Main characteristics

Fireproof glass is a material that differs from ordinary glass only in its resistance to high temperatures. These products can be used in conditions where this value can reach about 1 thousand degrees.

In production, such glasses are produced by adding special refractory compounds to the base composition, for example Al2O3, B2O3, etc. This allows you to develop not only heat resistance, but also heat resistance.

Moreover, these characteristics directly depend on the thickness of the product; the higher it is, the better it will withstand the effects of temperature.

Heat-resistant glass can be divided into several main groups:

- Class E. Products of this type are used for protection against hot gases and fire. Can be melted only with prolonged heating.

- Class 1. Such glasses are used for temperature protection.

- Class R.

- Class W. These glasses are not used as a protective material.

It should be noted that fireproof products are somewhat different from tempered glass. The latest products crumble very easily on impact and are not able to withstand high temperatures.

Preparatory stage

When considering how to cut tempered glass, you should consider the preparatory stage. Careful preparation allows us to achieve high quality. Cutting tempered glass at home is carried out taking into account the information below:

- During the production of the material, zones with internal areas of stress are formed. With rapid heating and cooling, such areas are redistributed. The inside of the glass becomes more viscous compared to the outer layer.

- At the time of processing, the workpiece must be securely fastened. A variety of devices can be used for this.

- The surface of tempered glass must be cleaned of contaminants. An example is oils or paint, which can significantly reduce the quality of processing.

In general, we can say that preparation for work is quite simple. However, without special tools and equipment, cutting will not be possible.

Glass processing

Cutting fire-resistant glass is a rather complex process that requires special tools. There are several ways to perform this procedure at home:

- Using a pobedite cutter with turpentine.

- An alternative is to use a thin diamond wheel. To optimize the process, be sure to water the cut to remove dust and cool the working part. At the same time, this must be done very carefully, without unnecessary stress.

Cutting tempered glass is absolutely excluded and is not performed with any tools. Although some home craftsmen manage to do this, it rarely happens without damaging it.

If you need to cut heat-resistant glass, it is advisable to entrust this to specialists who already have certain skills in solving such problems.

Watch the video to see how fireproof glass is made:

Personally, I have already encountered the need to cut such glass several times. And I didn’t see anything unusual or insurmountable here. I cut it the same way as usual - with a diamond glass cutter. Of course, the hardness of fire-resistant glass is much higher than that of ordinary glass, but a good glass cutter can easily cope with it. If desired and possible, you can make cuts on both sides and tap thoroughly along the cut line.

It is impossible to cut tempered glass in the usual sense. After hardening, the material changes its properties. Tempered glass is better known to the average consumer under the name “safe”. Cutting it in the traditional sense will result in the material simply breaking into many small fragments. However, despite the existing restrictions, with a strong desire, such material can be cut quite successfully. The work comes down to the fact that the glass is first annealed, and only then cut. The glass can then be reheated if desired to make it very strong and safe again.

Read also: Grinding attachments for engravers

The difference between tempered glass and regular glass.

Types of glass cutters

First of all, you need to remember that there are different types of glass: regular window glass, tempered glass, plexiglass, acrylic glass, corrugated glass, and ten more options. Also, even an ordinary one can be quite thick or, conversely, thin and very fragile. Depending on the type, the tool and cutting method are selected. But using a glass cutter is the most common option.

The construction market offers several options for glass cutters:

- Diamond can cut glass of almost any thickness and its service life is long. A diamond is used as a working element, which, if necessary, can be easily turned with an unsharpened edge;

- roller has a working part, which is made of an alloy of cobalt and tungsten and is characterized by increased strength . The number of rollers ranges from one to six and they can be replaced;

- The oil one has rollers and a reservoir with lubricant, which flows to the surface and reduces friction. When worn out, the roller itself and its fastening require replacement;

- with a compass function that allows you to cut circles. Most often, an ordinary oil glass cutter is mounted on a special device with a scale that allows you to set the diameter of the circle.

