Extra charge for large items

| Weight from 80 to 120 kg | +20% |

| Weight from 121 to 160 kg | +40% |

| Weight from 161 to 200 kg | +60% |

| Weight from 200 to 350 kg | +100% |

| Over 350 kg | Calculated individually |

The minimum cost of one product in a batch is RUB 1,000.00.

The minimum order cost for glass of each protection class (Br1, Br2, Br3, Br4) is 12,000 rubles.

The cost of packaging for a transport company (box) is 1000 rubles/m2, but not less than 500 rubles.

The cost of packaging in cardboard is 150 rubles/m2.

The main function of any type of protective glass is to prevent a destructive object from penetrating the protective glass. It should be understood that the very first impact of a destructive object on the protective glass leads to its damage (scratches, chips, cracks). But at the same time, the destructive object remains on the side of the damage.

The strength of glass before damage occurs is ensured by thermal strengthening (hardening). As a result of hardening, strength increases (the fracture threshold is 7-10 times relative to raw glass), but the viscosity of the glass is lost, which leads to its complete physical destruction after exceeding the fracture threshold.

Certificates and test reports

Click on the image to enlarge it

How bulletproof glass works

Regular and bulletproof glass are two completely different items. In any case, one design differs radically from another. However, bulletproof glass is not a completely bulletproof design. Limitations, of course, exist, since there are firearms of varying recoil strength.

This is approximately what the structure of reinforced glass looks like, which is already difficult to destroy by sufficiently large-caliber bullets fired from high-power firearms

Bulletproof glass is made up of several layers of durable transparent material with “layers” made from various types of plastics. Some bulletproof glass designs contain a final inner layer made of polycarbonate (a hard type of plastic) or plastic film.

This layer prevents the “spall” effect (when shards of glass or plastic break off from the impact of a bullet). This “sandwich” of layers is called laminate. A kind of bulletproof laminate is an order of magnitude thicker than ordinary glass, but at the same time has a relatively low weight.

Energy absorption property of the structure

When a bullet hits bulletproof glass, the impact energy spreads to the existing layers. Since the energy is distributed between different layers of bulletproof glass and plastic interlayers, the force spreads over a large area, which is accompanied by rapid energy absorption.

The effect on bulletproof glass of the simplest configuration, obtained from the impact of a bullet fired from a pistol at a short distance. As you can see in the picture, the structure was damaged, but did not collapse and did not allow a bullet to pass through

The movement of the bullet slows down to such a level of energy when the strength to overcome the obstacle is completely lost and is not capable of causing significant damage.

Bulletproof glass panels, of course, are damaged, but the plastic layers prevent the panels from breaking into small fragments.

Therefore, bulletproof glass should be viewed more as an energy-absorbing object in order to clearly understand the effect of this protective device.

How is bulletproof glass made?

The traditional design of bulletproof glass, as already noted, is represented by alternating glass panels (3–10 mm thick) and plastic. In this case, the plastic is present in the form of a thin film (thickness 1-3 mm), made on the basis of polyvinyl butyral (PVB).

Modern durable types of bulletproof glass represent a similar “sandwich” containing:

- acrylic glass,

- ionoplastic polymer (for example, SentryGlas),

- ethylene vinyl acetate or polycarbonate.

In this case, thick layers of glass and plastic are separated by thinner films of various plastic materials, such as polyvinyl butyrene or polyurethane.

The structure of a three-layer structure from a number of the first products: 1, 2 – ordinary glass; 3 – polyvinyl acetate resin mixed with polycarbonate glycol plasticizer

To make simple PVB bulletproof glass, a thin film of PVB is sandwiched between thicker glass to form a laminate. The formed laminate is heated and compressed until the plastic begins to melt, thereby forming a bond with the glass panel.

Typically, this process is performed under vacuum to prevent air from getting between the layers. The penetration of air into the interlayer weakens the structure of the laminate and affects the optical properties (distorts the transmitted light).

Then the device is placed in an autoclave and brought to full readiness under conditions of higher temperature (150°C) and pressure (13-15 ATI). The main difficulty of this process is ensuring proper adhesion of the layers of plastic and glass.

It is necessary to remove air from the space between the layers, to eliminate possible deformation of the plastic from overheating and excess pressure.

Where is bulletproof glass used?

The product comes in a variety of shapes and sizes to provide varying levels of protection for emergency situations. Most often, the use of bulletproof glass is seen as a characteristic phenomenon in the banking industry.

