In order to accurately cut glass, it is not enough just to have a high-quality tool (a separate article is devoted to the types of glass cutters and the features of their choice). It is also necessary to follow some rules that will allow you to get a good result.

What types of glass are there?

Without going into a detailed classification of glass, we note that in addition to ordinary glass, a home craftsman may be faced with the need to cut more complex glass. So, you should remember that cutting, for example, tempered glass at home will not work - the material will simply lose its properties or shatter into small pieces. Corrugated glass (and this is often used to create decorative elements of furniture and glazing of doors) should be cut from the smooth side. You can cut acrylic glass even without a glass cutter (if the glass is thin), just using a regular stationery knife.

Let's get to work.

Glass preparation. New glass usually just needs to be wiped clean before cutting. Used glass should be washed, then degreased and dried. To ensure that there is as little waste as possible after cutting, you can use special computer programs for optimal cutting of glass. It is better to combine the long side of the glass with the long side of the template (blank).

Old glass may lose its elasticity. You can make glass less fragile in the following way. Before work, you need to moisten the glass with water several times and let it dry (repeat 2-3 times).

Important! When working with any type of glass, you should not forget about labor safety equipment: safety glasses and thick gloves. You can also use special finger pads or simply wrap your fingers with adhesive tape.

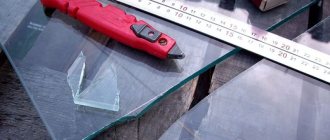

Before the cutting process, you need to prepare an absolutely flat surface, which should be covered with non-slip material. It is important that the glass fits tightly to the surface on which it lies.

Marking the glass can be done using a marker or a special pencil. To prevent the ruler from slipping, you can glue a thin piece of rubber on it. The thickness of the ruler must be at least 7mm so that the glass cutter fits tightly to it.

Before you start cutting, you should practice on unnecessary pieces of glass and check the glass cutter.

You need to hold the glass cutter in your hands like a pencil or pen. The line should be drawn in the direction of yourself, applying a uniform, but not very large force on the tool (with a diamond glass cutter it is better to rehearse in advance). When cutting, no glass dust or thick lines should be generated. If the work is carried out with a simple roller glass cutter, you can moisten the working element (roller) with oil, or lubricate the glass with it along the marking line. A slight cracking of the glass when cutting is a good sign. The glass cutter can only be drawn along the intended line once.

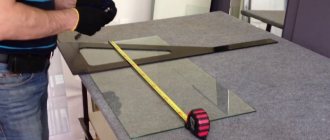

After the cut is made, the glass must be broken along the lines. Thin, small glass can be broken by hand. Large parts are placed on the edge of the table (a cut 3-5 cm from the edge) and broken, pressing on the part that hangs down. It is better to work with large parts with an assistant to prevent the glass from falling. Thick glass is sometimes cut on both sides and then tapped with a special hammer. Glass larger than 5 mm can be bitten off with pliers or wire cutters.

Obviously, if you follow simple rules, you can cut the glass yourself, thereby saving a lot of money.

Source: instrument-fit.ru

How to choose the right glass cutter

There are several varieties of this tool:

- oil;

- roller;

- curvilinear;

- diamond.

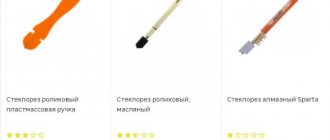

You can use each of the options to cut glass at home. However, they all differ in design and properties. It is necessary to study in more detail the process of cutting with different types of tools, then an idea of their intended purpose will be formed. Thus, the device of an oil glass cutter is in many ways similar to its roller counterpart, however, this model has a reservoir for filling the lubricant.

If you lubricate the surface while cutting with oil, the rate of development of the cutting edge is significantly reduced, which is due to a decrease in the intensity of friction. Lubricant is supplied automatically, which simplifies and speeds up work. The reservoir containing the oil is located in the handle. The service life of the tool is 5 thousand m. It can be used to work with material no thicker than 20 mm.