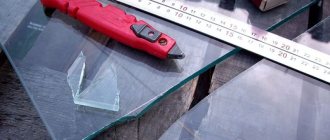

Before cutting glass with a glass cutter, you need to prepare it:

- clean from dirt, possibly wash and wipe dry;

- remove the slightest dust, since the smallest particle that a glass cutter stumbles upon can become a source of cracking;

- if used glass is used, it is also degreased with kerosene;

- drawing cutting lines.

What do you need to know about tempered glass before cutting it?

Tempered glass is characterized by increased strength. It is used for glazing balconies, loggias and light openings. A variety of furniture and translucent structures are created from this material. If you need to cut off tempered glass, you need to carefully prepare for this process, carefully studying all the features of the event.

First of all, you should study the properties of tempered glass. At its core, it is a thermally polished material. Unpolished and polished sheets of glass are used for its production. Direct hardening is carried out in furnaces specially designed for this purpose.

Glass cutting should be done on a flat surface with a cloth or piece of paper laid down.

In such a unit, the glass is heated to 680 degrees. At this temperature, partial softening of the material is observed. Next, the glass is rapidly cooled under the influence of uniform air flows. First, the surface layer cools down. During this process, the internal ones are subjected to residual compressive stress. It is thanks to this that tempered glass becomes so heat-resistant and mechanically strong.

According to average data, the strength of tempered glass is approximately 6 times higher than that of conventional material. It is quite difficult to break it without the desire to do it intentionally. Even if a tempered glass product breaks, the material will turn into many small fragments without sharp edges, so you won’t be able to get hurt by them the way you could with regular glass.

All stages of work, including edge processing, are carried out in production. This is done before the glass is sent to the tempering furnace. After all related measures have been completed, the hardened material is not subject to any mechanical stress. If you want to change anything, you will have to first anneal the glass.

Schemes of movement of a glass cutter on glass.

The scope of application of such material is quite extensive. Tempered glass is popular in construction and glazing of door and window openings; it is used to make showers, furniture and other structures. So if you are planning to make durable and reliable glazing, but do not have the skills to cut tempered glass, study the proposed instructions in detail and do everything in accordance with the instructions. If you think that such a process is too complicated for you, it is better to immediately contact the services of a specialized company to order products of the desired shape and size, with all the required cutouts and holes.

Safety regulations

The approaches to how to properly cut glass with a roller or diamond glass cutter are the same. The main thing is to follow certain rules and remember safety precautions:

- wear protective equipment: gloves and goggles;

- place the glass on a flat surface and check that it fits well and does not vibrate;

- scratch along the ends of the cut line so that you can ease the pressure and avoid chipping the edge;

- a diamond glass cutter is taken at the base of the handle and guided without much pressure along the intended line;

- The roller glass cutter is clamped with a pinch between the thumb, ring and middle fingers, and the index finger is responsible for the pressure. It should be pressed to obtain a whitish cut;

- On the reverse side, lightly tap along the cut line;

- move the glass to the edge of the table and break it off along the cut line.

There is a relationship between the width of the glass and the width of the strip that breaks off freely:

Craftsmen have their own style when working with glass surfaces, but you should adhere to some general recommendations on how to cut glass correctly:

- there is no strong pressure applied to the glass cutter so that the edges of the cut do not crumble;

- one line - one cut, you cannot “cut” again in one place;

- movements with a glass cutter must be fast and confident. Optimal: 1 m in 2 seconds;

- towards the edge, the pressure decreases, which allows you to avoid crumbling the edges;

- mark the table, not the glass itself.

So is it possible to cut glass after tempering?

In fact, tempered glass can be cut. But you need to properly prepare for this so as not to end up turning a whole sheet into a mass of parts with blunt edges. To destroy a sheet, it is enough to simply hit its end with any suitable object. To change the size of the product, create cutouts, etc., you need to adhere to the technology and, first of all, directly study the properties of tempered glass.

