Regulatory documents regulate the level of security of doors against burglary, resistance to destruction and external factors, fire characteristics, ability to withstand cold, moisture and noise. Product quality, long-term and trouble-free operation depend on the manufacturer’s compliance with all requirements.

1. State standards in the Russian Federation for metal doors 2. Basic requirements according to GOST 31173-2016 3. Classification of doors according to standards 4. Materials and components 5. Hinges, locks, locking hardware 6. Finishing 7. Requirements for sound insulation 8. GOST on thermal insulation 9. Requirements for outdoor or outdoor steel blocks

Basic requirements according to GOST 31173-2016

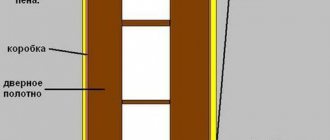

The document GOST 31173-2016 describes the basic requirements for the manufacture of metal doors with locking devices. In accordance with the standards, the metal door leaf is a welded structure consisting of steel sheets and profiles, which can be bent or rolled. It is recommended to join profile connections at corner points by welding or other methods without compromising the strength of the structure. A design using a typesetting sheet for the inner surface of the door leaf, connected from parts by welding and firmly attached to the frame profiles, is allowed. The outer wall must only be solid, otherwise it will not be possible to ensure strength and safety.

The door frame must be made of a bent rectangular profile, the cross-section of which does not exceed 40×50 mm and the wall thickness exceeds 1.5 mm. According to GOST 31173–2016, metal doors are additionally reinforced with stiffeners. You should install at least two profiles in the horizontal and vertical planes. It is also recommended to use inclined elements. Horizontal ribs must be located in the area where hinges and anti-removal devices are installed. To replace and repair the lock, a “window” should be provided on the inside.

According to the standards, external and entrance doors are equipped with two contours of sealing gaskets. They are mounted without gaps and are highly resistant to atmospheric and mechanical influences.

According to GOST, metal doors must comply with the regulated parameters:

- have a door leaf area of 9 sq.m;

- height for opening doors is below 2200 mm;

- width for opening leaf no more than 1200 mm;

- deviation from straightness of the edges of the canvas and frame is no more than 1 mm/1 m of length;

- the weight of the door structure does not exceed 250 kg.

GOST parameters for metal external doors

The adopted standard sets out the basic requirements for any product manufactured under the definition of metal doors. For example, the disassembled GOST 31173 is categorically different from GOST 24698, the same external doors, but of a wooden composition.

According to the technical act, metal entrance doors must be:

- Welded from bent profiles or strong steel sheets.

- At least one and a half millimeters in thickness in the metal sheet itself.

- The locking device should not be subjected to excessive pressure or pressure.

- It is designed so that the use of the closer does not cause additional inconvenience.

- With a minimum sound insulation of 20 dB.

It should be simple to install and operate so that even children can use the unit. Not only parts, but also additional elements of the door, such as hinge lubricant, must have high heat resistance qualities.

The structure must be completely sealed, which is ensured by at least 2 sheets inside the door block.

Despite the totality of strict requirements for products, the standard does not establish an absolutely specific area of application of the unit. Therefore, they can be used in any desired area, be it residential apartments or industrial warehouses.

Classification of doors according to standards

GOST 31173-2016 for steel door blocks provides a classification of metal doors according to various parameters.

Depending on the purpose:

- internal or entrance to the apartment;

- external for installation at the entrance to the house or vestibule.

By design:

- canvases with a closed contour;

- with a U-shaped box;

- with a U-shaped box and an additional threshold.

Depending on the number of leaves and opening side:

- single-field structures;

- double-leaf with different door widths and opening one or two halves;

- with blind, non-opening inserts of vertical or horizontal arrangement;

- with opening inward;

- opening onto the street.

Based on the presence of seal contours:

- single-circuit;

- with two or more circuits.

According to the method of external design of the door block:

- paints or powder paints;

- using artificial or natural leather and a layer of insulation;

- decorative film coatings;

- natural wood and cord of natural and synthetic origin;

- glass inserts or mirror panels;

- combining several materials.

According to the strength class corresponding to the degree of resistance to static, dynamic and impact loads:

- M1;

- M2;

- M3.

