PVC doors: Russian GOST, requirements, application

The state standard was first adopted by the Committee on Metrology and Standardization in the twenties of the last century, with the aim of organizing inter-industry interaction between manufacturers and providing a guarantee to the consumer in receiving products of appropriate quality and acceptable environmental friendliness.

In the Russian Federation, the catalog contains more than forty thousand documents, most of which have been agreed upon internationally by the CIS countries. It should be noted that since mid-2002, the requirements for certain categories of goods began to be advisory in nature, but this did not apply to PVC products. With regard to plastic doors, the provisions set out in the technical requirements of GOST 30970–2002, adopted for implementation by Resolution of the Civil Code of the Russian Federation of September 2, 2002 No. 114, apply.

Recommendations for use

Plastic doors do not require special attention, but due to their design features, some maintenance is necessary.

- Lubrication – hinges and locks are recommended to be treated with a special compound once a year.

- Adjustment - when the operating mode is intensive, it may be necessary to adjust the position of the blade, but also not more than once a year.

- Replacing seals - modern seals have a durability comparable to the durability of the profile and the entire structure. If the seal is maintained regularly, no replacement will be necessary.

- Important. It is better to entrust service work on the care of door and window structures either to their manufacturer or specialized organizations.

It is logical that PVC doors meet all consumer needs in terms of reliability, safety, tightness, energy efficiency and aesthetics. After all, PVC windows also protect your home, retain heat, and do not let noise and dust in from the street, while at the same time they look presentable and last for decades. And no one thinks of replacing them with steel ones in order to improve their barrier functions. Modern metal-plastic doors are a smart choice for a private home.

For those who are planning to install a door-window, it is useful to learn how to choose a high-quality design and how to install it in accordance with GOST. The video shows an analysis of typical mistakes when installing PVC blocks.

Subscribe to our Telegram channelExclusive posts every week

General information

The provisions of GOST RF 30970–2002 have been agreed upon by authorized official representative offices and are implemented in the following countries: Uzbekistan, Kyrgyzstan, Azerbaijan, Armenia, Kazakhstan. The scope of application is to streamline manufacturing technology, appearance, parameters of component elements, workloads, as well as the requirements in compliance with which the door block is mounted. The standard does not apply to the indicated parameters in relation to balcony systems, as well as systems for special functional purposes.

Important! The state standard is drawn up on the basis of the standards laid down for each element (derivative) of the structure, technological processes for assembling and installing the product.

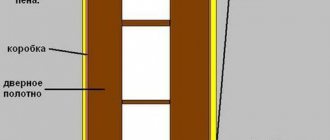

To create a unitary attitude to terminology in the preparation of documents, practical activities in production, sales and installation, names of elements using word forms have been introduced: door and opening, installed from the outside (from the inside), frame, leaf, swinging (sliding, folding, burglary-resistant), of a certain side opening the door block.

Selection of entrance and interior structures

Plastic doors are selected based on the following factors.

When producing PVC structures, manufacturers must strictly comply with GOST 30970-2002 and have a quality certificate for the product produced. When purchasing a finished product, they pay special attention to its passport and study the technical parameters and features. When making frames to order, they are interested in product standards, select the product, color and appearance, comparing samples.

Standard openings for a single-leaf door are 70-90 cm. If the opening width is more than 110 cm, double-leaf interior structures are selected.

Sliding or hinged panels are suitable as an interior frame. Sliding doors are installed on a roller guide if there is enough space in the room to install the mechanism.

For the installation of swinging PVC structures, the space for closing and opening the sashes is taken into account.

Interior doors made of PVC accordion type do not require much space, although they consist of 3-8 leaves, due to their compactness, they require higher installation accuracy. Adjusting the elements of such a design is a complex process. They are often used as partitions, delimiting kitchen or living spaces, especially in large houses.

Plastic doors to a private home are most often chosen for bathrooms, bathrooms, and kitchens. They are great as balcony structures.

A special feature of entrance doors is the presence of installed fittings with heavy anti-burglary locking mechanisms. Therefore, experts recommend installing structures not from profiles, but from wood or MDF coated with polyvinyl chloride. They are also suitable as an entrance to the terrace. If, nevertheless, the entrance door is installed from a profile, then there must be a seal between the frame and the leaf, and the structure is made of special PVC reinforced with steel liners, or the frame is equipped with a large number of chambers.

