More and more new materials appear on the domestic construction market from time to time. Some of them have long been popular in European countries, but for some reason they are undeservedly forgotten in our country. One example of such materials is profile glass or glass profile. It is used both in private and industrial construction for the construction of walls and partitions.

Stekloprofilit - what is it, where and how is it used?

This material has not yet found widespread use in domestic architecture. However, this may largely be a consequence of insufficient information. When you consider its performance, reliability and aesthetics, you can hope that profiled channel glass (that's one of its names) will soon become more popular. So, in this publication, let's figure it out: glass profile - what it is, where and how it is used.

General information about profile glass

A little history

Few of those who have already encountered this material know that the pioneers in its development and use were Soviet engineers N.M. Bystrov, G.A. Babinov, V.S. Shchukin and G.A. and N.P. Kabanov. Moreover, back in the USSR, profile glass began to be mass-produced at the Bor Glass Factory, and a special GOST (21992-76) was even developed for it. This new product was supposed to be widely used as walls and partitions in public buildings. Channel reinforced glass was also considered as a material for covering a translucent roof.

Fiberglass appeared abroad much later. However, it has turned out that today it is supplied to the Russian market mainly through imports: the production of this material in the Russian Federation has practically come to a standstill, and the proposed glass profile is manufactured mainly in European countries.

Features of glass profile

In Russia, profile glass is initially called “stekloprofilit”, but products from European manufacturers are often called by their imported name: “U-glass”, without translating or changing it. This doesn't change the essence.

The material is produced in a factory using continuous rolling technology, and this gives it a considerable number of advantages over conventional sheet glass. Stekloprofilit is produced in channel and box versions. In this publication, the main focus of consideration will be on channel versions of the material.

The characteristic shape of channel glass profile

The glass profile is given a U-shape; it can have a smooth surface or have some kind of relief “pattern”. As a rule, the surface texture is pleasant to the touch. Glass is also not always colorless - the variety of shades in which the material is produced allows it to be used in the design of facades and interiors. Glass profiles, in addition, can have different degrees of transparency, which allows you to create very interesting visual effects. And due to the fact that the material transmits light, a partition made of it, which is even removed from the window, will not block the natural light for the room separated by it.

Fiberglass partition separating two rooms

At the same time, oddly enough, this design has a fairly pronounced ability to dampen the spread of noise. Normal household sounds from a room with a glass wall will be practically inaudible in the next room. If external walls are built from fiberglass, they will also reliably protect the premises from street noise.

In addition, such profile glass can be classified as anti-vandal materials. A partition made of high-quality glass profile is quite difficult to break or scratch, as well as to be damaged by some kind of coloring compounds. In addition, the glass can be easily cleaned from various contaminants if necessary.

Therefore, glass profiles are successfully used to form external walls, to cover window openings and to erect internal partitions in public buildings, such as shopping centers, medical institutions, cafes and restaurants, train stations, sports facilities, etc.

A room with one window is divided into two isolated rooms by a transparent fiberglass partition.

An excellent solution would be a fiberglass partition if you need to divide a room with one window into two closed zones. It will not prevent light from penetrating into a room that does not have a window opening, and at the same time, the resulting rooms are completely isolated in terms of sound insulation.

Main technical characteristics of the material

Glass channels are large-sized products, the glass thickness of which is 6÷7 mm. Their maximum length is 7000 mm, the profile width reaches 750 mm. The light transmittance of profiles can be different and vary from 40 to 65% or more.

Non-reinforced glass channels are designed for short-term loads of no less than 1÷1.2 MPa.

A clear disadvantage of the material is its instability to high temperatures and open flames. Under such conditions, glass profiles crack quite quickly.

The table below contains for comparison some technical characteristics of channel-type glass profiles of domestic and foreign production:

| Origin | Light transmittance,% | Average density as part of the structure, kg/m³ | Thermal conductivity coefficient, W/(m×℃) | Ultimate compressive strength, MPa | Channel width and length, mm | Glass thickness, mm |

| Domestic material | 40÷70 | 800 | 0.4 | 4÷5 | 250÷300 / up to 6000 | 5÷6 |

| Foreign products | 55 ÷65 | 500 | 0.48 | 1÷1,2 | up to 750 / up to 7000 | 6÷7 |

Double-glazed windows with thermal mirror

These double-glazed windows were developed (USA) in the early 80s.

Structurally, they are a two-chamber double-glazed window, in which the middle glass is replaced with a heat-reflecting spectral-selective polymer film. The heat transfer resistance of double-glazed windows with a thermal mirror can reach 1.2 m2 degrees/W. Currently, the sale of such double-glazed windows in the US market accounts for about 5% of total sales. Their advantages are quite obvious: they have good thermal characteristics, are lightweight, and do not require large volumes of transportation of heat-reflecting glass, since the film is transported to the manufacturer of double-glazed windows in rolls. top of page

Review of glass profiles from leading foreign manufacturers

The most famous manufacturers presenting their products on the Russian market are German and Pilkington - Pilkington Profilit™, whose products are in demand all over the world.

This section will present some information about these manufacturers, as well as review the popular models of glass channels they offer to consumers.

The company Glasfabrik LAMBERTS GmbH & Co.KG has been operating since the “venerable” 1887. It was founded by engineer L. Lamberts and initially specialized in the production of glass products. The company's modern product range includes LAMBERTS LINIT profile glass, as well as patterned decorative glass varieties. The plant, of course, uses the most modern equipment and innovative technological processes. There is all the necessary certification according to strict EU standards.

This manufacturer is represented on the Russian market.

