for about 600 years, and after felling and processing, its service life is over 100-120 years. The strength and durability of larch can be proven by the example of the window frames of the Winter Palace and the piles of the palazzo in Venice. Many years of contact with water and other external factors did not deform the wood, and the structure itself did not rot. - Window weight. Depends on the type of window, its size, brand of glass, weight of fittings, type of double-glazed window (single-chamber, double-chamber, etc.), the presence of absorbents.

- A three-leaf window with a width of 1800 mm and a height of 1500 mm, a sash thickness of 78 mm, a double-glazed unit with a thickness of 36 mm will weigh about 91 kg.

- A double-leaf window with a width of 1400 mm, a height of 1500 mm, a sash thickness of 78 mm, a double-glazed unit with a thickness of 36 mm, and a weight of 71 kg.

- A single-leaf window with a width of 700 mm, a height of 1300 mm, a sash thickness of 78 mm, a double-chamber glass unit with a thickness of 36 mm, weighs 32.2 kg. The same window, but solid, has a mass of 28.7 kg.

- A balcony block with a width of 1550 mm and a height of 2100 mm (with a balcony door width of 750 mm, a height of 2100 mm, with a window width of 800 mm and a height of 1300 mm), a sash thickness of 78 mm, with double-chamber glazing 36 mm thick will weigh 87.2 kg.

- Thermal conductivity. Heat transfer resistance at temperatures from -30°C to +40°C reaches 0.13 W/m×K.

- Dimensions. The most common dimensions of window structures are as follows: single-leaf - 700x1400 mm, double-leaf - 1400x1400 mm, three-leaf - 1750x1400 mm.

- Noise insulation – from 36 to 50 dB.

- Waterproof. Larch has a high level of water resistance. Wood does not swell or deform due to the influence of moisture, but, on the contrary, becomes harder, stronger and of better quality.

It is clearly shown that larch does not absorb water and does not swell:

More information about wooden larch windows here.

Pine

This is a coniferous wood that has a soft structure. Pine is easy to process and sand.

Important. It can be used to make window structures of any complexity, even carved ones.

Due to the high resin content, wood gives a fresh forest aroma indoors, and the substances released into the air have a healing effect for people with respiratory problems.

Its main indicators:

Life time.

With good care, a pine window frame will last over 70 years. During the entire period of operation, pine is not susceptible to deformation, shrinkage, torsion, or warping.Since pine is an easily absorbent species, if it is pre-treated with protective agents, it will last as long as possible.

- Structure weight. It is impossible to accurately estimate the weight of a pine wooden frame with or without double-glazed windows. It all depends on the factors listed above (subsection “Larch”, item “Window weight”).

But you can calculate the mass of a single-chamber double-glazed window (kg) using the formula: the number of glasses in this package × the height of the package × the width of the package × the thickness of each glass (mm) × the specific gravity of 1 m2 of glass (with a thickness of 1 mm).If there are several cameras in a double-glazed window, then their total mass can be calculated by adding up the weight of each camera, determined by the formula given above.

- Thermal conductivity – from 0.5 to 0.69 W/m×K.

- Dimensions. The most common dimensions of pine window structures are: single-leaf windows - 700x1400 mm, double-leaf windows - 1400x1400 mm, three-leaf windows - 1750x1400 mm.

- Noise insulation – from 37 to 49 dB.

- Waterproof. Pine contains a lot of resin substances, due to which it has water-repellent properties. Wooden structures made from this type of wood are often used in areas with a humid climate. Pine also has good air permeability, which contributes to high-quality air exchange in the room and the absence of the greenhouse effect.

Important. Pine is a fragile wood, so strong impacts and mechanical damage can leave dents or scratches on the surface of the window.

For a more detailed article on the topic of wooden pine windows, follow the link.

Oak

One of the strongest types of wood. The value of oak window frames lies in their durability, which is possible thanks to careful treatment of the wood with antiseptics, long-term drying, sanding, painting and varnishing.

Oak windows look very noble. They are used for installation in offices, living rooms and kitchens. Characteristics of oak :

Lifetime.

In nature, oak can live for about 1000 years, and products made from it last for several centuries. The peculiarity of this species is that oak can “age” beautifully. This means that the age of the product does not affect its appearance.The older the windows are, the more solid they look. The main thing is to properly care for them and carry out preventive measures annually.

