Sooner or later, a household may need to replace glass on its own. But working with such fragile material is very dangerous. Therefore, in order to avoid injuries and unnecessary consumption of material, you should know the basic rules for working with this material and the selected tool.

Cutting ordinary glass is very simple and will not cause any difficulties for a person. You can cut such glass with a special glass cutter or even ordinary scissors.

If you have no idea how to properly handle this tool, you can watch numerous videos on this topic on our website. They will help you cut out the desired shape and provide the necessary information on working with a rather complex and fragile material like glass.

Safety regulations

When starting the procedure for cutting glass, be sure to keep in mind that working with this material requires compliance with safety rules, which are not recommended to be neglected. When untreated, glass has sharp edges that can easily cut the skin and cause infection. To avoid cuts, protect your hands with gloves and wear clothes with sleeves. Since glass tends to crumble into small, sharp fragments, we strongly recommend cutting with glasses.

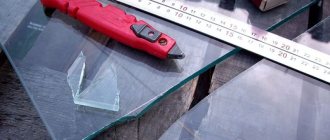

The glass cutting area must be level and stable. It is strictly not recommended to perform this operation on a knee, a rickety stool, or other questionable surfaces. Compliance with this rule will minimize the risk of glass falling onto the floor, and will also make the work more convenient and improve the quality of the cut.

If you have not previously had experience in handling glass, and do not yet know how to cut with a glass cutter, we do not recommend neglecting the above recommendations. Perhaps some experienced craftsmen can do this work with their eyes closed on their knees, but for beginners everything usually does not go so smoothly. Due to inexperience, you can make many mistakes: grab a sharp edge, drop the glass on your foot, or crush the cut site and get a piece of glass in your eye. If you are working with glass for the first time, and have not yet experienced this process, it is best to be fully prepared.

Types of glass and features of work

Cutting ordinary glass does not pose any difficulties. Not only glass cutters, but also ordinary tailor’s scissors do an excellent job with this task. But what should those who have set themselves the task of obtaining a glass product with a more complex configuration do? To do this, it is worth familiarizing yourself with the properties of some glasses.

- Tempered glass products . In fact, it is impossible to cut tempered glass at home - it loses its properties. If you want to purchase an item with elements of this material, it is worth considering cutting it in the early stages. In addition, work with it must be carried out by professionals, since the hardening process of the resulting product can only be carried out under certain conditions.

- Fluted glass . This patterned glass is especially popular in glazing doors or creating decorative interior elements. Unlike tempered glass, you can cut such glass yourself. Working with it is not much different from working with ordinary glass, the only difference is that the cut is made from the smooth side. A roller glass cutter is best suited for this.

- Acrylic or organic glass is a transparent plastic created on the basis of synthetic resins. No special tools are required to cut it. At home, a metal saw, cutter and other tools used for edge processing do an excellent job of this task. In addition, a regular stationery knife can handle glass whose thickness does not exceed 2 mm.

In any case, it is worth remembering that working with any glass must be accompanied by compliance with certain precautions. The presence of thick gloves and safety glasses are the main conditions for ensuring your own safety. It will not be superfluous to take care of the arrangement of the workplace. Since working with glass involves the presence of fragments, cover the work surface with any material that you won’t mind getting rid of. Feeling safe will allow you to achieve the best results.

Glass selection

One of the key factors for the success of any job is choosing the right material. This belief also applies to glass, which should be selected based on the task at hand. In the following paragraphs, we will give a couple of recommendations on how to determine the quality of glass and choose the optimal thickness. If you already have the material, you can go to the next heading or directly to the instructions on how to cut glass with a glass cutter.

Before we begin the description, we clarify that we are talking about ordinary window glass, which is most common in the construction markets. The first thing you need to pay attention to when buying glass is its end part. The edge of the canvas should have a bluish-green tint. Low quality glass has greener tones due to the higher iron content. This material is more fragile, but usually costs less.