Decorating a flight of stairs using profile channels allows you to save on lighting during the day

LAMBERTS LINIT products are widely in demand in Europe as a material for design facades of public and industrial buildings, as they help to significantly save energy in premises - factory floors, office buildings, swimming pools, cultural centers, etc. U-Glass products allow you to create light-transmitting structures with large glazing areas. They are actively turning to similar technology in the construction of individual housing. Installation of glass structures made from fiberglass is quite simple, as it does not require special equipment for fastening glass channels together.

Facade of a public building of a round shape, lined with fiberglass

The company produces glass profiles, the maximum length of which is 7000 mm, width 250 or 500 mm, with a standard wall thickness of 6÷7 mm.

Depending on how much the glass wall should retain heat in the room, a structure can be erected where the channels will be installed in one or two layers. If it is necessary to create effective insulation of the room, a 1.7W glass channel is used, which has an energy-saving coating and is installed using the double installation technique. In addition, to insulate the structure, a translucent heat-insulating material can be used, which is placed inside the formed glass profile chambers.

The insulation used in fiberglass walls has the ability to transmit light. The parameters of this type of insulation are constant; it has a thickness of 56 mm and a specific density of 5 kg/m².

If it is necessary to provide the premises of a building, the façade or window openings of which are covered with glass channels, with additional protection from the sun, profile glass with a special “SOLEX” coating is used.

If the enclosing structure must have increased strength, then for its construction you can choose glass profiles reinforced with metal mesh.

Below is a table that shows the options for LAMBERTS LINIT glass profile surfaces in terms of transparency and relief. The illustrations show, as an example, how the same bright object will be visible through a glass panel: on the left - from a distance, on the right - when approaching.

| Illustration | Name and brief description of the created effect |

| "504 PERL" . The name of this type of glass profile in translation means “pearl”. It should be noted that this glass relief, consisting of numerous transparent grains, beautifully diffuses light. It can truly be called a pearl in the collection of glass profile products. | |

| "CLARISSIMO" is an almost transparent version of glass profile. It can be used for installation in a window opening or for arranging a large panoramic window in residential premises. In addition, it can be combined with glass channels that have a matte or grooved surface. | |

| “CORD” are profiles with a corrugated vertical pattern, the strips of which have the structure of a thin twisted cord. Thanks to this relief, bizarre optical effects are created, and their change occurs depending on the angle at which the view falls. | |

| “ICE” - the relief of this glass resembles the surface of ice formed as a result of prolonged freezing of water droplets, or moisture frozen on the glass. | |

| "PRISMASOLAR" translates as solar prism. Profiles with such a relief can be installed vertically or horizontally. When installing them horizontally on the front side of the building, the lighting of the room will be adjusted depending on the height of the sun. | |

| “SOLAR” - this name translates as solar. When sunlight hits such products, their surfaces begin to glow with multi-colored sparkles. The glass is almost transparent, with a slight soft blur, which makes the surface visually appear silky. | |

| Glass channels, designated 1.7W , have a special heat-insulating film coating based on metal oxides, which reflects infrared radiation into the room. Thanks to this effect, the thermal insulation qualities of glass enclosing structures increase by 30% compared to conventional glass profiles. | |

| “AZUR” is the name for the coating of glass channels with any relief pattern, which gives transparent glass a bluish-gray tint. | |

| “SOLEX” is the name of the glass profile coating used for external glazing of buildings that need to be protected from intense solar radiation, especially ultraviolet exposure. Such glazing is relevant for the south side of the house, where the sun is directed into the walls and windows almost all day long. |

There are several other designations that indicate certain characteristics of the product.

- "LINIT TOUGH" is a designation for thermally tempered glass. It applies to all models of glass profiles, except those that have a different designation - “LONGITUDINAL WIRES”. The length of tempered glass products reaches 7000 mm. Its advantages include the following qualities:

— the mechanical strength of this material is five times higher than that of ordinary glass;

Experiment on breaking glass profiles from ordinary and tempered glass

— the hardened material breaks into small fragments upon impact, which are safer than large sharp pieces of glass;

— pronounced resistance to high and low temperatures, as well as to their sudden changes, which is especially important for external glazing, when the glass can heat up to 80÷120 degrees.

Interestingly, each batch of tempered glass products undergoes a special test - “Heat soak test”, which identifies specimens prone to self-destruction. The cause of spontaneous self-destruction is nickel-sulfide formations in the thickness of the material. If the glass has passed such a test according to European standards, then the risk of damage to the products during transportation is practically eliminated.

- “LOW IRON” is glass with a low iron content, due to which the material has almost no color. In addition, the low content of iron salts increases the light transmission coefficient of glass up to 90%. This glass is present only in the series designated P26/60/7 “SOLAR”.

- “LONGITUDINAL WIRES” is a designation for products reinforced with wire inserts. Their use is necessary when there is a high probability of mechanical damage to the structure. Such products belong to the 504 and Clarissimo series.

Prices for glass blocks

Glass blocks

Glass profiles production

"Pilkington" are glass profiles produced by the German company. The products are very well known and are supplied throughout Europe, the USA, and other countries, including Russia. In the construction traditions of European countries, the material is widely used in suburban construction both for the construction of facades and for the arrangement of partitions.

Pavilion for a swimming pool in a suburban area

This material is excellent, for example, for the construction of an indoor pool pavilion. Glass walls will protect the water from dust and dirt, and swimmers from the wind, while maintaining natural light throughout the day.

