Requirements for window blocks made of polyvinyl chloride profiles are established in GOST 30674-99 Window blocks made of polyvinyl chloride profiles. Technical conditions.

Let us highlight the main requirements of this regulatory document, which relate to the requirements for the quality and size of a window block made of PVC profiles (polyvinyl chloride profiles), as well as maximum deviations and which can be checked independently upon acceptance.

According to clause 5.1.6, products (or materials for their manufacture and components) must have documents on sanitary safety provided for by current legislation and drawn up in the prescribed manner.

Requirements for dimensions and maximum deviations

These requirements are given in section 5.2 of GOST 30674-99. Let's highlight the most important points:

5.2.2 Maximum deviations of the nominal overall dimensions of products should not exceed +2.0 mm and -1.0 mm.

5.2.3 Maximum deviations from the nominal dimensions of product elements, gaps in the rebates and under the overlap, the dimensions of the location of window devices and hinges must not exceed the values established in Table 1.

Table 1

| Size interval | Maximum deviations of nominal dimensions, mm | ||||

| inner size of boxes | outer dimensions of the sashes | gap in the vestibule (rebate) | clearance under fusion | Dimensions of arrangement of devices and hinges | |

| Up to 1000 | ±1,0 | -1,0 | ±1,5 | +1,0 | ±1,0 |

| From 1000 to 2000 | +2,0 -1,0 | ±1,0 | +1,0 -0,5 | ||

| St. 2000 | + 2,0 -1,0 | + 1,0 -2,0 | +1,5 -0,5 | ||

| Notes 1 The maximum deviation values are set for the temperature range of the measurement - 16-24 °C. 2 The values of the maximum deviations of the dimensions of the gaps in the rebates and under the overlap are given for closed sashes with installed sealing gaskets. | |||||

The difference in the lengths of the diagonals of rectangular frame elements should not exceed 2.0 mm with the longest side length of the sash up to 1400 mm and 3.0 mm - more than 1400 mm.

5.2.4 The difference in the front surfaces (sag) in welded corner and T-shaped connections of adjacent profiles of frames and sashes, the installation of which is provided in the same plane, should not exceed 0.7 mm, when mechanically connecting the imposts with the profiles of the frames, as well as with each other - no more than 1.0 mm.

5.2.5 If the processing of a weld involves making a groove, the size of the groove on the front surfaces should not exceed 5 mm in width, the depth of the groove should be in the range of 0.5-1.0 mm, and the cut size of the outer corner of the weld should not must exceed 3 mm along the weld seam.

5.2.6 The sagging of opening elements (sashes, leaves, vents) in the assembled product should not exceed 1.5 mm per 1 m of width.

5.2.7 The deviation of the nominal size of the distance between the overlaps of adjacent closed doors should not exceed 1.0 mm per 1 m of the length of the rebate.

5.2.8 Deviations from the straightness of the edges of parts of frame elements should not exceed 1 mm per 1 m of length in any section.

5.5.3 Curved profiles should not have deviations from the shape (warping, waviness) exceeding the width and height of the profile (±1.5) mm. The recommended minimum bending radius for white PVC profiles should be taken equal to five times the profile width, for other profiles - 5.5 times the profile width.

Appearance requirements

These requirements are given in section 5.3 of GOST 30674-99.

5.3.5 The appearance of the products: color, gloss, permissible surface defects of PVC profiles (risks, scratches, shrinkage cavities, etc.) must correspond to the standard samples approved by the head of the enterprise that manufactured the products.

Welded seams should not have burns, uncooked areas, or cracks. Changing the color of PVC profiles in places of welded seams after they have been cleaned is not allowed.

5.3.6 The front surfaces of profiles of doors and product boxes (except curved ones) must be protected with self-adhesive film.

Requirements for glazing (installation of double-glazed windows in the frame)

5.6.3 Double-glazed windows (glass) are installed in the rebate of the sash or frame on pads that prevent the edges of the double-glazed window (glass) from touching the internal surfaces of the rebates of PVC profiles.

Depending on their functional purpose, pads are divided into basic, support and spacer.

