home

> Glazing of facades

> Rooflights

Advantages Examples Calculation Application Our work Bonuses Prices Guarantees

Calculate the project

Specialists provide services for the design, production and installation of skylights on the roofs of buildings. We have extensive experience in implementing glazing projects using skylights of various types and configurations.

What is a skylight?

Video: Glazing of the dome of the Khoroshevskaya gymnasium building

A skylight is an engineering structure consisting of a rigid frame and translucent filling and is intended for natural lighting and ventilation of interior spaces. Anti-aircraft lights are installed on the roof, occupying no more than 15% of the total coverage area.

It has been proven that the light transmittance of structures located above a person’s head is 50% higher than the light transmittance of vertical windows. Thus, skylights provide better illumination than conventional windows located in the wall. Therefore, to create effective lighting, it is enough to place just a few small skylights on the roof.

Main functions

An anti-aircraft dome or skylight on the roof is a three-dimensional structure that has a number of practical functions. It ensures that daylight enters the building and becomes its only supplier where the project does not provide for the installation of windows or is impossible for technical reasons. In addition, the described element is capable of creating natural air circulation and helping to ventilate large areas without installing forced hoods.

By opening the doors of such a lantern, you can release the smoke that arises during a large fire. By decorating them with film stained glass, it is easy to make a purely technical object an integral part of the overall decor. Today, anti-aircraft domes are used by architects to decorate the facades of futuristic buildings. But this is not new know-how, but an invention well known in certain circles.

Decorative stained glass on the roof Source www.needpix.com

Similar domes adorn the Cathedral of St. Mary, located in Florence. The roof of the famous Capitol in Washington is the world's largest skylight. In the USSR, such structural units were used in the construction of large shopping centers. Currently, similar structures can be seen on the roofs of industrial enterprises, sports complexes, warehouses, luxury hotels and concert halls.

Thanks to their installation, owners save on electricity, which they have to spend on lighting large areas during the day, as well as on providing forced ventilation. Scientists have proven that in offices that are illuminated with skylights, work is much more productive. The presence of such technical characteristics explains why light elements are so popular today.

Light dome in GUM Source pinterest.cl

Types of skylights

Dome

Thanks to their dome-shaped shape, they have increased impact resistance. They are often used in the construction of round-shaped structures, in multi-story construction for additional lighting of staircase landings on the upper floors.

Gable

Unlike other types of skylights, they allow you to avoid direct sunlight entering the room. Budget option for skylights.

Four-slope

Differs from 2-slope in the number of edges. There are also options for multifaceted designs.

Light stripes

They are used in large rooms to increase illumination and represent a complex system of skylights. They are used in workshops, warehouses, and gyms.

Flat

Usually installed on a sloping roof. It is recommended to install flat lanterns at an angle of at least 15 ° so that water does not accumulate on it after rain.

Have questions about skylights?

Leave a request on the website, and our specialists will advise you in detail on your project.

To get a consultation

Installation rules

Installation of skylights is carried out by construction and installation organizations that have the appropriate licensing permits, because This is not only a critical stage in the installation of products and devices responsible for lighting, ventilation, and smoke removal in the event of a fire in the building; but also a type of work at height associated with danger, on inclined pitched surfaces of roofs, roofs, coverings of industrial buildings, public buildings.

The installation of skylights for mass use for standard projects for the construction of buildings and structures, as a rule, is carried out using standardized structures, the use of which is approved by the State Construction Committee of Russia; or products developed and manufactured by domestic and foreign companies on the basis of approved technical specifications and certification tests.

All this fully applies to strip, point types of anti-aircraft smoke removal lamps that have the correct geometric shape and a certain number of standard sizes; installation period, the operating experience of which goes back decades.

The situation is much more complicated with the installation of modern dome lanterns, which have both a fairly simple spherical, pyramidal shape and non-standard dome shapes, for example, a convex polyhedron, which requires appropriate qualifications and sufficient experience in installing such complex fragile structures; so that they not only look aesthetically pleasing from the inside of the building, letting light into it, but also perform the functions of natural ventilation and smoke removal in the event of a fire.

Therefore, to install translucent domes of skylights to remove smoke from tempered, reinforced glass or polymer sheet materials, it is necessary to involve specialized enterprises with experience in carrying out such work.

Design of skylights in

Proper design of the design of skylights fully reveals their functional characteristics and extends their service life. Before starting work, designers agree in detail with the customer on the design form, dimensions, type of opening, presence of reinforcement and location of skylights. Their design models can be: round, triangular, rectangular and polyhedral. In order for skylights to fulfill their main purpose: fast and timely smoke removal, the design is carried out taking into account strict compliance with current building codes and regulations:

- Anti-inflation resistance. The technical design of the skylight ensures constant, uninterrupted operation of the hood valve in any wind position;

- Compliance with dimensions: during design - the length of the skylight and during installation - between the mounting cups;

- Uniform distribution of skylights throughout the entire roof structure;

- Availability of mechanical and automatic opening methods.

