Glass is one of the most popular materials in construction. Being the main part of the window, it lets in sunlight while maintaining comfortable indoor conditions. It is used for glazing facades, decorative elements, dishes and even furniture are made from it.

In addition to classic window glass, the industry offers materials that are similar in appearance, but have much higher characteristics. One of the striking examples of such products is fireproof glass.

Types of fasteners and performance of work

The type of product is selected depending on the expected load:

- for fastening hanging mirrors or lamps, nylon dowels with a cross-section of up to 12 mm are suitable;

- when installing pipelines and bulky objects, choose metal parts;

- frame types of fastenings are used to fix window and door frames;

- universal facade dowels are used when installing external profiles for facing slabs;

- Only light objects are attached to wood screws - photo frames or decorative elements.

Installation is carried out in several stages.

In order for the products to fit tightly into the base, it is necessary to drill the holes correctly. To do this, it is best to use a hammerless drill or a hammer drill with the impact turned off. The drill should have a cross-section 1 mm smaller than the fastener itself. The only exception is steel hardware. For them, the hole will be reduced by 2 mm.

After cleaning the recess from concrete dust, install a dowel. The plastic fastener is screwed in using a screwdriver. Metal parts are driven into the mounting hole with a hammer. During the work, it is necessary to ensure that the product does not warp.

At the final stage, screw in a self-tapping screw or a standard mounting bolt. In this case, it is not advisable to use an electric tool, since when connecting to an aerated concrete block, the screw element may be damaged.

Fireproof, heat-resistant and heat-resistant - what's the difference?

When choosing glass for a fireplace or stove, special attention should be paid to its strength, because your safety primarily depends on this. It must be heat-resistant - resistant to sudden changes in temperature and capable of not deteriorating from sudden hot collisions

An ordinary glass product, when in contact with a flame, heats up to 500°C in half an hour, while a heat-resistant glass product, when interacting with a fire, can heat up by about 70°C in the same time.

The essence of fire resistance of glass is safety first and foremost - it prevents sparks from entering the room from the furnace, and also prevents ash and soot from entering the room. Its heat resistance is approximately 700°C.

Heat-resistant glass is a unique type that includes both high heat resistance and high-quality fire resistance. Quartz glasses are the most heat-resistant, capable of withstanding oven temperatures of up to 1000°C.

Conclusion

All problems and possible dangers related to the open flame of a fireplace or stove can be solved by installing heat-resistant glass, which can withstand the effects of elevated temperatures for a long time. The amount of this time directly depends on the characteristics of the glass and the operating process. Laminated heat-resistant quartz glass is the most optimal, comfortable and effective among other options.

Advantages:

- Protecting the room from sparks from the stove, preventing contact with open flames, which is very important for families with children;

- Preserves aesthetic use - does not interfere with observing live fire;

- Plays a role in the image of the house, creates a pleasant impression of the good taste of the owner.

Heat resistant glass

Glass is an inorganic substance. It is characterized by the properties of a solid; in the molten state it is a superviscous liquid. Its fragility, strength, density and heat capacity vary greatly and depend on impurities.

Recently, materials have been developed that have properties atypical for glass, such as fire resistance. The main parameter that distinguishes heat-resistant glass from other glasses is the temperature at which it retains its properties. It can withstand heating even at 1000 degrees Celsius, while its “colleagues” crack already at 80 degrees.

Characteristics of heat-resistant glass for fireplaces

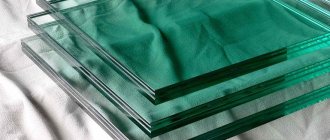

Fireproof glass for a fireplace has a number of characteristics that you should definitely pay attention to. Firstly, this is the maximum heating temperature, which is not recommended to be exceeded. Secondly, the strength of the fireplace glass itself. Next, you should pay attention to the thickness of the heat-resistant glass. In some models, the firebox design provides fireplace glass up to 4 mm thick.

The most important indicator for the consumer is the service life of the glass. The service life of glass depends on the maximum operating temperature of the fireplace. At temperatures no higher than 600 degrees, glass will last several thousand hours. At higher temperatures, the service life is reduced to a large extent. Therefore, it is not recommended to burn fireplaces with coal, overload the firebox with a large amount of firewood, or create a high draft mode.

A fireplace in our traditional concept is more of an open fireplace, but today closed fireplaces are more popular. This is primarily due to fire safety, as well as aesthetics; such a fireplace requires less attention. Externally, a closed fireplace resembles a traditional fireplace, at the same time it produces significantly more heat, in such a fireplace you can even control the combustion process and, most importantly, such fireplaces are safe. Fireplace glass allows you to enjoy the view of the fire without worrying about the safety of the room.

About the areas of application of fireplace fire-resistant glass

This material is often found in panoramic doors of stoves or fireplaces. It is also often used to install inspection panels that allow control of draft in the heating system. Experts note that fireproof glass for a fireplace can only be used in conditions where the temperature does not exceed 750 degrees. The material can also be used in barbecues and braziers. And the glass doors that all microwave ovens are equipped with are also made of this glass!

At the beginning of the article, we already mentioned one of the types of material - borosilicate glass. It is characterized by resistance to aggressive environments and a maximum temperature of 450 degrees. Thanks to these features, it can be used for screens of heating devices or lamps. It can also be found in laboratory or industrial equipment - where inspection pipes are made from glass.