When the glass cutter stops cutting glass efficiently, the cutting edge can be replaced. Unlike a conventional glass cutter, the oil model can be equipped with a fixed and movable (rotating) head. The last option is designed for making bends. The design provides 2 options for the location of the head: with a sharpening angle of 135 and 150°. In the first case, the tool can cut material no thicker than 10 mm, in the second - up to 20 mm. More details about the oil glass cutter in the video:

If you need to choose a glass cutter, you need to consider the roller model. The head is movable. Cutting part material: tungsten and cobalt. The number of rollers may vary; more advanced models are equipped with 6 such elements, but they also cost more. Standard glass cutters work with glass up to 4 or 6.6 mm thick.

A curved tool is designed for making curves and complex patterns. The roller can make circles, ovals and other geometric shapes. In structure it resembles a compass. The tool is equipped with a suction cup, through which it is attached to the material, and the main part containing the cutting edge, the handle. The design provides an adjustable scale and a system of two rods; using these elements, you can make a radius characterized by the necessary parameters. Scissors are also used as an alternative cutting method.

Diamond glass cutter

The main structural element is a diamond crystal. Location: bottom of the tool. It is used to cut glass with a diamond glass cutter. The cutting element can be artificial or natural; accordingly, the restrictions on the use of the tool vary. In the first case, the material should be up to 5 mm thick. This model is inexpensive. It fully justifies its properties. This glass cutter is sufficient for household needs.

Natural diamond can cut thicker material than synthetic diamond, but it gradually becomes dull. To restore the function of the glass cutter, the cutting edge should be sharpened using a disk or block. Check the degree of sharpness of the tool by touching the glass: if a thin cutting line is visible, then the cutting edge is ready for use. This model is presented in two versions:

- curvilinear;

- with a tetrahedral cutting edge.

The service life of diamond tools is 10 thousand m.

Preparing glass for cutting

The degree of complexity of the preparatory work depends on the condition of the material. So, if you need to get finished products from glass that was just purchased, you won’t have to make any special efforts. In this case, simply wipe the surface. No need to use special detergents. At the same time, use newspaper to remove stains and dust. This method makes it possible to quickly prepare glass surfaces. Do not use a cloth as there is a risk of lint getting on the glass surface. The only exception is microfiber.

Used glass is prepared more carefully:

- it must be washed using a special glass cleaner;

- the surface is wiped dry;

- At the last stage, it is necessary to degrease the glass; for this, use a rag soaked in kerosene.

Before starting work, the sheet must be dried, leaving it indoors. You can additionally cover the material with film so that you do not have to repeat the cleaning procedure. The preparatory stage also includes cutting the material. If you need to make a circle of glass or other shaped elements, it is advisable to draw the contours as close to each other as possible. Then the material consumption will be small. Long elements should be placed along the larger side of the glass sheet.

Preparation of material and work table

To make a quality cut, the glass surface must be thoroughly cleaned. If the glass has just been purchased, then it will be enough to wipe it with newspaper, which does not leave behind streaks and lint.

The work table should be level, without significant slopes. The surface of the tabletop does not need to be made too hard; it is best to make it from chipboard and cover it with soft textiles or other similar material for more convenient cutting.

How to cut glass correctly with a glass cutter

The material must be placed on a horizontal, flat surface, such as a table. First, make some markings. This is done with a simple pencil. If you try to make a cut without backup, the line will turn out crooked. For this reason, it is recommended to use a ruler. It is placed next to the applied marking line - the distance should correspond to the width of the cutting edge of the glass cutter.

The ruler will move. To prevent slipping, rubber (from a bicycle inner tube) is first glued to the bottom side. If work is just beginning, the cut should be made in the direction from the edge of the glass sheet towards you. Different types of tools should be held differently, for example, a diamond glass cutter is handled in the same way as a regular ballpoint pen. In this case, a thin, almost invisible line remains on the surface.

The roller tool is held perpendicular to the horizontal plane. The handle should be between the thumb and middle finger. During the cutting process, moderate pressure should be applied to the tool. In this case, a white line remains on the material. If you need to cut glass with a curved glass cutter, install a suction cup, then adjust the rod system, making it possible to obtain a hole or arc of the desired radius.

Features of working with various glasses

Material with standard characteristics is cut with a roller tool or well-sharpened tailor's scissors. In this case, any other types of equipment, if available, can be used to work with glass. It is not advisable to purchase them specifically because of the high price. It is not recommended to cut hardened material. This will cause the sheet to simply burst. Hardened surfaces are durable, so the dimensions and desired shape are set during the production process.

