I ordered a polycarbonate protective glass for a smart display and it turned out to be a couple of mm longer than the screen. How and with what can I carefully trim it? And where is it better to cut - from the top (corners) or from the bottom?

I think you can do without a knife. You will need sandpaper somewhere around 80-100 number, and some kind of flat object (ideally a wooden block). The sandpaper can either be glued to the block or nailed with nails or a stapler. Sand along the edge - this way there will be no chips. I see that the glass is also uneven from the bottom; both places can be polished. You may need 200 grit sandpaper or more if the glass edge is rough.

The device is protected from shocks and scratches by protective glass , which is several times harder than the most durable film. If the glass does not fit, it needs to be cut. It is best to do this with a laser engraver, which does not damage the layers in the glass.

It will not be possible to cut it with scissors or a glass cutter, since the protective glass crumbles. A paper cutter won't work either. The only thing that worked for us was using sandpaper on a block. It’s better to immediately take the correct measurements and buy the right glass right away.

If you are wondering about cutting the protective glass, it means that there is most likely no original accessory for your smartphone model, and the universal one does not fit in height or width.

Unfortunately, many smartphone users face this problem, despite the fact that the market for protective accessories is growing at a tremendous pace.

How to cut glass on a phone with your own hands at home

Let me note right away that you won’t be able to cut the glass of your phone with scissors, a stationery knife, a scalpel or even a diamond glass cutter. In the latter case, an elastic adhesive film applied to the thinnest glass will interfere. Other methods will not work as the cut edge will be damaged and the glass will not stick to the display.

A laser engraver is optimal for correction, which is used to cut the glass of smartphones and iPhones in industrial production. In many cities there are workshops that have the appropriate equipment. You can try to contact them, although the meager amount of work and the corresponding payment makes communication difficult.

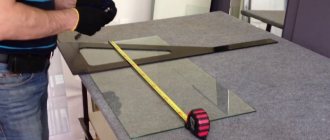

The most affordable way to adjust glass for a mobile phone at home is to use sandpaper. It is glued onto a wooden block to create an absolutely flat processing surface. It is better to use the finest sandpaper, for example, No. 80.

The glass to be processed is placed on a flat and clean surface so that it protrudes slightly beyond the edge of the base. The workpiece must be pressed firmly and then sanded with sandpaper along the end of the glass. In this way, it is relatively easy to reduce its size to 1 mm.

If you need to cut glass by more than 1 mm, it is better to use an engraver with a diamond cutting disc. When performing the operation you need to be careful. In this case, final processing and leveling can be done with a round stone or using sandpaper on a block. How to glue glass onto a phone, read the article Can you re-glue the glass on a phone yourself at home? The following video shows an example of cutting with an engraver.

Precautionary measures

When replacing anti-impact glass, we advise you not to ignore safety precautions. Make sure the main screen is not affected. The use of knives, paper clips, pins and other sharp or cutting objects is strictly prohibited. They may cause damage to the touchscreen.

You must act with extreme caution. It happens that one of the corners of the armored glass does not want to give in. If it is difficult to detach it from the screen, do not try to pull it away with double force. Just switch your attention to another corner.

The glass surface is held on the display due to the adhesive backing. Therefore, to remove armored glass, use both a suction cup and a plastic card. Then you will complete the job safely without damaging the cables of your smartphone.

Hands must be clean. Before work, wipe them with an antiseptic or a light alcohol solution. This will reduce the risk of “sticking” the anti-shock coating or the screen itself before connecting them.

Using film instead of glass: how to cut it?

If there are problems with the use of protective glass, you can use a special film. This option has both advantages and disadvantages: if you don’t have experience, it’s not so easy to stick the film on, and it doesn’t protect the display well from impact.

The service life of such a protective coating is limited. But the film is noticeably cheaper than glass, it is easy to trim, the film does not increase the thickness of the phone and does not interfere with its operation. In any case, it will protect the monitor from scratches and abrasions.

First, the film needs to be marked; to do this, you need to lay it on the back side (with the BACK mark) on the phone and trace the perimeter with a pencil. In this case, it is better not to plan several small holes that are difficult to make, but to replace them with one large one.