The choice of glass thickness should be made based on the required dimensions. To make working with the canvas more convenient and to minimize the risk of defects, the ratio of width, height and depth should be optimal. Glass with an area of 1 m² and a thickness of only 2 mm is highly likely to crack at the first wrong movement. When using canvases up to 50 cm, a thickness of 2-2.5 mm will be sufficient. From 50 to 100 – 3-4 mm. More impressive sizes should have a thickness of 5-6 mm or more. Take these recommendations into account when choosing glass in a store and save yourself from unnecessary trouble.

Diamond glass cutters

The oldest, but not inferior in quality to the newest inventions, is the diamond glass cutter. A small diamond crystal, cut in a special way, is very firmly soldered to the holder using a special silver solder. Manufacturers use two types of diamond cuts: curved - to make cutting glass easier for inexperienced people, and pyramidal with an installation angle of 20° - 22° to the axis of the tool - for professional use. When one cutting edge wears out, the diamond is turned 90° and the glass is cut with the other edge. A glass cutter with natural diamond can cut glass up to 10 mm thick, and with artificial diamond – up to 5 mm. But artificial crystals are much cheaper. The tool life is 10 - 12 km. A worn cutting element can be sharpened with a cast iron disc or a block coated with mastic with diamond dust. A diamond glass cutter is an excellent tool for both one-time work and ongoing use.

Preparatory activities

In order for the cut to be of high quality, it is necessary to first prepare the material for work. If the glass is new, then just wipe it. Newspaper is best suited for these purposes; it mainly wipes the surface dry and also does not leave lint or stains behind.

If the glass has been used before, then before cutting the material with a glass cutter, you will need to spend a little more time preparing it. First of all, such a surface will need to be washed thoroughly using special glass cleaning products. A thorough degreasing process should then be carried out. Alternatively, you can use kerosene. To do this, use a rag soaked in kerosene to thoroughly wipe the glass and wait until it dries completely.

At the same time, the glass preparation stage also includes cutting it. There is no doubt that you will be able to achieve the final result without waste, especially if you need to cut a product of irregular geometric shape. But if you make the calculation as correctly as possible, you can reduce the amount of waste several times.

Also, make sure that the working surface is fairly flat and without slopes, but not too hard; it is advisable to make the working surface from plywood or fiberboard, and cover the top with oilcloth or soft cloth.

Roller glass cutters

The most common type of glass cutter is the roller cutter. The great popularity is a consequence of the low cost of such instruments. But the possibilities are not rich - 350 m of glass up to 5 mm thick. A roller made of hard alloys is used as a cutting element. Typically, rollers made of a tungsten-cobalt alloy with a diameter of 6.6 mm and a sharpening angle of the cutting edge of 100° are used. The modest resource of the glass cutter is increased by adding additional rollers to the holder, which are installed in the working position within a minute. If you wet the cutting element with machine oil before each cut, you can significantly improve the quality of the cut and increase the service life of the tool. Dull rollers can be easily sharpened with a fine-grained abrasive stone, after securing them in a holder made of a screw and a hollow sleeve with an internal thread. Such glass cutters are most suitable for rare use in everyday life.

How to cut glass with a glass cutter: detailed instructions

If you are planning to cut glass, then first of all you should decide which glass cutter is best suited for your case. At the moment, there are two types of tools - diamond and roller.

How to cut glass at home

The diamond model is rightfully considered the leader among tools of this type. If you are going to use it at home, then the perfect model is one that has a beveled edge, which is very convenient for breaking off cut pieces. You can cut glass with such a glass cutter, almost ten kilometers of material, with a thickness of up to one centimeter. But at the same time, it should be taken into account that there are also cheap types in which an artificial diamond is installed, which allows cutting glass with a thickness not exceeding 5 mm.

Unlike a diamond cutter, a roller glass cutter has a working element in the form of a small roller, usually made of carbide materials, usually a tungsten-cobalt alloy, which is capable of cutting material up to 4 mm thick. The advantage of this type of tool is that the roller can easily move along the glass, without putting much effort into making a furrow.

