The spread of technology for manufacturing door blocks from polyvinyl chloride has led to the need to develop generally accepted standards for these products. Therefore, in 2002, an interstate standard (GOST 30970-2002) was published, regulating the requirements for door blocks made of PVC profiles. This regulatory document regulates the standards by which swing plastic doors are produced. The requirements of GOST 30970-2002 do not apply to plastic models for special purposes, including balcony doors.

The development and implementation of state standards is the only opportunity to oblige manufacturers to produce products that meet certain requirements. In the absence of a generally accepted GOST, manufacturers work according to specifications developed independently. As a result, similar products produced at different enterprises may have different properties and vary greatly in quality.

The implementation of GOST for products used in the construction industry is very important. After all, the reliability of the structures being built, and, consequently, the safety of people, depends on the properties and qualities of the manufactured products.

Requirements according to GOST

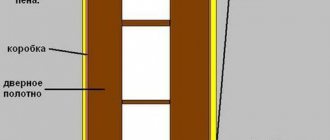

The regulatory document contains a clear description of the structure of the products and the drawings used for their manufacture. In addition, the installation stages are described in detail. So, doors made from PVC panels, according to GOST 30970 of 2002, must have dimensions not exceeding 6 sq.m. Moreover, each opening cannot have an area of more than 2.5 sq.m. The weight of the door structure should not exceed 80 kg. If permissible limits are exceeded, the manufacturer’s design strength calculation must be confirmed by a number of additional laboratory tests.

The standard also prescribes the installation method for PVC door blocks. Among other things, one of the very important aspects is the presence of a ventilation hole for the internal cavities of the canvas. Their required quantity was initially determined and specified in the list of standards.

The load on the door structure should also not exceed the norm. The maximum permissible difference in door leaf dimensions is also determined by GOST for a door area of 1.5 sq.m. cannot exceed 2 mm. If the dimensions of the canvas are larger, then the error in length and width should not be more than 3 mm. The dimensions of the grooves are also required to be specified in the regulatory document.

Features of the production of plastic doors

Plastic balcony doors are made using the same technology as PVC profile windows. Essentially, a balcony door is just a large plastic window with hinged or (less commonly) swing doors.

There are different requirements for interior and entrance doors, so in 2002 a regulatory document was adopted regulating the production of these products. Interior and especially facade plastic doors should be more burglar-resistant and reliable than models installed on a balcony block.

Specifications

Basic requirements for plastic doors, regulated by GOST:

- Heat transfer resistance – 0.8-1.2 m²*C/W (depending on the type of insulation).

- Sound insulation – not less than 26 dB;

- Air permeability – no more than 3.5 m³/h*m²

What is considered a defective plastic door?

A serious violation of GOST requirements or, in other words, a defective plastic door is considered to be:

- Significant deviations in dimensions from those stated in the documentation. The permissible deviation in dimensions is -1 mm/+0.2 mm.

Advice! There is a limited tolerance for measurement differences in the diagonal length of the door leaf. For doors with a total area of up to 1.5 m², this tolerance is 2 mm; if plastic doors have an area of more than 1.5 m², then the tolerance for measurement mismatch is 3 mm.

- A defective plastic door is considered to have various surface defects - chips, dents, scratches. Unacceptable surface defects include differences in the degree of gloss and shade that are visible to the naked eye.

- Quality doors should be easy to close and lock if they are equipped with latches or locks. According to GOST requirements, when closing the door, ensuring the required deformation of the seals, the force should not exceed 120N.

- The presence of deviations in the actual technical characteristics of the doors from the values stated in the documents is considered a defect.

Advice! GOST regulates not only the standards for the manufacture and characteristics of plastic doors, but also the rules for their installation. Plastic doors are installed taking into account the requirements of GOST 30971.

Main characteristics of doors

The mandatory level of sound insulation of the product must be 26 dB, and the air flow capacity must be at least 3.5 cubic meters per hour, provided that Dp = 10 Pa. External doors made of PVC, according to GOST, must withstand a minimum number of openings and closings equal to 500,000 times.

Door structures are also divided into groups based on their ability to withstand static loads:

- A) must withstand a drop of a load weighing 20 kg from a distance of 0.8 m;

- B) must maintain the integrity of the canvas when a load of 20 kg falls from a maximum distance of 0.5 m;

- C) withstands a drop of a load of 10 kg from a distance of no more than 0.4 m.

