2

3

Ordinary glass is a fairly fragile material that breaks easily when dropped. The fragments pose a danger to humans due to the high risk of injury from sharp edges. Relatively recently, tempered glass was developed, which is actively used in a variety of fields. The material is used in the automotive industry, in the manufacture of ceilings, canopies, etc.

Tempered glass - what is it?

A special technology is used in the production of tempered glass. When it is carried out, the surface of the material is uniformly heated to 650 degrees, followed by short-term cooling of the molten mass. As a result of significant temperature changes, the structure of internal stresses of the material changes. An increase in the bending strength of glass is accompanied by a change in the operational properties of the material. It is characterized by increased strength compared to conventional one. Tempered glass, when broken, breaks into small safe fragments (crumbs), the blunt rounded edges of which are safe for humans. Properties of tempered glass

Characteristics of Tempered Glass

Tempered glass is usually superior in a number of operational and technological parameters, which in a short time made it popular all over the world. High-strength glass is used in many sectors of the national economy. Thanks to him, many areas have made big strides in development.

The procedure for tempering glass materials is similar to tempering steel. First, the material becomes very hot and begins to melt. The glass is then rapidly cooled. The inner layers of the material cool many times slower than the outer layers. This leads to the formation of residual compressive stresses. Thanks to this technology, glass gains high strength and resistance to any temperature.

The strength of tempered glass is much higher than that of ordinary glass. However, if you hit it, the resulting fragments will be safer. The number of small pieces of material strictly corresponds to current standards. When struck with a hammer weighing 75 g. a sheet of glass should form 40 fragments measuring 100x100 mm. Avoid hitting the edges of the glass as they are quite dangerous.

Triplex

This is laminated glass made from several glass sheets connected by polymer films or compounds.

Main advantages

- Increased resistance to damage and impacts of any force. It is very difficult to break, but if this does happen, the fragments do not fly apart, but are held together thanks to the polymer compound;

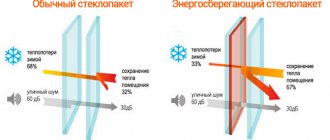

- Increased sound insulation - triplex does not allow noise to pass through, therefore it is used for the manufacture of soundproof double-glazed windows;

- Wide decorative possibilities due to the use of color films and various methods of decorative processing.

Flaws

- Significant weight, somewhat limiting the use of the material;

- Insufficient light transmittance due to the use of films.

Differences of tempered glass

The material has a number of advantages. The first and main thing is increased heat resistance. Tempered glass can be used to make high-quality facades. Other benefits include:

- Ability to withstand accidental impacts;

- High strength under strong bends. Unlike regular glass, tempered sheets can withstand significant loads.

- Safety. Upon impact, glass can break into fairly small, but safe, fragments. They are unlikely to cause significant harm to humans.

- Impact resistance. Production features make the hardened material more durable. A bag weighing 45 kg can fall on it. from a height of more than a kilometer, and the glass will remain unharmed.

Brief summary

Since it is impossible to visually determine the type of material installed in a specific hob model, it is better to trust the manufacturer in this matter. And in order for the surface of the stove to delight its owners with an impeccable appearance for a long time, one must strictly follow the manufacturer’s recommendations for cleaning and care, set out in the operating instructions. And, of course, any surface should be protected from strong impacts.

Where is tempered glass used?

High-strength glass sheets are widely used in interior design, as well as in the glazing of furniture, doors and other products. The material is often found in cars and public transport. Most balconies have tempered glass in their design.

So, what makes tempered glass different from regular glass? First of all, its quality. Increased strength affects safety, as a result of which hardened material is more often used in various areas of life.

Source: zavodstekol.ru

How is stalinite made?

Some of our clients do not know what tempered glass means.