Cash registers are usually equipped with bulletproof windows, and bulletproof boxes for exchanging documents and money are also used.

Protecting bank tellers with a multi-layer glass structure provides an increased level of security. This is one of those areas where bulletproof structures are used quite often

The quality of protection depends on the thickness of the product. The thicker the glass (the more layers), the better the energy absorption is ensured, and accordingly, the level of protection increases. Basic bulletproof glass has a thickness of 30-40 mm, but if necessary, this parameter can be doubled.

The only problem is that increasing the thickness of bulletproof glass inevitably leads to increased weight. Perhaps this is a minor problem for equipping a bank cash desk, but it becomes a significant problem, for example, in the case of the production of bulletproof glazing for cars.

Increasing the thickness of bulletproof glass also leads to a decrease in the transparency factor, since the light is “muted” by additional layers of construction. Sometimes this design creates additional difficulties, for example, in a car, when bulletproof glass impairs the driver’s visibility.

Standards for industrial products

There are different design standards in the global range. Thus, for use in the United States, the effectiveness of bulletproof glass is generally characterized by National Institute of Justice (NIJ) Standard 0108.

This standard defines the properties of ballistic resistant protective materials. The document lists seven types of armor, divided into five main types: (I, II-A, II, III-A, III, IV and “Special”).

Product configuration table based on the level of ballistics, showing what type of weapon attack the design can withstand

The highest classification (Type IV) can withstand one hit from a bullet fired from a 30-caliber armor-piercing rifle. In this case, the mass of the bullet is 10.8 g, and the measured flight speed is 868 ± 15 m/s.

The UK has also developed its own standardization, where the main standard is BS EN 1063: 2000. The document defines nine different types of bulletproof glass, where the products are noted:

- BR1 (for pistols and rifles),

- BR2–4 (for pistols),

- BR5–7 (for rifles),

- SG1–2 (for shotguns).

Other European countries use the CEN 1063 standard.

Glass armored with film

There are several types of protection of glass structures with protective anti-vandal and explosion-proof films:

Protection class A1 (protective anti-vandal glazing).

This protection class is recommended to be installed at facilities that do not have significant material assets and are under centralized or internal physical security (grocery stores, restaurants, bars, institutions, offices, industrial premises);

Protection class A2 (protective anti-vandal glazing).

This protection class is recommended to be installed on objects that have high-value material assets, historical and cultural values and are under centralized or internal physical protection;

Protection class A3 (protective anti-vandal glazing).

This protection class is recommended to be installed in bank operating rooms and control rooms (if the installation of bulletproof glass is not required). In the sales areas of jewelry and weapons stores, pharmacies. In museums and art galleries - in the form of screens and showcases to protect individual exhibits;

Protection class K4 - SB2(D) (anti-fragmentation - explosion-proof glazing).

This protection class is recommended to be used to give the glass a shatterproof effect when damaged, so as not to cause harm to others. Mainly used for installation on shop windows and in shopping and business centers.

A little general idea about the movement

Everyone has at one time or another had to catch a fast-flying ball in the air. The trick to this simple method of extinguishing energy is when the hand moves along the vector of movement of the flying object, gently stopping the flying ball.

This reduces the force of the obstacle (hand). As a result, hitting the ball feels completely painless. In scientific terms, the force of the ball acting on the palm of the hand is equal to the moment of the speed of movement.

The passage of a bullet through ordinary glass is inevitably accompanied by the destruction of the latter. Moreover, the bullet does not lose any energy of movement in this case of resistance

However, unlike the palm of a hand, a piece of glass does not have the properties of synchronous movement. If you fire a firearm at a piece of ordinary glass, it becomes obvious that this object is not able to bend and absorb energy.

As a result, the glass simply collapses, and the bullet overcomes the obstacle with virtually no loss of momentum. This is why ordinary glass is not able to protect against bullets, and in such cases, a bulletproof design is required that is more effective in absorbing the energy of movement.

Options for combining film with glass according to protection classes

“Glass with film that is safe to use” of protection classes CM1-CM4 can be produced using polymer films as follows:

- • SM1 – raw glass 4mm + film 56 microns;

- • SM2 – raw glass 4mm + film 112 microns;

- • SM3 – raw glass 4mm + film 200 microns;

- • SM4 – raw glass 4mm + film 300 microns.