If it is necessary to withstand a blow with a soft object, the indicators will be as follows:

- Group A is capable of withstanding a drop of a load weighing 450 kg from a distance of no more than 1.5 m;

- Group B can withstand the impact of a load of 300 kg falling from a distance of no more than 1 m;

- Group B must withstand a drop of a load weighing 60 kg, but the height cannot exceed 0.5 m.

In addition, the GOST standards specify the requirements for the door regarding the effort applied to open and close the door. Thus, internal doors made of PVC must be opened with a force applied by a person of 75 N. In this case, closing requires an applied force of 120 N.

Differences in color shades on the surface of the structure under normal lighting are unacceptable. In places where welding work is carried out, it is not unusual to observe color differences with the main part of the fabric. The seams of quality products cannot contain cracks.

To increase the protection of technical products, their surface is covered with a special protective film. Each of the elements used in the design must be tested and certified in a special laboratory.

Based on the personal wishes of the customer, it is permissible to use different colors when decorating the outer part of the product. Moreover, each of the structures must be equipped with special protection from exposure to UV rays.

What do numbers and letters mean in GOST

The manufacture of products from polyvinyl chloride profiles is regulated by GOST 30970 2002. Doors made in accordance with the requirements of this GOST are made in compliance with all technical requirements. The markings indicate letters and numbers, the meaning of which carries important information outlined below.

The combination of DPV means what type of product is presented: the letter “B” indicates that the block is internal, and the letter “N” (DPN) indicates external metal-plastic doors.

Next, the manufacturer makes clarifications on the use of the block.

- C - block is used to equip sanitary facilities.

- T - in vestibules, corridors.

- M - between rooms.

The following symbols indicate how the canvas is filled.

- Glazed doors are marked with the letter O.

- Blind plastic door - G.

- Decorative fabric, or lightened - S.

What kind of door design you see in front of you is clear from these symbols.

- P – product with a threshold.

- B – design without a threshold.

- F - indicates the presence of a transom.

- K - means that the box is closed.

Which direction a single-leaf door has when opening will become clear when reading the markings “L” or “R”. And if the product is double-sided, then you will see the letters “Dv” there. But the dimensions in millimeters will be indicated by subsequent numbers. PVC windows will be marked according to GOST in the same way.

For ease of perception, all this fits into the framework of a certain classification.

- Purpose of door blocks.

- Designs and solution.

- Type of filling.

- Execution of profile systems.

- Type of finishing.

The last 2 points provide for the number of cameras in the profile system of the block and painting or lamination with film.

Internal equipment

All steel structural elements are treated with protective materials to provide high-quality resistance to corrosion. When using aluminum, its nominal strength must correspond to the required parameters of the door block. The liner must be secured with a pair of screws or self-tapping screws. The fastening step cannot exceed 40 cm. When using colored profiles, this distance is reduced to 30 cm. The installation of amplifiers does not require the use of special tools. Installation of liners is done manually.

If the structure is supplemented with glass inserts, an anti-fragmentation coating must be applied. The glass itself is made by bonding it in several layers.

PVC, metal-plastic, plastic - what's the difference?

We are talking about the same product. The full name of doors or windows will sound like this: reinforced or metal-reinforced plastic (made of polyvinyl chloride) door blocks. Therefore, GOST for metal-plastic doors, GOST for plastic doors and GOST for polyvinyl chloride doors is expressed as a single accepted provision.

Special technical and operational characteristics and requirements

Door and window units must perform the main functions, which are expressed by the following operating characteristics:

- strength group from the strongest “A” to the weakest “B”;

- the durability of the profile is 40 years, the double-glazed window is 20 years, and the seal is 10 years;

- low level of heat transfer with an indicator from 0.8 to 1.2 m²xC/W;

- sound insulation should not fall below 26 dBA;

- air permeability should not exceed 3.5 m³ (hhm²);

GOST for PVC doors also meets the basic technical requirements:

- the profile must be connected firmly and tightly;

- products are manufactured with mandatory compliance and in accordance with technological documentation;

- in order to remove moisture from the outside of the blocks, special holes must be placed;

- to prevent the color profile from overheating, there are also holes coming out through the outer sides of the chamber;

- all components from which the blocks are assembled must be manufactured in accordance with the GOST standards established for them;

- the weight of canvases not exceeding 6 m² with an area of elements that open 2.5 m² cannot exceed 80 kg;

- the use of blocks must be safe, which is necessarily reflected in the design documentation and is confirmed by the presence of an appropriate certificate;

- compliance with existing fire regulations is required.