To ensure optimal conditions for transferring the weight of the glass unit to the product structure, support pads are used, and to ensure the nominal dimensions of the gap between the edge of the glass unit and the sash rebate, spacer pads are used.

Base shims are used to level the rebate bevels and are installed under the support and spacer shims. The width of the base pads should be equal to the width of the fold, and the length should not be less than the length of the support and spacer pads.

Support and spacer pads can combine the functions of basic pads.

The length of the support and spacer pads should be from 80 to 100 mm, the width of the pads should be at least 2 mm greater than the thickness of the glass unit.

5.6.4 Linings are made of rigid weather-resistant polymer materials. The recommended hardness value of the support pads is 75-90 units. according to Shore A.

5.6.5 Methods of installation and (or) design of pads must exclude the possibility of their displacement during transportation and operation of the products.

5.6.6 The design of the linings should not impede air circulation over the inner surface of the glazing rebate.

5.6.7 If the installation location of the lining coincides with the head of the fastening screw, the lining must not be skewed.

5.6.8 It is recommended to install no more than two support pads on any side of the glass unit.

5.6.9 The distance from the pads to the corners of the double-glazed windows should, as a rule, be 50-80 mm. If the width of the glass unit is more than 1.5 m, it is recommended to increase this distance to 150 mm.

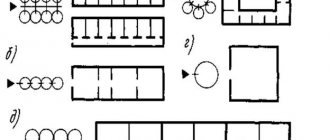

5.6.10 The basic layout of support and spacer pads when installing double-glazed windows, depending on the type of opening of window units, is shown in Figure 5. In balcony door units and in products with reinforced locking devices, it is recommended to install additional pads in the locking areas.

Figure 5 - Layout diagrams of support and spacer pads when installing double-glazed windows, depending on the type of opening of window units. Types of opening window units: a - non-opening; b - tilt and turn; c - rotary (swing); g - folding; d - hanging; e - installation of linings in figured window blocks.

5.6.14 Installation of double-glazed windows (glasses), as well as sealing of the sashes, is carried out using elastic polymer sealing gaskets. It is allowed to use glazing beads with a co-extruded seal for fastening double-glazed windows from the inside.

5.6.15 Sealing gaskets must be resistant to climatic and atmospheric influences.

5.6.16 The fit of the sealing gaskets must be tight, preventing the penetration of water.

5.6.17 Sealing gaskets must be installed continuously along the entire perimeter of the sashes and double-glazed windows. When installing in a ring, the joint of the gaskets should be in the upper part of the product. When installing gaskets with joints at 45° corners, the joints of the gaskets should be welded or glued (except for gaskets installed in glazing beads). Corner bends and welded joints of sealing gaskets for double-glazed windows should not have protrusions (bulges) that cause concentrated loads on the double-glazed windows.

It is allowed to disrupt the continuity of installation of gaskets in the sash vestibule in structures that provide for self-ventilation of products, as well as in other cases provided for by design solutions and established in the design documentation.

How to buy high-quality plastic windows?

To purchase guaranteed quality PVC windows, you need to follow a simple rule. Namely: contact only reliable and proven window companies that have a decent reputation in the market. has been offering plastic windows for a cottage or apartment for many years, and also has its own window production, equipped with the latest technology. We install PVC windows in Moscow based on REHAU profiles using advanced fittings from SIEGENIA-AUBI. You can also buy plastic windows from us in Vidnoye, order plastic windows in Reutov and other cities of the capital region.

Requirements for window devices (window fittings)

5.8.2 The type, number, location and method of fastening of locking devices and hinges are established in the working documentation, based on the size and weight of the opening elements of the product, as well as the operating conditions of the window units. In this case, the distance between hinges and locking points, as a rule, should not exceed 800 mm.

5.8.3 It is recommended to fasten the hinges using self-tapping screws through at least two PVC profile walls with a total thickness of at least 4.5 mm or through one profile wall and a reinforcing liner. If it is necessary to drill holes for screws, their diameter should be equal to the diameter of the central core of the screw.

When the opening elements weigh more than 60 kg, as well as in balcony door blocks and reinforced products, it is recommended to fasten the hinges into reinforcing inserts.