Glass profile "Pilkington" is produced with different glass effects, as well as with different degrees of transparency. The table below shows the options for glass channels available for sale:

| Illustration | Model name and brief description of the effect created |

| "Wired 8" literally translates as "wire". This is how it actually is - it is reinforced glass profile, which is perfect for constructing pavilion walls. The material, reinforced with wire located in the thickness of the glass, is more durable than products made from ordinary or tempered glass. | |

| “Wave Opal” (“Opal Wave”) - this name corresponds to the relief and deep matte of the glass. Thanks to the combination of these two factors, the glass has become almost opaque, making it difficult to see the exact outlines of objects behind it. This option is well suited for forming a shower stall in the bathroom, as well as a partition dividing the room. | |

| "Wave Low Iron " This name hides two characteristics of the material - the relief pattern, as well as the low content of iron-containing additives in it. Thanks to the second characteristic, even despite the matte effect, such glass has fairly good light transmittance. | |

| “Wave” is almost the same option as the previous one, but the amount of iron in the composition corresponds to the characteristics of ordinary glass. Due to this, the light transmittance and transparency of the material becomes lower. | |

| “Opal” - the name was chosen, apparently, because of the similarity of the dullness and shade of the glass with the natural stone “blue opal”. This option will look good in both residential and office interiors. | |

| “Clear” is almost completely transparent glass, giving high clarity of visibility of objects behind it. Such glass can be installed in a regular or panoramic window opening. Thanks to the design of the products and the thickness of the glass, glass profiles will perfectly protect the room from the wind and retain the heat accumulated inside the building. | |

| “Standard” - when choosing this name, the manufacturer most likely meant a standard, that is, the best relief design option produced by the company. Indeed, glass has the effect of heavy rain falling outside the window, from which drops fall on the glass and form beautiful stains. | |

| “Slim Line Opal” (“Light line – opal”), in fact, the matte resembles a thick blue haze. Thanks to this effect, the intensity of natural light will increase. | |

| “Slim Line” does not seem so light and pleasant, since the image of the object behind the glass is distorted. At the same time, looking through such glass is very unpleasant. Perhaps this option is suitable for certain cases. For example, where it is precisely necessary to avert prying eyes from trying to examine something. | |

| "Low Iron Opal" is a glass with a smoky blue opal effect, but perfectly transmits natural light into rooms. Suitable, like all other opal options, for arranging a shower stall, first floor facades, internal partitions, walls of pool pavilions, closed gazebos, etc. |

Additionally, Pilkington glass channels can have the following functions:

- Products may have an Antisol sun protection coating, which allows you to protect rooms glazed with this material from aggressive ultraviolet radiation. In addition, thanks to this coating, the glass does not heat up to high temperatures.

- The designation “Plus 1.7” is affixed to energy-saving glass profiles, which are capable of retaining heat in rooms. In combination with insulating material, structures built from glass channels are quite capable of performing the functions of a main wall even in conditions of low winter temperatures.

- The company also produces reinforced glass products and tempered glass channels. Thanks to these reinforcements, a two-layer partition, built from 7 mm thick glass profile, is able to withstand a particularly strong blow from a football or even a tennis ball.

Description of the profession and its features

Yes, let's start with the fact that a glazier is a person who works exclusively with a material such as glass. It is a hard, transparent and rather fragile material, which is made from pure quartz sand, soda and limestone. Glass for windows is made using special machines. They melt the mass and squeeze it through a narrow longitudinal slot, directing it between the rollers of the machine. It draws in and rolls a glass strip to a specified thickness and width. After this, the glass ribbon enters the uniform cooling operation. There, the hot glass is cooled to room temperature.

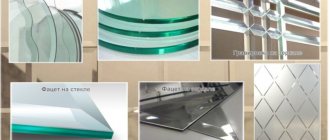

It should be noted that glass comes in different types. The most common type is sheet window glass. Glass can also be showcase, mirror, patterned and reinforced. The last type is not ordinary glass, but reinforced with a metal mesh inside.

As you might guess, the job of a glazier is to cut glass blanks of a certain shape and size from sheets. The main operations that a glazier usually performs are:

- cut;

- cutting;

- insert.

In other words, before cutting the glass, it is first cut, that is, the required distances and dimensions are measured. In order to do all this, a glazier needs special tools, devices and equipment. So, to cut glass, a master usually uses different glass cutters - diamond or steel. He uses rulers and meters for the measuring process, and squares to check the correctness of the angles. Also, the glazing process is often associated with the need to apply putty, and for this the worker will need a knife.

The cutting process itself is usually performed on a table, less often - it is done on workbenches

It is important that the table surface is extremely flat. If there are defects on it, this may cause the glass to break.

Especially if the master will cut the material using a glass cutter made of hard alloys. After all, such glass cutters mean that you will have to apply quite a lot of force to cut the glass.

It is noteworthy that a qualified glazier can work both independently and in a team. In general, he can find work in glass workshops, furniture factories, companies producing ready-made internal doors, mirrors, as well as in apartment and office renovation companies. There are also glass factories. However, there the profession of a glazier may have slightly different specifics.

What knowledge and qualities are required?

To perform his work efficiently, a glazier must understand the main types and properties of materials that are used in the work process. He should also be familiar with cutting and inserting thin glass panes and how the stud gun works. In addition, the glazier must understand sealants - their types and properties

And it is especially important that such a worker knows how to use a template table, which is used for cutting glass. He must also be able to remove and hang blind and casement bindings.

As for the professional qualities that a glazier must have, this includes special visual acuity, as well as a well-developed linear and plane eye. In addition, good hearing is important for a glazier, just as well-developed motor coordination is.

If a person has neuropsychiatric diseases, musculoskeletal disorders, as well as hearing and vision impairments, then he is unlikely to be able to master the profession of a glazier. After all, such an employee must be extremely careful in his work, patient and very responsible.

How is a glass channel installed?