According to the level of burglary resistance.

- conventional doors with anti-removal devices;

- reinforced, corresponding to strength class M2 and equipped with a perimeter locking mechanism and powerful hinges;

- protective class M1 with additional protection parameters.

Door blocks: GOST

In addition to the special classification, GOST 31173 of 2003 also provides examples of special modules that can only be used for specific purposes. Such, for example, are special security doors that have a specific scope of application.

Types of security door blocks according to GOST:

- Standard. Such modules can often be found in everyday life, because they are equipped with conventional M3 level locking mechanisms and pins that do not allow the entrance door to be removed or significantly damaged.

- Reinforced. Such examples are already more advanced in terms of protection, and this is ensured by reinforced hinges on which the door is held, as well as more complex locking mechanisms, the strength class of which must be at least M2.

- Protective. Here the main details remain unchanged, except that now each of them corresponds to the special M1 class.

As a rule, reinforced and security doors are easy to distinguish from others based on price criteria. In addition, when purchasing, they are always marked with a special marking with the additional letters U or Z.

Within the established rules, each batch of products must undergo acceptance tests.

During their course, not only security, but also fire-resistant, gas-resistant and other qualities are thoroughly checked and recorded.

Materials and components

In the production of door structures, materials, parts and components must be used that in all respects meet approved standards and technical regulations. The surfaces of steel elements must be flat and smooth, without cracks or curvature. On the front side, waviness not exceeding 0.5 mm is allowed. Door blocks and components are made only from materials that are not exposed to climatic factors.

Steel parts are checked for compliance with GOST 1050 or GOST 5632. According to the standards, gaskets are installed tightly around the perimeter of the door, without gaps. Requirements for the manufacture of seals, characteristics and installation are set out in the provisions of GOST 30778-2001.

Home steel doors: GOST

Most often, the main limitation on the choice of metal doors is their inconsistency with the dimensions of the door frame. According to GOST 31173, the basic parameters are a height of 2.2 m, a width of 1.2 m, as well as an area of 9 m2 and 250 kg of the weight of the canvas itself. Significant exceedance of specified values must be further verified by testing to establish serviceability.

Installation of steel entrance doors and its nuances:

- The gaps between the wall and the box should not exceed 2 cm.

- To secure the frame, you need to drive wedges between the wall and the door frame.

- Reinforcing pins must penetrate the wall at least 15 cm.

- One of the best means for sealing a door frame is polyurethane foam.

The main components of order delivery are the box itself and the locking mechanism. Eyes, finishing and other components must be additionally purchased or discussed in advance with the manufacturer.

Select and purchase quality products that meet regulatory technical standards. One of the most reliable, if we are talking about entrance doors, is a steel external door, the requirements for which are set out in GOST 31173 of 2003.

Hinges, locks, locking hardware

The design documentation determines the position and method of fastening hinges, locks and locking devices, as well as their technical parameters. Opening elements are selected taking into account the weight, dimensions and location of operation of the entrance structure. Installation of hinges on the frame and door leaf is carried out using welding or mechanical fasteners. It is allowed to use other fastening methods without compromising the strength of the structure. On the door hinge side, anti-removal passive crossbars should be installed, which are welded or pressed into prepared holes. Heavy structures and doors intended for public buildings are installed on three overhead hinges with a bearing unit or an adjustment mechanism.

The requirements for locking mechanisms are regulated by GOST 5089-97 and GOST 538. In order to achieve the declared degree of protection and safety, it is recommended to use locks of different designs in parallel. For example, cylinder and lever ones, or supplement them with code systems. It is not recommended to fix them by welding, so as not to damage the parts inside and impair performance. The depth of entry into the door frame socket of the lock bolt is at least 22 mm.

Taking into account the purpose, installation location and operating conditions, metal door blocks are equipped with closers, bolts, travel limiters, inspection eyes and chains. After installation, the fittings and locks must ensure smooth and easy opening, without rubbing or distortion, as well as reliable closure, as well as a tight and uniform fit to the box around the entire perimeter. Fastening and door products are additionally checked for compliance with GOST 9.303 “Metal and non-metallic coatings” and GOST 538 “Lock and hardware products”.