The technical characteristics of the GOST 30970 2002 door were established in 2002 with minor changes made in 2014. PVC windows GOST 30970 2002 must also meet specially developed standards that comply with GOST.

Classification of doors according to GOST

In the process of manufacturing PVC door structures, manufacturers are guided by GOST 30970-2002 adopted and approved in 2002. This document specifies the dimensional grid of the door structure and permissible deviations. In addition, GOST strictly defines the main characteristics of all structural elements, including the profiles used on the PVC door, as well as the devices used. The required product labeling system, as well as guarantees and acceptable packaging, are mandatory.

GOST 30970 was developed specifically for swing PVC door structures with a frame. The requirements do not cover canvases for special purposes, as well as door mechanisms installed on balconies.

According to the derived standard and based on the principle of the main purpose of the leaf, PVC doors are conditionally divided into the following types:

- Entrance, street placement;

- Tambour;

- Interior and inter-apartment, as well as located in the internal parts of common areas.

In addition, door leaves are divided into types according to the filling principle:

- Deaf;

- Decorative;

- Glazed;

- Light.

The door that allows light to pass through is conventionally divided into 2 sectors: transparent upper and opaque lower. Glass used for installation in PVC doors can be multi-layered, reinforced, or made using additional decorative elements in the form of various patterns.

During the manufacture of solid door structures, an opaque fabric is used. Also, based on the structure of the structure, doors are divided into single-leaf and two-leaf. Designs that have one leaf, based on the opening side, can be left or right. Doors with various figured inserts are decorative.

Based on the type of external finishing used, door structures can be:

- White;

- Painted;

- Laminated;

- Covered with a layer of varnish.

When choosing and purchasing PVC products, please note that the sales contract will necessarily indicate the type of material used for the door, the presence of decorative elements, as well as the mandatory designation of the exact parameters of the product. https://www.youtube.com/embed/QpHv0rjGnvk

The manufacturing procedure itself must be carried out in a strictly defined sequence of actions. During assembly, the frame structure is necessarily reinforced with steel elements

During the process of strengthening the structure, the greatest attention should be paid to corner areas. If there is a threshold, metal is used to make it

GOST 30970-2002 Door blocks made of polyvinyl chloride profiles. Specifications

30970-2002 Door blocks made of polyvinyl chloride profiles.

Technical specifications GOST 30970-2002

UDC 692.81:678(083.74) Zh35

INTERSTATE STANDARD

DOOR BLOCKS FROM POLYVINYL CHLORIDE PROFILES Technical specifications

DOORS OF POLYVINYLCHLORIDE PROFILES Specifications

OKS 91.060.50 OK.P 577200

Date of introduction 2003-03-01

Preface

1 DEVELOPED by the Center for Certification of Window and Door Technology with the participation of XT TROPLAST LLC, RUS SVIG CJSC and the Interregional Window Institute.

INTRODUCED by the State Construction Committee of Russia

2 ADOPTED by the Interstate Scientific and Technical Commission for Standardization, Technical Regulation and Certification in Construction (MNTKS) on April 24, 2002.

Voted for acceptance

Name of the state Name of the state construction management body Republic of Armenia Ministry of Urban Development of the Republic of Armenia Republic of Kazakhstan Committee for Construction Affairs of the Ministry of Energy, Industry and Trade of the Republic of Kazakhstan Kyrgyz Republic State Inspectorate for Architecture and Construction under the Government of the Kyrgyz Republic Republic of Moldova Ministry of Territorial Development, Construction and Communal Services of the Republic Moldova Russian Federation Gosstroy of Russia Republic of Uzbekistan State Committee for Construction, Architecture and Housing Policy of Uzbekistan

3 INTRODUCED FOR THE FIRST TIME

4 INTRODUCED AND EFFECTIVE from March 1, 2003 as a state standard of the Russian Federation by Decree of the State Construction Committee of Russia dated September 2, 2002 No. 114

1 area of use

This standard applies to door blocks made of polyvinyl chloride profiles with leaves of a frame structure and swing opening (hereinafter referred to as door blocks or products) for buildings and structures for various purposes. The standard does not apply to balcony door blocks, as well as to special-purpose door blocks in terms of additional requirements for fire safety, burglary resistance, etc. The scope of application of specific brands of products is established depending on operating conditions in accordance with current building codes and regulations, taking into account the requirements of this standard. The standard can be applied for product certification purposes.