General installation principles

Glass channel can be used to create a single, double or even triple thickness structure. When carrying out glazing in two layers, the channels are mounted in pairs. In this case, their side walls (shelves) are directed towards each other, resulting in the formation of a glass block having a rectangular cross-section.

Demonstration section of a two-layer enclosing structure made of glass profile, which clearly shows how the channels are connected to each other, as well as how they are installed in a metal frame.

Options for installation of glass profiles are shown in the table:

| Scheme options | Short description |

| Installation of glass profiles horizontally is most often done in cases where the height of the opening in the wall exceeds the length of the channel, that is, above 7000 mm. The connection of the channels is carried out according to the same principle as for horizontal installation. | |

| The vertical installation method is the most common when glazing building facades, as well as constructing partitions indoors. It is this diagram that is shown in the sectional photo of the structure. | |

| The radial method of installing glass profiles is used to form facade walls, as well as stairwells. This option is quite complicated and is made in one layer of glass profile. It is better to entrust installation work of a radius structure to specialists. |

Installation operations for partitions made of channel glass profiles

This section presents the vertical installation of a glass channel into a frame in two layers according to the diagram shown above.

Framed two-layer partition made of channel glass profile

The sequence of installation work for the construction of the partition is presented in the table:

| Illustration | Brief description of the operations performed |

| This project involves a vertical two-layer installation of glass channels into a wooden frame, onto the inner surface of which a special metal profile is fixed. | |

| Rubber gaskets are installed in advance into the vertical profiles fixed to the frame, against which the sides of the outer glass profile panels will rest. | |

| The glass channel is laid horizontally, measured, and if it has a length greater than the height of the internal space of the frame, a mark is made to cut off the excess. | |

| Next, a ruler is laid along the marked line. The illustration shows a special device made to fit the width of the internal space of the channel - this is certainly more convenient. Then, using a regular but high-quality glass cutter, the excess length of the channel is cut off. Using the same principle, you can immediately prepare all the required amount of glass profile. | |

| After this, you need to measure the length of the lower frame guide and find the middle of its length. With the orientation towards the mark made, the first channel will be installed and aligned, since in this case it is advisable to install the structure exactly from its middle. | |

| The next step is to install a plastic element in the center of the lower profile, which will serve as a stand for a pair of glass channels. | |

| Next, another M-shaped part is put on the upper edge of the first channel installed in the frame, which will protect the edges of the central shelf of the glass profile from contact with the metal and create the necessary seal. | |

| After this, the channel is installed on a plastic stand placed in a metal profile. | |

| After installing the channel in place, it must be aligned along the line marked on the frame, defining the middle of the base | |

| In the same way, install two adjacent channels, placing stands under them and putting M-shaped seals on top. | |

| The next step is to install a second one on the middle channel, directed oppositely by the side shelves, which will form the first complete section. This profile should take its place on the stand and under the M-shaped sealing piece. In this case, one outer side of the wall of the installed channel should be pressed against the inner left wall of the already installed middle channel. Its second shelf (right), with its inner side, should be pressed against the inner side of the left shelf of the channel installed on the right. | |

| After this, another channel is mounted on the sides of the installed three profiles, according to the scheme described above. | |

| Then the work continues in the same order - first, the first external channels are installed next to the installed structure on the sides, then counter, paired, ones are mounted on the previous parts. | |

| When the last two pairs of channel bars remain to be installed to the edge of the frame, proceed as follows. The third section from the edge should be equipped with only one, external channel. The outermost block is formed in the same way as the first one installed in the middle of the frame. | |

| The block, formed from outer and inner channels, is pushed into the vertical right post of the frame using a stand and pressed against the rubber gasket. | |

| Next, the stand and the outer channel with the upper part are installed in the remaining free space. After that, the third block from the edge is closed with an internal profile, and the last one is installed on the internal channel on the second external one from the edge. | |

| To make the structure airtight, its joints on the outside must be sealed with sealant. First, the sealant is applied around the perimeter of the frame, starting from its top crossbar. | |

| After this, the joint lines between the glass blocks are sealed with sealant. |

The process of constructing a partition is shown quite briefly, and yet there are important nuances in it. This process, as well as other installation options, can be studied in more detail in the video below.

Glass products

A wide range of products are made from glass: double-glazed windows, glass blocks, glass profiles, roofing corrugated sheets, door panels, etc.

Double-glazed windows are the most common type of glass products. Double-glazed windows are made from two (single-glazed) or three (double-glazed) sheets of glass, hermetically connected to each other along the contour. Between the sheets of glass there is a layer of dry air or inert gas.

The sheets can be joined into a double glazing unit by gluing, soldering or welding.

Double-glazed windows are used for glazing windows and other light openings. The use of double-glazed windows has significant advantages over conventional sheet glass glazing, since they do not fog up, do not freeze and do not require wiping the internal surfaces. Double-glazed windows have low thermal conductivity, and the sound permeability of windows with double-glazed windows is 2…3 times lower than usual.

The effective use of double-glazed windows is possible in combination with solving the problem of the quality of frames and window frames. Thus, the use of aluminum and plastic frames and frames eliminates heat loss through window leaks.

It is advisable to use glass blocks in cases where it is necessary to obtain a translucent enclosing structure with good heat and sound insulation characteristics.

Glass blocks are produced from hot glass melt using automatic presses that form block halves and then weld them. When cooling, a vacuum is formed in the blocks, providing good insulating properties. The inner surface of the blocks has corrugation, which gives the block light-scattering properties.

Glass block sizes range from 200×200 to 400×400 mm with a thickness of up to 100 mm. Blocks can be colorless or colored. The light transmission of the blocks is 50...60%. Thermal conductivity coefficient is 0.4…0.45 W/(m K), i.e. almost 2 times lower than that of brick. In addition to conventional blocks, two-chamber ones

(with a partition that reduces the thermal conductivity of the block by almost 1.5 times) and

light-directed

(with special corrugation, giving a directed flow of light).