Manufacturer's Warranty

When purchasing a product, a GOST door passport must be issued. In addition to the dimensions and design features, it reflects the certificate of conformity and provides a description of the technical characteristics mentioned earlier. And as standard for all passports, the completeness of the product is included. The complete set of the door block includes locking devices, door hinges, type of door finish, sealing gaskets, a closer and a door stop.

At the very end of the passport, the warranty period is indicated (at least three years from the date of purchase of the product), which is also indicated in the purchase agreement. In the contract, the manufacturer guarantees the buyer the preservation of all characteristics of the product, subject to compliance with the rules of transportation, installation of the product and operating rules. The document with which the buyer can challenge certain inconsistencies with the product’s passport data and the warranty period itself is the contract for the purchase of the door unit between the buyer and the manufacturer.

It should be noted that if you install the door unit yourself, you may not receive a warranty, since the manufacturer does not have the opportunity to check the door installation technology. Therefore, we recommend using the installation services of the company that manufactured your door, or using the services of certified teams of craftsmen.

Finishing

The choice of finishing material for a metal door is directly related to operating conditions. Its appearance and quality determine the price category of the design. During individual production, these parameters are agreed upon with the customer and included in the contract.

The standards of GOST 9.402, GOST 9.401 and GOST 9.032 regulate the method of protecting and finishing metal elements, the requirements for paint and varnish coatings and the method of marking them. According to the regulations, the first applied layer is a primer, which, after drying, is covered with protective and decorative materials.

What should be the condition of surfaces with a final paint coating can be found in GOST 9.301 and GOST 9.032.

When processing and finishing wooden elements, it is necessary to adhere to the provisions of GOST 2140. Thus, according to the standards, the roughness of the outer side does not exceed 60 microns, and the humidity of the solid wood used is 8–12%.

GOST R 53307-2009

GOST R 53307-2009 is relevant in the process of testing metal fire doors. This document is a guarantee of the quality of the product, as well as its ability to protect both property and human life from fire. Fireproof metal doors that have successfully passed tests have fire resistance, which allows them to be installed in offices, private homes, as well as in large industries. In addition, in accordance with GOST R 53307-2009, these products have a number of other characteristics, among which fire resistance should be highlighted. This effect is achieved through the use of special sealing material. For these purposes, the highest quality basalt wool is used. This material itself is endowed with significant fire-fighting characteristics and is also resistant to fire.

High-strength and heat-resistant steel is used as the main material for the production of fireproof metal doors. This material can withstand the effects of open fire for a long time. It does not melt or deform.

GOST R 53307-2009 prescribes the installation of heat-resistant tape around the entire perimeter of a fire-resistant metal door. The main purpose of this element of the door block is expansion under the influence of high temperature in the event of a fire. This gives her the opportunity to fill all the cracks and gaps.

This characteristic allows you to avoid smoke and carbon monoxide from entering the room through the doorway, which can significantly harm people’s health and even lead to death. In addition to the above, acrid smoke and soot will not cause damage to property, will not cover them with a layer of soot, and will not be able to permeate objects with a heavy burning smell.

Sound insulation requirements

An important indicator for reliable performance, affecting the quality of a metal door, is the level of sound insulation. The value is laid down in the design documentation and is subject to testing in testing laboratories. The requirements of SP 51.13330.2011 “Noise Protection” and GOST 31173 state that door frames have protection from external noise of at least 20 dB.

The sound insulation indicator is ensured by a tight fit of the canvas to the frame, elimination of the gap between the door and the floor by installing a threshold, and the use of sealing gaskets in the rebates. The locking mechanisms must press the door leaf against the frame, and the keyholes must close. It is also recommended to use noise-absorbing materials for filling and cladding.

The standards establish three classes of sound insulation for metal entrance doors:

- 1st - 20-25 dB;

- 2nd - 26-31 dB;

- 3rd - 32 dB or more.