The work process is carried out in the following order:

Clean and dry glass is placed on the surface of the work table. The necessary markings are made with a marker. Next, small cuts are made at both ends along the marked line. Please note that the material used must be in close contact with the surface of the desktop.

Afterwards, you need to put a ruler on the glass and draw a line along it with a tool. Holding a diamond glass cutter in your hands is exactly the same as a regular pencil; when passing along the marked line, you should only apply a little force. As a result, only a barely noticeable mark remains on the glass, which looks like a scratch. If the instrument is in good working order, then there must be a characteristic sound reminiscent of crackling. If the sound is creaking, then this means that its cutting element needs to be sharpened on a special block for this purpose.

During operation, such a tool should be held at a slight angle, the correctness of which is determined experimentally. Please note that a tool that is in the correct position relative to the glass will leave a colorless thin line.

A roller glass cutter, unlike a diamond one, must be held strictly at right angles to the surface of the glass, while pressing it with the middle and thumb, and pressing on it with the index finger. Please note that the roller tool is pressed a little more than a diamond tool, and the cut itself should turn out white.

In order to get a high-quality and, of course, even cut, remember a few simple rules that must be followed when working with glass using a diamond tool:

- Do not press on the glass while moving the glass cutter, otherwise the cut will be too deep and the edges will be uneven.

- Under no circumstances should another cut be made along the resulting line. Otherwise, the glass may break. The cut must be made as quickly as possible. For example, if we are cutting a length of a meter, then you need to spend no more than two seconds on it.

- In order for the workpiece to break quickly and accurately along the cut line, you need to lightly tap on the back side of the glass. After which you will not need any effort to break it off.

If you are just a beginner, it is best to practice on small pieces; this will help you determine the correct angle of inclination of the tool, gain experience, reduce losses, and also avoid mistakes in the future.

Cutting steps

The work is carried out in two steps:

- creating a scratch in the form of a groove on the surface;

- breaking into parts by bending force.

Technology for creating a groove using a glass cutter

When cutting, the tool is held with the hand in a vertical position, with the index finger placed on top of it.

The glass cut is made from the far edge to the near one. The speed of movement of the glass cutter should be uniform, the pressure on the glass should be the same. The cut is made only once.

By the quality of the scratch you can immediately judge the correctness of the cutting:

- a thin, transparent line from the roller indicates the sharpness of its edges and the correct cutting technology;

- a deep white cut is a sign of improper work by the craftsman or wear of the cutting part.

How to properly scratch

When cutting a groove, loads are created that work to shear the surface layer.

They cause deformations that form microscopic surface, lateral and deep cracks.

The correct cut is ensured only by those microcracks that are directed into the depth of the material - the middle ones. All others are not needed. They must be avoided.

The cutting quality is affected by:

- cutter sharpening angle;

- roller diameter;

- pressure on glass;

- position of the cutting organ.

How does the roller sharpening angle affect the cut?

As an example, let’s look at the designs of three cutters designed to work on industrial glass cutters of automatic robots.

The direction of the forces pushing the surface layer apart when creating a scratch is always perpendicular to the pressing plane. A sharper roller deflects the acting force more widely from the normal to the surface, creating a smaller area of stress penetration.

To cut thick glass, use a tool with a wider sharpening angle, and for thin materials, use sharp ones.

On factory models of glass cutters, the sharpening angle is already created to work with standard glass used for domestic purposes.

How does the roller diameter affect the cut?

Smaller dimensions allow better scratching of the outer surface of the workpiece. However, the designs of the glass cutter have already been adjusted at the factory to optimal performance, and the home craftsman will not be able to change anything here.

The tool is purchased ready-made with standard roller diameters. As they lose their sharpness, which rarely occurs in everyday life, the dull part is simply replaced with a backup one.