Stekloprofilit – long-sized (up to 5 m) profiled glass elements produced by horizontal rolling. Steloprofile can be box-shaped and T-shaped (U-shaped) profile. It is used in the same way as glass blocks for the construction of translucent fences (external walls and partitions) in industrial buildings, exhibition and sports halls, etc. Glass profiles are installed in metal frames with plastic or rubber seals.

Fiberglass is produced by pressing molten glass through very fine dies (holes in solid materials), followed by drawing and winding onto reels. Fiber diameter – 3…100 microns, length – up to 20 km (for continuous fiber). Shorter (1...50 cm) staple fibers are produced by melt blowing with steam. Glass fabrics and glass felts are produced from fiberglass, which are used as a reinforcing component in the production of fiberglass or as a base in rolled roofing and waterproofing materials (for example, glass insulation, glass roofing felt).

Foam glass - blocks of glass that has expanded while in a molten state. In structure and properties, foam glass resembles volcanic pumice and is used as a heat-insulating material.

What are the advantages of fiberglass sheeting?

To summarize, it makes sense to once again focus on the advantages of glass profiles:

- Homeowners have the opportunity to create internal partitions and external walls that reflect ultraviolet rays and transmit light perfectly. In addition, the material is excellent for fencing balconies, gazebos, swimming pools and other similar objects.

- Minimal risk of damage to glass profiles or deformation of the structure.

- The ability to create comfort, lightness and a sense of freedom in the premises.

- Quite fast and not so complicated installation of the material.

- Easy care of the external and internal surface of the structure.

* * * * * * *

So, if you are planning to build a new house and the process is at the design stage, then you can immediately think about installing such enclosing structures. And even in the case when it is necessary to divide a large room into two rooms, it is possible that glass profile will become the material that will pleasantly surprise and solve many problems.

In conclusion, here is the promised video on installation of glass profiles.

Types and characteristics

This type of building material can be either reinforced or non-reinforced. When reinforcing it, not only metal mesh can be used, but also fiberglass. In addition, the product can be made not only completely transparent or white matte, but also colored. The color shades are not so bright, but still pleasing to the eye. The colors are pale and come in the following variations:

- green;

- blue;

- white;

- yellow;

- with a special metal oxide coating (giving tint).

Ribbed, honeycombed, recessed, convex or completely smooth surfaces of sections of opaque or transparent appearance do not provide direct visibility. This is precisely the main feature of wall blocks. The physical properties of this material allow us to note a number of special characteristics of glass:

- high heat resistance rating (40-70˚);

- perfectly withstands mechanical loads;

- thermal conductivity is quite low, so it can be considered a heat insulator (0.76 W/m˚C);

- light transmittance – 73-82%;

- impact resistance indicators - 0.8-0.9 J;

- the sections are easy and safe to install;

- allow you to make radius glazing;

- the maximum length of the structure that can be installed using such sections, but without additional fasteners, is 7 m.

Main news

- A complex with offices and apartments will be built near the Kievsky railway station 10.20.2021

- Three houses for renovation, an apartment complex and a hotel were introduced into the North-East Administrative District this year 10/20/2021

- The President signed the Decree “On the establishment of non-working days on the territory of the Russian Federation in October – November 2022.” (information from the official website of the President of the Russian Federation dated 10.20.2021) 10.20.2021

- Order of DPiIR of Moscow dated October 19, 2021 N P-18-12-346/21 “On approval of the list of main types of economic activities, during the implementation of which measures are provided to support business entities during the period of unstable economic situation resulting from the spread of the new coronavirus infection and introduction of a high-alert regime in the city of Moscow, aimed at reducing the interest rate on loan agreements, in accordance with the All-Russian Classifier of Types of Economic Activities" 10/20/2021

- “Meeting with members of the Government” (information from the official website of the President of the Russian Federation dated October 20, 2021) (extract) October 20, 2021

- VII All-Russian Open Festival of Family Amateur Theaters “A Fairy Tale Comes to Your Home” opens in Moscow on 10.20.2021

- On October 21 at 15.00, the Center for Digital Transformation of Public Libraries of the City “New Reality” will open in the updated and modernized department of the V.V. Mayakovsky Library on the Fontanka River embankment, 44. 20.10.2021

- On October 21-22, 2022, the international scientific and practical conference “Preserving the past, creating the future” will be held at the St. Petersburg State Theater Library. The conference is dedicated to the 265th anniversary of the Theater Library. 20.10.2021

- On October 21 at 19.00 at the Oktyabrsky Concert Hall there will be a Gala concert “Celebration of the Romance “St. Petersburg Autumn” 10/20/2021

- Federal Tax Service of Russia dated 10/19/2021 N BS-4-11/ [email protected] 10/20/2021

- “Review of judicial practice in cases of protection of consumer rights” (approved by the Presidium of the Supreme Court of the Russian Federation on October 20, 2021) October 20, 2021

- Rostourism dated 10.20.2021 “In St. Petersburg, new tax incentives will be introduced for hospitality enterprises” 10.20.2021

- Draft Federal Law N 4764-8 “On Amendments to the Federal Law “On Environmental Protection” and Certain Legislative Acts of the Russian Federation” 10/20/2021

- A pilot project to organize dedicated lanes for public transport will be launched in the Moscow region 10.20.2021

- Construction of a large modern hospital will begin in Istra near Moscow 10.20.2021

Usage

Fiberglass is used in many types of construction and finishing work:

- reinforcement of walls for a higher quality finish;

- preventing the formation of cracks in the finish coating and masking existing cracks;

- preparing walls for applying a decorative coating - when using fiberglass, you don’t have to putty the surfaces with finishing putty;

- leveling walls;

- creating original effects on the surface of the finishing coating (for example, marble effect);

- use in roofing work as a basis for bitumen mastic (special types of material are used that improve the adhesion of the roof and mastic);

- pipeline protection;

- waterproofing work - fiberglass is used to strengthen and protect polyethylene sheets;

- organization of drainage systems.