One example of innovative technical glazing is the skylights of industrial buildings, which fulfill the requirements of: natural lighting, daily ventilation, smoke removal and architectural aesthetics. This equipment on the roof of a building has effective energy-saving properties. Modern lantern designs are made of durable, wear-resistant, fireproof alloys and are divided into the following types:

- Light, aeration, combined;

- Point, tape. The latter, in turn, are: transverse and longitudinal in relation to the location of the spans and roof of the building;

- With horizontal, vertical, inclined glazing.

Skylights are a classic on the exterior of industrial buildings. The design, production and installation of such structures from a reliable company is confirmed in practice by productivity and financial advantage for clients.

When designing the structures of skylights, we necessarily take into account these and a number of other SNiP requirements.

Manufacturers and prices

It is possible to purchase products from the following manufacturers on the domestic market:

- Velux. The Velux company manufactures roof windows and skylights and has offices in more than 40 countries. Budget solutions without the ability to open cost 26,000 rubles for a 60x90 cm model. The same option, only 150x150 cm will cost 56,000 rubles.

- M8 city. Belarusian manufacturer of roofing glazing. The cost of manufacturing a blind version is from 8,000 rubles per m2. With installation and other work - 12,000 rubles per m2. The price of swing models depends on the type of drive and ranges from 10,000 rubles for the electric version and 10,300 rubles for the pneumatic version. Cost with installation from 14,000 rubles.

- AWAK. Manufactures light domes, skylights and smoke removal systems. The cost of a square model 60x60 cm is 35,000 rubles.

In addition to the manufacturers listed above, products from other brands are available, for example, fakro and mcrprolight. The cost of a specific model can be found out after pre-ordering.

Subscribe

Cost of skylights

The cost of each project is calculated individually and depends on the technical features of the roof, the material of its covering, the maximum possible precipitation loads, the interior and exterior design of the building and other factors.

Prices for skylights

| Filling | Manufacturing and installation | Cost of aluminum profile with double glazing | Total cost of construction including installation |

| Self-supporting skylight made from a domestic profile | |||

| transparent single-chamber double-glazed window with triplex | from 2,600 rub./m2 | from 6,000 rub./m2 | from 8,600 rub./m2 |

| tinted single-chamber double-glazed window with triplex | from 2,600 rub./m2 | from 6,700 rub./m2 | from 9,300 rub./m2 |

| heated double glazing with triplex | from 3,600 rub./m2 | from 18,500 rub./m2 | from 22,100 rub./m2 |

Since each project is different, the final cost will vary depending on the specifics of the project.

Repair

The most common reason for the need for repairs is the occurrence of a leak, usually in the area where the roof meets the skylight frame. This problem is usually eliminated by replacing the seal and sealing the joints. The process begins with dismantling the faceplates, removing old sealant and other contaminants, and cleaning the steam ducts. If incorrectly installed or damaged elements are identified, they are replaced. Then the outer perimeter of the block and the adjacent areas are sealed.

Leaks through a double-glazed window are eliminated either by its complete replacement or local repairs. For example, polycarbonate sheets lend themselves well to soldering, so if they are slightly damaged, it is possible to install a patch that is visually invisible to others.

Industrial Applications

The development of such structures for industrial buildings is carried out in accordance with building regulations. Such standards take into account lighting of production areas and energy savings . Even the position of the sun on a working day and the location of the building itself on which the skylight will stand are taken into account. A nearby multi-storey building can interfere with its effectiveness - it can make it difficult for light to enter the target premises. When designing, all this is taken into account.

Industrial anti-aircraft lighting systems must include not only an automatic drive for opening them, but also backup manual control. This is necessary, first of all, in case of unforeseen emergency situations in which the automation may fail. At the same time, automation is needed for regular ventilation and creation of a favorable microclimate inside work areas. Fire safety requirements in production are not met by those skylights whose design does not imply their opening - the whole point is that they will not be able to release toxic combustion products in the event of a fire.

The size requirements for industrial anti-aircraft lighting are simple: they need to match the dimensions of the building on which they are installed. The materials from which they are made must meet the specifics of the production premises, for example, in production with harmful fumes, a polymer coating must be used for them.

Design features

Simplicity of installation is ensured by a well-thought-out design scheme. Its main elements are:

- Foundation. It is also called the crown or simply the base. This role is usually played by a profile made of stainless steel, aluminum or copper. The first option is used in large structures, where the load is not only the coating itself, but also precipitation in the form of hail, rain or snow. The most commonly used material is extruded aluminum (the strips are stretched under pressure and high temperature).

