/Accessories and decor/Curtains/

If you have bought or ordered vertical or horizontal blinds, then we suggest that you install them yourself, because you can cope with this task even without experience, the main thing is to have the desire, 1 hour of free time and several tools.

Attention! Installing blinds does not require special skills, but keep in mind that any damage that occurs during independent work will exclude the possibility of warranty repairs or exchange/return of curtains.

Depending on the type of curtains, your preferences and conditions, blinds are installed:

- In the window opening;

- On the wall;

- To the ceiling;

- On the window itself.

We have compiled 3 step-by-step instructions and a selection of useful videos with which you can mount horizontal and vertical blinds of any type in any way.

To install horizontal blinds on a wall or to the ceiling, as well as to install vertical blinds above a window, you need to prepare:

- Electric drill with concrete drill 6-8 mm;

- Self-tapping screws and dowels 6-8 mm;

- Tape measure or ruler and level;

- Pencil;

- Phillips screwdriver or screwdriver;

- If it is necessary to shorten and cut curtains to width: a hacksaw, scissors, threads, needles.

Varieties

Today, construction stores offer several types of blinds. Depending on the specific type, the features of fastening curtains change.

Horizontal blinds

You can find several varieties of horizontal blinds on sale. The lamellas in them are installed horizontally, which explains the name of the design. The thickness, width and type of material can be customized. The structure can be attached inside the frame, to the frame itself, to the slope or on top of the window block .

Horizontal blinds are most often installed in institutions

These blinds are installed in offices, production facilities and other places. These designs are universal - if desired, you can find horizontal blinds in almost any color and shade.

Vertical blinds

Due to their design features, such blinds are most often mounted on top of windows . The slats in this case are oriented vertically and are made of plastic or fabric. There are varieties on the market that differ in the length of the slats.

Vertical blinds are mainly installed in residential areas

This model is most often installed in private homes, but they are also in demand in offices. Vertical blinds are installed using self-tapping screws. As an alternative, installation to the ceiling is practiced.

Roller blinds

Roller blinds are made of fabric, completely cover the glass, and if desired, they can be raised by rolling them into a roll. Installation is carried out using brackets, screws or adhesive tape.

Roller blinds can be installed without drilling walls and doors - using double-sided tape

The need for drilling varies depending on the type:

- Vertical structures are mounted on top of the window or under the ceiling. In both cases you will have to drill the surface.

- Horizontal blinds can be attached to the top slope or to the window sashes. Without drilling, such structures can be mounted on the sashes of a window block.

- The interframe analogue, as you can easily guess from the name, is designed for installation inside the window itself. This option requires drilling the largest number of holes.

Variety of species

Horizontal

Horizontal blinds (Venetian shutters) are a canvas made of thin plates arranged horizontally. They are built into a rotating system of a special drum and a system of cords that sets them in motion. With their help, it is convenient to regulate the level of natural light in the room, so they are appropriate to use on windows in the bedroom, kitchen or bathroom.

The photo shows horizontal blinds in a home interior; they add special charm and comfort to the design of the room.

Horizontal blinds, in addition to standard models, are:

- Cassette curtains - this type of curtains has a system in which the lamellas, rising upward, are hidden in a special box - a cassette. They are compact and take up very little space, so they allow you to make maximum use of the window sill surface.

- Inter-frame horizontal blinds are installed between window frames and can only be mounted inside windows that have two independently opening frames, with at least 40 mm between the panes. Therefore, they are installed between wooden window frames, and it is technically impossible to install them inside a sealed double-glazed window.

Inter-frame blinds are controlled using a rope, which is pulled out through pre-drilled holes, which are then covered with a decorative plug

Vertical

Vertical blinds consist of a cornice and vertical slats attached to it using holders in the upper part, and connected with a chain in the lower part. They slide apart in both directions thanks to a rotary-sliding mechanism and a cord. More often they are made of fabric impregnated with special compounds, but there are also models made of aluminum or plastic.

