The ebb is the outer element of a plastic window in the form of a metal window sill. It is carefully mounted on construction foam and should hermetically protect the window sill area. Installing a low tide is an important step; it determines whether unnecessary moisture will enter the apartment or heat will be lost.

It often happens that the window is installed perfectly, but the sill itself is made a little poorly thought out or of poor quality. When it rains, the drops that fall at low tide make loud noises and splash around. Tides thunder when it rains if:

The metal strip of the ebb is made a little thinner than it should be due to the savings of the builders. The ebb is a little longer than expected and protrudes far beyond the edges of the window. This is a miscalculation of the architect or window installation company. The ebb is poorly secured and there is not enough mounting foam underneath; when struck, the ebb makes a loud sound. This is a poorly executed window installation job. There are no ebb tides or canopies on top, then the water flows in streams directly onto the window and ebb tide. In these cases, every rain occurs for the residents in a very nervous and tense environment. The loud roar of drops prevents you from falling asleep or going about your business. The window has to be closed tightly in order to somehow reduce the noise level in the apartment. The window itself gets splashed heavily.

If the tides thunder when it rains, what should you do? Solutions options:

Contact the company that installed the windows. If the warranty period has not passed, use an expert examination to find out the reason for the noisy behavior of the tides and force the installers to correct the defects. If the height of the window allows, you can independently try to understand the cause of the noise and eliminate it. All work should be carried out after ensuring your own safety. Try shaking the ebb to see if it is securely fastened. Fill the void underneath with foam.

When it rains, watch the drops at low tide and find out the noisiest place; more often than not, the entire low tide thunders due to water getting into a very small area. If the flashing is very long and this is the cause of the noise, try to cut off the outer edge from it.

Place or glue under the ebb any material that reduces noise and vibration - a piece of rubber or polyurethane, or coat it with durable mastic. Replace the ebb with a special plastic or polymer-coated one. This will significantly reduce the noise level.

It must be borne in mind that the ebb is not a decorative part, but a complex element of the window itself; you cannot replace it yourself. By contacting a company that installs PVC windows, you can solve the problem of rattling tides using the advice of experienced craftsmen.

Video on the topic: What to stick on the windowsill to stop the rain from knocking?

The rain is drumming. Soundproofing of the sill (window sill)!

Sound insulation of window drainage

What to do if the rain drums on the slopes?

Introduction

An integral part of the window block is the external ebb, which protects the installation seam from the street and gives the finished aesthetic appearance of the windows from the outside.

Since this part is made mainly of steel or aluminum, during rain, hail or melting snow, the sound of drops on the ebb can greatly disturb the residents of the house. The “sound of music” can be endless on dull autumn nights, and consequently interfere with sleep. How to deal with this? We hope this article will help you if you have this problem in your home.

Company advantages

- Freeze on the first day!

- We work 24/7

- 18 years of work

Still have questions? Leave a request and we will contact you shortly:

Listen to it without Gerden:

Ensuring low tide noise insulation during construction

First of all, to ensure that the ebb or visor does not make sounds during rain or strong gusts of wind, during the construction period the developer or installers installing window units must follow several rules, if correctly implemented, the sound insulation of the ebb will increase several times .

So, the first rule is to choose the right material thickness. Let us repeat that external drains are made mainly of steel or aluminum, and the resonating effect of the product made from them depends on the thickness of these materials. The thinner the steel (or aluminum), the greater the diaphragm effect the visor or shimmer has. And vice versa, the thicker and more massive the material, the greater its ability to both reflect and absorb sound waves.

Secondly, it is necessary to select the optimal width of the canvas, since it should not protrude too much from the wall of the house. The maximum permissible indentation of the decorative element in question is considered to be 2-3 centimeters, which, given the optimal area exposed to the effects of natural elements, reduces the noise level of this impact.

And finally, the most effective way to reduce noise from external drains or canopies is to use additional installation materials. These can be full-butyl tapes, which are glued to the back of the ebb (or the outer part of the canopy) and PSUL, which is glued in a strip to the slope, preventing the drumming effect of the ebb on the slope of the window block.