- Structure weight. The exact weight of an oak window cannot be given, but it is clear that it will weigh more than a structure made of larch or pine.

- Thermal conductivity – 0.54-0.55 W/m×K. The width of the chamber in a double-glazed window affects thermal conductivity. The thicker the package, the less heat loss through the windows will be.

- Dimensions. The same as for window structures made of pine and larch.

- Noise insulation – 43-45 dB.

- Waterproof. Oak has high moisture resistance. Even after 10 years of constant exposure to moisture, rotten areas will not appear on the windows, and they will not become deformed. And due to the fact that the material has a porous structure, it has good air exchange, so there will never be musty air in the room.

Important. Oak windows can be single- or double-chamber, with 2 or 3 double-glazed windows.

Wooden window installation technology

The installation of wooden windows largely repeats the installation operations of metal-plastic and aluminum structures. This is especially evident during renovation work, when old windows are removed from the opening and new ones are inserted.

To obtain an optimal result, it is recommended to adhere to the general scheme of planning and carrying out work or the installation flow chart. Such TTKs are in many ways reminiscent of installation instructions, and many manufacturers include such maps in the documentation included with the design.

Do-it-yourself installation of wooden windows involves the following main stages of work:

- Dismantling the old window (if the premises are being renovated);

- The opening is cleaned of old plaster, sealant, and mortar build-up;

- A detailed measurement is made and the distance from the wall to the frame along the entire perimeter is calculated;

- The structure of the window unit is dismantled, as a result of which only the supporting frame should remain;

- Waterproofing is installed;

- Installation and preliminary fixation of the block is carried out;

- Alignment and final fixation are carried out;

- Finishing of slopes, window sills, ebbs and trims is carried out;

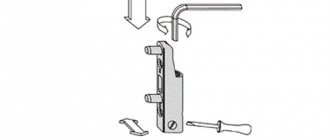

- The fittings are adjusted and additional accessories are installed.

Unlike a plastic profile, the weight of a 1 m2 wooden window ranges from 19 to 51 kg, depending on the thickness of the glass in the double-glazed windows and the type of material from which the frames are made. This factor is decisive in the difference in the installation technology of wooden and plastic windows.

Is it so important to know the parameters?

Statistics show that when choosing wood for windows, people are guided only by the opinions of their neighbors, their experience, or personal preferences. And only a few rely on the opinion of professionals. But in vain.

After all, the quality, service life of windows and their reliability directly depend on wood, and experts can point out the pros and cons of each type of wood, name its features and help with calculations .

Wood species such as oak, pine and larch belong to the middle class. And if necessary, it will be easier and cheaper to restore or replace them than if you use expensive wood. And knowing the features and characteristics of wooden windows, you can choose what suits a specific area, climatic conditions and interior.

In addition to the characteristics described above, it is worth paying attention to :

- Region where the tree grows .

For example, wood from Siberia is denser and higher quality than wood grown in central Russia. The growth rate of trees in the North is 2 times less than in other regions of the country. Thanks to this, the tree manages to acquire a complex structure and become stronger. And compacted wood has better water repellency and thermal conductivity, is less susceptible to shrinkage and drying out, and looks more aesthetically pleasing. - Type of cut . The processing method affects the service life of window frames. It is desirable that the material be sawn radially or semi-radially. Then the tree will have a high density, and the pattern of annual rings will be especially emphasized.

- Timber thickness . In the production of modern wooden windows, timber (three-layer, glued) is used. For the Russian climate, it is better to use timber with a thickness of at least 78 mm.

- Initial wood quality . For the production of window frames, wood with cracks, knots, or pockets with a high resin content should not be used. The finished surface must be smooth, have no differences at the joints or roughness, a layer of paint must be evenly applied over the entire area of the frame.

- Drying quality . It is impossible to personally control this stage, so you need to purchase wood only from trusted manufacturers and where they are always ready to provide certificates of conformity for the product.

- Method of splicing and gluing . Once the boards have been selected and processed, they can be joined first in length and then in thickness. To glue wood together, you need to use a special water-repellent glue, and position the boards themselves so that the fibers are in different directions. This will give the material additional strength.

- Number of chambers in double-glazed windows . For quiet, residential areas with a temperate climate, single-pane windows will be sufficient. For noisy areas with cold climates, double-glazed windows would be appropriate. And for the coldest regions and houses located in busy areas, three-chamber structures are suitable.