Based on the width of the lamellas, they are divided into narrow - 89 mm (American standard) and wide - 127 mm (European standard).

This type of blinds helps to visually expand a narrow room, but for small rooms it is better not to use them, as they take up a lot of space, because they are mounted above the window opening or even on the ceiling

Rolled

Roller blinds are a solid canvas that, when closed, rolls up onto a special shaft in the form of a roll. They can be mounted either on the ceiling or wall, or on the vertical part of the window opening.

Roller blinds are designed to completely cover the entire window or its individual sashes, so if you need to change the degree of shading during the day, then this option of curtains will not be entirely convenient

Preparation and measurements

To install blinds you will need the following tools:

- screwdriver or screwdriver;

- pencil or marker;

- roulette.

To ensure that all your efforts are not in vain, it is important to carry out the measurements correctly and accurately - only then will the design work effectively. In addition, it must be located absolutely symmetrically to the glass unit. Blinds attached with adhesive tape are more tolerant of errors - they can be corrected if desired. For analogues with self-tapping screws, additional holes will need to be made, which is unlikely to benefit the beauty of the window; flaws here are unacceptable.

At the first stage of installing blinds, measure the width and height of the window

To correctly position the structure relative to the window and floor level, you will need to measure the following parameters:

- window opening dimensions;

- length to the bottom edge of the curtain;

- distance between fasteners.

For horizontal blinds installed on sashes, you will need to additionally measure the dimensions of each glass. To the results obtained, add 2 cm to the top and bottom edges and 0.5 cm to the sides .

Adjusting the size of blinds

In order for the blinds to look good and not interfere with the opening of the shutters, it is important that their dimensions match the parameters of the plastic window. Therefore, measurements are taken before purchasing. If a mistake was made in them and the curtains do not fit the window, then in most cases, you can adjust the size yourself by simply cutting off the excess parts.

Cutting horizontal blinds to width and height

Not all options allow you to shorten the length of horizontal blinds yourself. To make sure that such manipulations are possible, you should read the manufacturer’s recommendations regarding sizing. Usually it is enough to remove excess lamellas and shorten the threads by moving the plastic stops and the last element to the end of the shortened structure.

It is possible to reduce the width of the blinds yourself. For this:

- The plug and protective covers are removed. The control mechanism is moved to the side.

- Excess parts are cut off with metal scissors. It is better to do this symmetrically on both sides.

- The cut edges are treated with sandpaper, removing all irregularities.

- The structure is being assembled.

Cutting vertical blinds to height and width

Vertical blinds for plastic windows are also easy to reduce in width, but difficult to shorten in length. After all, the lower edges of the lamellas require special processing; weights are suspended from them. Therefore, you will have to disassemble the structure, shorten each element separately, and rearrange the weights.

To reduce the width of a structure:

- The blinds are being taken apart. Excess slats are removed.

- The cornice is cut with a hacksaw. The edge is sanded, removing all irregularities.

- Excess runners are removed, and debris clogged inside is cleaned out.

- The structure is being assembled.

Cutting roller blinds to width and height

Roller blinds for plastic windows can be easily shortened both in length and width. The list describes the length-shortening process:

- Roller blinds should be hung on the window with the canvas completely straightened.

- Marks are made on the canvas at the height at which cutting is intended.

- The curtains are removed from the plastic window and laid out on a horizontal surface. The weight material is removed from the pocket.

- From the mark, move down 4-5 cm (this is the allowance for the new pocket). If the length is not enough, you can rip and straighten the pocket.

- The excess is cut off.

- Sew a new pocket. A weighting agent is inserted into it.

Shortening roller blinds in width is a little more difficult. For this:

- Hang the curtain on the window and make markings, marking the lines along which the canvas will be cut.

- The structure is laid on a horizontal surface and disassembled.

- The cornice is cut. Its length should be 1 cm greater than the width of the curtains. The edges of the cornice are treated with sandpaper.