How to reduce noise from the street in an apartment?

Of course, high-quality plastic windows with more than three cameras are a prerequisite on the path to silence. But there are also other considerations...

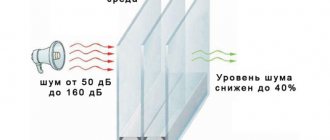

If the apartment room has a balcony or loggia, this already solves half the problem. Glazing a balcony/loggia helps to minimize noise almost completely, at least in a single room. The air cushion between the balcony windows and the room windows dampens sound vibrations.

Ideally, of course, you would need to create a vacuum between the layers of glass or windows, but this is not possible to do at home. If we remember physics, we know that sound travels faster in a dense medium. Sound does not travel in a vacuum. From this we can judge that if the air is cold, the molecules travel sound waves faster. It’s just that an air cushion with an ambient temperature higher than the outside temperature (in winter, for example) will transmit sound worse.

The same can be done with other rooms. Only on the other side - from the inside. As far as the window sill allows (the protrusion of the wall into the room from the standard installed frame), you can install a second window, and it does not have to be two or three chambers, it is important that it is dense. You will get the same “cushion” for sound dampening. The slopes inside (between the frames) can be finished with sound-absorbing materials.

Forest plantings provide excellent, albeit seasonal, sound insulation. Between our house and the railway, the distance is about a kilometer, you understand - trains are not luxury cars - the noise is terrible. When the house was built, two rows of poplar trees were planted in a checkerboard pattern, across the road from the house, between us and the railroad. In the summer, when the leaves bloom, you can hardly hear the iron, although in winter and especially in frosts, everything is exactly the same as it was, but we are grateful even for six months of peace.

Blinds on windows are also good sound insulation. They serve as another barrier to sound vibrations.

If you approach this issue comprehensively - internal soundproofing of walls, additional glazing with high-quality double-glazed windows, sound-absorbing wallpaper in the room, this will certainly give results.

Soundproofing low tide yourself

Let us repeat that the most effective method of suppressing noise from external drain elements is to apply butyl tape along the entire length of the installed drain. And, if it so happens that when installing window units in your home, the installers were not concerned about ensuring that the tide was silent, then you can fix this problem yourself. To do this, you need to purchase a special metallized full-butyl tape and glue it to the ebb and visor, if you have one.

The three- to four-millimeter butyl-rubber composition of the adhesive material will guarantee maximum protection from vibrations and noise transmission by the ebb, since its dense structure and heavy mass will block the cutting of the ebb in strong winds or from the impact of raindrops. And the foil coating will additionally provide thermal protection to the window unit if the back part of the ebb is covered with tape, or, conversely, will reflect direct sunlight if the outer part of the additional elements is glued.

Glazing selection

Balcony glazing protects from wind and prevents precipitation and dust from entering. By providing reliable thermal insulation, your home will be protected from the cold in winter. Glazing can be done independently. Successfully selected materials for glazing and knowledge of all the intricacies of the process itself are a guarantee of the quality of the work done. Windows from the Rehau Intelio profile will help ensure silence in the apartment, as they are one of the quietest.

Nowadays, balconies are glazed with the following materials:

- Wooden frames. They are very different in quality from traditional windows. They are more durable, resistant to moisture and are not afraid of fluctuations in air temperature due to the use of so-called laminated timber technology. Their service life is quite long, since they are coated with special protective materials. Wood is characterized by low thermal conductivity and excellent sound insulation properties;

- Metal-plastic frames are most often used in the production of windows. Such structures can last more than 40 years. They are resistant to corrosion and rotting. They do not require any additional processing or coating renewal. Thanks to the presence of drainage and micro-ventilation elements, the optimal air temperature is maintained in the room;

- Aluminum windows are very widely used on old balconies. Due to their light weight, they do not load the balcony structure. However, such material must be used with heat-insulating inserts to ensure comfort in the cold season;

- Frameless glazing. Such structures transmit light well and reliably protect from precipitation and wind. However, this option does not completely eliminate the noise, but only muffles it. The glass is attached to aluminum frames. The measurements must be as accurate as possible: any misalignment and the design will lose its functionality.