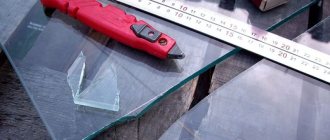

Next, the material should be laid on a flat surface and carefully cut using a metal ruler and a reinforced stationery knife. It will not be possible to cut the film with scissors, as they will break the edge of the protection and it will not adhere well to the screen.

A cloth for wiping the screen is usually sold along with the film. It must be carefully treated with the supplied napkin, and then you can stick the film on.

We prepare everything you need

Let's get ready, in addition to the smartphone, we will need: adhesive tape or stickers, protective glass and a set of cleaning wipes, special stickers for removing dust particles from the set included with the shockproof glass with an oleophobic coating.

It seems to me that you have already prepared all this, and if not yet, then we order with free delivery on Aliexpress. Learn how to buy on Aliexpress, it's very profitable. There are good but inexpensive glass screen protectors for smartphones or tablets and much more. I recommend preparing a couple of glasses in reserve, as the popular proverb says, “the first pancake is always lumpy.”

We find a place where there is less dust and make ourselves comfortable

So, we should have two napkins in envelopes, but don’t rush to open them. First you need to find a well-ventilated place where there is no dust in the air, for example near a window. We found a place, great, now, before gluing the protective glass, place the phone on a flat surface, preferably on a book, it will be easier and more convenient to do everything at home.

Make sure that everything you need is at hand and you can start replacing the glass. First, thoroughly clean the smartphone screen with a cloth soaked in alcohol solution, which is included in the kit. Then wipe dry with a dry cloth from the set; usually, a deuce is drawn on the bag. Then remove the glass from the case, but it is still too early to peel off the transparent film.

Difficulties in cutting safety glass at home

Safety glass is different from ordinary window glass that you may have encountered in everyday life, and it cannot be cut using the same methods as ordinary glass.

The main problems you will encounter when cutting such glass with a diamond glass cutter will be its minimum thickness (up to 0.3 mm) and the adhesive layer, which has an elastic structure and cannot be cut by this method. However, even if you can cut through this layer in another way (for example, with a utility knife blade), its edge will be damaged and will not stick to the screen. That is, there will be air in the place of the cut, and it will not escape. It is possible to use such an accessory, but it is not at all pleasant.

What is needed to remove a gadget from the display?

First you need to determine how to remove the old protective glass from your phone. To do this, you will need to stock up on several accessories that will make the replacement process easier.

Some of these items may come complete with an anti-shock coating for the display. If you bought armored glass without such a kit, do not fall into despair. You can also use improvised means.

We prepare the following equipment:

- Napkins . They must have a uniform and smooth structure without lint. For example, microfiber cloths. Wipe the screen with these wipes to clean your phone and remove all microscopic debris and glue. If you use more fluffy cloths, they will only add debris to the screen.

- Silicone suction cup . This accessory will greatly facilitate the removal of broken coverings with significant damage. But you can do without it.

- Plastic scraper . If you don’t have one at home, find some alternative option made of touchscreen-safe material. Small cardboards, plastic cards, spatulas or picks are suitable for this.

- Alcohol based liquid . For example, alcohol, vodka or alcohol-containing perfume (triple cologne). Each of these liquids safely removes adhesive residue and effectively cleans the screen. In addition to alcohol, you can use Bosch descaling agent.

- Gloves . It is also not necessary to use them, but this way you will save your hands from cuts. With them, when replacing glass, foreign debris will not appear between the main screen and the armored glass, which can be carried in with bare hands.

Alternative solutions to the problem

The fact that it is not possible to carefully cut protective glass at home does not mean that you will have to be left without a protective accessory. We offer several options to solve this problem.

Selecting protective glass from another model

In order to select such a protective glass. You will have to spend a lot of time in the accessory store, and if you are ready for this, then first you need to select a list of smartphone models with the same screen diagonal and aspect ratio. At the same time, it is also worth considering the placement of the earpiece (whether a cutout is needed for it), after which, with a huge list, you need to go to the store where you can apply protective glasses and weed out the unsuitable ones.

It is also worth clarifying that the likelihood that the cutout for the proximity and lighting sensors will coincide with their locations on your smartphone is close to zero, which means that they will not work under a layer of glass.