When purchasing, pay attention to the packaging. It should include the following elements and parts:

- the product itself;

- box;

- platbands;

- locks, latches, closers;

- passport;

- user manual.

If you want to update several door designs, it is better to choose not just one leaf at a time, but all at once, in order to eliminate the possibility that this model is not available from the manufacturer.

Classification characteristics

For unambiguous use by manufacturers and consumers of PVC structures in this direction, a list of the following characteristics is provided:

Further, the document divides each listed characteristic into groups corresponding to certain characteristics, assigning a letter designation, for example, “feature 1” includes:

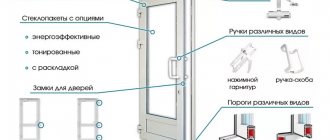

The classifier according to “sign 2” characterizes the door block as using glass (flat glass), solid (opaque panel), combined (top - glass, bottom - not).

Blind canvas

“Sign 3” assumes the division into single-floor, double-floor, burglar-resistant, transom, with a threshold (without it).

The characteristics of profile finishing in white shades, colored tint, decorative film, co-extruded, and also coated with paints and varnishes are fixed by “feature 4”.

“Sign 5” classifies swinging, sliding, folding products.

Sliding systems

Particular attention and interest for potential buyers may be in paragraph 4.2, which sets out short symbols and methods for deciphering them to fully determine the parameters of the product presented by the seller or manufacturer.

For example: DPV Km Bpr Op Pr R 2100×900 GOST 30970-2014 is read as door blocks with an internally installed PVC profile, combined filling, with the absence of a threshold element, single-floor design, right swing, dimensions 2100.00 mm by 900.00 mm. At the same time, practice shows that when choosing this category of product, the buyer is guided by his personal feelings of attractiveness and price, and not by the technical parameters of the product.

What is the difference between doors made of PVC profile and doors made of aluminum profile

Like window and door units, they are made not only from PVC profiles, but also from aluminum, and users have a logical question.

serebryak78FORUMHOUSE Member

I reread the profile topic for a long time, but I still didn’t understand what the key differences between PVC doors and aluminum doors are (except for the price, as I understand it?). I’m trying to decide for myself what to order entrance doors for three rooms from (outside-heated room).

Sergey Elnikov Technical specialist at VEKA

The differences are due to the difference in materials and their properties, which affect the technical and operational features of the finished solution. The PVC profile has a higher heat transfer resistance at a more affordable cost of construction than a door structure with similar characteristics made from aluminum profiles.

As a rule, entrance doors made of PVC profiles have restrictions on dimensions - the maximum leaf height is 2400 mm; maximum width – 1000 mm. If the dimensions of the sash exceed these parameters, it is necessary to either change the geometry of the structure taking into account the features of the PVC profile or use an aluminum profile.

To this we can add that aluminum is mostly used for the manufacture of window and door structures for public buildings, and metal-plastic profiles are more in demand in the private segment.

Profile requirements

When producing door systems, manufacturers must use a polyvinyl chloride profile that meets the requirements of impact viscosity and resistance to natural influences. Can be used with the design presence of one, two or more chambers. As a rule, a white profile is used.

Upon approval by the end user, door blocks can be manufactured in a different color, but their use without a coating that protects from external factors (ultraviolet radiation) is prohibited.

Door system profile

Advantages of laminated PVC profiles

The advantages of such designs include durability, a large selection of shades, and the ability to adapt to any interior. This should also include all the advantages of PVC windows and doors that remain relevant for structures with lamination. According to manufacturers, covering the window frame and door leaf with laminated film only improves their quality. Disadvantages: high cost compared to the classic white version.

Installation requirements

The requirements for installation activities are partly advisory in nature. The procedure for using agreed upon architectural documentation for construction (repair) work carried out in each individual room (structure) is provided, taking into account decisions on the connection of the product to load-bearing (main) walls. Moreover, calculations are made including operating loads, external (internal) thermal and barometric parameters.

Self-installation of such systems is not recommended and is carried out with the assistance of companies whose specialization is construction and installation work. It is mandatory to draw up an acceptance certificate that provides for a warranty encumbrance on the performer of such work. The customer also has the right to request, in addition to the instructions, accompanying documentation of the following nature:

Important! When deciding to install the system yourself, you need to study the attached technical documentation and installation recommendations. It is advisable to consult with a specialist in the construction field on the use of fastening material, depending on the condition of the walls to which the product will be adjacent. It is imperative to comply with safety precautions during work, as well as to prevent the occurrence of situations that provoke a fire.