As for fireplace glass specifically, today they are produced in a fairly wide range - from the usual front position to installation in a wide variety of planes. Very often, side fireplace walls are also made from it.

Note! Another area of application is floor covering next to the fireplace - it is not only beautiful, but also safe. This coating is not afraid of fire, sparks, or falling fireplace accessories.

But not only fireplaces are made from this glass. So, even dishes are made from it - for example, for cooking in microwave ovens.

Varieties

The very concept of “fire-resistant glass” includes a wide range of materials that differ in production technology and purpose.

There is a distinction between glass that protects from high temperatures and glass that does not interfere with heat transfer, but protects the room from combustion products and prevents the spread of fire. The first is used in fire protection systems, the second in heating systems, for the manufacture of cooking surfaces and dishes. There are three main types of fire-resistant glass:

- reinforced;

- hardened;

- compositional.

Wired fire-resistant glass can withstand loads associated with temperature changes due to the presence of a metal mesh inside. This solution makes it possible to provide the product with sufficiently high heat resistance, but noticeably limits the scope of its application due to low transparency. Such materials are widely used in fire protection systems.

The technology for producing tempered glass includes the procedure of repeated heating and cooling of the material (hardening). Both single-layer glass and multi-layer glass units are available for sale. In double-glazed windows, the space between the sheets is filled with a special transparent multi-component gel. These solutions are quite affordable in price and at the same time have good consumer characteristics.

Special mention should be made of composite heat-resistant glass. In a general sense, this is not glass, but glass ceramics. The material has a virtually zero coefficient of thermal expansion, which allows products made from it to withstand extremely high temperatures.

Preparatory stage

When considering how to cut tempered glass, you should consider the preparatory stage. Careful preparation allows us to achieve high quality. Cutting tempered glass at home is carried out taking into account the information below:

- During the production of the material, zones with internal areas of stress are formed. With rapid heating and cooling, such areas are redistributed. The inside of the glass becomes more viscous compared to the outer layer.

- At the time of processing, the workpiece must be securely fastened. A variety of devices can be used for this.

- The surface of tempered glass must be cleaned of contaminants. An example is oils or paint, which can significantly reduce the quality of processing.

In general, we can say that preparation for work is quite simple. However, without special tools and equipment, cutting will not be possible.

Thermally strengthened glass

Thermally strengthened glass also provides higher resistance to thermal and mechanical stress compared to conventional glass. These glasses are approximately twice as strong as thermally untreated glass. In the event of destruction, thermally strengthened glass breaks into large pieces, since this releases much less mechanical energy (Figure 2). This is due to the fact that during heat treatment these glasses are subjected to less stress compared to tempered glasses. When thermally strengthened glass breaks, it typically remains in place in the window frame or sealant around the perimeter of the façade opening. Thermally strengthened glass is not safety glass in itself, but is widely used in safety laminated glass.

Figure 2 – Nature of destruction of thermally strengthened glass [1]

How to make glass from sand

Most likely, you know that sand is needed to make glass, and indeed, it is the most important ingredient. To make a glass product transparent, quartz sand without metal impurities is used, which gives the material colored shades.

To make glass you will need siliceous sand, otherwise called quartz.

Since quartz sand has a melting point of 2300⁰C, components are needed that will help reduce it in order to make the manufacturing process easier and more affordable. Such an ingredient was sodium carbonate or ordinary soda ash, thanks to which the smelting temperature was reduced by almost half.

Baking soda (sodium carbonate) lowers the temperature required to produce glass sheets.

Soda makes glass water-permeable, which makes it impractical in everyday life and in production. To give the material strength, calcium oxide or lime is added to the alloy. Additionally, the composition may contain magnesium or aluminum oxides for maximum resistance to physical and chemical factors.

To produce thin decorative glass, such as crystal, lead oxide is used as an additive, which gives the products shine and fragility. Lanthanum oxide is commonly present in eyeglass lenses due to its ability to refract light rays.

The most commonly used additive in the production of decorative glass is lead oxide, which adds shine.

Sapphire glass for glasses is made with the addition of aluminum oxide, which makes it maximum hard and resistant to physical damage. To make colored glass, iron oxide is added to the alloy to produce red, nickel for brown and purple tints, copper and chromium for green, cobalt for blue and other metals.

In production, glass is made in several stages: first, the key components are melted together in a furnace to form a homogeneous alloy, then sent to a container made of tin, which does not mix with the glass, maintaining its homogeneity. Already at this stage, the glass gradually cools, becomes smooth and thin.

To obtain a homogeneous mass, it is necessary to remove the bubbles - to obtain this effect, glassmakers constantly stir until the molten glass mass thickens.

The alloy cools completely when moving along a conveyor, the length of which can reach 100 m; this is necessary to prevent the formation of excess pressure inside the alloy, which can lead to future defects. After the conveyor, the glass is further processed to create various products.

Glasses differ only in the constituent material used for manufacturing. But the process itself is almost the same.