In this same block we will also include fittings of universal glasses from different manufacturers, since with the same diagonal, different manufacturers make glass with different heights and widths. In this case, you can look at these indicators in the glass characteristics in the online store.

Trimming the universal protective film

If you cannot cut the protective glass at home, then with the film things are different, but you should follow some recommendations so as not to damage the adhesive layer.

You can cut not only universal film, but also any other film.

To do this, place it on the smartphone screen with the side marked 1 down, trace the contours, but do not mark small holes, you will not be able to cut them out so as not to damage the silicone layer, instead of several small cutouts, it is better to make one common one for them.

Place the film on a hard work surface and cut with a sharp utility knife or scalpel in one motion. Do not use scissors, they will bend the edge and it will not stick in this place.

Next, you can glue the film to the device screen, having previously treated it from grease and dust with the wipes included with the film.

The protective film is not as hard as glass, but in most cases it is enough to protect the screen from scratches and abrasions.

Although this option is not the most reliable, most of the time the smartphone in such a case is closed and the likelihood of damage to the screen is minimal. And if you combine the protective film with a book case, you can keep your screen in excellent condition throughout the entire period of use.

And as a nice bonus, we offer readers of this article a 10% discount on protective accessories in the online store Floy.com.ua

To do this, use the promotional code art10 when placing an order, and the order amount will be reduced by 10% .

Source

News:

Hello! We are sincerely glad to see you on the website of our club! Most likely, the FULL DRIVE lifestyle is close and understandable to you.

Here you can meet and communicate with people who share and understand your aspirations and hobbies.

Before you start communicating, please read the Forum Rules

There are times when it is necessary to cut off part of the protective glass for a smartphone. There are several ways to do this.

For example, using a sharp stationery knife or scalpel. Before starting work, the unused part of the glass should be covered with some kind of cloth or napkin, this is necessary so that small fragments do not damage it. After the excess part is cut off, the edges should be smoothed using sandpaper (no more than 1 type of hardness), so that they do not subsequently cut your hands or tear your clothes.

You can also get rid of excess edges using only sandpaper. But this method is only suitable if the edges are very small. It is best to take 80-100 sandpaper, more is possible, it all depends on the roughness and thickness of the glass and stick it on some object with a flat surface, for example, on a wooden board. It is better to process along the edge to avoid splinters.

If the glass is already glued to the phone, the chance of cutting it becomes very small, since in this case it can break into many small fragments. It is advisable not to do this at home; it is better to contact a specialist or buy a new protective glass.

Many smartphone users often have the problem of the protective glass peeling off the screen; most often this begins to happen in the corners, and then across the entire surface. This occurs when air, dust or dirt gets under the glass. In this case, the glass must be carefully removed, washed on both sides with warm water and, without wiping, carefully glue it back to the screen. Then, using a cloth, carefully remove excess drops of water from under it (due to excessive moisture, the glass will slip at first), put it to dry for 3-4 hours, after it has dried and you will make sure that the glass no longer moves , squeeze out the last drops of water with your fingers.

Another option to cope with the problem of the protective glass peeling off is to prepare sugar syrup, it has an adhesive base. Apply it to the areas of the screen where the glass comes off. It can also be applied to the entire screen. To do this, remove the glass, wipe the phone screen with alcohol, and spread the syrup in droplets along the entire length of the screen. When gluing the glass, the syrup will be distributed over the entire plane and the glass will stick very well.

When purchasing a phone, you want it to last as long as possible. Touch screens on modern technology are very sensitive and fragile; they can easily be damaged, which is why they will not last as long as they could. In this case, many people have a question: “How to ensure a long life for a touch screen; what is better to buy film or protective glass?” Each of these options has its own pros and cons.

There are quite a lot of protective films: glossy, matte, mixed (combines the properties of glossy and matte films), mirror, antibacterial, anti-spyware. Each of them has its own specific advantages.

The films are quite thin and don't add much bulk to your phone. With such an accessory, the gadget can be placed in any case, but they tend to slow down the sensor.

As for the protective glass, it is noticeably thicker than the film, which is why the smartphone is given a certain small volume and will not be able to fit into certain types of cases. Glass is also a little more expensive, but it is also more reliable, especially in the event of a fall.