How does pressure on the roller affect the cut?

The depth of penetration of a scratch into the glass depends on the applied cutting force. When choosing a sharper cutter for thin material, you should take into account that it is dangerous to create a high load with it, because you can simply crush the material.

To make it easier to cut the workpiece when performing such work, always ensure that the glass is clean and treat its surface with special liquids that:

- lubricate the roller;

- provide a hydraulic cushion;

- reduce the effect of the Rebinder effect, reducing the strength of the outer surface;

- wedge the material.

At home, you can easily get by with kerosene for these purposes. It is convenient to apply it manually with a piece of rag or use a specially designed glass cutter.

How does the roller position affect the cut?

The picture with the sharpening angles of the cutter makes it clear that the roller must be guided strictly perpendicular to the glass surface.

Its deviation from the normal will lead to lateral displacement of the median crack and incorrect chipping.

About the number of cuts

There is a misconception among beginners that one scratch is not enough and that several repetitions must be done. They say they will deepen the crack. So such masters use a glass cutter several times in the same place.

This is a gross mistake: with each movement, repeated deformations of the material and additional cracks are created in all directions. They reduce the overall strength of the workpiece and can lead to improper fracture during bending.

Fracture methods

After a cut with deep cracks is made on the surface, you will need to divide the workpiece along this line. This operation is performed in four ways:

- manual bending;

- using matches or thin sticks;

- on the edge of the table;

- by tapping method.

Manual bending of the workpiece

The glass is taken by the edges near the cutting line with your hands, squeezed tightly with your fingers and an opposite bending twisting force is created, directed outward from the groove made.

This is quite enough to accurately separate the workpiece from the main sheet. This method is used by most glaziers.

Bend on matches

Matches or thin, even wooden sticks are placed in one line on the table. The glass is placed on them with a cut line so that the scratch is located on top.

Place your palms evenly over the surface and break the glass with a sharp downward movement. The magnitude of the force is determined experimentally, starting with small values.

The fracture is smooth and of high quality.

Bend on the edge of the table

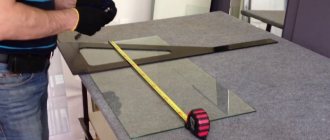

Glass with a scratch is placed on the edge of the working surface of the table with the cutting line facing up. Combine it with the edge of the stop.

With the palm of one hand they press the glass surface to the table, and with the other they grab the protruding edge and with a sharp downward movement separate the workpiece.

The method is well suited for beginners.

Tapping method

The glass is placed on the edge of the table, extending the cutting line beyond its limits. Hold the part to be cut with one hand. Using the glass cutter head, precise blows are applied to the place where the middle cracks form. They gradually expand and deepen due to the loads created.

The peculiarity of the method is that the impact should not develop lateral cracks caused by deformation of the glass during cutting. They will create an uneven chip and ruin the workpiece.

During the application of blows, the expansion of the chip is visually observed.

If the break doesn't work out

We must be prepared for such a situation. It can occur due to lack of experience or technology violations.

The damaged part on the protruding side of the unbroken edge can be carefully removed using the slots on the side of the glass cutter or pliers. The edges will be sharp and jagged. They will have to be ground down with an emery stone.

The correct cut on glass is created through skills developed based on an understanding of the design features of glass and the technology of the glass cutter.

How else can you cut glass?

What to do if you don’t have a glass cutter at hand? There are ways in which glass is cut with non-standard tools. This operation can be carried out with a soldering iron, grinder, nichrome thread and even ordinary scissors! Let's find out how to properly cut glass with your own hands using each of these methods.

- Using a soldering iron. First, cuts are made with a file at the beginning and end of the cutting line. Then you need to carefully run a well-heated soldering iron along the entire line. Due to the temperature difference on the sides of the surface, the glass will crack, after which all that remains is to carefully break it off.