Door blocks made of PVC are produced at enterprises (regardless of ownership) using special equipment. The staff is undergoing training. Suppliers of components must have appropriate certification.

An example of assembling a plastic door in a small enterprise is shown in the video below.

Source

Types of plastic doors

In modern construction, a wide variety of doors made of plastic are used.

Classification by purpose

Plastic doors can be used for:

- Facade or external;

- Internal.

The last type of doors is divided into entrance doors installed in entrances or common corridors, interior doors, balcony doors, doors for bathrooms and saunas.

By filling type

According to this parameter, the following types of plastic doors are distinguished:

- Deaf. These are doors that have a leaf filled with sandwich panels or other opaque material.

- Glazed. Models with a glass insert, this can be multi-layer glass, patterned or tinted glass.

By type of design

Plastic doors, like regular swing models, can be:

- Single-leaf and double-leaf.

Advice! Double-leaf models can have doors of both equal and different widths. In addition, there are double-leaf models in which both doors are movable, or those in which one of the doors is fixed in a fixed position.

In addition, the doors can be equipped with a threshold or have a frame structure in which the role of the threshold is assigned to the bottom strip of the frame.

By type of finish

Based on this feature, the following types of plastic doors are distinguished:

- Completely painted white;

- Completely colored in any shade other than white;

- Laminated, that is, covered with decorative film. The film can imitate various surfaces, most often it imitates the structure of wood or stone.

So, plastic doors are produced according to GOST requirements; the regulatory document sets out the basic requirements for the products.

GOST 30970-2014 Door blocks made of polyvinyl chloride profiles. General technical conditions

Buy GOST 30970-2014 - a paper document with a hologram and blue seals. more details

We have been distributing regulatory documents since 1999. We punch checks, pay taxes, accept all legal forms of payment without additional interest. Our clients are protected by law. LLC "CNTI Normocontrol"

Our prices are lower than other places because we work directly with document providers.

Delivery methods

Applies to door blocks made of polyvinyl chloride profiles with frame structures for buildings and structures for various purposes. The scope of application of specific types of door blocks is established depending on operating conditions in accordance with current building codes and regulations, taking into account the requirements of the standard. The standard does not apply to balcony door units, as well as to special-purpose door units in terms of additional fire safety requirements, etc. The standard can be applied for product certification purposes.

Information from the Bureau of IGU Standards on the additional accession of the country of Kazakhstan (KZ, Gosstandart of the Republic of Kazakhstan) was published in IUS 7-2018

Types: PVC, MDF or veneer

PVC doors have gained a place in the product market as they have a number of advantages. They are easy to install, and their low weight contributes to this. A small load on the hinges will allow the structure to avoid sagging in the future. Even pendulum models provide less force than if the canvas were made of a different material.

Structures made from PVC, like MDF, are non-toxic, environmentally friendly and fire-resistant - they are allowed to be installed in medical institutions, where pendulum models are also popular. A PVC film is applied to the surface, which easily turns into a pattern or design. The decor will look the same for many years - bright, clear and pristine. Moreover, this coating is resistant to sunlight.

It can withstand not only sunlight, but also humidity, which means there is no need to worry about corrosion and rotting.

The benefits don't end there. Despite the economy class, these doors have good sound and thermal insulation qualities, even pendulum models, so they are often used as office doors. Their quality guarantees their original appearance - after 5 years from the date of purchase, the surface does not fade or wear out.

High-quality technical characteristics are successfully combined with low cost, which is several times lower than the pricing policy for coatings that use MDF, veneer or eco-veneer.

General technical conditions

(EN 14351-1:2006, NEQ) (EN 1191:2012, NEQ) (EN 1192:1999, NEQ)

Preface

The goals, basic principles and basic procedure for carrying out work on interstate standardization are established by GOST 1.0-92 “Interstate standardization system. Basic provisions" and GOST 1.2-2009 "Interstate standardization system. Interstate standards, rules and recommendations for interstate standardization. Rules for development, adoption, application, updating and cancellation"

Standard information

2 INTRODUCED by the Technical Committee for Standardization TK465 “Construction”

3 ADOPTED by the Interstate Council for Standardization, Metrology and Certification (protocol dated December 5, 2014 No. 46-2014)

The following voted for adoption:

Short name of the country according to MK (IS0 3166) 004-97

Country code according to MK (ISO 3166) 004-97

Abbreviated name of the national standardization body

Ministry of Economy of the Republic of Armenia

Gosstandart of the Republic of Kazakhstan

4 By Order of the Federal Agency for Technical Regulation and Metrology dated December 12, 2014 No. 2036-st, the interstate standard GOST 30970-2014 was put into effect as a national standard of the Russian Federation on July 1, 2015.