5.8.5 Locking devices must ensure reliable locking of opening elements of products. Opening and closing should occur easily, smoothly, without jamming. Handles and bolts of appliances should not move spontaneously from the “open” or “closed” position.

5.8.6 The designs of locking devices and hinges must ensure tight and uniform compression of the gaskets along the entire sealing contour in the recesses.

Double-glazed window

A double-glazed window for a plastic window consists of two or three glasses, hermetically connected using spacer frames and sealant. In this case, the frames are equipped with a built-in layer of desiccant that dries the internal space between the glasses. To increase the level of thermal insulation, the space between the glass can be filled with inert gas.

In addition to standard ones, double-glazed windows with improved sound and heat insulation characteristics are produced. This makes it possible to select windows that will best suit the operating conditions. Increasing the sound and heat protection properties is achieved by changing the interglass distance and using special glasses. For example, double-glazed windows can be equipped with energy-saving, reinforced, frosted or decorative glass.

We will answer all your questions!

Requirements for the design of a window unit

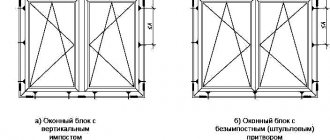

5.9.2 Impost parts are attached to adjacent PVC profiles of the frame (sash) using steel or plastic fasteners, screws or screws.

It is allowed to use welded T-shaped and cross-shaped connections of imposts. In this case, the strength of the connections must be no lower than the strength established for corner connections.

5.9.3 Corner and T-shaped connections of profiles must be sealed. It is allowed to seal the mechanical connections of PVC profiles with weather-resistant elastic gaskets. Gaps up to 0.5 mm can be sealed with special sealants that do not impair the appearance of the products and protect the connections from moisture penetration.

5.9.4 Product designs must include a system of holes: for draining the cavity between the edges of the glass unit and the folds of the profiles; water drainage; wind pressure compensation; reducing heating of colored profiles.

5.9.5 Each glazing field must have holes for draining the cavity between the edges of the glass unit and the folds of the profiles. The holes should be located in the deepest parts of the folds and not have burrs that prevent water drainage. For systems with a middle seal, the holes must be located in front of the middle seal on the outside.

In the lower profile of the sash there must be at least two holes with a maximum distance between them of 600 mm, in the upper profile with a length of up to 1 m - two holes, and more than 1 m - three. Recommended hole sizes are at least 8 mm in diameter or at least 5x10 mm in size.

The location of the holes should not coincide with the installation locations for the linings under the double-glazed windows. The holes in the profile walls must be offset relative to each other by at least 50 mm.

5.9.6 The lower profiles of boxes and horizontal imposts must have at least two drainage holes measuring at least (5x20) mm, the distance between which should be no more than 600 mm.

The drainage holes must be offset in the profile walls by at least 50 mm. The holes must not have burrs that would impede water drainage.

For systems with a middle seal, the slots must be located in front of the middle seal on the outside.

The holes on the front surface of the box should be protected with decorative visors.

5.9.11 The depth of pinching of a double-glazed window (glass) in the folds of profiles, as well as the depth of pinching by glazing beads, should not be less than 14 mm.

Window opening elements

When considering how plastic windows are designed, you cannot miss the slopes, window sill and ebb. Without them, the theme does not look complete, just like the window openings - the instructions for installing window blocks provide for the installation of these structural elements without fail.

Slopes

Window slopes are elements of the frame of a window block on the sides and top on the inside and outside of the building, closing the technological gaps between the frame and the wall from external influences (rain, snow, wind), while providing heat and sound insulation, as well as completeness and elegance appearance of the opening. They can be made of plastic, wood, drywall and plaster.

More detailed information about slopes can be found here.

Windowsill

The window must include a window sill.

A window sill is a structural element of a window, which is a board, plastic panel or stone slab, mounted into the lower part of the window opening from the room side at the same level as the bottom of the frame or directly below it. The main functions are to provide heat and sound insulation of the opening, additional functions are to give it a finished, aesthetic appearance.

All the details about the window sill are here.

Low tide

The ebb is installed on the outside of the window on the lower part of the window opening. Protects the wall from all types of moisture and snow, and the mounting foam in the technological gap from sunlight.