Unlike film, glass does not spoil the clarity of the image and does not impair the sensitivity of the screen. They also have a wide variety, for example: from a silicone base, from a restraining layer, with anti-reflective coating, with a protective layer, from an oleophobic coating.

These two accessories have their own advantages and disadvantages, so it’s up to you to decide which is best for your phone.

Very often there is a problem of air bubbles under the protective glass of the phone. The question arises: where do they come from and how to get rid of them? There are several options to eliminate them.

- Try to drive them out by swiping some thick cardboard, such as a credit card, across the screen.

- The most ordinary needle can also come to the rescue. Simply pry up the part of the glass where the air bubbles have accumulated and release them, and then press the glass back so that the air does not get there again.

- Take a hairdryer, place it 30 centimeters from your smartphone and heat the glass at medium temperature for two minutes, then place the phone under a stack of books or some other press for 7 hours.

- If there are a lot of bubbles, you will have to clean the glass of excess debris. Remove the protective glass and clean it using tape, then wipe the screen with alcohol and place the glass back.

How to cut glass without a glass cutter

Tools for cutting glass were not always as widespread as they are today. In the second half of the last century, people came up with their own ways to conquer this capricious material, without using a glass cutter. In fact, to cut non-tempered glass up to 8 mm thick, you can use many available items, you just need to have a little skill.

It is better to start listing items suitable for working with glass by identifying the types of impact on this material. The main methods include thermal, when glass is heated in a certain place, and physical, when it is cut by brute force. The industry uses a waterjet cutting method, when glass is processed using expensive equipment under strong water pressure.

To cut glass using the thermal method, all you need is a small piece of string and a flammable liquid like alcohol or acetone; a soldering iron and a burning apparatus can also be used as a cutter. To cut glass by physical force, you can use a file, a pobedit drill, a nail, a thin diamond disk, and even ordinary tailor's scissors. Of course, some of the listed items are difficult to get a good chip, but with the right skill, a quite suitable result can come out. Now, knowing how you can cut glass without a glass cutter, you can move on to the process itself.

How to cut glass without a glass cutter

Before we begin a detailed description of glass cutting techniques, we would like to remind you about safety. Always wear work gloves and safety glasses while working to avoid cuts and small debris getting into your eyes. Be careful not to apply excessive pressure to the glass.

Burning thread

We soak the thread in a flammable liquid and fix it on the glass along the cut line. We set it on fire, wait for it to burn completely and immediately place it in cold water or pour it onto the heating site. The main thing is that the glass cools down as quickly as possible and bursts due to temperature changes. A characteristic click will signal the success of the work. If the glass does not crack, you can try repeating the operation.

This method breaks bottles fairly smoothly, but does not always work with large glass sizes. It is also very fire hazardous and requires a fire extinguisher or a container of water on hand, which is already required.

Soldering iron

Having marked the line of the future cut on the glass, take a file and make a small groove with it from the very edge. Having retreated 1-2 mm from it, we heat the place with a soldering iron until a microcrack forms between it and the mark. Next, we retreat from the crack itself to the same distance and gradually move towards the finish point. This takes a long time to cut glass, but you can get any shape. To speed up the process slightly, the glass can be periodically cooled by applying a damp cloth to it.

Scissors in water

A simple method of directional chipping of glass. Allows you to easily cut out round shapes, but is not suitable for creating straight lines. For such cutting, you will need ordinary scissors and a container of water, which will serve as a kind of lubricant. The maximum glass thickness should not exceed 4 mm.

The cutting process using this technique is extremely simple. We take a piece of glass to be processed, immerse it in water and break off small pieces from the edges with scissors. Water will prevent the glass from cracking, allowing you to make a controlled chip. In this way you can get oval and round shapes.

Diamond blade

Not the safest way to cut glass, requiring increased care and mandatory compliance with safety rules. It can easily break glass and throw a fragment in any direction. Otherwise, the method is quite effective and can cope with the task. For cutting, you will need a special tool (grinder, drill or drill) with a diamond disk 0.1 mm thick.