- Bulgarian. This tool is found in almost every home, so it is not surprising that it has also been adapted for working with glass. In order to cut glass with a grinder, you will need a thin diamond disc. With its help, a thin groove is made along the entire cutting line, along which later chipping occurs. But when cutting with a grinder, you need to make sure that the glass does not overheat, and be sure to use coolant. You need a good tool, otherwise the glass will simply shatter from its vibration. When working with an angle grinder on glass, it is imperative to protect your respiratory organs and eyes. Getting the smallest glass dust into them will not lead to anything good. Therefore, if you cut a sheet of glass with a grinder, you need to stock up on glasses and a respirator.

- Using heating and cooling. A thread soaked in a flammable substance is laid along the cutting line and set on fire. Immediately after it goes out, the cutting line is cooled with water. A sudden temperature change will cause the glass to crack. Another option is to heat the glass with a nichrome thread through which an electric current passes. In this case, no water is required, the temperature difference between the two surfaces of the sheet is sufficient.

- Scissors. Thin glass up to 3 mm can be cut with ordinary tailor's scissors, if this operation is performed by immersing the scissors and glass in a container of hot water. The process feels like cutting thick cardboard.

What tools to use?

Many of us are accustomed to thinking that glass can only be cut correctly and efficiently with a glass cutter. But what to do if you need to cut a piece of glass urgently, but you don’t have this tool at hand? There is another unusual, but no less effective method that helped our great-grandfathers get out of this situation. Such a tool is ordinary scissors, available to any owner. Let's look at each method in detail.

Option 1: glass cutter

The technology for cutting glass with a glass cutter is quite simple. To do this, you must comply with certain conditions and choose the right glass cutter. Today, the choice of this tool is quite wide, which allows you to turn work into pleasure.

- Diamond glass cutter, time-tested and remains a leader in its field to this day. Glass cutters with a beveled cutting edge are suitable for home use. This tool is designed to cut glass up to ten kilometers and is suitable for any thickness of the material used. From time to time, such a glass cutter needs to be sharpened on a special whetstone.

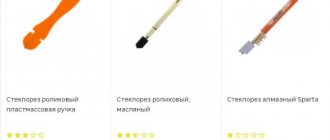

- Roller. As the name suggests, the cutting part of such a glass cutter is made in the form of a roller made of a durable cobalt-tungsten alloy. The number of rollers can be from one to six.

- Oil. This tool works on the principle of a roller glass cutter, with the difference that a reservoir with oil is built into its handle, which is automatically supplied to the roller. Suitable for cutting thick glass.

To learn how to choose a good glass cutter, watch the video:

So, having dealt with the glass cutter, place the glass on a flat surface. Mark the glass and get to work. To make the task easier, you can use a ruler. It is worth considering the point that the line must be drawn the first time, otherwise a repeated attempt will lead to cracking of the surface. When cutting glass with a glass cutter, you need to apply equal force along the entire length of the line.

Option 2: ordinary scissors

Cutting glass with scissors like paper is not a fairy tale, but a completely everyday reality. For this purpose, you will need the scissors themselves (sewing scissors are best for this) and a tank of water (preferably hot). It is necessary to apply markings on the glass in advance, and then elementary physics comes into play: scissors create a microcrack, and the capillary effect completes the process. Of course, the result obtained will differ from that achieved with a glass cutter, but if necessary, this method can help out significantly.

Tempered glass processing

The question often comes up on forums: how to cut tempered glass? The answer is simple: tempered glass cannot be cut or drilled. Whenever you try to do this, it loses all its properties and simply shatters into small pieces. Tempered glass was used in cars before triplex technology was invented. During the accident, glass fragments should not have injured passengers. So you shouldn’t even try to cut tempered glass with any tool.

To understand how to cut glass with your own hands, you just need to take it and try it. The choice of method depends on individual skills and the availability of the necessary tools. But all these options are quite feasible at home.

Types of glass cutters

To cut glass, a special tool is used, which is known to everyone. It can be of several types:

- roller;

- diamond;

- oil;

- compass.