2 Normative references

This document uses references to the following standards: GOST 111-2001 Sheet glass. Technical specifications GOST 166-89 Calipers. Technical specifications GOST 427-75 Metal measuring rulers. Technical specifications GOST 538-2001 Lock and hardware products. General technical conditions GOST 5089-97 Locks and latches for doors. Technical specifications GOST 7502-98 Metal measuring tapes. Technical specifications GOST 8026-92 Calibration rulers. Technical specifications GOST 9416-83 Construction levels. Technical specifications GOST 10354-82 Polyethylene film. Technical specifications GOST 22233-2001 Pressed profiles from aluminum alloys for translucent enclosing structures. Technical specifications GOST 24866-99 Double-glazed windows for construction purposes. Technical specifications GOST 26433.0-85 System for ensuring the accuracy of geometric parameters in construction. Rules for performing measurements. General provisions GOST 26433.1-89 System for ensuring the accuracy of geometric parameters in construction. Rules for performing measurements. Factory-made elements GOST 26602.1-99 Window and door blocks. Methods for determining heat transfer resistance. GOST 26602.2-99 Window and door blocks. Methods for determining air and water permeability GOST 26602.3-99 Window and door blocks. Method for determining sound insulation GOST 30673-99 PVC profiles for window and door units. Technical specifications GOST 30698-2000 Tempered glass for construction. Technical specifications GOST 30778-2001 Sealing gaskets made of elastomeric materials for window and door units. Technical specifications GOST 30826-2001 Multilayer glass for construction purposes. Technical specifications GOST 30971-2002 Assembly seams of junctions of window blocks to wall openings. General technical conditions

3 Classification and designation

3.1 Products are classified according to the following main characteristics: purpose; type of filling of door panels; design solution option; design of profile systems; type of finish. 3.1.1 According to their purpose, door blocks are divided into: external (entrance to buildings, structures, as well as vestibule); internal (interior, for plumbing units, entrance to the apartment and other door blocks intended for use inside the building). 3.1.2 Based on the type of filling of the door panels, door blocks are divided into: glazed (filled with double-glazed windows or various types of sheet glass: patterned, tempered, multi-layer, reinforced, etc.); solid (filled with panels or other opaque materials); light (with translucent filling of the upper part and dull filling of the lower part of the canvas); decorative (with a complex architectural pattern). 3.1.3 According to the design options, door blocks are divided into: single-leaf (left and right-hand versions), double-leaf (with a frame or mullionless vestibule, including with leaves of different widths), with a vertical impost and adjacent blind or translucent frame filling; with a transom (opening or non-opening); with a threshold on mechanical connections, without a threshold, with a closed frame box (an option in which the bottom block of the box is welded to the vertical ones and has the same profile). 3.1.4 Based on the design of profile systems, door blocks are divided into products with two-, three-, or more chamber profiles. 3.1.5 Based on the type of profile finishing, door blocks are divided into: white, painted in the paste; colored, dyed in mass; finished with decorative film (laminated); with co-extruded face covering; painted with paints and varnishes. 3.2 For door blocks, the following structural designation scheme is accepted:

XXXX Х-Х XX Type of product DPV - door block made of PVC profiles internal DPN - door block made of PVC profiles external Option for filling the door leaf D - solid O - glazed C - light D - decorative Design options P - with threshold B - without threshold K — with a closed frame F — with a transom L — left single-field R — right single-field DW — double-field Height size, mm Width size, mm Designation of this standard

Notes 1 It is allowed to additionally enter a letter designation after the designation of the type of product, specifying the purpose of the door blocks: C - for plumbing units, M - interior, K - apartment (for the entrance to the apartment), T - vestibule, U - reinforced, etc. (for example, DPVS - internal door block made of PVC profiles for plumbing units). 2 It is allowed to enter the size of the box width in millimeters in the size designation.

Examples of symbols: DPV S B Pr 2100-970 GOST 30970-2002 - door block made of PVC profiles, internal, light, without threshold, single-leaf, right-hand opening, height 2100 mm, width 970 mm. DPNU G P L 2300-970-130 GOST 30970-2002 - door block made of external reinforced PVC profiles, blind, with a threshold, single-leaf left opening, height 2300 mm, width 970 mm, with frame width 130 mm. When drawing up a contract (order) for the manufacture (supply) of individual products, it is recommended to indicate the design solution option, including a description of the design of the profiles and the filling of the door leaf; drawing indicating the opening pattern; type of door devices; appearance requirements and other requirements as agreed between the manufacturer and the customer.