- The fabric is cut along the line. If the fabric frays, the cut sides are hemmed, leaving 1 cm on each side for an allowance in advance.

- The weighting material is shortened. It should be 1-1.5 cm shorter than the width of the canvas.

- The curtain is being assembled. Now you can hang it on the window.

Installation of vertical blinds

Installing vertical blinds is actually not as complicated a process as it might initially seem, and anyone can cope with this task. If the length of the curtain is short, then installation is carried out inside the window opening. Otherwise, the structure is installed under the ceiling or on the wall.

The algorithm of actions here is as follows:

- Marking. The first step is to calculate the center point of the window - it should be on the same level as the center of the cornice. To avoid mistakes, marks should be made along the edges of the structure. Places for screws should be marked on both sides approximately 0.5-0.6 cm closer to the center of the window.

- Rating by level. During the process, it is necessary to ensure that the slats are positioned vertically. The lower part should be 1-2 cm from the floor. A similar distance should be maintained to the window sill if installed directly into the opening.

- Bracket mounting. The holes for the dowels should be prepared in advance, so all that remains is to install them. The bracket is attached using self-tapping screws. Subsequently, complete clips can be installed on these elements for camouflage. When drilling into a wall, you should act very carefully, as otherwise you may break off part of the wall.

Vertical blinds are secured with self-tapping screws to the wall or ceiling

Installation of chain and lamellas. After attaching the cornice, all that remains is to hang the slats, install the runners, and also attach the adjusting chain. An important point: the slats must be hung in the same order in which they are in the box. Otherwise, you can ruin the entire drawing (if there is one) .

Installation of window blind mounts on the wall

Installing blinds on a wall is no more difficult than hanging them on a window frame. For this method, you usually choose a curtain size so that the sides extend beyond the window. The length may be different - the installation technology does not change depending on this parameter.

Step-by-step instructions for installing blinds on the wall above a plastic window:

- Assembling the curtain. Remove the top cover from the cornice.

- The cornice is applied to the wall above the window (the height at which the cornice will be located can be any). Markings are made on the wall in the places where the fasteners will be installed. It is convenient to make markings with a pencil through the holes in the cornice.

- Holes are drilled at the marked points.

- The cornice is screwed directly to the wall with screws or the brackets are first attached and then the cornice is inserted into them. If the window is flush with the wall, then for ease of opening the sashes, be sure to hang brackets.

- The cornice is covered with a top cover.

Installation of horizontal blinds

Attaching horizontal blinds to plastic windows is somewhat more complicated. The main thing is to strictly follow the instructions:

- The first step is to secure the upper fasteners. This is done using a screwdriver. First, the holes are prepared, after which the bracket is attached with self-tapping screws.

- We hang the cornice. It should be fastened until it clicks.

- The holes for the lower fasteners are drilled by hand. When choosing a diameter, you should take into account the dimensions of the thread retainer connecting the lamellas. Most often, horizontal blinds require additional holes on the sides. This helps to insert the clamp connected to the lamella fabric into the corners.

When installing horizontal blinds yourself, you must carefully follow the instructions.

Important: self-installation must be done as carefully as possible. Very often the slightest mistake results in the entire structure not functioning correctly.

Designs and installation methods

Any blinds include a cornice (a plastic or metal rectangular profile in which the mechanism is hidden), slats, and a control element (in the form of a plastic chain or thread). Designs often also have a control rod, which, when rotated, changes the angle of inclination of the lamellas and the degree of “transparency” of the window.

Typically, such curtains come with fastenings that allow you to quickly and easily assemble the blinds. However, some manufacturers produce products without such an addition. In addition, the basic configuration is not suitable for all installation methods.