If you need to cut corrugated material, characterized by patterns on the surface, you need to remember that its properties do not differ from ordinary glass. This means that it is permissible to work with it using a roller glass cutter. A diamond analogue will also work if it is available, but in this case there is no need to purchase an expensive tool. The cutting edge will cut the sheet from the smooth side.

Organic glass does not require the use of a glass cutter, since it is a material based on synthetic resins. This is a type of plastic, which means you can use a metal saw or a utility knife to cut it. To avoid having to collect splinters and shavings later, the surface of the work table must be cleared of foreign objects and covered with protective material.

Safety regulations

The approaches to how to properly cut glass with a roller or diamond glass cutter are the same. The main thing is to follow certain rules and remember safety precautions:

- wear protective equipment: gloves and goggles;

- place the glass on a flat surface and check that it fits well and does not vibrate;

- scratch along the ends of the cut line so that you can ease the pressure and avoid chipping the edge;

- a diamond glass cutter is taken at the base of the handle and guided without much pressure along the intended line;

- The roller glass cutter is clamped with a pinch between the thumb, ring and middle fingers, and the index finger is responsible for the pressure. It should be pressed to obtain a whitish cut;

- On the reverse side, lightly tap along the cut line;

- move the glass to the edge of the table and break it off along the cut line.

Expert advice! You can get an even cut line by using a ruler.

To prevent the ruler from slipping, it is glued with double-sided thin tape. This will also make the break easier. There is a relationship between the width of the glass and the width of the strip that breaks off freely:

| Glass width, mm | Strip width, mm |

| 3 | 3 |

| 4 | 5 |

| 5 | 7 |

| 6 | 9 |

| 8 | 12 |

Craftsmen have their own style when working with glass surfaces, but you should adhere to some general recommendations on how to cut glass correctly:

- there is no strong pressure applied to the glass cutter so that the edges of the cut do not crumble;

- one line - one cut, you cannot “cut” again in one place;

- movements with a glass cutter must be fast and confident. Optimal: 1 m in 2 seconds;

- towards the edge, the pressure decreases, which allows you to avoid crumbling the edges;

- mark the table, not the glass itself.

Preparing for cutting

The preparatory stage is one of the most important in the work; the preparation process largely depends on what kind of glass you plan to cut. So, if it is new, you can simply wipe it with old newspaper or paper so that small fibers do not settle on it and streaks do not appear.

If the working material has already been used, then preparation here will take more time and effort. First, you will need to rinse it well using a special chemical cleaner for glass. Next, degrease with a rag dipped in kerosene, and finally dry it indoors so that dust does not fall on the surface.

In addition to such preparation, the material will also need to be cut. Naturally, you should understand that you will not be able to achieve ideal waste-free work when working with this material, especially if we are talking about manufacturing a product of irregular geometric shape.

But if you make an accurate calculation in advance, you will significantly reduce the amount of waste generated.

In this case, the ideal option would be to combine the longer side of the glass with the long side of the prepared workpiece. The scraps remaining after work do not need to be thrown away; they can also be useful in the future when creating other glass products.

What is Krizet glass?

This is a special type of glass with a surface in the form of a repeating relief pattern. Often, the machine rolling method is used for production. A specified pattern remains on one or both surfaces, which is obtained using rolling cylinders with a specific pattern. They have found application in interior design, the production of interior doors, furniture, and also in window glazing. Patterned products are not recommended for use in rooms where there is a large amount of dust or soot. A classic design with the smallest details perfectly emphasizes the refined taste of the owner. The material is suitable for any interior, regardless of style.

Advantages:

- Original look.

- The optimal thickness is 4 mm.

- Unique texture.

- Easy care.

- High strength.

- Long service life.

Such glass must transmit and diffuse light streams. The light transmission coefficient for colored Krizet glass is 30-60%, for colorless glass it is 75-80%. These properties are influenced by the composition, color and characteristics of the products.