The material is suitable for application to any surface - concrete, plasterboard and can even be glued over a layer of old paint (it is better to scratch grooves on it to improve adhesion).

The use of “web” is recommended especially for those surfaces that are subject to constant mechanical stress. Wallpaper, paint and other materials fixed on top of fiberglass will last you longer without changing the original attractive appearance, even if the structure shrinks.

The glued fiberglass dries quickly, and the application of subsequent finishing will be more efficient. This way you will save time and effort on repairs.

It is ideal for application under ceilings as it will provide a flawless finish. Fiberglass glued to the outer corners will help you quickly and beautifully paste wallpaper in this area.

Technological features and formula for calculating such material

The material is produced in a special way - continuous rolling, using T-, semicircular and channel-type profiles. Using oxygen fuel and special equipment - latest generation furnaces, silica, quartz and other substances are melted. Then the mass in a molten state enters the belt. There, the rollers give the mass a U-shaped contour, and at the same time the required thickness - 6-7 mm. Afterwards the profile is cooled and cut into the required sizes.

The finished product is produced not in one piece over the entire area of its overall design, but in sections. That is, the large-sized structure itself (for example, a straight interior partition) is made up of small sections using special profiles. In total, 4 types of such standard profiles are used - K 22, 25, 32 and 50. And non-standard ones include three types - K 22/60/7, K 25/60/7, K 32/60/7. If wire inserts (reinforcement) are found, then usually such products are marked for a normal profile - NP, and for a specialized profile - SP.

Width, thickness and length can be found out from special tables provided by the manufacturer.

To calculate the length of the glass, a special formula is used: L=HX (mm).

And the number of sections can be calculated using the formula: N=BY.

e

In this case, B is the width of the frame (taking into account the use or absence of sealant), e is the length of the axis of the profile glass itself, and Y is the connecting dimension. The values for this calculation are also taken from the table:

| Frame side profile (both sides) | Side connection dimension "Y" (mm) |

| 810 820 950 S + 950 N 980 | single + double glazing |

| 80 80 55 65 |

Terms used in the manufacture of fiberglass

- usually the ratio of diameter to length. In composites, it is the ratio of fiber or filler in the composite matrix.

Chopped Strand - Fiberglass reinforcement that uses short strands of continuous rovings arranged in a random pattern and held together with a binder.

— A material, such as fiberglass reinforced plastic (FRP), composed of two or more different substances. They combine to form functional or structural characteristics not possible with a single material.

- the process of increasing the density of materials. As with fiberglass laminate, compression causes the product to shrink and shrink.

- Parallel threads with a sizing coating, drawn together into one or more threads and wound in a cylindrical package.

- Also called a "dome", it is an inverted cup of fiberglass that covers the roofs of buildings, churches and other architectural forms.

— A conventional surface coating that forms a dense surface structure, has strong adhesion and almost no shrinkage.

is a general term for a thread-like material whose length is at least 100 times its diameter. Fiber also refers to parts of a single element of matter from which the threads to be woven are formed.

- a common material used to reinforce plastic.

- The smallest unit of fibrous material that is formed by spinning or drawing into a single long continuous unit.

fibrous - a tube consisting of finely twisted fibers with a uniform structure.

— Inorganic additives, especially particulate additives, into the composite matrix to improve product characteristics such as shrinkage control, surface smoothness and water resistance.

- any of a large class of materials with varying optical and mechanical properties that is typically hard, brittle, translucent, or transparent and is considered a supercooled liquid rather than a solid. Fiberglass mixed with various resins is the main ingredient of a fiberglass product.

glass to resin - The amount of glass compared to the amount of resin in a fiberglass product. Generally, the higher the concentration of glass, the greater the strength and durability.

- one of many synthetic and natural compounds with high molecular weight. They consist of millions of repeating links, each of which is quite lightweight and simple.

- any of a variety of translucent, yellow, brown and transparent, semi-solid or solid substances of plant origin, such as amber and copal. Resins are used in synthetic plastics, inks, varnishes, adhesives, etc.

Application of glass in construction

Recently, more and more glass is used to produce sheets for glazing. Such sheets are used for finishing the facades of various buildings. For this purpose, various types of glass and types of facade glazing are used. Architects prefer tinted, transparent and translucent glass. They have increased mechanical strength and therefore such glass is practically impossible to break.

The scope and applications of glass do not end there. Fiberglass is a unique building material. Obtained by processing glass, glass fiber is impact-resistant, fire-resistant, environmentally friendly, it does not rot or deform, and also has high heat-insulating and sound-absorbing characteristics. Fiberglass is used to produce glass fabrics, glass wool, reinforced and plastic fiberglass, glass fiber, glass wallpaper, and fiberglass mesh. These materials are used in construction as insulation and connecting elements.

– Glass weight

– Plexiglas weight

Stekloprofilit in the USSR. We could build glass houses.

This material can be used to assemble internal and external self-supporting fences.

They are good for filling light openings in buildings and even replacing concrete walls. Building with walls made of fiberglass. Source Yandex pictures Building with walls made of fiberglass. Source Yandex pictures

The production of glass profiles was started for the first time in the USSR in the city of Borsk, Nizhny Novgorod region.