Therefore, it is worth considering the manufacturing process of such products in more detail. These spare parts undergo special hardening. In order to harden them, you need to heat the part to a very high temperature. It can reach 680 degrees. Then, auto glass for foreign and Russian cars is quickly cooled by blowing cold air. During the cooling process, compressive stress is formed on the surface of the spare part. It increases the mechanical strength of the material and its resistance to temperature changes. Some manufacturers tint finished products, but not more than 5% darkening. Therefore, it is quite difficult to determine the shade of tint by eye. If you don't know how to check the color of a part, take a piece of white paper and place it under the glass part. The paper will immediately take on a pale blue or light green tint.

Very high strength is the main difference between tempered glass and regular glass. For this reason, the material is used not only in the automotive industry. It is made from:

- impenetrable windows in psychiatric wards;

- shop windows;

- glass furniture;

- heat-resistant dishes;

- railway structures.

Glass ceramics

Glass ceramics is a completely different material: it successfully combines the best qualities of glass and ceramics.

The technological process for the production of glass-ceramic panels is as follows. Special components are introduced into the molten glass mass, heated to 1600 °C, which radically change the composition and physical properties of the resulting material. The main purpose of additives is to achieve a controlled crystallization process.

The fact is that when an ordinary glass mass cools, uncontrolled crystallization of the material occurs with the formation of crystals of different sizes.

The heterogeneity of the mass of crystals causes increased fragility of ordinary glass.

In the production of glass-ceramic surfaces for hobs, the material of the so-called LAS system (Lithium, Aluminum, Silicium) is used. This is when parts of lithium oxide and aluminum oxide are added to a base mass of silicon oxide (the standard raw material for glass production).

The final crystallinity of the resulting material depends on the amount of lithium and aluminum oxide additives. Upon completion of crystallization, glass ceramics consists of two crystalline phases: the predominant phase of the quartz solid solution in the material and the residual phase of glass crystallization. The temperature coefficients of these fractions balance each other, so in a LAS system with a crystallinity of 60-80%, the material has zero thermal expansion. Due to this, high resistance of the material to repeated sudden temperature changes is achieved, the modular value of which can reach 750-1000 ° C.

Glass-ceramic panels have a low thermal conductivity coefficient over the entire width of the surface; in practice, this results in no heating of the stove outside the cooking zone. The surface outside the burners remains barely warm.

Unlike the production of traditional ceramic products, when manufacturing products from glass ceramics, the stages of pressing and sintering of finished samples are not carried out, therefore glass ceramics do not have such a property as porosity.

Finished specimens have properties that combine two materials - the strength of ceramics and the tightness of glass.

The obvious advantages of glass ceramics include:

- ability to withstand local temperature changes up to 750-1000 °C;

- high mechanical strength;

- directed thermal conductivity;

- high heat transfer efficiency.

Glass ceramics also has disadvantages that should be taken into account:

- tendency to scratches on the surface of the plate;

- predisposition to chipping along the edge of the surface;

- high price;

- special requirements for the utensils used. Pots and pans made of non-ferrous metals (copper, aluminum, etc.) can leave persistent, difficult-to-remove marks on the glass-ceramic surface;

- in case of damage, the glass-ceramic plate breaks into large fragments with sharp edges that can cause injury;

- To keep the stove clean, special cleaning products are required.

As a rule, glass-ceramic surfaces are used in high-temperature hobs, where there is direct contact of hot cookware with the surface of the stove.

How to test tempered glass

Before buying auto glass, many Russians want to make sure that what they are purchasing is truly Stalinite and not a fake. Therefore, it won’t hurt you to know how to distinguish tempered glass from regular glass. There are several ways to check. Let's look at them in order:

- Try to break it. If the material breaks easily, then it is ordinary glass. You can also split hardened ones, but with serious effort. As a result of breaking, you will receive fragments. They should have rounded corners if it is Stalinite. This method is not suitable for the average buyer. After all, you will not destroy a spare part purchased with your own money in order to determine its strength. Therefore, it is better to use other verification methods.