5 This standard conforms, in terms of technical requirements and test methods, to the following European regional standards:

Translation from English (ate).

In the Russian Federation, this standard cannot be fully or partially reproduced, replicated and distributed as an official publication without permission from the Federal Agency for Technical Regulation and Metrology

5.2.11 Sliding and folding door units can be internal group B and external group A (for example, in private housing construction as doors to winter gardens, terraces and other architectural solutions).

The specified designs of door blocks can be completely glazed or with a blank opaque part. Sliding and folding functions of door blocks are provided by corresponding devices in accordance with GOST 30777.

5.2.12 Door blocks of groups A and B can be made in a burglar-resistant version using corner reinforcements and a multi-bar burglary-resistant locking system with class 4 locks in accordance with GOST 5089.

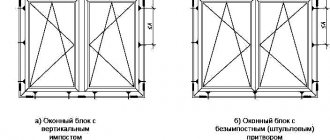

5.2.13 Impost parts and thresholds are attached to adjacent PVC profiles of the frame (leaf) using steel or plastic fasteners, screws or screws. Examples of fastening imposts and thresholds are shown in Figures 6, 7.

Mechanical and welded T-shaped and cross-shaped connections of imposts must provide the required resistance to operational loads on door blocks.

5.2.14 Corner and T-shaped connections of external door block profiles must be airtight. It is allowed to seal mechanical connections with weather-resistant elastic gaskets. Gaps up to 0.5 mm in size can be sealed with special sealants that do not impair the appearance of the products and protect the connections from moisture penetration.

5.2.15 The designs of external door blocks must include a system of functional openings for draining the cavity between the edges of the glass unit (panel) and the folds of the profiles and for draining water. The holes should not pass through the walls of the main chambers of the profiles and should not have burrs.

In case of using colored profiles, it is recommended to make holes through the walls

external chambers of canvas and frame profiles to reduce their heating. Door blocks with a closed polyvinyl chloride frame must have holes for water drainage.

The number, dimensions and location of all types of holes are established in the working documentation.

5.2.16 Door units must be safe to operate and maintain. The safety conditions for using door blocks of various designs are established in the design documentation (for example, door blocks used in children's institutions must be glazed with tempered, laminated or other types of safety glass).

Door units of group A must be designed for operational loads in accordance with the current set of rules [1].

5.2.17 Installation of products should be carried out taking into account the requirements of GOST 30971.

General requirements for installation of products are given in Appendix A.

5.3 Dimensions and maximum deviations

5.3.1 The nominal overall dimensions and architectural drawings of door blocks are established in the design working documentation (order, contract). Examples of architectural drawings of door block panels are shown in Figures 8-10.

The nominal dimensions of product units, profile sections, reinforcing inserts, profile combinations are established in the technical documentation for their manufacture.

5.3.3 Maximum deviations of the nominal dimensions of the elements of door blocks, gaps under the overlap, dimensions of the location of door devices and hinges must not exceed the values given in Table 1.

Table 1 - Limit deviations In millimeters

Internal box size

External size of canvases

Clearance under fusion

Dimensions of arrangement of devices, hinges and other dimensions

St. 1000 to 2000 inclusive.

1 The maximum deviation values are set for the measurement temperature range of 16 °C-24 °C.

2 The values of the maximum deviations of the dimensions of the gaps under the overlap are given for closed panels with installed sealing gaskets.

5.3.5 If the processing of a weld involves making a groove, the size of the groove on the front surfaces should not exceed 6 mm in width, the depth of the groove should be in the range of 0.3-1.0 mm. The cut size of the outer corner of the weld should not exceed 4 mm along the weld.

5.3.6 The sagging of the door leaf in the assembled door block with a threshold should not exceed 1.5 mm per height of the door block leaf.