Low tide self-soundproofing technology

In order to independently provide the external decorative elements of the window with sound insulation, it is necessary to first dismantle the previously installed sills and canopies.

Next, the removed elements should be degreased so that the butyl rubber-based tapes can easily attach to their surface. Tapes, matched to the width of the ebb, are cut into strips of the required length and glued to the back side of the ebb and the outer side of the visor.

And finally, the elements treated in this way are attached back to the slopes using special polymer soundproofing dowels.

In the end, we can draw the following conclusion: if the developer, when installing windows, did not bother about soundproofing the external parts of the window structures of your house, and the sounds of beating drops or gusts of wind prevent you from sleeping peacefully, then this problem can be eliminated on your own or with the help of specialists, but with minimal financial costs.

If during bad weather you can hear the noise and rumble of the canopy from the balcony, and raindrops knocking on it interfere with sleep, then some action should be taken. Today we’ll talk about why the ebb tide begins to make noise, what methods can be used to fix the problem, and what materials will be required for this. .

A knock on the window sill. How to remove noise?

Guerlain is used for sealing interpanel joints in residential and industrial construction, in the aviation and automotive industries, and when installing roofs using polymer membranes. When using EPDM or EPDM membranes, the problem is the quality of the overlap. Special adhesives, if used at all, are very expensive. The use of 2-sided self-adhesive Guerlain tape, which has excellent adhesion to this type of membrane and durability of more than 25 years, helps solve this problem. Leaks in pitched roofs are the most common problem, especially in the spring. When installing new roofs made of sheet material (tin, copper, etc.) using Guerlen tape sealant, it eliminates the possibility of leaks in the roof structure. During emergency roof repairs, Guerlen-FA material, which has aluminum foil as a protective layer, is widely used. Guerlain was developed for sealing suspended ventilated facades, the service life of which is 50 years of operation in the average climate of Russia, which is confirmed by tests carried out by the Research Institute of Building Physics. In 2005, a system of sealing materials based on Guerlain was developed for the installation of window systems in accordance with GOST 30971-2002.

The reasons why the balcony roof or its canopy is noisy.

As a rule, a balcony canopy is nothing more than an ordinary piece of tin iron, which is given the desired shape and appearance by bending it. Its main function is to protect against the penetration of atmospheric precipitation. It is thanks to this that a full-fledged “drum” is obtained, and it is worth noting that the wider it is, the louder the sound will be. And this is due to the laws of physics and the propagation of sound waves.

* Oscillations and vibrations of the roofing material often occur due to wind blowing into existing cavities and cracks in the roof, as well as when the roof does not fit tightly against the wall of the balcony.

Sealing with polyurethane foam

The drip system must be attached with self-tapping screws to the frame and foam to the base. If the technology for installing additional elements is not followed, a gap will form between the metal and the brick. The lack and complete absence of sealant not only provides “drumming” when it rains, but also leads to freezing of the substitution profile.

By removing this void, you can significantly reduce the vibration level of the sheet and increase sound and heat insulation.

- The ebb is separated from the glass unit.

- The external window sill is filled with polyurethane foam.

- Before the foam begins to harden, the cast structure is returned to its place.

In addition to polyurethane foam, any roofing sealant will work.

Source

What to do if the canopy on the balcony rattles?

Typically, soundproofing a balcony is carried out together with other sets of work - glazing, insulation and sealing. You need to remember about issues related to the canopy at the very early stage of the above work, because otherwise you will either have to live with noise at the window, or call people to perform high-altitude work (which is quite expensive), or start the process of upgrading the balcony all over again. Here are the following tips with which in certain situations you can solve the problem: a radical, but not very simple solution is to completely replace the iron structure in favor of a plastic one, since this option completely eliminates any extraneous noise. If possible, you can cut the visor so that it does not stick out so much and, accordingly, has a smaller area without a frame.