Production technology

Ideally even sheets of glass are obtained by pouring a quartz-lime mixture brought to a temperature of about 1000 °C into a special bath of molten tin (lead was originally used, but it was later replaced with light alloy metal to reduce production costs). On this basis, the liquid mass is formed into sheets with perfectly parallel outer sides. The glass melt is protected from external influences by a gas mixture of nitrogen and hydrogen, and the thickness of the products is formed by controlling the spreading process of the molten mass. Today, float glass production is carried out using 3 technologies:

- Soviet

- a 2-stage method based on the sequential supply of glass from a melting plant into a bath of tin, and then onto a gas-air cushion at a temperature of 650 °C, where the final formation and cooling of the strip occurs. The production process is completed in the kiln. There, at a temperature of 570-580 °C, any tension spots on the surface of the sheets are eliminated. This technology began to be developed and implemented in 1959. It differs from the analog English method in temperature conditions and sequence of actions. Thanks to this, Soviet technologists were able to obtain better characteristics for the lower surface of the glass tape. - English

is a basic technology that was developed in 1952 by Alastair Pilkington. The technique is based on free gravitational drainage of glass melt into a tray with molten tin, the temperature of which is 600 °C. For a long time, Pilkington was unable to obtain dimensional sheets of sufficient width. The first batches had a width of 300-760 mm. It was possible to increase this parameter to 2540 mm only by the beginning of 1959. Although it is argued that the Soviet methodology was developed independently of the English one, there is a high probability that our scientists still took into account the unsuccessful experience of their British colleagues. - American

- created in 1974 and differs from the technologies of glaziers from Britain and the USSR. This method is based on the operation of a unit with a special design of a unit for draining glass melt from the melting plant into the bath where the molding takes place. Due to the same level of the horizontal layer of the melt when it is transferred from the furnace and enters the container with tin, uniform formation of sheets is ensured. This allowed the products of American manufacturers to surpass the optical characteristics of float glass from the USSR and England.

The thermal firing procedure is mandatory for any of the 3 listed technologies. After all, it is this process that makes it possible to avoid a decrease in mechanical characteristics that is possible with sudden cooling of the glass tape. To avoid deformation processes, products are subjected to heat treatment for a certain time at a temperature of 570-605 °C. After this procedure, the glass is cooled to 80 °C, the tape is cut into sheets and the finished product is packaged on pallets.

Glass processing

Cutting fire-resistant glass is a rather complex process that requires special tools. There are several ways to perform this procedure at home:

- Using a pobedite cutter with turpentine.

- An alternative is to use a thin diamond wheel. To optimize the process, be sure to water the cut to remove dust and cool the working part. At the same time, this must be done very carefully, without unnecessary stress.

Cutting tempered glass is absolutely excluded and is not performed with any tools. Although some home craftsmen manage to do this, it rarely happens without damaging it.

If you need to cut heat-resistant glass, it is advisable to entrust this to specialists who already have certain skills in solving such problems.

Watch the video to see how fireproof glass is made:

Required Tools

As previously noted, cutting tempered glass can only be done using special equipment and tools. It is as follows:

- Special furnace for processing tempered glass.

- Thermostat.

- Square.

- Marker for marking the surface.

- Grinding stone.

- Special glass cutter.

- A rod with a diameter of 6 mm, made of wood.

- Goggles designed to protect the eyes. When cutting, chips may be formed that fly away from the cutting zone.

Cutting tempered glass with a grinder

Using special equipment, tempered glass can be cut to precise dimensions and high quality edges.

Types of float glass

Basically, thermopolished glasses are divided into clear, colored and extra transparent (coated). These products are the basis for the manufacture of all other types of glass:

- hardened (heat-strengthened);

- reflex;

- triplex;

- energy saving;

- multifunctional;

- darkening;

- self-cleaning.

Float glass is also sandblasted and chemically etched. This allows you to apply images and patterns to it or matte its surface using different colors.

Colored float glass with a large sheet area can crack during operation if they are used on a façade plane that is not uniformly illuminated by the sun. Due to the uneven distribution of energy and the appearance of a critical temperature difference in different areas of the same sheet, there is a high probability of cracks appearing. To avoid this, on unevenly illuminated surfaces it is recommended to use colored glass with a light absorption coefficient of no more than 25%.

Fire glass markings

Most of the information regarding the characteristics of fire glass can be found from its labeling. Letters of the Latin alphabet are used for designation:

- E – resistant to destruction;

- I – has high resistance to heating to a critical temperature;

- W – retains heat and does not allow heat to pass into the adjacent room.

The manufacturer guarantees the preservation of the declared characteristics for a certain time. Time in minutes is indicated after the letter marking. For a better understanding, you can consider examples:

- EIW 60 – the product is resistant to destruction, resistant to heat and retains heat for 60 minutes.

- EI 60 – resistant to destruction, prevents heating for 60 minutes.

- EI 30 – resistant to destruction, prevents heating for 30 minutes.

Disadvantages of the material

It is worth remembering that most types of fire-resistant glass are fragile. When working with this material, shock loads and excessive pressure on its surface should not be allowed.

Fire-resistant glass is difficult to process. Many types of glass are not cut at all, or laser or hydraulic devices are used for cutting. Cutting it at home is extremely difficult. It’s better to measure several times to make sure the dimensions are correct than to try to fit the sheet to your needs.

When there is simply no other option other than cutting, a small grinder with a diamond wheel will come to the aid of the craftsman.

You must work with extreme caution, avoid excessive pressure, and constantly moisten the cut area with oil. Cutting glass with fire-resistant properties will be a long and dirty procedure, and no one will guarantee a positive result.