5.3.7 The maximum deviation of the nominal size of the distance between the overlaps of adjacent closed panels and transoms) should not exceed 1.0 mm per 1 m of the length of the vestibule.

5.3.8 Deviation from straightness of the edges of parts of frame elements should not exceed 1.0 mm per 1 m of the length of the PVC profile used.

Curved profiles must not have deviations from the given shape (warping, waviness) exceeding ±1.5 mm in width and height of the profile.

GOST 30970-2014

Reduced heat transfer resistance of door leaf panels, m 2o C/W, not less

Sound insulation, dBA, no less

Air permeability at AFq=10 Pa, m 3 /(h m 2), no more

Reliability, opening cycles, not less:

— for door blocks of group A with high traffic volume;

— for door blocks of group B;

— for interior swing door blocks;

1 The value of the reduced heat transfer resistance is for reference. If necessary, this indicator is confirmed by calculations or laboratory tests.

2 For external door blocks, the water resistance limit can be set as an indicator of water permeability in accordance with GOST 26602.2.

GOST 30970-2014

5.4.2 For door blocks of group A, resistance to wind loads is established in accordance with [1].

The wind load should include the following parameters:

— pressure change from 400 to 1800 Pa;

— change in the deflection of the bars from 1/150 to 1/300 of the length of the bar.

5.4.3 Door blocks must be resistant to static loads. Static loads and strength of welded corner joints when tested according to scheme A (see Figure 12) are given in Table 3.

When tested according to scheme B, welded corner joints must withstand a load doubled.

Door block group

Strength of welded corner joints of panels (boxes), N, not less

Static loads acting in the plane of the web, N, not less

5.4.4 Door blocks must withstand operational dynamic loads when opening (simulating an impact on a slope) and when closing with an impact on a foreign object in the ledge, created by a freely falling load (solid body), in accordance with the requirements of Table 4.

Door block group

Load drop height, m

5.4.5 When determining the strength (reliability) of fastening the structure in the openings and fastening (fixing) the filling of the leaf, door blocks must withstand impact loads created by the load (inelastic soft body) given in Table 5. Door leaves are tested on both sides.

Door block group

5.4.6 When determining the resistance of the structure and door leaf material to penetration, door blocks must withstand impact loads created by the load (solid body) given in Table 6.

Door block group

5.4.7 The static load acting on the movement elements (rollers, rollers, hinges, etc.) of sliding doors must be no more than 1000 N.

5.4.8 The static load acting on the upper corner (90°) of the folded leaves of folding door units must be no more than 1000 N.

5.4.9 Burglar-resistant door blocks of groups A and B must withstand static loads in the plane of the leaf of at least 1300 N and from impact with a soft inelastic body of at least 250 J.

5.4.10 It is recommended to establish the performance indicators of door units for a specific purpose in the design working documentation for the construction (reconstruction, repair) of buildings and confirm them with test results in testing centers accredited to conduct such tests.

5.4.11 The force applied to the door leaf of groups A and B when closing until the required compression of the sealing gaskets should not exceed 100 N. The force required to open the door leaf should not exceed 50 N. For door units of group B, the closing forces and openings should be no more than 25 N (ergonomic requirements).

5.4.12. The appearance of the products [color, gloss, permissible surface defects of PVC profiles (risks, scratches, shrinkage cavities, etc.)] must correspond to standard samples approved by the head of the manufacturer.

Differences in color, gloss and surface defects visible to the naked eye from a distance of 0.6-0.8 m under illumination of at least 300 lux are not allowed.

Welded seams should not have burns, uncooked areas, or cracks. Changing the color of PVC profiles in places of welded seams after they have been cleaned is not allowed.

5.4.13 The front surfaces of the profiles of door leaf frames and frames (except for curved ones) must be protected with self-adhesive protective film.

5.4.14 Materials and components used for the manufacture of door blocks must comply with the requirements of standards, technical specifications, and technical certificates approved in the prescribed manner.

5.5 Requirements for PVC profiles and metal reinforcing liners

5.5.1 Requirements for PVC profiles

For the manufacture of door blocks, PVC profiles are used in accordance with GOST 30673 with wall thickness for class A profiles, two-, three-chamber and with a larger number of chambers from hard, non-plasticized polyvinyl chloride, modified for high impact strength and resistance to climatic influences in accordance with the requirements of GOST 30673 .