Rain tests plastic windows

Warm spring days are just around the corner, which means it’s time to carry out large and small repairs of PVC windows or replace old wooden windows that have not justified themselves in winter with new plastic windows that are not afraid of rain, hail, thunder and lightning, as well as sleet, the portal reports WINDOWS MEDIA.

We usually associate rain outside the window with the sound of drops on the glass, streaks of water, hail on the window sill and fireworks of lightning strikes. It's nice to watch the “thunderstorm in early May” through the window, sitting in an easy chair.

However, this idyll of man and nature can be disrupted by a leaky plastic window in terms of moisture resistance, impact resistance and noise insulation.

Plastic windows that are not afraid of rain

Not only is the winter exam important for plastic windows, they must pass it with dignity all year round. The most pronounced detector of the quality of a window system in the spring-summer period, and especially in autumn, is a common natural phenomenon - rain.

There are quite a lot of parameters of a modern Euro-window that could adequately withstand rain.

The profile is important because it will determine whether the window is durable and will function properly. The sealing system will make the window airtight and prevent water from entering the house.

Very important characteristics are heat and sound insulation, with the help of which we find out whether a plastic window will protect the house from heat loss on a dank autumn day and the penetration of noise from lightning discharges in the spring.

It is also important to take into account wind resistance, water resistance and breathability - these parameters determine that even in the heaviest downpours and storms our apartment will be dry, warm and quiet.

PVC profile that is not afraid of rain

The profile system must, first of all, be resistant to any external loads, which is determined by the quality of the material, as well as the design of the profile. The main parameter characterizing a window profile is its class. The maximum possible is class A.

This means that the outer walls of the PVC profile have a thickness of 3-2.8 mm, and the width of the inner chamber is at least 5 mm. This design provides greater stability and durability, as well as greater protection against noise and temperature changes.

If you choose a high-quality window profile, you can avoid troubles associated with deformation of the profile, and therefore the PVC window itself.

It is important to first pay attention to whether the profile is made from 100% virgin materials, because this has a significant impact on the quality of the window.

More modern designs can contribute to resistance to rain - plastic-aluminum windows, which are a combination of PVC profile and aluminum lining. A combined window of this type will increase the potential resistance of the profile system to rain and hail.

Window seal that is not afraid of rain

The role of the window seal is to protect against moisture, reduce excessive air exchange and prevent the penetration of noise from the outside. No window can do without well-chosen seals. Therefore, when purchasing plastic windows, in addition to double-glazed windows and profile systems, you should also ask the seller about the type of seal that is used for the selected product.

If your house already has plastic windows, then in the spring before you start cleaning the windows, you should check the condition of the seal.

If it does not cause fears that the first spring rain will become a guest in the apartment, then it is enough to lubricate the seal with a special technical means. Otherwise, this important window element should be replaced.

Today the market offers a wide selection of seals that can not only be adapted to the climatic conditions of your region, but also enhance the aesthetics of a plastic window thanks to the color scheme.

Window fittings that are not afraid of rain

Window hardware systems are the elements of windows and doors that we mainly look at when we want to protect our home from burglary. Few customers are willing to look at solutions that guarantee protection from rain, although these are no less important than energy efficiency or ease of maintenance.

The fittings are made from metal alloys, so a very important aspect is its corrosion resistance.

Prolonged contact with water or working in conditions of high humidity with a low-quality product can lead to the appearance of rust, the consequences of which can be disastrous for the entire plastic window.

Therefore, it is necessary to purchase accessories from trusted brands that have an impeccable reputation in the market for many years.

Poor-quality fittings or poor pressing of the sash to the frame can negate the work of the rubber seal, and in some cases cause water to enter the house through the resulting gaps.

In case of prolonged heavy rain, this aspect may unpleasantly surprise you after returning home.

The sound insulation of a plastic window further deteriorates, which also does not add to the aesthetic perception of this natural phenomenon.

To extend the durability of the fittings, you should include adjustment and maintenance in the mandatory window cleaning procedure in the off-season.

In spring and autumn, the fittings should be lubricated with special compounds developed for these purposes.