- The frame is the base into which the next element will be inserted.

- Translucent base. This role can be played by polycarbonate, acrylic, as well as double-glazed windows. In the latter case, the outer layer can be armored, and the inner layer can consist of triplex. The presence of an air gap in the bag reduces thermal conductivity and maintains the room temperature well. Colors and designs can be very different - all at the request of the customer. The design can be matte.

- In opening skylights, an additional element is the fittings, as well as mechanisms that provide mobility. They can be operated by physical force using handles, or be fully automatic with hydraulic or electric lifts. In such cases, wiring and a control panel are also added.

- A separate module may be a smoke removal nozzle.

Polycarbonate lantern

As a translucent material, polycarbonate excellently diffuses light flux, resulting in more uniform illumination of the room than when using various types of glass or acrylic. Installation of an arched structure is simple, since when installing it, ridge elements are avoided and the number of profiles is reduced (as a rule, they are made of aluminum).

In cases where there are no requirements for increased strength and there is a need for better light diffusion, it is preferable to use cellular polycarbonate. To give the structure strength, monolithic panels are used. To prevent the snow melting process from being delayed and the lantern from being closed, large sheets of thickness should not be used.

You can install skylights for smoke removal yourself, if they have a simple design. The main point that you should pay attention to when performing work is to tightly fasten the frame to the roof so that moisture cannot get under it. In this case, silicone sealants or rubber seals are used.

Recommendations for the design and installation of lanterns for natural lighting of premises (page 2)

3.2.6. The design of skylights should ensure that their static operation is independent of the load-bearing elements of the coating.

The supporting contours of skylights in coverings made of prefabricated reinforced concrete elements should be installed on special slabs with openings (see series 1.465.1-15, 1.465.1-20, 1.465.1-21) or on monolithic reinforced concrete covering structures with light openings, and in coverings made of profiled steel decking - onto steel purlins.

3.2.7. The supporting contours of skylights must rise above the roof by at least 300 mm. The angle of inclination to the horizon of the light-transmitting filling of skylights must be at least 12°. The edges of the supporting contours of the lanterns can be inclined. The angle of inclination of the edges to the vertical should not exceed 30°.

Examples of design solutions for various types of lanterns with light-transmitting elements made of double-glazed windows, organic glass and polycarbonate and their support units are shown in Fig. 3.3—3.8.

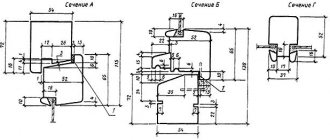

Rice. 3.3.

Rooflight with light-transmitting elements made of double-glazed windows

1

— double-glazed window;

2

- reference contour;

3 —

flashing;

4 —

sealing rubber gasket;

5

- bolt;

6 —

protective metal mesh;

7

- seal;

8

— clamping element;

9 -

thrust element;

10

— sealing mastic;

11 -

screw;

12 -

apron;

13

— waterproofing carpet;

14

- insulation;

15 -

vapor barrier

Rice. 3.4.

Opening skylight with single glazing

and opening mechanism

1 —

glass unit;

2 -

reference contour;

3 —

steel frame;

4

- insulation;

5

- apron;

6

— protective mesh;

7

— clamping element;

8

— rubber gaskets;

9 —

opening mechanism;

10 -

bolts;

11 —

load-bearing purlins;

12 -

profiled flooring

Rice. 3.5.

Rooflight with light-transmitting element made of organic glass

1 —

double-layer organic glass dome;

2 -

reference contour;

3 -

wooden

frame; 4 —

insulation;

5 -

apron;

6 —

clamping bar;

7

— clamping clamp;

8

- seal;

9 -

load-bearing purlins

Rice. 3.6.

Interface units between double-glazed windows in a skylight with a frame made of aluminum profiles

1 —

glass unit;

2 -

load-bearing element;

3 -

clamping element;

4 —

fastening element;

5

- seal;

6 —

connecting plastic element;

7

— flashing

Rice. 3.7.

Interface nodes for light-transmitting filling elements

from cellular polycarbonate:

A -

flat;

b -

ribbed

1

— panel made of sago polycarbonate;

2

- flashing made of:

a

- aluminum and

b

- polycarbonate;

3

— end plate made of polycarbonate;

4 -

seal;

5

— steel supporting profile;

b

- aluminum supporting profile;

7

- panel fastening detail

Rice. 3.8.

Connections between cellular polycarbonate panels and a wall

1

— panel made of cellular polycarbonate;

2

- aluminum fastening profile;

3

- wooden crossbar;

4 -

lathing lath;

5

- apron

3.2.8. Parts of the supporting contour and supporting frame of skylights are made of thin sheet steel in accordance with GOST 19903-74 and GOST 19904-90 and cold-formed steel profiles in accordance with GOST 8278-83*, GOST 8282-83*, GOST 30245-94*. The connection of the supporting contour parts and frame elements should, as a rule, be made using bolts or self-tapping screws. It is allowed to connect elements by welding.