The cutting process itself is quite simple, but it requires some skill and a steady hand to guide the tool clearly along the line. We place the piece of glass to be processed on a flat place, then take a cutter and draw a line on the surface of the glass with a disk. The main thing is not to dive deep, but only lightly touch it so that a small hollow is formed, similar to a wide line from a glass cutter. Next, we simply break the glass in the right place.

To reduce the likelihood of glass chipping and reduce the amount of glass dust while working, you can periodically water the cutting area with water.

File

Another way to cut glass at home without a glass cutter or expensive power tools. To work, you will need a file and a little experience in handling glass. Please note that the file must have corners, so a round one will not work.

To cut glass, it is enough to make several cuts on its surface with the corner of a file. You need to apply a little more pressure on the file than average so that the force is enough to form a clear groove, similar to the cut of a glass cutter. When the place of the chip is marked, we simply break the glass on the edge of the table or by placing a match under the place of the cut.

This method requires a certain skill, and if you are faced with cutting glass for the first time, we strongly recommend that you practice on small, unnecessary fragments before moving on to the main material.

Pobedit drill

If you know first-hand what glass cutting is, then we suggest considering another way to cut glass without a glass cutter. If you have some experience, one drill with a Pobedit tip may be sufficient for this operation. The main thing is that the drill is more or less new, with sharp corners on the head.

The process of cutting glass with a drill is in many ways similar to a conventional roller glass cutter. The differences include a higher pressure force, but otherwise all actions are standard. We lay the glass on a flat surface, mark the cutting line, apply a bar, and draw a line along it from top to bottom. Before cutting, rotate the tip so that the sharpest angle makes contact with the glass. Having received a clear line, we break the glass along the cutting line.

The method of cutting glass with a Pobedit drill requires skill and practical experience in handling this material. Beginning craftsmen have very little chance of making an accurate cut using this method, but with patience and straight hands, the desired result can be obtained.

Screen protection - glass or film? And most importantly - why? (Survey)

I’ll say right away that gluing protective films to the screen has always seemed stupid to me. Well, really, it’s like a remote control in a bag. People who did this were usually guided by two reasons. Firstly, so as not to catch scratches on the screen and subsequently sell the phone for more money in excellent condition. Secondly, to get some additional options. Anti-glare films are available, for example. Or matte, with protection from peeping neighbors in transport.

There is also a category of people who receive their devices with a film already attached, and they simply do not remove it. I had a friend who stubbornly did not remove the film from her smartphone with the inscription “Please, remove the protective film.” Some second-tier manufacturers glue films (protective, not transport) to the screens of their devices at the factory by default. This is true for budget smartphones and tablets whose screens have plastic rather than glass protection.

But enough about the films. I became interested in their alternative in the form of protective glass a year ago, when I broke the glass on my iPhone (then 5S). After the replacement, the phone was poorly assembled, and the new screen turned out to be of poorer quality. So my new “six” received protective glass right away, you never know. And then I ordered several more different glasses to compare them.

So, what are the advantages of protective glass (as opposed to film):

- Most likely, the original glass of the screen will save you in the event of an unfortunate fall (I confirm - I have hook hands and experience).

- It is much easier to stick glass than film, under which any speck of dust bubbles up.

- The glass is more pleasant to the touch, it has a good oleophobic coating and protection against scratches.

- The glass is stronger and holds more securely; it won’t come off accidentally, for example, when putting the phone in a narrow pocket.

There are no downsides, in my opinion. But there are some peculiarities. The glass is thicker than the film, but personally I don’t feel it in any way. It cannot noticeably thicken or make the phone heavier. And if you have a smartphone/tablet of some very rare model, then you may not find suitable glass for it. But you can’t cut it like a film.

What types of glass are there?

Protective glass is a simple thing, like five kopecks, but it has its own characteristics. Firstly, thickness. Usually 0.3 mm, but 0.26 mm can also be found. I don't see any difference between these options. In addition, the description often contains the expression “2.5D”. This means that if the edges of the glass are slightly rounded, they are more pleasant to touch.