Lubricating the fittings will protect the metal from the negative consequences of contact with moisture, and fittings that are not afraid of rain will last much longer.

Double-glazed window that is not afraid of rain

A good solution is to buy a double-glazed window with increased sound insulation. The Rw coefficient in decibels tells how a window insulates a room from sounds coming from outside.

It is especially worth paying attention to this factor if the house is located near busy streets, railways and airports. In this case, you should choose a sound-insulating double-glazed window with an Rw coefficient of 36, 39, 40 or even 50 dB.

However, if the noise outside your home does not exceed 60 dBA, then even for the heaviest downpours with thunder and hail, a window with a coefficient Rw = 30 dB is sufficient.

Installation

Soundproofing of a balcony must be carried out in strict compliance with all safety standards and requirements.

To soundproof a balcony canopy, it is recommended to use sheet soundproofing materials, for example, the ZvukoIzol membrane. Such materials have high performance indicators and are easy to install. The required section is glued to the surface of the visor and, to avoid the formation of air pockets, is smoothed using a spatula using even movements. All existing gaps between the balcony structure and the canopy are filled with polyurethane foam.

Balcony canopies rattling during rain are not uncommon. High-quality sound insulation of the balcony roof can solve the problem. There are several reasons for this unpleasant phenomenon. Depending on this, the material and method of performing the work are selected.

Recommendations for organizing work

You can provide reliable sound insulation to your balcony roof with your own hands. Dismantling the decorative ceiling cladding is the most labor-intensive part. After the completion of the main stage of work, it will need to be returned to its original place.

When the decorative trim of the roof has been removed, a visual inspection of the quality of fixation of the metal roof is carried out. Existing gaps are eliminated with insulating material.

The surface of the canopy or canopy is cleaned of all contaminants. After which it is covered with the material chosen for sound insulation. Organization of work during the warm period does not require additional fixation measures. It is enough to remove the protective film and press the material with the adhesive side to the inner surface of the roof.

A blowtorch or a hair dryer will come to the rescue. If work with open fire is carried out indoors, you should take fire safety measures.

The source of the rumble may not necessarily be raindrops. Excessive width of the canopy is one of the reasons for annoying noise on the balcony. To ensure sound insulation, it is enough to leave a visor 15 cm wide and remove the excess area.

Poor quality fixation of the material on the roof is another reason for the formation of vibration and oscillations. If you seal the cracks and strengthen the fastenings, the sound insulation of the balcony will noticeably increase.

The sound insulation process itself is not difficult, but working at height is associated with a high risk to health and life. Therefore, it is better to entrust the arrangement of the balcony roof to industrial climbers who have the necessary skills and equipment to organize high-altitude work.

Causes of noise on the balcony

Often the balcony canopy makes an unpleasant noise during rain or strong wind. Extraneous sounds disturb not only the apartment owners, but also nearby neighbors. Before you try to reduce the noise level from the roof with your own hands or with the help of specialists, you should identify the source of its occurrence. Among the most common reasons are:

- When decorating the balcony roof, the stage of installing sound insulation was skipped. Install it from the inside using special gaskets. Climbers and installers who organize the process from the outside will help correct the error after the completion of the improvement.

- The metal roof on the outrigger was poorly secured. When raindrops hit, the sheets begin to vibrate and shift, making annoying sounds.

- The need for sound insulation arises on a balcony with an extension, where the angle of inclination is small. Polyurethane foam poured under the lower slope will help solve the problem.

- Insufficient number of fasteners or their poor quality fixation. Soundproofing the balcony canopy will reduce or completely eliminate unpleasant sounds. During the work, additional corners and spacers are installed. It will also not do without high-altitude specialists.

- A loose fit of the canopy to the wall or a gap in the roof cavity is another cause of oscillations and vibrations, accompanied by noise.

News

How to clean a plastic window sill from rusty stains

On the eve of the holiday, housewives put on a spree: among other things, they wash plastic windows until they are white. One of the most difficult stains is rust stains. They usually appear under flower pots. How to clean a white plastic window sill from rusty stains, read in this article - we have collected the best recipes from experienced housewives.