The ways in which you can hang blinds on a plastic window are shown in the table.

| Way | Explanation |

| Each curtain is individually fitted to its own window sash | This option allows the doors to be opened wide for ventilation. To assemble lamella curtains on plastic windows, both the drilling method and special magnetic fastenings are used. |

| Blinds cover only the window, but do not touch the walls | To achieve this effect, the blinds need to be hung on the upper slope. This option is only suitable for sliding or fixed windows. |

| Installation of blinds box to the ceiling | This method is usually used if a long structure is used that hangs below the window or reaches the floor. If this installation option is chosen for a short curtain ending at the level of the window sill, then it is desirable that the distance between the window and the slats be at least 5 cm. This is necessary to ensure free opening of the shutters for ventilation when the blinds are lowered, as well as normal ventilation in the window area |

| Hang on the wall above the opening | The cornice is attached to the wall above the window close. This option is suitable for wide window sills, since in this case the curtain will not interfere with the opening of the windows. |

| Installation on additional long brackets on the wall | First, brackets are attached to the wall above the window, and then the cornice is hung on them. This option is suitable for window openings with a short window sill, since without additional distance the curtains will interfere with the opening of the sashes. |

How to hang blinds on a plastic window is worth deciding before purchasing. After all, the required size of curtains will depend on this.

Roller blinds

In the case of roller blinds, there are several mounting options, so before you start, you should choose the most convenient one. The first is installation on self-tapping screws, which in essence is no different from the option described above, the second is on a special adhesive tape, which is used instead of self-tapping screws, and in the third, the roller blind is hung on the sash.

To fix roller blinds, use brackets or adhesive tape

Important: do not forget about degreasing the plastic - it will help significantly improve the adhesion of materials.

Material of manufacture

The choice of blinds is not limited only to the functionality of the design, but also to the material from which they are made.

Aluminum

– lightweight material, not susceptible to temperature changes. Curtains made from it can be placed in rooms with high humidity and dust, but they have a small drawback - noise in the event of a draft. To clean them, you can use a sponge dipped in soapy water or even a vacuum cleaner.

For the manufacture of lamellas, a tape is used from a special bend- and fracture-resistant aluminum alloy with a heat-resistant color coating of acrylic.

Aluminum can be easily painted in different colors, so blinds made from this very practical material can become a bright highlight in a house or apartment.

Textile

(cotton, polyester or mixed fabric), after pre-treatment with special compounds, is used for the manufacture of vertical or roller blinds. Depending on the density of the fabric, they can be 100% light-proof and also create light shading, which is why they are best placed in the bedroom, nursery or living room.

Textile blinds can be cleaned dry or wet, but it is still not advisable to hang them in rooms with high levels of humidity and pollution

Tree

does not tolerate high humidity, and it is also not advisable to install products made from it next to a radiator, stove or fireplace, as they may become deformed. Wooden structures are made from very thin plates, which undergo preliminary preparation, including lamination.

Thanks to their color scheme, wooden blinds will bring nobility and sophistication to the interior; they should be placed in offices, dining rooms or living rooms

Plastic

used for the manufacture of blinds for industrial premises, as it is resistant to most acids and solvents, mineral oils and alkalis. Such products do not absorb odors, they are easy to care for and do not fade in the sun.

Products made from thermoplastic polymer vinyl chloride - plastic, do not accumulate dust and dirt, they are resistant to deformation, as well as temperature changes, therefore blinds made from it always retain their original shape

Inter-frame curtains

Inter-frame curtains are used only for double frames. Installation of blinds of this type is somewhat more complicated than the previous ones, and the process itself will result in an inevitable violation of the integrity of the profile: you will have to drill at least two holes through which the handle and cord to control the system will be cut out.

The curtains themselves are mounted in the inner sash, or more precisely, in its upper part, and the bracket is mounted directly to the upper profile. Installing the structure is in many ways similar to working with horizontal blinds.

Inter-frame curtains are installed in double glazing

Do-it-yourself installation of the system is carried out according to the following algorithm:

- The window frame unwinds and the blinds are applied to the inner sash. This is used to check the size matches.