Stekloprofilit - channel. Source Yandex Pictures Stekloprofilit - channel. Source Yandex Pictures

Currently, it has not been produced there for a long time. However, later the material was widely used abroad. And its production was located mainly outside our country.

Project of a building made of fiberglass. Source Yandex pictures Project of a building made of fiberglass. Source Yandex pictures

Why didn’t the use of glass profiles take root in Soviet times? Did the article say that it is “two to three times cheaper than existing glass building materials”?

It is difficult to answer this question unequivocally. Maybe because it’s not the price at all, but the quality of that time?

Fiberglass inside a modern building. Made to look like a waterfall. Source Yandex Pictures Fiberglass inside a modern building. Made to look like a waterfall. Source Yandex Pictures

After all, in the USSR they were used to building everything to last forever and reliably. And glass profile, despite all its strength relative to other glass, had the disadvantage of not withstanding high temperatures. In a fire, it is unlikely to be destroyed, but it can crack easily. And at that time it was not particularly distinguished by the variety of assortment.

Fiberglass with a pattern. Source Yandex Pictures. Fiberglass with a pattern. Source Yandex Pictures.

However, in our time, modern Russian and foreign analogues of glass profiles have become more reliable and practical. In addition, new types of material have appeared such as colorless, with a darkening stripe, with a stripe and silk-screen printing and many other options.

Colored glass profile. Source Yandex Pictures. Colored glass profile. Source Yandex Pictures.

Anyone who has practical experience using this material, or perhaps knows something about it from friends, please share your opinion. Let's discuss!

Changing a double-glazed window in a window block made of PVC profiles

Please tell me the price for replacing double-glazed windows in a window block made of PVC profiles.

Similar topics: Find more: PVC window block

Price for repairing scratches on a PVC window block, repairing seams on wall tiles Author: Maxim Ivanov. Can you please tell me the price for repairing scratches on a PVC window block using liquid plastic Cosmofen and is it possible to select a similar material? As well as cleaning the seams of ceramic wall tiles and greasing.

URGENTLY. Conversion rates for FSSC to current prices. Author: Tatyana S. sooooo :woohoo: for example, a brick is 2 times more expensive than a real one, and a real PVC window block is 3 times cheaper :silly: so think about how scary it is to live :cheer: but if the estimate with translation index is drawn up to a complex of different .

Double-leaf PVC window block with two tilt-and-turn sashes Author: Sergey. Good day! Can you please tell me what price according to the FSSC can be applied to the material of a double-leaf window block made of PVC profile with two tilt-and-turn sashes? Thank you

I dismantle PVC window blocks. At what price is it better to do this? Author: Olesya. Please tell me, I am dismantling PVC window blocks. At what price is it better to do this? My only option is to take it as an installation with a coefficient for dismantling. But here's the odds. take for dismantling .

Indices of changes in construction and installation work by type of work - replacing wooden window blocks with PVC Author: Ivan. Good afternoon. Can anyone give me an estimate for replacing window blocks with PVC in the city of Kurgan in an administrative building. Which index to use for construction and installation works and which document regulates this? Indexes to FERs of the Ministry of Construction.

What does profiled glass mean?

Stekloprofilit are panels made of durable glass, which are manufactured in very large sizes and belong to the category of large-sized ones. It is used in the arrangement of buildings and structures, as well as fences with a translucent design, which can be included in the project.

The method allows glass to be inserted into frames immediately with a seal, so they will never fall out. In this case, the profiles are laid in a locking manner so that they will always firmly hold the panel, no matter what its weight. In addition, special holders - pads - are also used. It is enough to study the schematic sequence of installation to understand the reliability of the entire structure.

With the help of this material it is very convenient to equip not only straight partitions indoors, but also corner and curvilinear, arched structures. This allows you to create a niche in the room, a bar counter, separate the kitchen area from the living room in a studio apartment, divide the combined bathroom, etc.

Suspiciously cheap

When buying glass wallpaper, you should not lose your vigilance and purchase products from trusted manufacturers. German and Swedish companies have earned this reputation. Wallpaper made by hand will fail at any time:

- even when you try to unroll the roll, it may simply crumble in your hands;

- tear when gluing;

- lose its attractive appearance not after 20, but after 2 paintings.

You should always inquire about the availability of a certificate. When it is not there or its authenticity is suspicious, you should refuse the purchase. There is no need to be fascinated by the cheapness, unless, of course, the store is running a special promotion that is accompanied by widespread notification.

It’s a shame when the deception is discovered after applying low-quality coatings to which high-quality glue was not spared. It will be almost impossible to do anything except putty and level the walls persistently and for a long time, and run to the store for new rolls.

Preference should be given to trusted manufacturers

Exchange of glass profiles of poor quality, how to exchange glass profiles

Glass profile exchange period

Exchange of glass profiles is possible during the warranty period, and if the warranty is not established or has expired, then within two years from the date of transfer of the glass profiles.

What can you count on

You can not only exchange glass profiles for another, but also fully compensate for losses incurred as a result of the sale of low-quality (defective) glass profiles to you;

Recalculation and additional payment

When replacing glass profiles of poor quality with glass profiles of the same brand (same model and (or) article), the price is not recalculated.

When replacing glass profiles with the same but different brand (model, article), if the price of the old glass profile is lower than the price of the new one provided in exchange, you will need to pay the difference in prices.

if the price of the old glass profile is higher than the price of the new one provided in exchange, the difference in prices is paid to the consumer.

the price of glass profiles to be replaced is determined at the time of its replacement.