Glass cutter and its classification

Most often, a special tool is used to cut glass - a glass cutter. It is good because it is very convenient to use. In order to properly learn how to cut glass with its help, you need to follow the operating rules and choose the right tool of one type or another. And since the range of glass cutters is wide, this will not be a problem.

Glass cutters come in the following types:

- Diamond - this type of tool is the most common and has been tested for decades. For home use, it is best to choose options with a beveled cutting edge. With their help you can cut glass up to 10 meters long and of different thicknesses. However, we must not forget to periodically sharpen them on a special whetstone;

- roller - a feature of such tools is that their cutting part has the shape of a roller based on a durable alloy of cobalt and tungsten. The number of rollers can be from one to six;

- oil - these glass cutters work on the roller principle, but differ in that their handle has a reservoir with oil, which is supplied to the roller automatically. They are used for cutting thick glass.

Glass Krizet in the interior

The uniqueness of the material lies in the soft, uniform dispersion of light, thereby creating the illusion of a neutral and quiet space. Direct sunlight does not penetrate into the room, but the light remains quite bright. Due to the alignment and softening of directional light flows, Krizet glass has become popular in the production of partitions, decorative inserts, and interior doors.

Today they are used in office spaces, cafes, small apartments and huge mansions. When choosing such glass, I advise designers to take into account the general style direction of the room. Crisette is a stylish, bright decor, so they must match the design concept, as well as the color of other finishing materials in the interior.

How to cut correctly

Before you start working with this tool, you need to mark it with a simple or special pencil. It will be much more convenient to cut the material using a ruler at least 8 mm thick so that the glass cutter fits as tightly as possible. The ruler is placed on the surface of the material, then the tool is pressed against it, and then the cutting process is performed. To prevent the ruler from slipping on the surface, you can stick rubber particles on it, which can be taken from a bicycle inner tube. The ruler should be placed so that it is slightly further from the marking line.

For home work, a diamond or roller glass cutter is suitable. Diamond is more functional, but if we are talking about a corrugated surface, then only a roller will do. Remember that grooved, matte or patterned surfaces should only be cut from the smooth side.

The cutting should start from the main edge of the glass sheet. Further along the ruler, without stopping, draw a line in your direction. An important condition for ensuring that the work is completed efficiently is the correct placement of the tool. Here the situation depends on its type:

- When working with a diamond tool, it must be held in your hand almost vertically - like a pencil. Lead it in such a way that the mark that represents the diamond faces the ruler. If the work is done correctly, the cut line will turn out colorless and thin;

- but the roller glass cutter is held perpendicular to the surface of the glass. It is best to hold it between your middle and thumb and press on top with your index finger. In this case, you need to press harder than with a diamond tool. And the cut line is white.

Sometimes cut glass may break on the edge of a hard glass surface.

It is recommended to practice on used parts of glass before starting work, in order to avoid mistakes and damage to the material.

How to cut glass at home without a glass cutter

Twine, gasoline and lighter

The method described below will tell you how to cut glass evenly if you don’t have a glass cutter at hand. Everyone knows that the material is afraid of sudden temperature changes. This property can be used to cut it. For work you will need: twine with a maximum thickness of 2 mm (cotton only), lighter, gasoline (kerosene).

The glass sheet is placed on the table and a line along which it needs to be cut is marked with a marker. Measure and cut the twine so that it covers the entire length of the cut. After that, it is poured with gasoline and applied to the line on the glass. The twine must be set on fire so that it lights up along its entire length. When the thread goes out, water it with cold water. As a result, the glass will crack at the location of the temperature difference. If the crack does not extend across the entire sheet, then you need to repeat the procedure and lightly tap along the cut line.

Soldering iron

A straight cut is not always needed, and in this situation a file and soldering iron will help out. If you don’t have a soldering iron, a wood burning device will do.

The process is long but creative. First, mark the glass and use a marker to draw a cutting line on it. Then, at the edge, at the beginning of the mark, using a file, make a groove, which will serve as a guide. Having retreated a couple of millimeters along the line, use a soldering iron to heat the glass until a crack appears from the groove to the heating point. Then they retreat another couple of millimeters and repeat the process.

To make things go a little faster, the glass can be cooled with a damp cloth or dishwashing sponge.