Metal door standards

The development of standards for metal doors is dictated by high requirements for a number of reasons: compliance with the parameters of doorways in construction, performance of security functions, insulating properties, their strength and a number of other parameters. Their compliance during manufacturing is necessary for the consumer, otherwise they will not perform the required functions. GOST 31173-2003 provides a fairly wide range of manufacturing parameters from indoor entrance doors to secure doors to expensive houses and cottages. Steel doors are very popular in our country.

The standards are intended for serial and small-scale production, where it is possible to debug the technological process in accordance with them, where there is control of their compliance using appropriate methods and confirmation of test results in special centers accredited to carry them out. This is difficult to achieve in individual production. Compliance with standards provides the consumer with the necessary consumer qualities.

GOST on thermal insulation

Insulating the front door allows you to minimize heat loss and eliminate contact between cold and warm environments. The provisions of the standards establish standards for high-quality thermal insulation of the door block. These include the presence in the frame of at least two sealing contours and filling the space of the door leaf with special heat-insulating materials, such as mineral and basalt wool, polystyrene foam, expanded polystyrene, as well as wooden blocks and fiberboard sheets. Installation of seals is carried out without gaps at the joints, with a tight fit to the rebate. The material for external doors is selected with high resistance to temperature fluctuations and moisture.

For external metal insulated doors, GOST 31173–2016 establishes a classification based on the reduced heat transfer resistance:

- Class 1 - corresponds to 1.0 m °C/W or more;

- class 2 - in the range of 0.70–0.99 m °C/W;

- Class 3 - 0.40–0.69 m °C/W.

GOST 51072-2005 requirements for security entrance doors

According to GOST 51072-2005 “Safety doors,” a security door is a protective device that has in its design a door leaf, a door frame and one or more locking devices and is resistant to established methods of exposure.

The security door must be fire-, bullet- and burglary-resistant, while the door frame must have the same protective properties.

Resistance to burglary is determined according to GOST R 51113. Security doors are divided into 6 resistance classes: H0, 0, I, II, III, IV with a minimum resistance value in EU units of 15, 30, 50, 80, 120, 180, respectively.

Stability class H0 allows the installation of 1 locking device; doors of other stability classes are equipped with 2 or more locks.

We present to your attention a short video - a report from a steel door production plant. It clearly demonstrates the technology for manufacturing high-quality products.

Fire protection structures

As mentioned above, the standards in question do not apply to special-purpose doors. What documents do manufacturers rely on in this case? Take, for example, fire doors: SNiP 21.01-97 regulates the requirements for the fire resistance limit (see GOST: installation of fire doors).

- This indicator is a certain time period during which the door can withstand the influence of extremely high temperatures and not lose its load-bearing capacity, as well as its heat-insulating properties. It is clear that special requirements are imposed on such structures.

- The vestibules must be sealed, and the canvases must be equipped with closers. There are types of doors that are normally used open. In this case, the manufacturer’s responsibility is to equip them with automatic equipment that is activated during a fire and disguises the canvas.

Note! Another very important requirement: the door leading to the emergency exit should not have a locking mechanism that cannot be opened without a key. Moreover, not only the materials from which the canvas is made must be non-flammable, but also the fittings installed on it.

- Installing fire-resistant doors in a privately owned house is voluntary. But there are categories of buildings that must be equipped with fire doors. For example, in multi-storey buildings whose height exceeds 50m, all exits must be equipped with such structures - including vestibules, staircases and elevator shafts.

- The fire resistance limit of structures installed at these points must be at least half an hour. Doors with the same characteristics are also installed in elevator halls of single-section buildings, as well as technical basements. In public buildings, all entrance areas must be equipped with fire-resistant blocks.

Doors that meet fire safety requirements can be made not only of steel, but also of aluminum - with the door frames filled with fire-resistant glass. In this case, they not only provide the possibility of unhindered evacuation of people in a force majeure situation, but also perfectly complement the interiors and exteriors of buildings.

SNiP requirements: installation of a metal door indoors

The production of steel doors is regulated by a special regulation, GOST, which was approved on March 1, 2004, and SNiP rules (sanitary norms and rules). The standards of these provisions apply to the production of steel structures equipped with locking mechanisms, which are recommended for installation in residential or non-residential premises. But the production of doors with high safety or stability requirements is not within their competence.