On a note. The more cameras, the greater the weight of the window and its thickness.

Technological map for installation of wooden window blocks

Professionals recommend starting to install a wooden window with your own hands only when the instructions have been fully studied and all operations are clear. A typical technological map allows you to understand all the intricacies of the work and, without being tied to a specific model, install windows, following the general technology of performing the work.

The TTK contains several sections in which the technological process of the installation is disclosed with a description of the necessary tools, the method of performing the work, and labor costs. Sections may be supplemented with additional information that you need to know and understand.

The technology of construction work using TTK regarding the replacement or installation of a wooden window unit includes several sections:

- General – it provides a description of the terms used in the map;

- Organization of work execution – contains subsections describing both general operations and individual processes;

- Requirements for the quality of work performed;

- Costs of material and technical resources;

- Safety regulations;

- Environmental protection and compliance with environmental requirements.

Typical technological maps can be supplemented with separate instructions on how to install a window unit in a brick house, concrete panel or frame-panel structure. Photos and videos of works can be used as supplements.

A typical flow chart for installing a window block made of solid rock may look like this:

Organization of work execution

| Stage of work execution | Contents of work | Time to complete | Materials and tools used |

| Preparatory stage | Carrying out measurements, determining the scope of preparatory work, calculating labor costs. Assessing the need to use additional tools and materials. Estimation of additional costs for labor protection | 1-1.5 hours 1 person | Roulette, level, calculator. |

| Main stage | Dismantling the old block | 1.5 hours 2 people | |

| Removing frames; Cutting lintels; Removing plaster from slopes; Dismantling the window sill, ebb, platbands; Removing cement deposits, removing debris | 1.5 hours 2 people | Tools: Hammer; Chain Saw; Scrap; Hammer; Construction hammer | |

Preparing the opening:

| 1 hour 1 person It will take 2-4 hours for the primer to dry | Spatula, cement, sand, dry plaster mixture 0.5 kg per 1 m2, deep penetration primer 0.4-0.9 l/m2 | |

| Preparing the structure for installation | |||

| Removing frames with double-glazed windows | 0.5 hour\1 person | Chisels, a set of tools for working with double-glazed windows | |

| Frame installation: | 1-1.5 hour | ||

| Preparing the frame for installation, installing a moisture barrier | 0.10 | Stapler, moisture-proof membrane, polyethylene film, bitumen mastic 0.2 kg.m2 | |

| Inserting a frame into a window opening; Preliminary fixation with wedges; | 0.1 hour | ||

| Vertical and horizontal alignment; | Wooden wedges, spacers. | ||

| Reliable fixation of the frame with wedges; | Metal plates, Laser or water level, rubber hammer | ||

| Fastening metal plates with dowels - it is necessary to secure the mounting plates to the dowels in the wall of the opening; | Dowels at the rate of 4 pcs. for 1 mounting plate | Hammer, hammer, pliers | |

| Sealing the opening cavities with polyurethane foam; | Operating time 0.5 hours. Foam polymerization time 2-4 hours | Polyurethane foam, foam gun | |

| Installation of double-glazed windows | 1-1.5 hour | Screwdrivers, chisels, | |

| Removing dust from the internal surfaces of the frame | 0.10 hour | Rags, brushes | |

| Removing foam build-up | 0.2 hour | Painting knife | |

| Installation of double-glazed windows, installation of opening frames. It is necessary to glaze blind sashes and hang opening ones on hinges. | 1 hour | Screwdriver, screwdriver, set of tools for installing double-glazed windows | |

| Installation of external window elements, finishing of the opening | 2-2.5 hours | ||

| Cleaning the opening from foam deposits | 0.2 hours | Painting knife, spatula | |

| Finishing external slopes (carried out before installing blind and hinged sashes): It is necessary to seal the cracks, apply a layer of external putty, and install platbands if necessary. | 2-3 hours | Drip profile, polyurethane foam, silicone sealant, self-tapping screws, putty for exterior use, | |

| Window sill installation | 1-1.5 hours | Window sill profile, foam, wedges or mounting plates | |

| Finishing slopes from the inside | 3.5-4 hours | Depending on the technology used for performing the work, finishing with sandwich panels or plaster mortar may be used. | |

| Final stage | Adjusting the sashes, installing a ventilation valve, installing blinds. During the operation, it is necessary not only to adjust the operation of the locking mechanism, but also to secure, if necessary, the design of the blinds. | 2-2.5 hours | Screwdriver, consumables for fastening devices |

SECTIONS OF DESIGN DOCUMENTATION CONTAINING INFORMATION ABOUT DISMANTLING WASTE GENERATED

Information about the dismantling waste generated at the designed facility is contained in the sections of the design documentation that provide for dismantling work. These may be the following sections[1]:

- "Master plan and transport";

- "Technological solutions";

- "Architectural and construction solutions";

- "Engineering equipment, networks and systems."