File

For the first method, you need a file with corners; a round tool will not work. To cut glass, you should make several even thin strips on it with a tool. You need to press the file a little harder than average, and in the end you will get a clear, shallow strip, as if using a glass cutter. After this, you should simply break the glass on the edge of the table, or do this by placing a match under the cut.

The method is recommended for people who already have the skill to communicate with glass. If this is the first time such work is being done, it is better to try your hand at small pieces of glass in advance.

Scissors

It’s worth mentioning right away that the technique allows you to cut thin glass, no more than four millimeters. When working, it is recommended to wear safety glasses and protect your hands with gloves. You will need a container with water, in which, in fact, everything will happen.

Water acts as a lubricant, allowing you to cut the desired shape using scissors. No matter what tool you come across will not work - you need something serious, like tailor's scissors. Cutting is carried out according to pre-applied markings. The cutting force is comparable to what is needed when working with hardboard.

One more nuance: the container must be deep enough so that the layer of water above the glass immersed in it is large. To what extent it can be verified empirically, you should first experiment with an unnecessary piece of glass.

Charcoal cutting

Below we will talk about how to properly cut glass using a charcoal pencil (you can do it yourself). It allows you to cut various shapes from the material. To make the tool you will need: charcoal (linden, birch) and gum arabic. The coal is ground into powder, gum arabic is added to it and a kind of dough is kneaded. Round sticks are made from the mass, after which they are thoroughly dried.

Cutting with scissors

In addition to a glass cutter, scissors can also be used to cut glass. But this also needs to be done correctly. To work you will need:

- the scissors themselves, it’s better to take sewing ones;

- a tank with (preferably) hot water.

As in the previous case, apply markings to the glass in advance. During the work process, when cutting with scissors, a microcrack is created, and in the end everything ends with a capillary effect. This is all elementary physics.

The result obtained, of course, will not be ideal, but if there is a need to do something urgently, then this cutting method will do.

Features of working with different types of glass

If you work with ordinary glass, cutting will not cause any difficulties. Both a glass cutter and simple scissors are suitable for this purpose. But if you use glass with a complex configuration to produce products, then things are more complicated. Features of the work will largely depend on the properties of the materials:

- tempered glass - in general, it is better not to cut this material at home, otherwise it will simply lose its properties. But if you need a product with elements of such material, and you need to make it yourself, then it is better to cut it in advance. And remember that it is better to entrust the work to specialists, since the hardening process takes place only under a number of conditions;

- corrugated material - patterned glass sheets are often used for glazing doors or when creating decorative interior solutions. But unlike hardened material, this one can be cut at home. The work process is not much different from cutting ordinary glass, but, as mentioned earlier, you should cut only from the smooth side and preferably using a roller glass cutter;

- acrylic or organic material - it is a transparent plastic made from synthetic resins, but is still called glass. No special tools are needed to cut such materials. At home, you can use a cutter, metal saw and other edge processing tools for this purpose. And if the thickness of the material is 2 mm or less, then you can cut it with a simple stationery knife.

Source: tokar.guru

How to properly cut corrugated glass with a glass cutter

Rules for cutting tempered, grooved and fire-resistant glass

Very rarely, it may be necessary to cut fireproof glass, for example to replace it in an oven or fireplace door. At home and without special skills, such a procedure should not be carried out, since heat-resistant glass is a split system consisting of several tempered and non-tempered glasses. But some craftsmen use a grinder with a diamond blade of very small diameter. To avoid crumbling when cutting fireproof glass with a grinder, pour oil over the cut line. If you use not a grinder, but a machine with a diamond wheel, you can cut tempered glass at home. In this case, a cooling emulsion must be continuously supplied to the cutting wheel. You can cut it, but all the properties of such glass will be nullified. The technology for manufacturing tempered glass often involves imparting certain properties to an already finished product, such as a fireplace door.

Another type loved by designers and often used in everyday life for decorative purposes is corrugated glass. It differs from the usual one in that it has a non-smooth surface on one side. It is necessary to cut corrugated glass on the flat side with any glass cutter, but an oil cutter is preferable. To make it convenient to work, the table is covered with a soft cloth, on which a glass sheet is placed.

About the author: vremont

« Previous entry