There are also “3D” glasses, they are designed for the currently popular phones with rounded screen edges. For example, Samsung Galaxy S6 Egde and iPhone 6/6S. True, technically we are most often not talking about solid curved glass; they are very fragile and difficult to manufacture. Manufacturers are coping with the situation in different ways. The coolest one is when the glass is the size of a phone screen, but not rounded. In this case, dirt and dust gets clogged under it. A more elegant solution is when curved metal sides are attached to ordinary glass (and to keep it all in place, there is a protective film on top). It looks good, although it's not for everyone. The metal edges seemed sharp to me.

My current favorite is glass with carbon fiber frames. Looks like the original iPhone panel. But it is relatively expensive (don’t buy cheap analogues, they look bad).

There are protective panels with different colors of screen edges - a way to refresh the appearance of your phone.

Of course, there are also regular protective glasses for phones with curved screens. They cover the front panel until it bends, that is, part of the glass still remains unprotected. In principle, this looks good, but it’s not very convenient when using gestures, when you have to move your finger from the very edge of the screen. It turns out to be some kind of obstacle, even if it is “2.5D”.

There are glasses with screen protection from prying eyes. There are “2 in 1” options, when protective glass is offered for both the front and rear panels.

The strength level for all glass sold is declared as 9H and is clearly illustrated. In my experience, glass still actively “catches” scratches, but it is not noticeable.

Protective glasses for smartphones are especially popular, but there are also a lot of them for tablets.

The easiest way, in my opinion, is to order from eBay or Aliexpress. I don’t chase brands, the penny “noname” is of quite decent quality, in branded packaging, complete with accessories for cleaning the screen. In our stores they sell the same thing, but at a premium. The main thing is to choose an experienced seller and read reviews (Ali has a lot of them in Russian, many with photos).

The simplest protective glasses cost from 1-3 dollars, while tricky ones for curved screens are more expensive. Delivery is usually free.

I repeat, it is easier to glue glass than film. It miraculously hides even small specks of dust that would turn into bubbles under the film. The kit usually includes wet and dry wipes, as well as dust removal stickers. Experts recommend gluing glass in a bathroom with a shower running. So that there is high humidity and all the dust is “nailed.” But I did pretty well without it.

The main thing is to place the glass so that it does not “squint” in one direction or another. This is important because it contains “eyes” for the camera and sensors. If it doesn’t work out exactly the first time, you can carefully peel off the glass and try again. Again, a plus - the film will not survive this. If large specks of dust do get under the glass, they can be removed using the Velcro from the kit or a piece of tape by carefully lifting the glass. That's all science is.

For absent-minded girls like me who periodically drop their phone, protective glass is a godsend and salvation. And even if you have never dropped the phone, think about it, maybe it’s worth protecting yourself? It’s a shame when, because of one awkward move, you have to pay a lot of money to replace the screen.

How to cut a mirror without a glass cutter

The mirrors around us: in the car, bathroom or women's cosmetic bag, are in structure ordinary glass with a layer of metal applied to the back surface. Cutting glass with a mirror coating is practically no different from regular glass and can be done with a regular glass cutter or using the methods described above. When you don't have a special tool at hand, the most effective cutting tool is a file or diamond blade. Let's take a closer look at how to cut a mirror at home without a glass cutter, using improvised means.

The first step is to prepare the surface to be treated: wash, degrease and dry. The mirror must be clean, without stains or strong streaks. Otherwise, the cut line may be drawn and the chip will be uneven. The working surface where cutting will be done must be flat and not very hard. You can lay a thick cloth or a piece of linoleum on the table.

Having prepared the material and workspace, mark the line of the future cut on the mirror. It is better to draw straight lines using a ruler or staff with a height of at least 5 mm. To prevent the stop from slipping, you can glue a strip of electrical tape to its bottom. Next, take a file, grinder or other tool and make a cut along the marked line. A more detailed process of various cutting methods is described above.

When the cut is ready, all that remains is to break off the mirror in the right place. To do this, you can place a small object (match, pencil, nail) under the cut line and apply light pressure on both sides. You can chip the glass on the edge of the table or gently tap it from underneath with a small metal object (drill or spoon). If the glass does not break, you do not need to press very hard. It is better to make the second cut a couple of centimeters from the first.