- Markings are made for fastening, as well as points for the cord and control handle, after which holes with a diameter of about 5 mm are drilled.

- The brackets are inserted into the calipers, the cords and control handles are brought out, with the cord through the lower hole.

- Inter-frame blinds are mounted on the sash with special inter-frame brackets.

- An adapter is installed on the frame, and a control handle is connected to the flexible terminal.

- The control handle and cord lock is installed.

- The frame twists back.

The blinds control element is brought out through the frame.

As you can see, the technology for installing blinds on plastic windows without drilling is completely unsuitable here. The principle itself is similar to the installation of all other design options, with the only difference being that you have to disassemble the frame, screw the bracket into the interframe space, and remove the controls through the drilled holes.

Fastening and assembling blinds

Next, the places where the baguettes are attached are marked. Wall brackets are screwed to the marked places with self-tapping screws, and ceiling brackets are attached to them with screws. A baguette with built-in controls and sliders is inserted into the ceiling fixture and snaps into place.

Next, the lamellas with lamella holders are sorted, if the material of different colors is chosen. If the lamellas are the same color, then you should hook one piece with the lamella holder into the groove of the runner until it clicks.

To check, you need to slightly pull the lamella down and to the sides. Continue hanging this way until the end of the material. All lamellas must be hooked on one side - the wrong side or the front side, so that it does not happen that some seams end up on the outside, and some on the inside.

The next stage of work will be a simple lesson, you can connect children to the installation. A weighting material is placed in the slot of each lamella at the bottom with the “ears” facing up. Next, you need to fold the bottom chain in half and, starting from the uncut side, snap the chain links into weights, cut the ends of the remaining chain to size.

Useful tips

In order for blinds to serve for many years, you should follow some operating rules:

- When purchasing, you should carefully check the package and all equipment, especially fasteners. They must be of high quality.

- You should choose the adjustment mechanism wisely - it should be on the side that is convenient for use.

- Make sure that no one opens the windows while the blinds are not yet fully closed.

- The rotary handle must not interfere with or touch other fittings.

- Don't forget about periodic maintenance.

- It is quite possible to install blinds on windows yourself, but it is better to entrust its repair to a professional.

- Plastic structures are preferable: they are much easier to care for.

- You should not clean the system too often, this will only lead to rapid wear of the protective layer.

Installing the device yourself, as you can see, is not a difficult task at all, be it metal, plastic or wooden blinds on plastic windows. The main thing is to have quality instructions at hand. Thanks to this material, you can hang your blinds as quickly and efficiently as possible.

We hang aluminum curtains and blinds on sliding windows

The sliding window sashes do not open, but are moved to the side like a wardrobe. Therefore, in this case, hanging curtains on each sash separately or on the window frame will not work.

What is the best way to hang aluminum blinds?

To install blinds on sliding windows, the cornice is attached to the wall above the window or to the ceiling. In this case, the canvas should be at some distance from the glass. In the case of sliding windows, special brackets are used to hang blinds on the wall. They will provide the required gap between the curtain and the window opening.

To hang a cornice on the ceiling, step 2-4 cm away from the wall with the window. Vertical blinds are best suited in this situation.

Operating rules

Vertical blinds must be properly maintained.

Usually this is dry cleaning; heavily soiled areas can be wiped with a damp rag or sponge; a simple soap solution is used for this. For fabric blinds, wet cleaning is used. The curtain is soaked in soapy water; you cannot rub the surface of the slats; they just need to be rinsed after a certain time (depending on the type of detergent).

Movement diagram of vertical blinds.

What is required to clean blinds? Procedure:

- The bottom chain is removed to free the slats. The weights that hold the strips in a certain position are carefully removed. The slats are lowered into soapy warm water. Gently wipe the mechanism and chains with a damp sponge. All dirt should come off the slats, then they should be rinsed and taken out to dry. Next, the curtain is reassembled.

When cleaning blinds yourself, do not use bleach.