Stamps

The price of fireproof glass for a furnace directly depends on its manufacturer. Below are the main manufacturers of this product:

- SCHOTT GLAS . The German manufacturer, which is fully responsible for the quality of the product, offers for purchase transparent heat-resistant or mirror glass ROBAX, which will be suitable for fireplaces and stoves of various types. Also, when ordering from this company, they are cut to the size required by the customer. You can calculate the cost of your order on the website. Delivery is carried out to any region of the Russian Federation.

- First Moscow mirror factory . Engaged in the manufacture of all types of fire-resistant glass according to individual customer sizes, and, if necessary, organizes any additional form of processing. You can calculate the cost on the official website.

- NIPPON NEOCERAM N-0 . The Japanese company offers to purchase super clear glass, which has greater transparency than its German competitors. Invariably withstands all sudden temperature changes. The shelf life exceeds 30 years, and the expansion coefficient is catastrophically close to zero. Available sheet sizes: 2100 by 1266 mm and 4 mm thick or 2100 by 1266 with a thickness of 5 mm. The price depends on the selected size.

- SCHOTT CERAN . A German company offering to purchase black glass, which has increased transmission capacity - it can transmit heat with minimal losses. One side is polished, the other has a special wave-like surface. Prices depend on size and are presented on the website of Russian suppliers.

- CrossFire Cerama . Transparent glass with an interesting golden tint that can withstand temperatures up to 1000°C. The cost is about 9,000 rubles.

Application

Heat-resistant glass is popular in the kitchen. Ovens and dishes are made from it. A common product made from this material is also a fireplace. Quartz glass is used in the production of optical fibers, Fresnel lenses, crucibles, insulators, etc. Borosilicate glass is used for optical glasses, dishes, and reflecting telescopes.

Fireproof glass cookware has many advantages. It can withstand even open fire and is durable. The material is quite inert and does not oxidize when heated, so it does not change the taste of the dish. It is not subject to corrosion and scale formation.

Manufacturing Features

The production of fire-resistant glass is a complex technological process that includes constant monitoring at every stage. Production technology varies, it depends on the type and purpose of the material.

Borosilicates are used to produce inexpensive but high-quality types of fire-resistant glass. Quartz glass is more expensive. The components are mixed, melted, rolled. The resulting sheet material undergoes a cycle of specific production processes, consisting of chemical treatment, hardening, followed by high-temperature polishing. All this is designed to ensure the proper level of heat resistance and give the glass an attractive appearance.

Fire-resistant glass must undergo temperature tests, based on the results of which a product certificate is issued.

What types of glass fireplace doors are there?

When considering all the options for creating glass fireplace doors, you need to decide on the shape of the door.

Typically, flat and segmented door shapes are considered. Flat doors can be:

- Rectangular;

- Square;

- Round;

- Trapezoidal;

- With a rounded top.

Such flat doors can consist of one leaf or be double-leaf. In the first case, the frame contains one solid piece of glass, in the second, each of the doors has its own glass.

But as for the volumetric form, there are options here:

- Straight flat glass;

- Convex dome-shaped glass;

- Door made of three segments.

Such doors are usually installed with transparent or tinted material. True, tinting is applied during the production process; it is very difficult to do this at home.

A technology such as stained glass is also used, which uses several types of glass, different in color, which form the desired ornament or pattern. But unlike classical stained glass, individual fragments are connected during the melting process, and not using the classical method using lead or copper tape and tin solder.

Thermally strengthened glass in laminated glass

Multilayer glass is sometimes called laminated glass, as well as triplex glass. They are made from two or more glasses with a special film placed between them. This entire “structure” is glued together at elevated temperatures and pressures in a special autoclave.

Laminated glass is safe because when it breaks, glass fragments remain glued to the film, which reduces the risk of damage to people.

Laminated glass can be made from both conventional annealed glass and thermally strengthened glass. The use of thermally strengthened glass in laminated glass has the following advantages:

- Thermally strengthened glass is twice as strong as annealed glass of the same thickness. This increased strength allows larger panes to meet wind load requirements without the need for thicker annealed panes.

- Thermally strengthened glass reduces the likelihood of glass destruction under the influence of thermal and mechanical loads.

Thermally strengthened glasses introduce characteristic optical distortions into laminated glass, such as marks from the tempering furnace rollers. However, these distortions are much less noticeable than for tempered glass. The design feature of laminated glass can give rise to a new type of optical distortion: a lens effect in places where the film is thick or where the two glasses are not parallel.

What it is?

Heat-resistant furnace glass is an incredible advance in the development of glass production methods. Thanks to its composition and high-quality production method, it has:

- good sound insulation - muffles internal noise in the furnace;

- excellent strength - it is almost impossible to scratch or break it;

- high thermal stability - does not lose its resistance during sudden temperature changes;

- decent appearance - reliably watching the stove flame through it does not cause any discomfort;

- long period of use;

- guaranteed safety - sparks from the fire in the stove will not be able to penetrate into the room.

Other characteristics:

- It can be single-layer or multi-layer, which determines the number of degrees it can withstand: the greater the number of layers, the higher the possible temperature gap (up to 1000°C);

- Thickness is 4 or 5 mm, in some cases it can be thicker;

- For a longer period of use, you can use the maximum traction mode;

- It can have different external characteristics: transparent, colored, embossed, with a pattern.

How to choose the right glass?