4 Technical requirements

4.1 General provisions and design requirements

4.1.1 Products must comply with the requirements of this standard and be manufactured according to design and technological documentation approved in the prescribed manner. 4.1.2 The door leafs have a frame structure welded from PVC profiles reinforced with steel liners. The corner joints of the canvas frames are additionally strengthened with corner reinforcements. The vertical and upper horizontal profiles of the box have a welded connection; the lower profile of the frame (threshold) can be made of metal alloys or absent (with a door block without threshold design). It is allowed to manufacture closed boxes completely welded from PVC profiles (including the lower horizontal profile). Imposts are fixed in frame elements using mechanical connections or welding, and metal thresholds are secured using mechanical connections. Examples of architectural drawings and design solutions for the main connections between leaves and frames of door blocks of various designs are shown in Figures 1-7 and Appendix B.

Figure 1 - Examples of architectural drawings of door blocks

Figure 2 - Examples of architectural drawings of door blocks with decorative filling of door leaves

Figure 3 - Examples of architectural drawings of door blocks with decorative filling of door leaves of high complexity

a B C D

a, c - opening inward; b, d - opening outwards Figure 4 - Examples of assemblies of the upper and lower vestibules of door blocks

…

Types of plastic doors

In modern construction, a wide variety of doors made of plastic are used.

Classification by purpose

Plastic doors can be used for:

- Facade or external;

- Internal.

The last type of doors is divided into entrance doors installed in entrances or common corridors, interior doors, balcony doors, doors for bathrooms and saunas.

By filling type

According to this parameter, the following types of plastic doors are distinguished:

- Deaf. These are doors that have a leaf filled with sandwich panels or other opaque material.

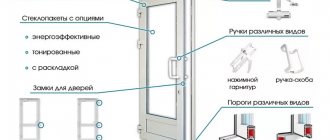

- Glazed. Models with a glass insert, this can be multi-layer glass, patterned or tinted glass.

By type of design

Plastic doors, like regular swing models, can be:

Single-leaf and double-leaf.

In addition, the doors can be equipped with a threshold or have a frame structure in which the role of the threshold is assigned to the bottom strip of the frame.

By type of finish

Based on this feature, the following types of plastic doors are distinguished:

- Completely painted white;

- Completely colored in any shade other than white;

- Laminated, that is, covered with decorative film. The film can imitate various surfaces, most often it imitates the structure of wood or stone.

So, plastic doors are produced according to GOST requirements; the regulatory document sets out the basic requirements for the products.

Requirements for filling door leaves and PVC profiles

According to GOST, door void fillers must be made from multilayer slabs, which in turn consist of plastic (aluminum) facing panels. Inside such a tile there should be an insulating or single-layer sheet of foamed polymer. For interior products, you can use tile or facing materials. If the filler is a translucent sheet, then it is best to use durable types of glass coatings recommended by GOST.

For example:

- Tempered glass coating;

- Multilayer;

- Reinforced;

- Equipped with anti-fragmentation films;

- Tinted;

- Patterned;

- Double-glazed windows or glass glued together.

If opaque fabrics are used as filler, then they must correspond to the weight and structure of the product. This filler is made from solid, weather-resistant polymer material. It should not move during installation and transportation of the door batch.

The filler should not block the access of oxygen.

PVC sections are made from solid polyvinyl chloride, which has modified high impact toughness and resistance to atmospheric and climatic changes. Entrance and interior doors are made of white PVC profiles, which can later be painted. The use of PVC profiles that have not been treated with protective agents is prohibited.

Strength groups of metal-plastic doors

When purchasing, the strength group of the door is also an important indicator. There are only three of them: A, B, C. The strongest, according to this GOST classification, are the doors of group A. You can also find out about this by reading customer reviews.

What deviations can be considered a defect in the production of PVC doors?

Production in violation of the requirements of the State Standard occurs in cases where:

- There is a difference in the dimensions of the finished product and the dimensions indicated in the design documentation. The difference should not be more than 2 mm and less than 1 mm. The difference in diagonal length for PVC doors should not exceed 2 mm for a door leaf measuring 1.5 sq.m and 3 mm for larger doors.

- Scratches, chips and other deformations are found on the door leaf, as well as differences in color or gloss that are visible to the naked eye.

- The door opens and closes with strain and force.

- There are deviations in technical specifications from those stated in the documentation.

- Deviations from GOST requirements during installation.

When purchasing a PVC door, do not forget that you have the right to demand compliance with the requirements of the State Standard from any company operating in the Russian Federation.