It is recommended to make external door blocks from white PVC profiles, painted in the mixture. By agreement between the consumer and the manufacturer, it is allowed to manufacture external door blocks from PVC profiles of other colors and types of finishing of the front surfaces. The use of colored profiles painted in the paste without a protective decorative coating on surfaces exposed to ultraviolet rays is not allowed.

5.5.2 Requirements for metal reinforcing inserts

5.5.2.1 The main PVC profiles of door blocks are reinforced with metal liners. When making external and entrance door blocks to an apartment, steel reinforcing liners with an anti-corrosion coating with a wall thickness of at least 2.0 mm should be used. For internal door blocks, it is allowed to use steel reinforcing liners with a wall thickness of 1.5 mm, as well as liners made of aluminum alloys with mechanical properties that meet the requirements of GOST 22233.

5.5.2.2 The shape, wall thickness and moments of inertia of the reinforcing liners are established in the technical documentation for the manufacture of door blocks, taking into account operating conditions.

The distance from the liner to the corner (end) of the reinforced part of the profiles is taken equal to (10 ± 5) mm. In the case of using corner reinforcements, as well as when mechanically fastening imposts, the dimensions of the connections are established in the working drawings.

Joining or tearing of reinforcing liners along the length within one PVC profile is not allowed (including when making holes for door devices and locks).

5.5.2.4 Reinforcing liners must fit into the internal chambers of PVC profiles tightly, by hand, without the help of special devices.

5.6 Requirements for filling door panels and sealing gaskets

5.6.1 It is recommended to make the opaque filling of door block panels (panels) from three-layer panels consisting of plastic or aluminum facing sheets filled with insulation, or from single-layer panels of rigid foamed polyvinyl chloride. The thickness of the facing sheets must be at least 15 mm.

It is allowed to use sheet, roll or tile facing materials as panels for interior door blocks.

Examples of types of filling of door panels are given in Appendix B.

5.6.2 Design solutions for fastening parts of filling parts of lockable door leaves must exclude the possibility of their dismantling from the outside.

5.6.3 It is recommended to use strengthened types of glass to fill the panels: tempered glass in accordance with GOST 30698, laminated glass in accordance with GOST 30826, reinforced glass and glass with anti-fragmentation films in accordance with regulatory documents, double-glazed windows in accordance with GOST 24866, sheet glass in accordance with GOST 111, as well as special types of glass according to regulatory documents (patterned, tinted, etc.), multilayer panels according to regulatory documents.

The type of glass used should be specified in the working documentation for the construction (reconstruction, repair) of the building. The use of unstrengthened glass with dimensions greater than 1250 mm in height, more than 650 mm in width and less than 4 mm in thickness is not permitted.

5.6.4 To increase architectural expressiveness and strengthen the structure of door blocks, it is allowed to install frames (slab frames) into the frames of door leaves. It is allowed to use double-glazed windows with an internal decorative frame or install glued decorative layouts on the outer surfaces of the filling of the canvases.

5.6.5 The depth of pinching of a double glazed unit (glass) or panel in the folds of profiles, as well as the depth of pinching with glazing beads, is recommended within 14-18 mm.

5.6.6 Double-glazed windows (glass) are installed in the rebate of the sash or frame on linings that prevent the edges of the double-glazed window (glass) from touching the internal surfaces of the rebates of PVC profiles.

Depending on their functional purpose, pads are divided into basic, support and spacer.

The length of the supporting and spacer pads should be from 80 to 100 mm, the width should be at least 2 mm greater than the thickness of the glass unit.

The distance from the pads to the corners of the double-glazed windows should, as a rule, be 50-80 mm.

Requirements for the installation of opaque filling of panels (panels) are established in the manufacturer’s technical documentation, taking into account the weight of the panel and the design of the door block.

5.6.8 Installation methods and (or) design of the linings must exclude the possibility of their displacement during transportation and operation of the door blocks.

5.6.9 The design of the linings should not impede air circulation over the inner surface of the glazing rebate.

5.6.10 The basic layout of support and spacer pads when installing double-glazed windows, depending on the method of opening the door blocks, is shown in Figure 11. It is recommended to install no more than two support pads on any side of the glass unit. Distortion of the pads during installation is not allowed. In products with reinforced locking devices, it is recommended to install additional spacers in the locking areas.