It is forbidden to wash the lamellas or use hard brushes.

It is important not to bend the strips; after rinsing, they are removed from the water and hung in place when wet. If the fabric is wet, then you need to carefully iron the strips through the layer of fabric.

Fiberglass slats can be cleaned with a washing machine or a regular vacuum cleaner. Metal and plastic curtains should be cleaned with a damp or dry sponge and wiped regularly. Wooden blinds are wiped down a couple of times a week.

Features of attaching a cornice to a niche in a plasterboard structure

This option for creating an interior, when the cornice of the blinds is hidden deep into the plasterboard structure, is finding more and more fans, because in this case the interior seems more festive and elegant, the eye is not distracted by additional elements, such as the cornice, places where the slats are attached, and the line of the ceiling space immediately rests into the louvered covering.

The cornice is hidden by a plasterboard structure

The installation method in this case is no different, except that you will have to work more carefully and use a longer tool, because drywall can be removed from the surface of the concrete floor at a distance of up to 10 cm.

Step-by-step instruction

To install blinds efficiently, decide on the installation method and take the correct measurements. The structure can be secured in different ways. Screws, double-sided tape, magnets, and brackets can be used. The order of work depends on the type of system being installed. Let's look at the features of each process in more detail.

Metering

By the time the measurements are taken, you need to know exactly the order of subsequent installation. If you plan to install blinds in a window opening, measure its width and subtract 4 cm from the resulting value. This will be the width of the blinds, since a gap of 2 cm should be provided on each side.

To determine the height of the canvas installed in the window opening, subtract 2 cm from the height of the window opening. Thanks to this gap, there will be no difficulties when opening the window.

If the blinds are mounted on the wall, they will have to completely cover the window openings. To do this, add 10 cm to the width and height of the latter. In this case, the installed system will be 10 cm longer than the window opening. On each side it will “go” onto the wall by cm.

If the installation is carried out in the sash, it must be taken into account that it will open together with the installed blinds. In this case, the geometric parameters of the canvas are consistent with the dimensions of the glass unit. Add 3 cm to its width at the rate of 1.5 cm on each side.

If the blinds are in the same plane as the wall and it is decided to use metal brackets for fastening, to find the width of the blinds, add 10 cm to the width of the window opening.

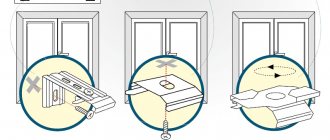

Installation of horizontal blinds

Such designs come with everything you need. For installation you only need a screwdriver. The work is performed in the following sequence:

- Unpack the product. Carefully remove the control stick from the cornice so that it does not break during installation and does not interfere with the installation;

- We attach the brackets to the product, choosing a place at some distance from the mechanism;

- We unfold the blinds and apply them to the sash to make sure that the geometric parameters fully comply;

- We mark the places where holes need to be drilled;

- According to the applied markings, we drill holes and screw the brackets;

- We install horizontal blinds into the prepared fasteners;

- We check the functionality of the installed structure;

- Install the previously removed control stick.

- We mark the location of the anti-wind element;

- We screw the element to the sash;

- We insert the blinds into the anti-wind.

If after fitting it turns out that the geometric parameters of the blinds do not correspond to the dimensions of the sash, the design can be adjusted. To do this, untie the knots under the bottom guide and remove the excess slats. After this, the lower guide is fixed by tying the cords and placing plugs.

If you still have questions about the procedure for installing horizontal blinds, we suggest watching the following video to understand in detail the intricacies of the process:

Installation of vertical blinds

The installation procedure for vertical blinds may vary. Even before installation work begins, you need to decide on the installation location. Acceptable installation on:

- frame;

- ceiling;

- wall.