Read also: DIY collet clamp for a router

Example 1. Tempered glass cutting technology.

The manufacturing technology of tempered glass is such that during its production, zones called internal stress areas are formed. When heated and further sharply cooled, the stress zones are redistributed. As a result of such changes, the inner layers retain the characteristics of a liquid body, remaining viscous, and the outer layers become much more durable when compared with simple glass that has not undergone the tempering procedure.

When point blows are applied to the end zones, another redistribution of the existing stresses occurs. Due to microcracks, the integrity of the sheet is compromised, so that if handled incorrectly, even the slightest blow will lead to the formation of extensive webs of cracks of various sizes. The glass will simply collapse at the slightest external force. This principle is the basis for car windows: they can be easily broken by a sharp blow from a sharp object. The film makes the glass injury-proof: it holds the fragments and does not allow them to harm the driver.

Thus, tempered glass receives its special properties directly during the tempering process. According to the technology, the material is first cut into the required pieces, holes are made, the shape is set, and after that it is hardened. Experts recommend refraining from further mechanical processing. However, if you are serious and categorical, first prepare your tools and remember the important nuances of cutting tempered glass.

How to cut tempered glass at home?

Tempered glass is considered one of the most common materials. To increase its strength, hardening technology is used. After carrying out such a procedure, the degree of machinability of the material is significantly reduced. When considering whether it is possible to cut tempered glass, we note that only by using special technologies can the occurrence of a defect be avoided. Today, cutting tempered glass can be done at home, using a variety of tools.

Tempered glass cutting

Preparing for cutting: important points

In the hands of an inexperienced craftsman who wants to cut tempered glass, the product will instantly shatter into many fragments. The only effective option is laser cutting. However, it is unlikely that such a device can be found at home. Therefore, you will have to go another way, which requires preliminary annealing of the glass. Instructions will be given below.

Techniques for cutting glass using a ruler.

It is important to consider the fact that as re-annealed glass cools, the outer part will cool faster than the inner part. If the surface of the glass has already cooled, this does not at all confirm the readiness of the interior of the material. By slowly cooling the glass, large amounts of stress are prevented from forming in it. Thanks to this, it becomes possible to obtain a cut of higher quality. This point must be taken into account when cutting tempered glass yourself.

To complete this challenging job you will need the following:

- Directly tempered glass.

- Warm water.

- Bake.

- Thermostat. The presence of this element is desirable, but you can do without it.

- Marker.

- Square.

- Grinding stone.

- Glass cutter.

- Wooden rod. A product with a diameter of 6 mm will be sufficient.

- Protective glasses.

How to replace a glass cutter

Not only professional tools will help when cutting glass, but also not quite ordinary ones, for example, such as scissors or a grinder. They can easily cope with such work under certain conditions.

Scissors cannot cut glass in the air, but you can cut glass with scissors in water. In a liquid, gravity is less and the scissors make not a cut, but a microcrack. This crack plays the role of a capillary into which water will enter. Capillary water has a wedging effect at weak points of crystallization and the glass breaks off in pieces.

Interesting! If it is necessary to cut out shaped parts, the glass is placed in cold water and then boiled for several hours. After cooling, the tension inside is relieved and the material becomes soft.

There are several ways and options for cutting thick glass. The simplest one is to use an oil glass cutter if the thickness is no more than 20 mm. But as an option, you can use a grinder. The dimensions of the tool should be small and convenient. The diameter of the circle is the smallest, then it will be easier to work with.

Required Tools

As previously noted, cutting tempered glass can only be done using special equipment and tools. It is as follows:

- Special furnace for processing tempered glass.

- Thermostat.

- Square.

- Marker for marking the surface.

- Grinding stone.

- Special glass cutter.

- A rod with a diameter of 6 mm, made of wood.

- Goggles designed to protect the eyes. When cutting, chips may be formed that fly away from the cutting zone.

Cutting tempered glass with a grinder

Using special equipment, tempered glass can be cut to precise dimensions and high quality edges.