“Shock-resistant glass with film” of protection classes P1A – P3A can be produced using polymer films as follows:

- • P1A - raw glass 4 mm + film 200 microns + 112 microns or raw glass 5 mm + film 300 microns;

- • P2A - raw glass 4 mm + film 300 microns + 200 microns or raw glass 5 mm + film 300 microns + 112 microns;

- • P3A - raw glass 4 mm + film 300 microns + 300 microns or raw glass 5 mm + film 300 microns + 200 microns.

| Protection class according to GOST | Film thickness, microns | Recommended Application | |

| 54171-2010 | 32563-2013 | ||

| SB1(E) | SM1 | 50 µm | Protective anti-vandal glass with film. |

| SB1(D) | SM2 | 100 µm | Protective anti-vandal glass with film, safe during operation, resistant to impact with a soft body. |

| SB2(D) | SM3 | 200 µm | Anti-fragmentation explosion-proof glazing to prevent glass destruction during acts of vandalism and terrorist attacks. |

| A1 | P1A | 300 µm | This protection class is recommended to be installed at facilities that do not have significant material assets and are under centralized or internal physical security (grocery stores, restaurants, bars, institutions, offices, industrial premises). |

| A2 | P2A | 400 µm | This protection class is recommended to be installed on objects that have high-value material assets, historical and cultural values and are under centralized or internal physical protection. |

| A3 | P3A | 600 µm | This protection class is recommended to be installed in bank operating rooms and control rooms (if the installation of bulletproof glass is not required). In the trading floors of jewelry and weapons stores, pharmacies. In museums and art galleries - in the form of screens and showcases to protect individual exhibits. |

Execution options in the company FOTOTECH

Choose from the range of bulletproof FOTOTECH products the protection class you need - C1, Br1, Br2, Br3, Br4, Br5 or Br6 - in accordance with GOST 30826-2014 and GOST 32566-2013. Our bulletproof structures provide reliable protection for VIPs, senior executives, cashiers of bank branches and institutions, checkpoint workers and other facilities, as well as material assets from shots, burglary and robbery. The thickness, weight and other parameters of glass depend on the required protection class.

GOST R 51136-2008 (old)

| Glass protection class | Weapon | Name of the weapon | Characteristics of the damaging element | Firing distance, m | ||

| Core type | Weight, g | Speed, m/s | ||||

| 1 | Makarov pistol (PM) | 9-mm pistol cartridge 57-N-181S with PST bullet | Steel | 5,9 | 305-325 | 5 |

| Revolver type "Nagant" | 7.62 mm revolver cartridge | Lead | 6,8 | 275-295 | 5 | |

| 2 | Special small-caliber pistol (PSM) | 5.45 mm pistol cartridge 7N7 with PST bullet | Steel | 2,5 | 310-335 | 5 |

| Tokarev pistol (TT) | 7.62 mm pistol cartridge 57-N-134S with PST bullet | Lead | 5,5 | 514-445 | 5 | |

| 2a | Hunting rifle 12 gauge | 18.5 mm hunting cartridge | Lead | 35 | 390-410 | 5 |

| 3 | AK-74 assault rifle | 5.45 mm 7N6 cartridge with PS bullet | Steel non-heat-strengthened | 3,5 | 890-910 | 5-10 |

| AKM assault rifle | 7.62 mm cartridge 57-N-231 with PS-34 bullet | Steel non-heat-strengthened | 7,9 | 710-740 | 5-10 | |

| 4 | AK-74 assault rifle | 5.45 mm 7N6 cartridge with PP bullet | Steel heat-strengthened | 3,4 | 890-910 | 5-10 |

| 5 | SVD rifle | 7.62-mm cartridge 57-N-323S with LPS bullet | Steel non-heat-strengthened | 9,6 | 820-840 | 5-10 |

| AKM assault rifle | 7.62 mm cartridge 57-N-231 with PS-34 bullet | Steel heat-strengthened | 7,9 | 710-740 | 5-10 | |

| 5a | AKM assault rifle | 7.62 mm cartridge 57-B3-231 with B3 bullet | Special | 7,4 | 720-750 | 5-10 |

| 6 | SVD rifle | 7.62 mm 7N13 cartridge with ST-M2 bullet | Steel heat-strengthened | 9,6 | 820-840 | 5-10 |

| 6a | SVD rifle | 7.62 mm cartridge 57-B3-3 with B3 bullet | Special | 10,4 | 800-835 | 5-10 |