- Heat the material strongly and then lower it into cool water. This is a more affordable method, but it requires heating equipment.

- Look at the glass surface at a slight angle using a bright backlight. Stalinite will have an uneven, rippling reflection, while simple glass will have a uniform reflection.

- Place the spare part against a light background and look at it through sunglasses. The hardened material will have streaks.

You learned how to determine whether glass is tempered or not. All that remains is to choose and pay for the product. If you have no idea where you can order such products, please contact our company’s online store. We will provide you with products for any car models and install the parts.

Characteristics of tempered glass and its differences from ordinary glass

Tempered glass is in great demand today, despite the fact that its cost is higher than regular glass.

Currently, tempered glass is used for interior or exterior decoration, as well as for the production of various products.

Thanks to this, this material is gaining increasing popularity.

How tempered glass is made

To understand what stages the production of tempered glass includes, you need to know that the physical parameters of the products will depend on the total number of temperings. This process takes place in two main stages:

1) At the first stage, glass sheet is produced. Specialists mix the required proportions of sand with quartz and, as a result, a glass mass is obtained, which is subsequently rolled. When rolled, the glass acquires a sheet configuration.

2) Hardening activities are carried out many times in order to change the basic parameters of the glass.

Heating can reach very high temperatures, and then the products are blown with cold air. This ensures durability and no risk of mechanical damage.

Advantages of Tempered Glass

· In terms of strength, this glass is very reliable.

· Tempered glass is not affected by sudden changes in temperature conditions.

Due to its heat resistance, such glass can be used both for glazing building facades and for the production of shower cabins.

· Even if the glass can break, it is safe in terms of the absence of injuries. If tempered glass breaks, it shatters into many rounded pieces that are not sharp.

The nuances of working with tempered glass

Of course, all materials have certain disadvantages, to a greater or lesser extent. In particular, regarding this type of glass, we can say that they cannot be processed after hardening.

So, if a manufacturer wants to obtain, for example, a pattern or cutting to size, then these activities are carried out before hardening.

How to distinguish tempered glass from ordinary glass?

Suppliers who want to cheat often take advantage of the fact that in appearance these two types of glass are similar to each other, but still, there are certain differences:

– if you lightly tap on the surface, the sound will be different (tempered glass produces a duller sound);

– the presence of mesh contours on tempered glass, which can be recognized using polarized lenses;

– you can use a special technique to check the quality of glass.

Source: www.kremlinrus.ru

Production

The process of producing tempered glass consists of two main stages.

- The first stage is identical to the technology for producing ordinary glass and consists of heat treatment of mixtures of quartz and sand taken in the required proportions, the result of which is the production of a transparent glassy mass. By rolling, such a mass takes on a sheet shape.

- The second stage is repeated hardening, which changes the physical properties of the material. It is produced by heating to extremely high temperatures followed by blowing cooled air. This process leads to an increase in surface compressive stress and increased resistance to mechanical overload. When broken, such glass breaks into fragments with characteristic blunt edges.

The physical properties of the material will depend on the number of hardening procedures applied. To avoid damage to the surface during operation, you must carefully read its performance characteristics before installation and use.

How to distinguish tempered glass from non-tempered glass?

Dear, tell me, who knows:

HOW TO DISTINGUISH TEMPERED GLASS FROM ORDINARY GLASS AT HOME?

Please, only to the point!

In other words, there is no way to distinguish.

I rummaged around on the net. Some write that you can tell the difference with polarizing glasses. Supposedly wearing glasses, a grid is visible on the tempered glass.

How plausible is this, who knows?

In other words, there is no way to distinguish.

I rummaged around on the net. Some write that you can tell the difference with polarizing glasses. Supposedly wearing glasses, a grid is visible on the tempered glass.

How plausible is this, who knows?

You take tempered glass, lay glass of the same thickness, not tempered, next to it, and slowly knock with a metal object (like a crystal wine glass) just not on the end. Tempered glass produces a duller sound than non-tempered glass.