Door block with swing opening Non-opening element of the door block

Door blocks with swing opening for complex filling of the leaf

PTTTT

5.6.11 The sealing of the door curtains and installation of filling of the curtains is carried out using elastic polymer sealing gaskets in accordance with GOST 30778 or other regulatory document. It is permissible to use glazing beads with a co-extruded seal.

5.6.12 Sealing gaskets for external door blocks must be resistant to climatic and atmospheric influences.

5.6.13 The fit of the sealing gaskets must be tight.

5.6.14 The number of contours of sealing gaskets in the rebates of door blocks and the requirements for their installation along the perimeter of the rebate are established in the manufacturer’s technical documentation, depending on the purpose and design of the door blocks. For door blocks of groups A and B, at least two sealing circuits are recommended.

Corner bends and welded joints of sealing gaskets for double-glazed units (glasses) should not have protrusions (bulges) that cause concentrated loads on the double-glazed units (glasses).

5.7 Requirements for door devices

5.7.1 When manufacturing door blocks, door devices and hinges are used that are specially designed for use in door blocks made of PVC profiles.

The type, number, location and method of fastening of locking devices and hinges are established in

working documentation taking into account the size and weight of opening elements, as well as operating conditions of door blocks. Possible options for the location of hinges are shown in Figure 11. The door leafs should be hung on two hinges. It is recommended to equip external door blocks with multi-bolt locks with locking at least at three points.

When using hidden hinges in the entrance doors of buildings, it is necessary to carry out additional tests to determine the heat transfer resistance to prevent freezing in the hinge area.

Depending on the purpose of the door blocks, in the design documentation, as well as when placing orders, it is necessary to provide for the complete set of door blocks with door closing devices (closers), opening angle limiters (stops), eyes, etc.

5.7.3 Hinges used for the manufacture of door blocks must comply with GOST 5088.

The hinges are attached to the canvases and boxes using reinforcing inserts. For interior door blocks with leaves weighing less than 60 kg, hinges can be fastened through two walls of a PVC profile with a total thickness of at least 4 mm. The hinges are fastened to boxes and canvases using self-tapping screws. If it is necessary to drill holes for screws, their diameter should be equal to the diameter of the central core of the screw.

5.7.4 It is recommended to use hinges adjustable in three planes on external and entrance door blocks to the apartment.

5.7.5 Locking devices must ensure reliable locking of opening elements of products. Opening and closing should occur easily, smoothly, without jamming.

5.7.6 The designs of locking devices and hinges must ensure tight and uniform compression of the gaskets along the entire sealing contour in the recesses.

5.7.7 Door devices, hinges and fasteners must comply with the requirements of GOST 538 and have a protective and decorative (or protective) coating in accordance with the regulatory document. The coating of devices for completing door blocks of groups A and B must be resistant to corrosion.

5.8 Completeness, marking and packaging

5.8.1 The completeness of door units when delivered to the consumer must meet the requirements established in the order.

A set of door blocks may include additional, connecting and other profiles for various purposes in accordance with GOST 30673, as well as locks, latches, closers and other door devices. A set of keys to locks must be handed over to the customer in a sealed form against the signature of the customer (buyer). Component profiles and parts of locking devices protruding beyond the plane of the door block may be supplied unmounted, complete with door blocks. By agreement between the manufacturer and the consumer, separate transportation of double-glazed windows (glasses) is allowed.

Full factory-ready products must have installed devices, double-glazed windows, infill panels, sealing gaskets and a protective film on the front surfaces of the main profiles.

5.8.2 The delivery package must include a quality document (passport, see Appendix B) and operating instructions for door units, including installation recommendations.

5.8.3 Each door block is marked on the non-front side with a waterproof marker or label indicating the name of the manufacturer, type of door block, date of its manufacture and (or) order number, sign (stamp) confirming acceptance of the product by technical control. By agreement between the manufacturer and the consumer, it is allowed to apply markings to the protective film.

5.8.4 The main profiles, door devices, locking products and double-glazed windows included in the door block must be marked in accordance with the regulatory documents for these products.

5.8.5 Packaging of door blocks must ensure their safety during storage, loading and unloading operations and transportation.

It is recommended to pack door blocks in polyethylene film in accordance with GOST 10354.

PVC with double glazing

Plastic doors can be with or without double-glazed windows - in an economical version. The first option, with a double-glazed window, consists of a frame that is attached to the opening and such a canvas has a hollow chamber structure. At the same time, warehouse or medical swing doors are often made with round glass so that it can be seen if they are about to be opened sharply.