How to clean a plastic window sill from rust using improvised means

First of all, housewives try to get rid of stains using improvised means. Let's start with them.

Many people advise cleaning plastic window sills from rust with hydrogen peroxide. Hydroperite is diluted with water 1:1 and the surface is rubbed with this composition. This method is suitable for smooth window sills - they should not be rubbed with abrasives to prevent microcracks in the coating.

An important point: first try on the lower part of the window sill to see how the plastic reacts to liquid. If suspicious stains appear, it is better to use another folk method or a specialized remedy.

Window sills with a rough surface are scrubbed with baking soda or soda ash. But they do not take a dry mixture, but a slurry - dilute the powder with water or hydrogen peroxide. By the way, these compositions also remove stains from coffee and tea leaves - some housewives shared that they water the flowers with tea or coffee to feed them. And along with rust, tea and coffee traces often appear.

Another available method is Sif cleaning agent with a whitening effect. It is quite liquid, so it will not damage the window sill. You can apply it with special wipes for car panels - they will not scratch even smooth plastic.

What are the benefits of specialized cleaning products for plastic windows?

If folk methods and improvised means do not help, the last thing left is to buy a specialized cleaning composition. They are designed to minimize unwanted reactions on the plastic surface. Therefore, you can safely apply it to the windowsill.

Another advantage of special compounds is that they work as antistatic agents. And dust will not settle on the treated window sill as intensively.

How to clean a plastic window sill using a melamine sponge

Housewives praise this “tool” vying with each other. Melamine sponge copes well with difficult stains and rust is no exception. To remove a stain, you don’t even have to use a cleaning agent—the sponge effectively removes any traces.

The only disadvantage of this method is that the sponge does not last long - during the washing process it crumbles. But one is enough to clean the entire window - not only the window sill, but also the frames.

It is not recommended to wipe glass with melamine sponges - stains will remain.

Requirements for soundproofing materials

You can make a soundproofing finish for an iron roof using various materials. There is no universal remedy; each case requires an individual approach. Main selection criteria:

- Strength. The product must maintain its integrity under mechanical stress.

- Lack of response to changes in humidity levels and temperature changes.

- Resistance to ultraviolet radiation. The material must not decompose or release toxic substances when heated.

- A product of sufficient thickness will help make the balcony silent.

- A simple and reliable fastening can facilitate the process of soundproofing a roof.

Fulfillment of all conditions will ensure the reduction or complete disappearance of sounds from rain and wind.

Basic materials for sound insulation of balcony iron roof

To insulate balconies and loggias from noise, materials are used that are glued to the inner surface of a metal sheet - the close contact of the insulating material, in addition to dampening sound due to its structure, causes an increase in the total mass of the covering sheet, and this additionally dampens sound vibrations.

Sound insulator Izolon

Isolon (PPE) is a material based on polyethylene foam with a foil side to improve insulation; fixation to a metal surface is carried out using an adhesive layer applied to one of the sides. Soundproofing Izonol is available in slabs (1×1.1 m and 2×1.4 m) and rolls up to 200 m long, 1 – 50 mm thick, width varies in the range of 0.55 – 2 m. To cover the roof from the inside with a noiseless material, cut off pieces of the required size, remove the protective film from the adhesive surface and press the insulator tightly against the steel sheet, covering the joints with construction tape.

Izonol has the following technical characteristics:

- Shelf life – up to 80 years.

- The reduction in impact noise depends on the thickness, the average value is 20 dB.

- The specific heat capacity is 1.95 kJ/kg*s.

- Material density 26 – 45 kg/m3.

- Water absorption no more than 0.1%, vapor permeability 0.001 mg./m.Pa.

- Reflection of thermal energy by the foil surface is up to 97%.

- The operating temperature range is -60 C – +120 C.

- Isonol is elastic, the indicator is 130% with a relative elongation of 250%.

- The material does not support combustion; in the presence of fire retardants in the composition, its flammability belongs to class G2-G4.