When selecting the best among many alternatives, you should first pay attention to the following product indicators:

- The proposed temperature regime during the use of the device, which is indicated in the product passport. In order for the glass to serve you for a long time, this figure should not be exceeded. Basically, the selection here comes depending on the type of fuel that will be used to operate the stove;

- Thickness, which affects its strength and quality;

- Shelf life is a very important factor. Depends on the number of degrees that are planned to be maintained during operation;

- The strength achieved as a result of hardening, as well as the number of layers from which the product is made.

Works with glass

If you have already decided on the choice of glass suitable for your stove, for a longer service life, ensure it is properly cared for. Heat-resistant glass plays a protective role; the temperature inside the furnace reaches very high marks, so that soot residues may remain there. To clean them properly without damaging the glass, follow the tips below:

- To avoid damaging the glass polish with hard sand particles, do not use abrasive cleaners that contain them. Clean with special products to avoid consequences in the form of scratches;

- It is not recommended to clean when the glass has not yet cooled down after use. This can damage its protective layer.

Organization of cutting

If you choose to cut the glass to the desired size with your own hands, the ability to perform this action depends on its structure. If it is not hardened, it can be cut with a special glass cutter or a grinder and a segmented diamond blade. Let's consider an alternative cutting option using a grinder:

- Take a grinder and a segmented diamond disc for stone processing (it is better to use the one with the smallest diameter for ease of use), you will also need water or oil;

- Determine the exact dimensions of the intended glass, draw lines on it along which you will cut for convenience;

- Begin cutting carefully without using strong pressure; Cutting glass

- Constantly wet the cut areas with water or oil to remove debris and keep the work area cool.

- Be prepared for the area to be messy when the job is completed.

Properties of glass

Density

glass depends on its chemical composition.

Density is the ratio of the mass of glass at a given temperature to its volume, depends on the composition of the glass (the higher the content of heavy metals, the denser the glass), on the nature of the heat treatment and ranges from 2 to 6 (g/cm3). Density is a constant value; knowing it, you can judge the composition of the glass. Quartz

has the lowest density - from 2 to 2.1 (g/cm3),

borosilicate

glass has a density of 2.23 g/cm3, the highest is optical glass with a high content of lead oxides - up to 6 (g/cm3).

The density of soda-lime

glass is about 2.5 g/cm3,

crystal glass

is 3 (g/cm3) and higher. The tabulated value for glass density is the range from 2.4 to 2.8 g/cm3.

Strength

. Strength is the ability of a material to resist internal stresses resulting from external loads. Strength is characterized by tensile strength. The compressive strength for various types of glass ranges from 50 to 200 kgf/mm2. The strength of glass is influenced by its chemical composition. Thus, the oxides CaO and B2O3 significantly increase the strength, PbO and Al2O3 to a lesser extent, MgO, ZnO and Fe2O3 almost do not change it. Of the mechanical properties of glass, tensile strength is one of the most important. This is explained by the fact that glass works worse in tension than in compression. Typically, the tensile strength of glass is 3.5-10 kgf/mm2, i.e. 15-20 times less than the compressive strength. The chemical composition affects the tensile strength of glass in much the same way as it affects the compressive strength.

Hardness

glass, like many other properties, depends on impurities.

On the Mohs scale, it is 6-7 units, which is between the hardness of apatite and quartz. The hardness of different types of glass depends on its chemical composition. Glass with a high silica content - quartz

and

borosilicate

. An increase in the content of alkali oxides and lead oxides reduces hardness; Lead crystal has the least hardness.

Fragility

- the property of glass to collapse under the influence of an impact load without plastic deformation. The impact resistance of glass depends not only on its thickness, but also on the shape of the product; flat-shaped products are least resistant to impact. To increase the impact strength, oxides of magnesium, aluminum and boric anhydride are added to the glass composition. The heterogeneity of the glass mass and the presence of defects (stones, crystallization, and others) sharply increase fragility. The resistance of glass to impact increases when it is annealed. In the region of relatively low temperatures (below the melting point), glass is destroyed by mechanical stress without noticeable plastic deformation and, thus, belongs to ideally brittle materials (along with diamond and quartz). This property can be reflected by specific impact strength. As in previous cases, changing the chemical composition makes it possible to regulate this property: for example, the introduction of bromine almost doubles the impact strength. For silicate glasses, the impact strength is from 1.5 to 2 kN/m, which is 100 times lower than that of iron. The fragility of glass is affected by the uniformity, configuration and thickness of the products: the fewer foreign inclusions in the glass, the more homogeneous it is, the higher its fragility. The fragility of glass is practically independent of its composition. With an increase in glass composition B2O3, SiO2, Al2O3, ZrO2, MgO, the fragility decreases slightly.

Transparency

– one of the most important optical properties of glass. It is determined by the ratio of the number of rays passing through the glass to the total luminous flux. Depends on the composition of the glass, its surface treatment, thickness and other indicators. In the presence of iron oxide impurities, transparency decreases.

Heat resistance

glass is characterized by its ability to withstand sudden changes in temperature without breaking and is an important indicator of glass quality.

Depends on thermal conductivity, coefficient of thermal expansion and glass thickness, shape and size of the product, surface treatment, glass composition, defects. The higher the thermal conductivity and the lower the coefficient of thermal expansion and heat capacity of the glass, the higher the thermal resistance. Thick-walled glass is less heat-resistant than thin-walled glass. The most heat-resistant glass is with a high content of silica, titanium and boron. Glass with a high content of sodium, calcium and lead oxides has low heat resistance. Crystal

is less heat resistant than regular glass.