The most widespread is the latter option using a special L-shaped bracket. The work is performed in the following sequence:

- The location of the L-shaped brackets on the wall is marked and they are fixed;

- The cornice is placed and fixed in the brackets, with control over the correct location of the controls;

- The sliders unfold perpendicular to the plane of the window;

- Slats are installed;

- The lamellas are fastened with a lower chain;

- We check the functionality of the installed system. The lamellas should rotate freely around their axis and move to the side.

We invite you to watch the following video, which describes in detail the procedure for performing installation work. This will allow you to understand in detail the intricacies of the process:

Installation of roller blinds

If you decide to give preference to roller blinds, you should carefully study the manufacturer’s instructions before starting installation. It describes in detail the procedure for performing installation work. In the most general case, installation is carried out in the following sequence:

- We unpack the structure and lay out all the elements in the presented sequence;

- We pass the fishing line through the bracket several times, ensuring that it is securely fixed. If this is done poorly, there is a risk of it being torn out during operation of the system. In this case, you will have to dismantle the structure and reinstall it;

- We assemble the main parts according to the manufacturer's instructions;

- We thread the chain into the control unit. This can be done using a thin tool. A thin screwdriver can be used for this purpose;

- We insert the control unit together with the holder into the fabric winding shaft;

- Open the sash and install the holders along with the leaf on the sash. We center their position relative to the sash;

- Assembling the lower part. We insert weights into the place specially designated for it;

- We install special plugs on both sides of the weights;

- Install the holders on the bottom of the frame;

- We tighten the fishing line by carefully twisting the plastic handle. Constantly control the tension force;

- We thread the chain into the snail, following the manufacturer's instructions;

- We connect the chain;

- We mark the location of the snail and fix the fasteners using double-sided tape;

- We check the functionality of the installed structure.

If you still have questions about the installation procedure, we suggest watching the following video:

In this case, screws are used to secure the holders. This somewhat complicates the installation procedure. If in the first case dismantling is quite easy, then in the second case after dismantling there will be holes in the frame.

Instead of mechanical fastening, double-sided tape can be used. In this case, before installation, the frame must be thoroughly washed and degreased. Otherwise, it will not be possible to securely fix the fastener to the surface.

Drilled fasteners

This type of installation is much more reliable and durable, since screws screwed into a window frame or wall better withstand the weight of the structure and the constant mechanical loads placed on it.

Drilling requires precise preliminary measurements and perfect horizontal alignment using a level

Drilling the frame leads to damage to the window profile. Although they are insignificant (they do not interfere with sound and heat insulation), if you decide to remove the blinds in the future, when you remove the structure, noticeable marks will remain that will have to be masked, for example, with silicone or liquid plastic. Roller or horizontal systems are usually placed inside the window. To hang vertical blinds, drill into the ceiling or wall above the window opening.

Installation with drilling can be done independently or entrusted to specialists

For installation you will need:

- pencil;

- building level;

- screwdriver;

- drill (with drills 3 and 6 mm);

- hammer;

- screwdriver (flat or Phillips).

How to hang horizontal blinds

First, we mark the places for the mounting plates or brackets: measure 6 cm from the glass on both sides and mark with a pencil the places for the upcoming drilling. The line between the intended holes must be checked using a level so that it is strictly horizontal

This is important for the correct and long-term operation of the blind system. A window profile (especially not a new one) can crack when screwing in screws, so it is recommended to first use a thin drill in the marked fastening places, and then screw the screws into the prepared holes

On opening windows, holes for fastening brackets are made in the upper part of the sash

Holes for screws for brackets are drilled in the upper part of the sash (on opening windows) or on the outside of the glazing bead (on fixed windows). Then you need to hang the blinds, securing them in the brackets. When placing a blind system inside a window opening, a fishing line (clamp) is pulled to hold the roller blind or slats near the glass when the sashes are opened. A hole for the fishing line is drilled in the lower glazing bead (below the main beads) or on the side of the sash, the fastener is threaded through the plugs, achieving medium tension, and tied into a knot. All decorative and working parts are installed on the mounted structure: trim, latches, fastenings for the lever and chain.