It should be noted that the section “Engineering equipment, networks and systems” consists of several subsections, which, as a rule, are developed by engineers of different specialties:

- “Power supply, power electrical equipment and electric lighting”;

- "Refrigeration";

- "Air supply";

- "Automation";

- "Communication and signaling";

- "Water supply and sewerage";

- “Heating, ventilation and air conditioning”;

- "Heating network";

- "Gas supply system";

- "Thermal power solutions".

Each of the listed subsections can provide information about waste generated as a result of dismantling work at the facility being designed.

Thus, information about generated waste can be contained in almost every section of the project documentation. To speed up the search for this information, the environmental designer can contact the Chief Project Engineer (hereinafter referred to as the Chief Engineer), who must know which sections of the project documentation provide for dismantling work and, as a result, waste generation.

Information about the materials generated during dismantling work (including their names, units of measurement and quantity) is given in the graphic parts of the above sections of the project documentation in the form of tables.

Thus, the necessary information can be found in the graphic part of the “Architectural and Construction Solutions” section on the “Dismantling Plan” sheet (Example 1).

Example 1

| Name | Qty | Unit change |

| Dismantling window blocks | 47 | PC. |

| Removing door blocks | 4 | PC. |

| Dismantling facade tiles | 274,86 | m2 |

| Dismantling concrete canopies | 28,88 | m2 |

In the graphic parts of the subsections of the section “Engineering equipment, networks and systems”, information about dismantled structures should be found, as a rule, on the “Bill of quantities” sheets. Example 2 shows the corresponding table in the subsection “Water supply and sewerage”.

Example 2

| No. | Name of works | Qty | Recyclable materials, scrap metal | Qty |

| 1 | Dismantling of pipelines made of steel pipes, no. 15–32, m | 133,5 | scrap metal, kg | 282 |

| 2 | Ball valve DN 15, pcs. | 55 | scrap metal | |

| 3 | Heated towel rail made of steel pipes no. 32, pcs. | 12 | scrap metal |

In the graphic part of the “Master Plan” section, information about the dismantled materials is contained on the sheet “Plan of dismantled coatings” (Example 3).

Example 3

| Name of works | Quantity |

| Dismantling of existing tiled footpaths with a thickness of 0.06 m, m2 | 560,0 |

| Removable coating made of fine-grained asphalt concrete 0.05 m thick, m2 | 1180,0 |

| Removable concrete side BR100.30.15, m.p. | 230,0 |

It should be noted that construction waste is generated not only during dismantling work, but also as a result of cutting down trees and shrubs. The volumes of felling are indicated on the sheets “Taxation Plan” and “Taxation Sheet” of the “General Plan” section: the trees and shrubs that grow on the land plot allocated for the location of the designed facility are listed here, indicating the number and names of trees to be preserved, replanted and removed, and shrubs, as well as their size, age, quality condition, species.

Adjusting wooden window units

The technical map of the main operations also indicates the quality control parameters of the work performed. When making adjustments, it is important not only to insert the glass correctly and secure it in the frame, but also to ensure that the recommended gaps between the glass unit and the frame are observed. In addition, when adjusting, the position of the locking device is set depending on the time of year. When installing a ventilation valve, be sure to check the presence of holes in the frame, external protective visors, and the strength of the valve fastening.

Weight of a wooden window block during dismantling

To comply with safety rules, the accompanying documentation for finished blocks indicates both the weight of a wooden window with glass m2 and the total gross weight of the entire structure. A double-glazed window made of hardwood weighs 20-25% more compared to the same size structure made of a plastic profile. The weight of a double glazing unit with a glass thickness of 4 mm weighs 22 kg, with a frame of 78 mm made of hardwood the weight will be 32 kg. Dismantling 1 m2 of such a structure, according to the technical specifications, will require 1-1.5 hours.