The heat resistance of ordinary

glass ranges from 90-250 °C, and

quartz

: 800-1000 °C. Annealing in special furnaces increases heat resistance by 2.5-3 times.

Thermal conductivity

- this is the ability of a material, in this case glass, to conduct heat without moving the substance of this material. Glass has a thermal conductivity coefficient of 1-1.15 W/mK.

Thermal expansion

is an increase in the linear dimensions of a body when it is heated. The coefficient of linear thermal expansion of glass ranges from 5·10-7 to 200·10-7. Quartz glass has the lowest coefficient of linear expansion - 5.8·10-7. The thermal expansion coefficient of glass largely depends on its chemical composition. The thermal expansion of glass is most strongly influenced by alkali oxides: the higher their content in the glass, the greater the coefficient of thermal expansion. Refractory oxides such as SiO2, Al2O3, MgO, as well as B2O3, as a rule, reduce the coefficient of thermal expansion.

Elasticity is the ability of a body to return to its original shape after removing the forces that caused the deformation of the body.

Elasticity is characterized by the elastic modulus. The elastic modulus is a value equal to the ratio of stress to the elastic relative deformation caused by it. A distinction is made between the modulus of elasticity under axial tension and compression (Young’s modulus, or modulus of normal elasticity) and the shear modulus, which characterizes the resistance of a body to shear or chipping and is equal to the ratio of the shear stress to the shear angle.

Depending on the chemical composition, the normal elastic modulus of glass ranges from 4.8x104...8.3x104, the shear modulus is 2x104-4.5x104 MPa. Quartz glass has an elastic modulus of 71.4x103 MPa. The elastic and shear moduli increase slightly when replacing SiO2 with CaO, B2O3, Al2O3, MgO, BaO, ZnO, PbO.

Properties of Corning glass

| Glass code | 0080 | 7740 | 7800 | 7913 | 0211 | |

| Type | Silicate | Boro-silicate | Boro-silicate | 96% Silicate | Zinc-titanium | |

| Color | Transparent | Transparent | Transparent | Transparent | Transparent | |

| Thermal expansion (multiply by 10-7 cm/cm/°C) | 0-300 °C | 93,5 | 32,5 | 55 | 7,5 | 73,8 |

| 25 °C, up to temp. hardening | 105 | 35 | 53 | 5,52 | — | |

| Upper limit operating temp. for annealed glass (for mechanical properties) | Normal operation, °С | 110 | 230 | 200 | 900 | — |

| Extreme operation, °С | 460 | 490 | 460 | 1200 | — | |

| Upper limit operating temp. for tempered glass (for mechanical properties) | Normal operation, °С | 220 | 260 | — | — | — |

| Extreme operation, °С | 250 | 290 | — | — | — | |

| 6.4 mm thick, °C | 50 | 130 | — | — | — | |

| 12.7 mm thick, °C | 35 | 90 | — | — | — | |

| Heat resistance, °C | 16 | 54 | 33 | 220 | — | |

| Density, g/cm³ | 2,47 | 2,23 | 2,34 | 2,18 | 2,57 | |

| Optical voltage sensitivity coefficient, (nm/cm)/(kg/mm²) | 277 | 394 | 319 | — | 361 |

Review of physical and chemical properties of Duran, DWK glasses

| Properties | Linear expansion coefficient α (20 °C - 300 °C) × 10⁻⁶ | Deformation point, °C | Density, g/cm³ | Hydrolytic resistance DIN ISO 719 IN | Acid resistance DIN 12 116 | Alkali resistance ISO 695 |

| Glass type | ||||||

| Duran | 3,3 | 525 | 2,23 | Not changed by water | Acid resistant | Moderately soluble in alkalis |

| Fiorax | 4,9 | 565 | 2,34 | Not changed by water | Acid resistant | Moderately soluble in alkalis |

| Soda-lime-silicate glass | 9,1 | 525 | 2,5 | Refractory for instruments | Acid resistant | Moderately soluble in alkalis |

| SWB | 6,5 | 555 | 2,45 | Unchangeable by water | Acid resistant | Slightly soluble in alkalis |

Review of the physical properties of Kimble, DWK glasses

| Types of glass | 33 Borosilicate glass | 51 Borosilicate glass |

| Properties | ||

| Strain point, °C | 513 | 530 |

| Annealing temperature, °C | 565 | 570 |

| Linear expansion coefficient α (0 - 300 °C)×10⁻⁷ | 32 | 55 |

| Density, g/cm³ | 2,22 | 2,33 |

| Visible light transmittance, thickness 2 mm | 92% | 91% |

Review of physical and chemical properties of Wheaton, DWK glasses

| Types of glass | Borosilicate glasses | Soda-lime-silicate glass | ||||||

| 180 | 200 | 300 | 320 | 400 | 500 | 800 | 900 | |

| Properties | ||||||||

| Strain point, °C | 510 | 505 | 525 | 510 | 530 | 515 | 510 | 496 |

| Annealing temperature, °C | 560 | 560 | 570 | 560 | 570 | 550 | 548 | 536 |

| Linear expansion coefficient α (0 - 300 °C)×10⁻⁷ | 33 | 33 | 55 | 54 | 60 | 61 | 88 | 91 |

| Density, g/cm³ | 2,23 | 2,23 | 2,33 | 2,39 | 2,41 | 2,42 | 2,48 | 2,50 |

| Acid resistance | Acid resistant | Acid resistant | Acid resistant | Acid resistant | Acid resistant | Acid resistant | Moderately soluble in acids | Moderately soluble in acids |

| Alkali resistance | Slightly soluble in alkalis | Slightly soluble in alkalis | Slightly soluble in alkalis | Slightly soluble in alkalis | Slightly soluble in alkalis | Slightly soluble in alkalis | Highly soluble in alkalis | Highly soluble in alkalis |