Plastic does not require special care, but wooden structures must be painted regularly. Regularly clean from dirt and dust, use professional detergents, this helps to extend the service life.

Basic indicators

It is also worth considering the technical characteristics of such products. In many respects, doors coated with film are superior to other models. It is this that guarantees the improvement of the qualities of the base material and its protection.

Technical characteristics of PVC doors:

- Increased strength - excellent resistance to impacts and mechanical damage. Capable of withstanding heavy loads.

- Moisture resistance – the coating protects the doors from the penetration of water, steam, and accumulated condensate into their structure.

- Resistance to sunlight and heat - the film does not fade in the sun, does not bubble and is quite resistant to changes in temperature.

- Antibacterial characteristics - thanks to special treatment at the production stage, the fabric does not contribute to the growth of bacteria. In addition, this material itself perfectly resists fungus and mold.

- They do not dry out - fluctuations in air humidity and temperature do not in any way affect the condition of the doors and their integrity.

- Fire safety - PVC can withstand fire and high temperatures, and in the event of a fire, such doors can even contain the spread of flames for some time.

- Environmental friendliness - during the operating period and even when the surface is heated, the film does not emit harmful toxic substances.

Please note: only manufacturers who use high-quality raw materials can guarantee safety and durability.

Thanks to special production technology, PVC-coated doors are environmentally friendly products

Such characteristics of PVC-coated doors speak in their favor. However, there are certainly some negative aspects. Therefore, you need to turn to an analysis of the advantages and disadvantages of the product.

Production technology

PVC doors got their name due to the coating of the door leaf. What it is? PVC is an abbreviation for the name of the material - polyvinyl chloride. Essentially it is a polymer, a film that is used to cover the canvas to give it an aesthetic appearance. In addition, it improves the technical characteristics of the base. The features of such products should be considered in more detail.

Conventional interior doors with PVC coating are a panel on a frame, covered with a decorative and protective film. What it is? In fact, standard models differ little from other types of doors in their design. Two sheets of MDF or fiberboard are attached to a frame made of solid timber. The inside of such a product is most often filled with cellular cardboard like a honeycomb.

The PVC coated door has a simple design, but is reliable and practical

The highlight is the outer covering – PVC. It protects the base material primarily from moisture. To ensure reliable adhesion of MDF to the coating, the film is attached on specially equipped machines. The canvas must be perfectly clean, without the slightest grains of sand and free of grease. It is placed in the camera along with the film. Next, the following happens: the temperature of the internal environment increases, thus heating the PVC coating. It softens and thanks to this it can take any shape. In a vacuum environment under high pressure, the film is pressed against the door.

This technology allows you to reliably fix polyvinyl chloride on products of any shape. The hot pressing method is also used for the production of furniture, in particular kitchen fronts.

Design options

One of the advantages of PVC-coated doors is their appearance. Modern technologies allow us to annually expand the range of available colors. What could such products be?

PVC-coated doors can be of any style, including glass decorative inserts that look impressive

The door covering can be plain in neutral colors or striking in its brightness and richness. A very popular option is imitation of wood structure. Of course, it is very easy to notice the artificiality of the design, but such doors still look very attractive.

Glass inserts, volumetric elements, curves and panels can be used as additional decor. Thanks to the application technology, such a coating fits tightly to every millimeter of the canvas area, regardless of its shape and texture. If we summarize all this, the conclusion suggests itself - PVC-coated doors are an excellent budget option for home interiors in any style.

Features of balcony doors

GOST requirements for PVC balcony doors are somewhat different. They are described in detail in GOST 30673 - 99.

- These blocks use various channels and valves that can improve the humidity conditions of an apartment or house.

- To enhance sound insulation, special valves are installed in the products, which absorb noise.

- Balcony doors can withstand increased operating loads, for example, strong winds, as required by established standards. Increased attention is paid to resistance to static loads.

- In the technical designations of the block passport you can see the letter M, which is added when using a frost-resistant version of the product.

- The design of balcony blocks is installed with increased attention to fire safety.

- To increase the heat-insulating properties, balcony double-glazed windows are filled with a special gas.

- GOST for plastic balcony doors provides for strengthening the profile of products with liners coated with an anti-corrosion compound.