Roller glass cutters have a round cutting tip. An alloy of cobalt and tungsten is usually used to make it. In this case, the number of rollers in one tool can vary from one to six. Unlike other analogues, such a tool is inexpensive, due to which it has received great appreciation.

Diamond glass cutters are used by professionals in their field. Despite the high price, it was, remains and will always be the undisputed leader in the field of glass cutting. It is better for home craftsmen to choose a professional diamond glass cutter that has a beveled cutting edge, as it will cut more linear meters of almost any thickness. You just need to store it in a special case. A diamond crystal is used for the cutting tip, and it is known to be the hardest mineral that can be found on Earth. Once you leave a small scratch on the glass, it will crack with the slightest force. Diamond glass cutters require periodic sharpening using a special whetstone.

Oil tools are similar to their roller counterparts, the only difference being that there is an oil capsule in the handle. It is automatically fed to the roller during operation and to the glass surface. This cutter is well suited for solving the question of how to cut thick glass with a glass cutter.

Using a compass is convenient for cutting round or oval shapes. It consists of several elements and looks like a well-known school stationery item.

Tips for cutting glass

Professionals always have in their arsenal tricks and secrets that they have gained from their own experience. Use them to make the process easier.

- Use your ears, the sound of cutting glass will help you determine whether you are doing everything correctly. A steady hiss is what you should hear. The appearance of a squeak indicates the need to sharpen the instrument.

- Increasing pressure does not mean doing it better. A roller tool requires more force than a diamond one, but if white splinters appear along the seam, ease the pressure to avoid crumbling the cut.

- Do not add pressure at the edge of the glass, but, on the contrary, reduce it 5 mm before the edge. This will protect the instrument from damage.

- Using a glass cutter, draw one confident line, without repetitions or secondary cuts. Break the glass immediately, without delaying it until later.

- You can make the task of the glass cutter easier and extend its service life by using oil or paraffin. Apply oil to the roller or glass before cutting.

- To make breaking the glass easier, place the ruler you used for drawing under it. A marker or pencil placed exactly along the cutting line will also work.

What properties does silicate glass have?

Types of glass

How to prepare glass batch?

Glass mat - what is it, types, application photos, pros and cons

How to cut ceramic tiles with a glass cutter?

If the tiles and the glass cutter match each other in properties and characteristics, you can proceed directly to cutting.

Preparing for work

First, you should decide on the number of tiles and purchase ahead of time a little more elements than the calculated area. This will allow you to perform a training cut and protect against defects. You will need the following set of tools:

- glass cutter;

- a strong ruler or triangle 2-3 mm thick;

- device for marking - marker or pencil;

- thin strip of wood;

- device for grinding - file, needle file, drill with a grinding attachment.

Since it is recommended to use a roller glass cutter to cut tiles, you will need roller lubricant. Among the preparatory work, we can mention the obligatory soaking of the ceramics. Water will fill the smallest pores and cavities in the material, the tile will become less fragile and will not crumble when cutting. The minimum soaking time is 1 hour, the optimal time is at least 3 hours.

Markings on tiles

After calculations for laying the tiles are determined with the configuration and dimensions of the product. The markings are applied with a marker on the glossy side. The marker can be replaced with a soft pencil or felt-tip pen.

It is necessary to take into account that a glass cutter will not take a strip less than 1 cm wide, and it will not be possible to break such an edge after cutting. Therefore, experienced craftsmen recommend leaving an allowance of about 1 cm - it is better to grind off excess ceramics than to cut the element again.

Performing ceramic cutting

Step-by-step instructions for working with ceramic tiles:

- The tiles are laid with the glazed side facing out. Measure and mark the correct distance from the edges.

- Pressing a ruler or square to the cutting line, use a glass cutter to make an even groove. The ruler should be pressed along its central part, and the glass cutter should be pressed with moderate force and as evenly as possible so that the depth of the groove is the same along the entire length of the tile.