What it is

Heat-resistant furnace glass is an incredible advance in the development of glass production methods. Thanks to its composition and high-quality production method, it has:

- good sound insulation - muffles internal noise in the furnace;

- excellent strength - it is almost impossible to scratch or break it;

- high thermal stability - does not lose its resistance during sudden temperature changes;

- decent appearance - reliably watching the stove flame through it does not cause any discomfort;

- long period of use;

- guaranteed safety - sparks from the fire in the stove will not be able to penetrate into the room.

Other characteristics:

Well-known manufacturers of thermal glass for furnaces

You can buy special glass for a stove or fireplace in specialized stores. It should be noted that glass from world-famous manufacturers can cost many times more than glass produced by small companies. Glass from German manufacturers is famous for its high quality.

One of the most famous manufacturing companies of Robax heat-resistant glass is SchottGlas.

Glass is distinguished by the fact that it can withstand very long exposure to high temperatures. CrossFireCerama is famous for its democracy. It produces single-layer fire-resistant glass with a pleasant golden hue.

Installation nuances:

- Pay attention to how the linear expansion coefficients of steel and ceramics relate.

- You need to be very careful when attaching fireproof glass to the fireplace frame. It is necessary to ensure that the pressure on the entire surface of the glass is uniform.

- A heat-resistant cord must be laid between the glass and the frame to compensate for the expansion of the metal.

The only drawback of heat-resistant glass is its contamination. Over time, unsightly soot appears on the glass. Today, the problem can be solved by purchasing glass capable of self-cleaning: it also needs to be cleaned, but this will be much easier. To clean the glass, use a damp cloth and detergent.

Main types of heat-resistant glass

Several brands of glass are used in stoves and heating appliances:

- Quartz glass options are among the most heat-resistant and refractory;

- Borosilicate glasses;

- Multilayer glass sheets coated with cerium oxide.

The most affordable tempered glass installed in the doors of gas ovens and broilers can withstand heating up to a maximum of 300°C, so they cannot be used as the main material for the fireplace door.

In addition, tempered glass is unsafe due to its high fragility and tendency to crack. In some cases, it is allowed to install tempered glass materials as a second, decorative glass in the fireplace door.

Fused quartz has the best heat resistance; the maximum heating temperature even in direct contact with a flame is 800-850°C, but quartz has a significant drawback - even a small mechanical load leads to instant destruction of the glass surface.

Glass based on silicon and boron oxides are widely used in heating devices, including fireplaces. Borosilicate surface is used as hobs on electric and induction cookers. This material can withstand heating up to 700°C without loss of mechanical strength.

In addition to high heat resistance, borosilicates and quartz glasses have the ability to withstand thermal shock with a temperature difference of up to 400°C without destruction.

Tempered glass

Tempered glass has higher strength and resistance to thermal stress than thermally strengthened glass. Their resistance to impact loads is 4-5 times higher than that of ordinary glass without heat treatment. When broken, tempered glass shatters, releasing large amounts of energy in the form of small, round pieces (Figure 1). This nature of destruction reduces the risk of those who are nearby at this time. Therefore, these glasses are considered safe.

Figure 1 – Nature of destruction of tempered glass [1]

The nuances of caring for fireplace glass

If you have installed a fireplace or stove with a glass door, then you are most likely familiar with the problems of how to clean soot from glass.

Quite often, the fireplace is considered the center of attention in the house, and it should always look neat. To do this, you will have to take into account some of the nuances associated with caring for it.

The process is simplified if the door has an automatic glass cleaning system. In this case, you will not have to wash it often, but it is still not recommended to forget about water procedures.

You shouldn’t put off cleaning until later; it’s better to do everything in a timely manner to save time and effort. The right solution is to periodically wipe the glass with a special compound.

Fireplace glass needs to be cleaned regularly.

The correct fuel must be used to fire the fireplace. Coniferous varieties produce the most soot due to the high level of resin content. In addition, the firewood must be thoroughly dried before use to minimize the percentage of soot generated.

To clean the glass surface, you must use liquid compositions or solutions with the addition of ammonia, prepared independently.

By following these simple rules, you can keep your fireplace glass clean at the highest level.

Features of care

Heat-resistant glass will last a long time and look elegant if it is periodically wiped with a damp cloth. For cleaning, you can use products to remove dirt from ovens, stoves and microwaves; diluted citric acid, ammonia, white ash. Soot must not be removed with abrasive means. Difficult stains are removed with special solutions for the care of heat-resistant glass. Cleaning is done after the door has cooled. A lot of soot accumulates when pine wood is burned. Deciduous trees contain a lower amount of resin, which reduces the rate at which dirt forms on the glass.