Metal constructions

Locks and locking devices

The locks themselves, their structure and reliability can be studied for a long time. But it is worth remembering that there must be a reinforcement plate in the door structure in the area where the locks are installed. The thickness of the steel should be at least twice as thick as in other places. If the additional lining is made of super-strong steel (manganese), this is an additional plus for choosing this particular metal door.

Not only the lock is important, but also the presence of reinforcement

What kind of locks should I put?

For those who do not want to delve too deeply into the study of types of locks, you just need to know that for a sufficient level of reliability, it is advisable to have two locking devices of different systems. Most often they install cylinder and lever ones. On the door they should not stand next to each other, but at a distance from each other. The greater this distance, the better - this reduces the possibility of pressing the door, since the locks are spaced at a considerable distance. It is also advisable to have a latch on the inside. Its design is at your discretion. This is so that if someone is at home, the door cannot be opened from outside. A greater number of constipations brings more trouble to the owners than inconvenience to the burglars.

Choosing locks for a metal door is a serious matter.

One of the traditional locks can be replaced with an electronic lock. It does not have a keyhole; it is opened not with ordinary keys, but with a remote control, like on an anti-theft device for cars. A good option, but it costs a lot. Installing a “two in one” type lock with two systems is not entirely correct. After all, two locks are needed precisely so that the bolts are spaced as far apart as possible.

When choosing a lock for a metal door, European or American brands are often preferred. Yes, they are more expensive, but more reliable. The Italian companies Cisa, Mottura have proven themselves well, the Turkish Kale, the Austrian EVVA, the German Saturn and Diamant are quite good. If the budget is limited, there are good Russian ones: St. Petersburg Kerberos (with a cut-off lever) and Barrier.

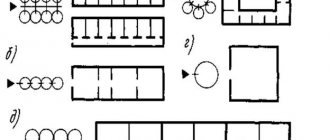

Additional locking devices

Some doors are equipped with additional devices to protect against mechanical burglary. These are pins and bolts that, when the lock is turned, move out of the door leaf, entering the holes made for them in the door frame. There are several types of these devices: thrusters, deviators and crabs.

If, when you turn the key, pins appear at the top and bottom of the door leaf, these are rods. If additional pins come out in a horizontal plane (usually at the top and bottom on the lock side, but can also be on the hinge side) these are deviators. The deviators can be of any shape - in the form of round pins or rotary hook-shaped ones. If the pins appear both from the bottom/top and from the loop side, this system is called a “crab”.

Schemes of additional crossbars to increase the burglary resistance of the door

All of them are good as additional measures against mechanical burglary: if they try to press the door leaf away from the door frame, they will greatly complicate the task. But if they open it with a master key or some other “intelligent” method, this will not help. In addition, please note that all bolts operate from the lock. So if you decide to choose a metal door with crossbars, the lock must have exits to connect to them. If they are not there, all additional constipation is useless.

What determines temperature resistance?

The resistance of metal doors to temperature does not depend on the thickness of the metal used in manufacturing. Fire safety is affected by:

- Thermal insulator used. In GOST 31173-2003, in the section devoted to the design of metal doors, the following is proposed for use as a filler for cavities between the inner and outer shell: polystyrene foam, mineral wool, wood or wood chip fillers. Naturally, thermal insulation made of polystyrene foam or wood is not suitable for the manufacture of fire doors. And the density and thickness of the mineral filler also affects the time that a metal door will resist the effects of fire.

- The size of the gap between the door leaf and the frame. The smaller this distance, the greater the door’s resistance to temperature. The standard for the manufacture of metal door blocks allows maximum deviations of no more than 3 mm.

- Availability and quality of self-foaming sealant. Fire self-foaming tape is installed around the perimeter of the door leaf. As the temperature rises, the seal foams and hermetically closes the gap between the frame and the sash, preventing combustion gases from entering the room.

- GOST 31173-2003 establishes that the sealing gaskets used must comply with sanitary standards and other technical regulations and standards adopted in the prescribed manner. Seals must be present around the entire perimeter of the sash and the fit of the sash must be tight.