It is impossible to cut tempered glass in the usual sense. After hardening, the material changes its properties. Tempered glass is better known to the average consumer under the name “safe”. Cutting it in the traditional sense will result in the material simply breaking into many small fragments. However, despite the existing restrictions, with a strong desire, such material can be cut quite successfully. The work comes down to the fact that the glass is first annealed, and only then cut. The glass can then be reheated if desired to make it very strong and safe again.

The difference between tempered glass and regular glass.

Features of protective glass for phones

Protective glass not only provides protection for the smartphone, but also distributes the impact over the entire surface, preventing pinpoint impact. To protect the touchscreen from damage, the screen takes the impact, weakening it to a minimum. As a rule, the resulting damage to the protective glass takes the form of cracks and chips. Because of this feature, it will be extremely difficult to tear off the tempered glass from the display, because even one fragment can lead to scratches on the touchscreen.

Do not try to lift the edge with your fingers, picking it off with your nail - this action will not lead to the desired results. It is possible to carry out the removal procedure or even replace the protective coating with a new one correctly and without additional damage only after careful preparation.

What do you need to know about tempered glass before cutting it?

Tempered glass is characterized by increased strength. It is used for glazing balconies, loggias and light openings. A variety of furniture and translucent structures are created from this material. If you need to cut off tempered glass, you need to carefully prepare for this process, carefully studying all the features of the event.

First of all, you should study the properties of tempered glass. At its core, it is a thermally polished material. Unpolished and polished sheets of glass are used for its production. Direct hardening is carried out in furnaces specially designed for this purpose.

Glass cutting should be done on a flat surface with a cloth or piece of paper laid down.

In such a unit, the glass is heated to 680 degrees. At this temperature, partial softening of the material is observed. Next, the glass is rapidly cooled under the influence of uniform air flows. First, the surface layer cools down. During this process, the internal ones are subjected to residual compressive stress. It is thanks to this that tempered glass becomes so heat-resistant and mechanically strong.

According to average data, the strength of tempered glass is approximately 6 times higher than that of conventional material. It is quite difficult to break it without the desire to do it intentionally. Even if a tempered glass product breaks, the material will turn into many small fragments without sharp edges, so you won’t be able to get hurt by them the way you could with regular glass.

All stages of work, including edge processing, are carried out in production. This is done before the glass is sent to the tempering furnace. After all related measures have been completed, the hardened material is not subject to any mechanical stress. If you want to change anything, you will have to first anneal the glass.

Schemes of movement of a glass cutter on glass.

The scope of application of such material is quite extensive. Tempered glass is popular in construction and glazing of door and window openings; it is used to make showers, furniture and other structures. So if you are planning to make durable and reliable glazing, but do not have the skills to cut tempered glass, study the proposed instructions in detail and do everything in accordance with the instructions. If you think that such a process is too complicated for you, it is better to immediately contact the services of a specialized company to order products of the desired shape and size, with all the required cutouts and holes.

Features of stickers for some models

The main feature of each individual product will be the size of the glass and the presence of holes for function keys. As an example, it would be relevant to study the features that protection for an iPhone has, for example, a product such as Zool iPhone 5 0.1mm 9H.

Such pieces of glass have such features as an exact match to the size of the smartphone, the presence of a special coating for comfortable operation of the device, and increased protective properties of the glass combined with an ultra-thin design. However, as with other products, it is unlikely to be possible to remove the glass and put it back in place a second time.

Remember that you are putting a screen protector on your iPhone for security, not aesthetics or functionality. Carefully match all edges and holes before placing the glass screen on the device.

So is it possible to cut glass after tempering?

In fact, tempered glass can be cut. But you need to properly prepare for this so as not to end up turning a whole sheet into a mass of parts with blunt edges. To destroy a sheet, it is enough to simply hit its end with any suitable object. To change the size of the product, create cutouts, etc., you need to adhere to the technology and, first of all, directly study the properties of tempered glass.

Example 1. Tempered glass cutting technology.

The manufacturing technology of tempered glass is such that during its production, zones called internal stress areas are formed. When heated and further sharply cooled, the stress zones are redistributed. As a result of such changes, the inner layers retain the characteristics of a liquid body, remaining viscous, and the outer layers become much more durable when compared with simple glass that has not undergone the tempering procedure.