- Isonol is a non-toxic material; the polyethylene foam, aluminum foil and water-based acrylic adhesive included in the composition are inert substances.

Vibroplast

Sometimes, to reduce the noise of metal balcony roofs, expensive materials are used to dampen vibrations in cars, which stick to the surface due to the adhesiveness of the components in the composition. Vibrating paste consists of bitumen and mastic and is produced in small sheets up to 20 mm thick. with one-sided foil coating. Typically, such sound insulation is applied by applying a sheet to a metal surface and then heating it, but there are also types with cold application.

Vibroplast increases the weight and reduces the noise characteristics of the roof, while having low thermal protection, so the use of thick sheets is more effective. Also, the disadvantages include the possibility of the sheet peeling off when the roof is very hot.

Bitumen based tapes

Not too expensive bitumen-based roofing tapes are made from oil, coal and shale; they are waterproof, chemically resistant and do not lose their properties in the temperature range from -40 to +90 C.

The disadvantages of bitumen coating include flammability and softening under the influence of high temperatures.

Sound insulation of an iron roof on a balcony is made by materials glued to its surface from the inside or outside - sound absorption occurs due to the properties of the material and the increase in the mass of the sheet.

At the same time, insulating a room from sound with your own hands using popular rolled stone wool insulation is not very rational - due to the loose fit to the roof sheet, its effectiveness is lower, and installation requires the installation of a complex profile frame with further cladding.

Troubleshooting options

As a rule, sound insulation is included in a set of measures when glazing a balcony, when the roof is insulated and sealed. A well-organized process provides protection from external sounds in adverse weather conditions. But if the work was carried out poorly and the roof on the loggia or balcony periodically begins to make noise, there is a need for additional sound insulation. The method for solving the problem directly depends on the cause of the extraneous sounds.

The most commonly used measures are:

- The canopy is soundproofed with soft polymers designed to reduce the sound of raindrops.

- In case of poor-quality fixation of the roof, additional strengthening of the structure is carried out.

- Change the angle of the canopy on the balcony.

- Incorrectly selected visor parameters require trimming.

Drastic measures include complete replacement of the metal visor with a plastic structure. It is easier to soundproof a loggia than a balcony. Typically, only the front part needs insulation, and the sides are left unchanged.

Brick wall decoration

If your house is built of wood or SIP panels, the construction of brick fortifications will help solve the problem of wet walls. This will be a kind of shell for the building. A brick jacket will help protect the building from moisture.

In order for the new masonry to perform its functions, you need to leave a gap of at least 4 cm between the old and new walls. A membrane vapor barrier must be installed here.

It is recommended to treat the brick from the outside with a special liquid waterproofing based on bitumen. This will create additional protection from rain, even very heavy rain.

Brickwork, of course, will protect the walls from moisture, but their appearance will be completely different. If you appreciate the beauty of the natural material from which the log house is built, it is better to choose another option for processing the facade and ceilings.

Weighting of the casting structure

Adding the extra weight of thin-gauge steel can also pay dividends. Gluing the underside of the flashing with roofing tape, rubber or other material will help increase the weight.

- The window sill profile is unscrewed, cleaned, and allowed to dry.

- The roofing tape is warmed to room temperature if the work is carried out in winter, and tightly glued to the bottom of the profile.

- If necessary, add several more layers of tape and return the ebb to its place.

The issue of sound insulation, including window insulation, should be addressed at the stage of designing a house. But if the problem of noisy low tides already exists, then you can choose any of the presented methods and ensure peace of mind.

Source

Sealing with polyurethane foam

The drip system must be attached with self-tapping screws to the frame and foam to the base. If the technology for installing additional elements is not followed, a gap will form between the metal and the brick. The lack and complete absence of sealant not only provides “drumming” when it rains, but also leads to freezing of the substitution profile.

By removing this void, you can significantly reduce the vibration level of the sheet and increase sound and heat insulation.

- The ebb is separated from the glass unit.

- The external window sill is filled with polyurethane foam.

- Before the foam begins to harden, the cast structure is returned to its place.

In addition to polyurethane foam, any roofing sealant will work.