GOST R 30826-2014 (New)

| Glass protection class | Weapon | Name of the weapon | Characteristics of the damaging element | Firing distance, m | ||

| Core type | Weight, g | Speed, m/s | ||||

| C1 | Hunting rifle 12 gauge | 18.5 mm hunting cartridge | Lead | 3,4+/-0,1 | 400+/-10 | 5+/-0,1 |

| BR 1 | 9 mm APS, ind. 56-A-126 | 9x18 mm pistol cartridge with PST bullet, ind. 57-N-181S | Steel | 5,9 | 335+/-10 | 5+/-0,1 |

| BR 2 | 9 mm SR-1, ind. 6P35 | 9x21 mm cartridge with P bullet, ind. 7N28 | Lead | 7,93 | 390+/-10 | 5+/-0,1 |

| BR 3 | 9 mm PYa, ind. 6P35 | 9x19 mm cartridge with PST bullet, ind. 7N21 | Steel heat-strengthened | 5,2 | 455+/-10 | 5+/-0,1 |

| BR 4 | 5.45 automatic AK74, ind. 6P20 | 5.45x39 mm cartridge with PP bullet, ind. 7N10 | Steel heat-strengthened | 3,5 | 895+/-15 | 10+/-0,1 |

| 7.62 automatic AKM, ind. 6P1 | 7.62x39 mm cartridge with PS bullet, ind. 57-N-231 | Steel heat-strengthened | 7,9 | 720+/-15 | 10+/-0,1 | |

| BR 5 | 7.62 SVD rifle, ind. 6B1 | 7.62x54 mm cartridge with PP bullet, ind. 7N13 | Steel heat-strengthened | 9,4 | 830+/-15 | 10+/-0,1 |

| 7.62 SVD rifle, ind. 6B1 | 7.62x54 mm cartridge with B-32 bullet, ind. 7-B3-3 | Steel heat-strengthened | 10,4 | 810+/-15 | 10+/-0,1 | |

| BR 6 | 12.7 rifle OSV-96 | 12.7x108 mm cartridge with B-32 bullet, ind. 57-B3-542 | Steel heat-strengthened | 48,2 | 830+/-20 | 50+/-0,5 |

Stratobel AGC laminated glass

Our company uses Stratobel laminated glass produced by AGC Glass Russia in glazing structures. Stratobel laminated glass provides strength indicators that meet the European classifications EN 112600, EN 356, EN 1063.

Stratobel triplexes can be made from glass with different properties to solve a wide range of construction problems. The layers of triplex can be special glasses:

- low emission

- sun protection

- hardened

- heat-strengthened

- curved (bent)

- frosted

- sandblasted

- mass colored

- patterned (structural)

- with noise-insulating intermediate film

Safety glass and double glazed windows

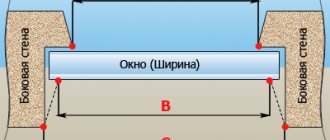

A double-glazed window is a structure made of several glasses.

To achieve a high degree of security, not ordinary glass, but special protective glass is installed in the double-glazed window. There are many types of protective glass: some are strengthened by gluing a special film, others by tempering. Regardless of the type of manufacture, the “protective glass” in a double-glazed window looks approximately the same. It is impossible to distinguish protective glass from ordinary glass, except in cases where it is marked - an indelible “label” indicating its degree of protection

.

Structure and characteristics of the material

Bullet-resistant material consists of several sheets of tempered inorganic glass, polymer films or liquid resin for gluing or coating workpieces.

Straight or bent sheets of different types and thicknesses are used in production. As a result of heat treatment, the film polymerizes and the layers join together. A monolithic structure with high impact strength is formed. If such material does break through, the fragments remain on the film and do not cause harm. The product has other special properties:

- heat resistance (when using hardened workpieces up to 200°C);

- resistance to moisture and UV radiation;

- no optical distortion;

- frost resistance.

The light transmission of bulletproof glass depends on the composition, the presence of tinting and color, and the protective properties depend on the thickness and number of layers. These characteristics are calculated during product design to achieve the required level of safety. In most cases, they opt for a three-layer construction to avoid excessive weight and increased cost. It also eliminates the risk of significant misstatement. The number of layers is increased in case of a real threat to human life.