Thus, tempered glass receives its special properties directly during the tempering process. According to the technology, the material is first cut into the required pieces, holes are made, the shape is set, and after that it is hardened. Experts recommend refraining from further mechanical processing. However, if you are serious and categorical, first prepare your tools and remember the important nuances of cutting tempered glass.

Distinctive features of modern safety glasses

2.5D processing is a special processing of the ends along the entire perimeter. Glass processed in this way has a slight bevel at the end and additional hardening. The presence of a bevel improves tactile sensations, and the transition between the smartphone body and the glued protective glass becomes almost imperceptible both visually and to the touch.

The oleophobic coating, as noted above, prevents the formation of dust and grease, and allows the smartphone display to always remain clean. This happens because the special coating repels fat and dirt. In addition, you will feel how easily your finger glides across the screen, which undoubtedly makes using the phone easier.

Preparing for cutting: important points

In the hands of an inexperienced craftsman who wants to cut tempered glass, the product will instantly shatter into many fragments. The only effective option is laser cutting. However, it is unlikely that such a device can be found at home. Therefore, you will have to go another way, which requires preliminary annealing of the glass. Instructions will be given below.

Techniques for cutting glass using a ruler.

It is important to consider the fact that as re-annealed glass cools, the outer part will cool faster than the inner part. If the surface of the glass has already cooled, this does not at all confirm the readiness of the interior of the material. By slowly cooling the glass, large amounts of stress are prevented from forming in it. Thanks to this, it becomes possible to obtain a cut of higher quality. This point must be taken into account when cutting tempered glass yourself.

To complete this challenging job you will need the following:

Step-by-step instructions for cutting tempered glass

Cutting tempered glass involves preliminary annealing of this material. The process involves heating tempered glass evenly. The main task of this stage is to eliminate the stresses that appeared in the material during the previously performed hardening. It is these stresses that are the main obstacle to cutting safety glass. Get rid of them and you will be able to realize what you planned.

Annealing is performed in the following order. First, the glass is soaked in water at a constant temperature. It is necessary to soak until the temperature corresponding to the viscosity in the furnace unit is reached. It is equal to η = 1013 Poise. The time it takes to soak depends on how large a piece of glass you are cutting.

Example 2. Tempered glass cutting technology.

Glass brands Bullseye, Effetre and Lauscha are soaked at a temperature of +504 degrees Celsius. Borosilicate glass requires a higher soaking temperature, +566 degrees. And for Satake brand glass, the optimal temperature is +477 degrees. It takes an average of 20 minutes to soak small beads. Larger beads should be kept for an hour. Large paperweights are aged for 12 hours or more. Especially large products weighing 40 kg or more in some situations require hardening for a period of several months.

The glass must be gradually cooled to a temperature below the deformation temperature. It is equal to η = 1014.5 Poise. The process should be done fairly slowly so that additional stress does not occur. Satake brand glass is cooled at a temperature of +399 degrees Celsius. For cooling products of other brands, a temperature of +427 degrees is suitable. The glass must be cooled in the oven to room temperature.

Put on your safety glasses and start cutting the annealed glass. Take a square and mark the cutting line. The square must be held along the left line. Cut along the line with a glass cutter. Press with medium force, making a scratch along the marking line. It is allowed to carry out only 1 time along the line.

Next, you need to take a wooden rod 6mm in diameter, place it under the cutting line and apply a quick and sharp pressing force on both sides. If done correctly, the glass will break into 2 neat pieces. The edges of the resulting parts must be processed using a grinding stone. This will make the product more durable and safe.

If desired, the glass can be re-tempered. It is better if a professional does this work. The procedure requires appropriate skills and special equipment, so a beginner simply cannot cope with it.

Since the process of cutting tempered glass, which in practice is cutting annealed glass, is multi-step, you can simplify the task by purchasing plain glass, cutting off the desired sections from it, or preparing the desired holes and tempering it. This will save money, effort and time.

The list of necessary tools and devices mentioned a thermostat. It is needed to maintain the temperature in the oven at a constant level. You can do without it, but it’s easier with it.

Therefore, cutting tempered glass is very difficult. If you do not want to spoil the finished product, it is better to order new tempered glass or cut regular material and then either temper it or order it. Good luck!