In other words, there is no way to distinguish.

I rummaged around on the net. Some write that you can tell the difference with polarizing glasses. Supposedly wearing glasses, a grid is visible on the tempered glass.

How plausible is this, who knows?

It’s possible, I checked it personally. I wouldn’t call it a mesh, but you can tell the difference without any problems.

p.s. +1 to Perun too

It’s possible, I checked it personally. I wouldn’t call it a mesh, but you can tell the difference without any problems.

p.s. +1 to Perun too

Timon, we are talking about ordinary sheet tempered glass, not automobile glass. Right.

Timon, we are talking about ordinary sheet tempered glass, not automobile glass. Right.

Right. + I remembered that I also saw a device, um, not big in size, for identifying glass.

I also know about the device, but it costs money. Yes, and buy it only if you want it permanently. But glasses will come in handy in the car.

Thanks everyone for your help.

Right. + I remembered that I also saw a device, um, not big in size, for identifying glass.

We're probably talking about this device https://www.rusglazier.ru/?id2=1496. It's a good device, I use it to check the voltage in tempered glass, how much the glass can be ground down (they just make mistakes with the dimensions, so you have to grind it down).

No. We are talking about this device (https://www.1glass.ru/index.php?productID=1219).

By the way, there are those who work with him. What can be replaced?

No. We are talking about this device (https://www.1glass.ru/index.php?productID=1219)

I didn’t like this device: it’s expensive and its only function is to determine the glass (tempered or not). The stress meter can be used for both fusing and tempered glass (post 9) and is much cheaper.

“Please tell us more about the lantern! Or rather, about both lanterns. Who makes them? What is it called?

When there is no special flashlight, you can determine whether the glass is tempered or not using Polaroid glasses. Due to the voltage difference between tempered glass. light passes through it, breaking at different angles. And through polarized glasses I can see dark spots on the surface of the calico.

Based on the scheme, the refraction and perception of light rays through the device and glasses can be represented in the form: \||\||\||\ Whereas for non-tempered glass: ||||||||||||| – it is completely transparent.

But you cannot make holes in tempered glass, nor can you cut it. Along the edge there remains a tension-free area 5-10mm wide, which can be sanded/polished on a machine (for example, you slightly touched the edge and got a small shell).

How to distinguish tempered glass from non-tempered glass?

When placing an order, you should carefully check the name of the material from which the order will be made.

The product is much larger or smaller than what I ordered

The unit of measurement in which the order is placed is millimeters (mm). Bring the source data to a unified measurement system (mm).

Color shades on the computer and the finished product do not match

Each electronic device has its own specific color settings. The same image can look completely different on a computer, phone, TV, or printed on a printer. To prevent possible unpleasant consequences caused by the peculiarities of color rendering, before manufacturing the product, we recommend that you make a color proof (apply a small fragment of the image to the selected material). Only if a color proof is made, the manufacturer will be able to guarantee the identity of the product and the sample.

A product made of tinted glass differs in shade from the previously manufactured one.

Different glass manufacturers use different color pigments when making bulk tinted glass, and the concentration of these pigments in each batch may vary slightly. The identity of color in the manufacture of tinted glass is not regulated by GOST. Therefore, items not manufactured at the same time may have slight color differences.

The original color on thick glass does not fully match the RAL palette

Due to the physical and chemical properties of the materials, there is no absolutely transparent glass (regular glass has a greenish tint, cleared glass has a bluish tint). The thicker the glass, the more saturated the shade will be. After applying the paint to the glass, the natural shade of the glass and the actual color of the paint are superimposed. This feature should be taken into account when choosing a color palette.

Why does glass have a greenish tint?