Optical distortions are determined visually by the recognition of images in the form of black and white stripes or a “brick wall”. The angle between the direction of observation and the plane of the sheet, at which distortions are not observed, must be at least 30°.

What types of armored windows are there?

Rice. 6. Types of protection.

In a general sense, all windows with protective functions are divided into three main classes:

- Protection A – against shrapnel and vandalism (a stone or ball hitting the window);

- Protection B – shockproof option, withstands up to 30 blows from an axe, hammer or reinforcement;

- Protection B helps protect the premises from firearms, from pistols to rifles.

Many companies involved in window installation offer customers armored options, but the recognized European leaders are Rehau and KBE windows; in Russia, their analogue is Novotex.

Rehau

Rice. 7. Triplex glass.

The German manufacturer offers three main glass options for secure windows:

- Shockproof film - its main function is not so much to prevent the impact itself, but to prevent fragments from getting into the apartment; it helps to fix broken glass in the frame, and also helps in the event of a fire, preventing the spread of fire.

- Tempered glass - due to the peculiarities of production, its functions become equal to steel, and if it breaks, the fragments, although they will not remain in the frame, will not be able to injure anyone due to their structure.

- Triplex glass is the strongest and most expensive protection option - several glasses, each of which has protective functions, are glued together with resin or pressed on a machine, which provides not only ideal protection, but also high levels of noise reduction and heat protection.

KBE

Rice. 8. KBE windows.

The windows of this manufacturer have amazing characteristics:

- The special glass composition and its lamination guarantee safety even if a car crashes into the window at a speed of 70 km/h;

- The PVC profile structure and German fittings make it possible to protect windows from cutting and other impacts on the frame and components;

- High levels of transparency - despite serious protective mechanisms, glass transmits only 3% less light than non-armored glass;

- Wide selection of glass lamination - if you want a gold or silver window, you can get it;

- European polymers do not threaten the environment and are environmentally friendly.

Novotex

Rice. 9. Novotex Techno.

The Russian manufacturer has worthy analogues of German safety double-glazed windows - this is the Techno series.

It has the ability to make metal inserts into the window frame and sash; Increased burglary protection is installed by removing the 13 mm hardware groove. The width of the frame allows you to use glass of the desired thickness; you can install up to five protected cameras.

Advances of the 2000s

In 2005, it was reported that US military researchers were developing a class of transparent armor incorporating aluminum oxynitride (ALON) as the outer "strike" layer. The manufacturer of ALON has demonstrated that traditional glass/polymer requires 2.3 times the thickness of ALON to protect against a .50 BMG projectile.[12] ALON is much lighter and performs much better than traditional glass/polymer laminates. Aluminum oxynitride "glass" can defeat threats such as .50 caliber armor-piercing rounds using a material that is not too heavy.[13] Various types of other materials are also being developed that closely resemble glass.[ citation needed

]

Spinel ceramics

Certain types of ceramics can also be used for transparent armor due to their properties of increased density and hardness compared to traditional glass. These types of synthetic ceramic clear armor produce thinner armor with the same stopping power as traditional laminated glass.[14]

Air chamber glass

The newest type of curved transparent vehicle armor has an air chamber between the glass and the polycarbonate. Level IIIA armor (9mm high velocity) consists of 8mm thick laminated glass (impact surface), 1mm air gap and 7mm polycarbonate. This solution stops bullets in a completely different way. Glass, being hard, deforms a flying bullet. The deformed bullet completely penetrates the glass and is stopped by flexible polycarbonate. Weight reduction compared to traditional glass polycarbonate is 35%. 25 kg per square meter for level NIJ 06 IIIA (NIJ 07 HG2). It is also thinner (16.2mm) compared to conventional glass-clad polycarbonate (21mm).[ citation needed

]

Features of double glazing for armored windows

Windows protected with armored film, fittings or frames have their own main features:

- Such windows are heavier than ordinary ones, unless we are talking about a simple protective film sticker on them;

- The use of steel structures and powerful fittings - all materials are selected so that the possibility of impact on them is minimized;

- Fastening the glass to the frame prevents intruders from removing the glass;

- Stiffening ribs and a reinforced profile inserted into the frame prevent the window from being squeezed out;

- Safety in case of damage to the structure - this point is quite important; if the glass is broken, you will not be injured by its fragments, since the protective film holds all the fragments in the frame; in the case of tempered glass, the properties of the fragments are such that they do not injure.

Rice. 10. Characteristics.