- There is no need to cut through the entire thickness of the tile; the remaining layer can be easily broken by hand.

Fracture along the cutting line

Craftsmen distinguish two ways of breaking cut tiles:

- Place a strip or nail under the groove from below, press on the central zone and split;

- Place the ceramics on the workbench so that one of the edges hangs from it - it will be enough to simply press on the hanging part with your hand.

If there is a need to break off a narrow ceramic strip, you should use pliers.

The fracture will be smooth only when a single clear cut is made on the surface. It is prohibited to move the tool along the element several times.

The work is completed by grinding, which will allow you to obtain a smooth edge and remove burrs and chips. Coarse sandpaper, a grinding stone or a file will come to the rescue.

Features of working with non-standard glass

Tempered glass cannot be processed at home; when mechanical stress is applied to it, it crumbles or breaks into pieces. Corrugated glass is cut with a glass cutter in the same way as regular glass, but on the smooth side.

Corrugated glass is cut on the straight side

Acrylic glass is not actually glass. Thin material is cut using simple scissors or an ordinary knife. A thick sheet can be drawn along a ruler with a piece of a hacksaw blade, several times, and then bent and broken along the mowing line.

Making new glass for cars

TO

category:

Car body repair

Making new glass for cars

Next: Wallpaper work during body repairs

The production of glass for bodies from sheet glass includes the following operations: 1) glass cutting; 2) rough grinding of glass edges (grinding); 3) fine grinding (disting); 4) bevelling (cutting the edges of glass at a certain angle by grinding); 5) grinding of recesses; 6) glass drilling.

1. Glass cutting

Cutting glass is a complex operation. It begins with making a template from thick paper according to the required glass shape.

The template is placed on a workbench covered with carpet, and, having placed the glass to be cut on it, the cutting line is lubricated with kerosene, turpentine or liquid soap. Using a pattern visible through the glass, the glass is cut with a diamond. The pressure of the hand holding the diamond should be uniform; and the diamond should be slightly inclined in the direction of the cutting edge. The correctness of cutting is determined by the master carver by ear. The diamond should produce an even and clear sound.

For thick glass, a diamond with a large grain is used, for thin glass, a diamond with a fine grain. The hardness of the best diamonds on the Mohs scale is 10; specific gravity - 3.5.

Straight lines are cut using a ruler, and curves are carefully traced using a diamond along the markings. The notch is made to the edge of the sheet of glass from which the workpiece is cut, so as not to break the glass when separating the workpiece from the rest of the sheet and to make it easier to break.

The separation of the cut part of the glass is carried out in different ways, depending on its type. The mirror glass is moved to the edge of the table so that its outer part sags, and, starting from the corner of the sagging part, gradually presses on the glass along the cut line until a crack is obtained. This operation (like all others when cutting glass) must be performed carefully so as not to damage the workpiece. The lubricant used during cutting penetrates into the crack and makes it easily visible to the eye. Lightly tapping the crack with a cutter holder or pliers breaks off the glass.

If the width of the piece being broken off is less than 25 mm, use glass pliers (Fig. 99, a), which have wide and flat jaws that allow you to firmly grasp the glass without breaking it, or a mandrel with a groove (Fig. 99,6).

“Triplex” of the old production, after cutting both outer glasses, is heated along the cutting line with hot nichrome wire (Fig. 97) until heat penetrates the plastic layer, which softens when heated and can be easily separated. To perform this operation, a wire coil is placed on the glass along the cut line and the wire is installed in the cutouts of asbestos-lead installations. The end of the wire is connected by wire to the electrical network. Another wire with a terminal is fixed in such a place on the wire to heat it to a cherry-red color. After heating the glass, the unnecessary piece is pulled away from the workpiece with pliers, without bending the glass and holding the workpiece with your hand.

The heated plastic mass softens and the cut part of the glass falls off. Glass less than 25 mm wide is separated with pliers.