Don't forget to take the following documents with you:

warranty card; general passport (why do you need a passport when returning (exchanging) goods); sales or cash receipt for purchased glass profiles, but if such documents are missing, you have the right to refer to witness testimony.

If the seller does not agree to exchange low-quality glass profiles under warranty

Checking the quality of glass profiles: even if the seller does not agree to exchange low-quality glass profiles, he is obliged to accept the glass profiles of inadequate quality and conduct a quality check. The buyer has the right to be present during the quality check. Read more about this in the article “Checking the quality of goods”.

examination of glass profiles: if the seller, even after checking the quality of glass profiles, insists that it has deteriorated due to the fault of the buyer, he must conduct an examination of it. In this case, the examination is carried out at the expense of the seller. The buyer has the right to be present during the examination and, in case of disagreement with it, to challenge the examination conclusion in court. Read more about this in the article “product examination”.

replacement of glass profiles: if the examination establishes that the glass profiles have deteriorated through no fault of the buyer, then the seller is obliged to exchange the glass profiles for a new one; otherwise, the buyer will have to reimburse the seller for the costs of storing the glass profiles and conducting the examination.

claim: if the seller refuses to comply with the requirements established by law, then he must write a written claim. Rules for writing claims can be found in the article “how to write a claim correctly.”

Going to court: If the seller refuses to comply with the statutory requirements even after receiving a written complaint, it is necessary to go to court with an appropriate demand. Basic recommendations for going to court can be found in the article “Applying to court for consumer protection.”

examination of glass profiles: if the seller does not agree to the exchange, the buyer must conduct an examination of the glass profiles himself. In this case, the examination is carried out at the expense of the buyer, since the responsibility for proving that the deficiencies of the glass profiles arose before their transfer to the consumer or for reasons that arose before that moment lies with the buyer.

Exchange of glass profiles: if the examination establishes that the glass profiles have deteriorated through no fault of the buyer himself, then the seller is obliged to exchange for a new one.

claim: if the seller refuses to comply with the requirements established by law, then he must write a written claim. Rules for writing claims can be found in the article “how to write a claim correctly.”

Going to court: If the seller refuses to comply with the statutory requirements even after receiving a written complaint, it is necessary to go to court with an appropriate demand. Basic recommendations for going to court can be found in the article “Applying to court for consumer protection.”

Changing a double-glazed window in a window block made of PVC profiles

Please tell me the price for replacing double-glazed windows in a window block made of PVC profiles.

Similar topics: Find more: PVC window block

Price for repairing scratches on a PVC window block, repairing seams on wall tiles Author: Maxim Ivanov. Can you please tell me the price for repairing scratches on a PVC window block using liquid plastic Cosmofen and is it possible to select a similar material? As well as cleaning the seams of ceramic wall tiles and greasing.

URGENTLY. Conversion rates for FSSC to current prices. Author: Tatyana S. sooooo :woohoo: for example, a brick is 2 times more expensive than a real one, and a real PVC window block is 3 times cheaper :silly: so think about how scary it is to live :cheer: but if the estimate with translation index is drawn up to a complex of different .

Double-leaf PVC window block with two tilt-and-turn sashes Author: Sergey. Good day! Can you please tell me what price according to the FSSC can be applied to the material of a double-leaf window block made of PVC profile with two tilt-and-turn sashes? Thank you

I dismantle PVC window blocks. At what price is it better to do this? Author: Olesya. Please tell me, I am dismantling PVC window blocks. At what price is it better to do this? My only option is to take it as an installation with a coefficient for dismantling. But here's the odds. take for dismantling .

Indices of changes in construction and installation work by type of work - replacing wooden window blocks with PVC Author: Ivan. Good afternoon. Can anyone give me an estimate for replacing window blocks with PVC in the city of Kurgan in an administrative building. Which index to use for construction and installation works and which document regulates this? Indexes to FERs of the Ministry of Construction.

Glass solar collectors

Such glass has been a long-time dream of everyone involved in the use of non-traditional and renewable energy sources. Indeed, if it were possible to use the huge glazed surfaces of buildings to generate electricity, this would dramatically change the situation with energy shortages, urban pollution, etc. And this task is not so fantastic. Very active work is being done in this direction, primarily in the USA, Japan, Australia, and a number of Arab countries. According to the US Department of Energy, it can be expected that by 2010 such glass will already be in use. Today there are fragments of considerable size available and in use for opaque parts of buildings (Florida Solar Energy Center, USA). There are also translucent coatings for translucent parts of fences. The main factor hindering the use of such coatings and glasses is their very high price today. However, there is every reason to believe that this price will begin to decline in the near future.

top of page

GESNr 56-24-01

Replacement of glass profile elements in window openings

LOCAL RESOURCE STATEMENT GESNr 56-24-01

PRICE VALUES

The price contains only direct costs of work for the period 2000 (prices in Moscow and the Moscow region), which are calculated according to 2009 standards. To draw up an estimate, you need to apply the conversion index to the prices of the current year to the cost of the work.

You can go to the pricing page, which is calculated based on the standards of the 2014 edition with additions 1 The basis for using the composition and consumption of materials, machines and labor costs are GESN-2001

LABOR COSTS

We draw up a resource estimate for GESN with our own hands.

OPERATION OF MACHINES AND MECHANISMS

CONSUMPTION OF MATERIALS

TOTAL BY RESOURCES: 20,449.03 RUB.

TOTAL PRICE: RUB 22,931.58.

Look at the cost of this standard as amended in 2022 open page

Compare the price value with the value of FERR 56-24-01

To draw up an estimate, the price requires indexation of the transition to current prices. The price was compiled according to the GESN-2001 standards, as amended in 2009, in 2000 prices. To determine intermediate and final price values, the DefSmeta program was used