The greenish tint of ordinary glass is due to the presence of iron oxides in its composition. Clarified glass contains less iron oxide, so it is more transparent and has a slightly bluish tint. When we look at the edge of the glass, we see light entering through the opposite edge and spreading through the thickness of the glass by total internal reflection, like a light guide. This light passed at least several centimeters of glass, so it acquired a tint that is not noticeable in a thin layer (by analogy with the thickness of water: the water in a glass is transparent, but in the sea it is blue, and the thicker the water, the darker it is).

The surface of tempered glass has a wave-like appearance

Wide vertical stripes or spots, visible when observed at an acute angle to the glass surface, are so-called “hardening spots”, which are an optical manifestation of surface and internal stresses that arise in the glass during the heat treatment (hardening) of sheet glass. This optical effect can be observed on almost any tempered glass under certain lighting conditions. “Toughened spots” are a consequence of the optical inhomogeneity of tempered glass, are not considered a defect and are not regulated by GOST 30698. (The European standard EN 12150-1 states that this optical effect (anisotropy, iridescence), also called “leopard spots,” can be visible on tempered glass under certain lighting conditions when viewed at an acute angle to the glass surface. EN 12150-1 does not regulate the requirements for this effect.)

What is hardening

Tempered glass is ordinary sheet glass produced by heating to the tempering temperature (650-680 °C) followed by rapid, uniform cooling with cold air on both sides. As a result of this treatment, residual mechanical compressive stresses are formed in the surface layers of glass, ensuring its increased mechanical strength, heat resistance and safety in case of destruction. When such glass breaks, it breaks into many small fragments with blunt edges that are not capable of causing serious injury. Thus, tempered glass has three main useful properties: heat resistance, impact resistance and safety.

The only vulnerability of such sheet glass is its sensitivity to impacts at the end, since in this place residual stresses can easily be released and break the entire glass.

Tempered glass cannot be cut, drilled or otherwise machined.

Production time up to 20 days; Tempered glass, of course, can also break, but in this case the risk of injury is eliminated, since the fragments will be small and will not

have sharp edges.

What is the difference between tempered glass and regular glass?

To make it clearer, let us tell you separately about tempered and non-tempered glass.

Tempered glass:

- Shatters into small crumbs during combat

- During a fight it explodes and shatters completely; it is impossible to simply chip off a corner of tempered glass; it’s either all or nothing.

- Cannot be processed. After tempering, glass cannot be drilled or the edges processed in any way. The only thing that is possible is to do sandblasting engraving.

- In order to temper glass, it must be processed, the corners must be blunted, the holes must be made with a countersink, i.e. The tension on the glass must be relieved. Otherwise, the glass will break in the oven.

- In appearance, unless special markings have been made, it is impossible to distinguish tempered glass from non-tempered glass.

Peculiarities

Due to such properties of tempered glass as safety and strength, it is often used in construction, railway, automobile, furniture making, and psychiatry. Moreover, it is used to create dishes, display cases, and barriers at hockey rinks.

Another useful property of tempered glass is heat resistance. What does it allow you to do? When glazing houses and premises, there is no risk of exposing the substance to thermal shock. That is, such material can easily withstand even extreme temperature changes.

What could make the glass described vulnerable? Just a blow to the butt. Such a mechanical effect can easily destroy the tension of the glass and completely break it. This effect is used in modern design styles. Sometimes a door is installed with glass inserts with decorative cracks on it. These small flaws combine to create a web-shaped pattern.

Tempered glass cannot be drilled, cut or otherwise processed.

The main difference and advantage of tempered glass:

- strength increases by more than 5 times compared to ordinary glass;

- Impact strength increases several times;

- heat resistance increases to 1800 degrees, which prevents the destruction of tempered glass from overheating or temperature changes;

- provides resistance to vibration loads;

- glass becomes safer when broken, due to the absence of sharp edges on the crystals of the broken glass.

When tempered, glass almost does not change its optical properties: transmittance, reflection, absorption.