Basic properties of fire-resistant fireplace glass

So, we found out that heat-resistant glass is manufactured specifically to withstand thermal energy. Consequently, they have a low thermal expansion rate. Perhaps the best type of fireplace glass is quartz - it is known to withstand temperatures of about 1000 degrees! This also includes borosilicate glass, as well as several other types.

Note! The heat resistance of this material depends on a number of factors, including the chemical composition, dimensions, quality of the material and the degree of heat transfer. Heat resistance is increased by hardening, polishing and chemical treatment, at the same time all surface defects are removed

The material made in this way is widely used in the construction of fireplaces. And thanks to the use of innovative technologies, fireplace glass is not only heat-resistant, but also safe. It has low noise output, and if desired, it can be laminated or tinted

Heat resistance is increased by hardening, polishing and chemical treatment, at the same time all defects on the surface are removed. The material made in this way is widely used in the construction of fireplaces. And thanks to the use of innovative technologies, fireplace glass is not only heat-resistant, but also safe. It has low noise output, and if desired, it can be laminated or tinted.

If we compare heat-resistant glass with simple glass, then in half an hour it heats up to about 50-200 degrees - much depends on the type and production method (for comparison: ordinary glass warms up to as much as 500 in the same half hour).

Note! Today, not just fire-resistant glass is produced, but even glass-ceramics, albeit transparent, with a low thermal expansion rate. The material not only protects the combustion chamber from fire - it also allows you to enjoy watching the flames play

If the fireplace is equipped with this glass, the room will be reliably protected from fire and random sparks

At the same time, it also provides excellent air supply, which is important for normal fuel combustion. The material not only protects the combustion chamber from fire - it also allows you to enjoy watching the flames play

If the fireplace is equipped with this glass, the room will be reliably protected from fire and random sparks. At the same time, it also provides excellent air supply, which is important for normal fuel combustion.

The material not only protects the combustion chamber from fire - it also allows you to enjoy watching the flames play. If the fireplace is equipped with this glass, the room will be reliably protected from fire and random sparks

At the same time, it also provides excellent air supply, which is important for normal fuel combustion.

How to distinguish a fake when purchasing?

Nowadays, a huge number of companies are trying to sell tempered glass for stoves, attributing to it heat-resistant properties, but in fact it does not have these properties and cannot be used in fireplaces and stoves, because it is produced using a different technology.

To avoid being scammed by such companies:

- When purchasing a product, it is important to always pay attention to the documentation of the product, and also purchase only from companies that have already taken a good place in the market for complete reliability.

- It is also recommended to study reviews on the Internet about the product you like and the company from which you want to order it, in order to be completely confident in your decision.

- And of course, first of all, pay attention to the presented characteristics of the product and make sure that they are suitable for you.

What to look for when purchasing?

We have figured out the parameters of heat-resistant glass and, if you intend to purchase it, we advise you to familiarize yourself with the list of characteristics and be sure to take them into account when choosing a specific model.

- First of all, this is the maximum warm-up temperature, which cannot be exceeded during operation.

- The next parameter is the strength of the material.

- After this, look at the thickness of the fire-resistant glass. A number of types of fireboxes provide a thickness of up to 0.4 centimeters.

- Finally, an important indicator is the service life, which depends on the maximum temperature in the fireplace. If it is, say, 550 degrees, then the material can last a couple of thousand working hours. If the permissible limit is exceeded, the service life will noticeably decrease. It is because of this that professionals do not advise heating with coal, overloading the combustion chamber with fuel and creating very high draft.

Traditionally, fireplaces are open, although modern models are also closed. This is more aesthetically pleasing and safer, since such a fireplace can easily be left unattended.

Note! Visually, closed models are very similar to open ones, but they emit more thermal energy. At the same time, the combustion process itself can be controlled without particularly worrying about fire safety in the house

The list of characteristics that fireproof glass has for a fireplace is unreliable if you do not talk about a number of problems. The main enemy of the material is considered to be soot. And if the fireplace is closed, then the glass becomes covered with it over time, due to which the aesthetics deteriorate. In order to avoid this problem, fireplaces are equipped with special protection against soot - an air recirculation system is installed inside the structure. Thanks to this, the glass is reliably protected from soot.

There is also a technology for pyrolysis cleaning of heat-resistant glass, which consists of self-cleaning - soot burns out under the influence of high temperatures. But this requires surface treatment with metal oxide. Externally, this protective layer is invisible, and does not affect aesthetics in any way. But infrared rays from such a layer are reflected and directed back into the structure, which is why the temperature of the glass increases by about a quarter when compared with ordinary fire-resistant glass. The soot that settles on the surface burns instantly, leaving the glass clean and the flame clearly visible.

Materials for making fireplace glass

The heat resistance of fireplace glass depends not only on its chemical composition, but also on the intensity of heat transfer over the entire surface of the glass, the quality of the surface itself and the size of the product. Thermal resistance is increased by hardening, fire polishing and chemical treatment, while all defects on the glass surface are eliminated. It is these glasses that are most widely used in the manufacture of fireplaces in country houses, as well as in apartments.

Modern technologies make it possible to make glass for fireplaces not only heat-resistant, but also soundproofing and safe; it can be made laminated or tinted. In this case, it all depends on your wishes and the functional need for using such heat-resistant glass.