Tempered glass has all these qualities - a modern high-quality material that is used in construction, interior design, the automotive industry, the production of tableware and furniture. This type of glass has a number of objective advantages such as:

- Increased mechanical strength , tempered glass, which can be ordered on our website, is very difficult to break. And that is why it is used in facade glazing.

- Safety Even if the glass is broken , it breaks into many fragments with blunt edges that cannot be cut on.

- Resistance to vibration and temperature changes All types of tempered glass perfectly withstand sudden and seasonal temperature changes, as well as wind and vibration loads.

Safety tempered glass is often called “stalinite” or “glass-ceramic”, which can cause a little confusion among the buyer. After the tempering procedure, the strength of such glass increases by seven times compared to ordinary glass. The only drawback this material has is the inability to process it. Any attempt to cut, polish or drill it will destroy the product. Therefore, already cut sheets of glass or glass products are subjected to tempering. Tempered triplex glass has the highest strength index, which makes it an ideal material for use in facade glazing. This material is also perfect for glazing balconies and loggias, fences in retail areas, office partitions, etc.

Cost difference

For many consumers, the choice of one material or another is based on the final cost. That is, people are guided not so much by the scope of use of the material and its technical qualities, but by the cost. But this is strictly not recommended. Since everywhere there are standards and requirements for both glazing and the manufacture of various glass objects.

Comparing the cost, it is worth noting that triplex costs several times higher than tempered glass:

- cost of 1 sq.m. tempered glass, 12 mm thick, varies within 2 thousand rubles;

- cost of 1 sq.m. hardened triplex, 6 mm + 6 mm thick, costs from 32,000 rubles.

To summarize, we can say that the choice of material should be made based on personal wishes and preferences, the scope of their application, and financial capabilities (since both materials have a significant difference in price, and expensive triplex is not always rational to use in everyday life). Some glass structures are best made only from triplex, while for others, tempered glass is the ideal choice.

In any case, triplex has higher impact resistance, enormous possibilities for decoration (which is important when implementing creative design solutions), and higher sound insulation (this should be taken into account by those who live in noisy areas). But tempered glass has better light transmittance, heat resistance and a more favorable price.

Glass Tempering Technology

The tempering process is similar to how steel is tempered and does not change regardless of the thickness of the tempered glass. The glass product is heated to a temperature of 600-700C° and subjected to rapid cooling. This changes the characteristics of the glass layers. The surface layer is sharply compressed, acquiring a high level of surface tension. On the contrary, the inner layer does not have time to cool down and creates a tensile force. All together this gives tempered glass high strength. The only weak point of this material is the end, a blow to which can lead to instant destruction of the entire product.

The thickness of tempered glass can range from 4 to 20 mm, so incredibly durable products can be made from it. And if you want to create a durable and safe translucent structure, then tempered glass, the price of which will please you, will be the best material for this. Contact us in any way convenient for you, and soon you will receive the high-strength glass products you need.

What to plant at the dacha in the fall?

What flowers can be planted in autumn?

What perennial flowers are planted and replanted in the fall?

- Astilbe Astilbe. ...

- Lupine Lupine is best planted in the first weeks of September. ...

- Heuchera Heuchera is replanted after flowering has ended. ...

- Dicentra Dicentra is also planted with a reserve of time for rooting before frost. ...

- Poppy

- Perennial aster...

- Nivyanik...

- Pyrethrum

What seeds can be planted in the fall?

Among the perennial flowers whose seeds are planted in the ground in late autumn, the most commonly chosen flowers are lavender, delphinium, primrose, and gentian. You can also plant winter-hardy varieties of cyclomena, hellebore, aquilegia, lupins, cloves, chamomile, and yarrow.

What trees are best to plant in the fall?

The best fruit crops for planting in autumn: apple and pear trees of winter-hardy varieties, raspberries, currants of all types, gooseberries, honeysuckle. Among ornamental trees, seedlings of chokeberry, birch, chestnut, willow, walnut and all conifers tolerate replanting in the fall.