For the manufacture of supporting contours of skylights, sheets of fiberglass and asbestos cement, profiles and sheets of aluminum alloys and other materials can also be used.

3.2.9. The supporting structures of the light-transmitting filling elements (frame) of skylights can be made of aluminum or steel profiles. Fastening of elements of light-transmitting filling (double-glazed windows, polycarbonate panels) is done using flashings secured to the supporting structures with screws or self-tapping screws.

The strips are made from aluminum or cold-formed steel profiles.

3.2.10. The supporting contours must be insulated and protected from corrosion. Materials used for anti-corrosion coatings must comply with the requirements of SNiP 2.03.11-85.

3.2.11. To insulate the support contours of skylights, you should, as a rule, use slab effective insulation from non-flammable (NG) or low-flammable (G1) materials with a density of no more than 250 kg/m3. Such materials can be used as rigid and semi-rigid mineral wool boards in accordance with GOST 9573-82, thermal insulating foam plastic boards in accordance with GOST 20916-87, polystyrene boards of the PSB-S type with fire retardant in accordance with GOST.

3.2.12. It is recommended to stick insulation boards onto the walls of the support contour using hot bitumen mastic with heat resistance up to 100 °C in accordance with GOST 2889-80.

3.2.13. To seal and seal the joints of the elements of the light-transmitting filling of the lamps with each other and the joints between these elements and the supporting contour, polymer profiled and flat porous gaskets (GOST 19177-81, GOST, GOST) must be used, and for their sealing - silicone or thiokol sealants, non-hardening self-adhesive tapes and other similar materials in accordance with relevant regulatory documentation.

3.2.14. The aprons of skylights should be made of galvanized steel sheet with a thickness of 0.5-0.7 mm according to GOST.

3.2.15. The joints between elements of light-transmitting filling should be sealed with foamed polymer material.

3.2.16. Seals, gaskets, sealants and other polymeric materials used in the construction of skylights must be protected from direct solar irradiation by flashings or aprons.

3.2.17. Polymer materials used for the manufacture of lanterns must have permission for their use from the State Sanitary Inspection authorities.

3.2.18. Methods of fastening and sealing elements of the light-transmitting filling of lanterns must ensure that their temperature deformations are independent of the load-bearing elements.

3.2.19. To install overhead natural lighting in rooms with suspended ceilings, it is recommended to use skylights with light-conducting shafts (Fig. 3.9). The surfaces of the inner edges of the supporting contours of lanterns and light transmission shafts should be painted with materials having a reflectance coefficient of at least 0.85. Installing glazing in the plane of a suspended ceiling is not recommended.

Rice. 3.9.

Anti-aircraft lamp with light guide shaft

1 —

suspended ceiling;

2

— light-transmitting filling;

3 —

protective mesh;

4

- support kennel;

5

- light transmission shaft;

6 -

roof

3.2.20. To ensure the safe operation of skylights with light-transmitting elements made of sheet glass or double-glazed windows, safety welded mesh with cell sizes of 50´50 mm, made according to GOST 2715-75* from galvanized wire with a diameter of 2 mm, must be installed under them. Meshes should be made in the form of separate sheets framed by bent corners or reinforcing bars. The nets are hung on hooks installed on the walls of the support contour.

When using light-transmitting elements from double-glazed windows, the bottom layer of which (facing the room) is made of protective laminated glass or glass with a protective polymer film glued to its surface, a safety net may not be installed.

3.2.21. It is recommended to fill light openings in non-insulated roofs with profiled asbestos-cement or steel sheets with translucent profiled or corrugated PVC inserts, the cross-sectional shape of which corresponds to the shape of the main roof sheets.

The translucent inserts are fastened to the purlins using self-tapping screws or bolts with special washers and gaskets installed along the ridges (Fig. 3.10).

Rice. 3.10.

Fastening points made of light-transmitting corrugated PVC to the covering beams:

A -

steel,

b -

wooden

1 —

PVC light transmitting element;

2

— overlay;

3 —

fastening element;

4

- clamp;

5

— washer;

6

— protective cap;

7

— sealing gasket;

8 —

beam

3.3. Light aeration lanterns

3.3.1. To install overhead natural lighting and ventilation of rooms where excess sensible heat exceeds 23 W/m3, as a rule, rectangular single-tier light-aeration lanterns should be used (Fig. 3.11). Technical documentation for these designs is presented in albums of the 1.464.2-25.93, 1.464-11/82, 1.464-13/82 and 1.464.3-22 series.

Two-tier light-aeration lanterns (series 1.464-13/82) can only be used with an appropriate feasibility study for the feasibility of their use.

Rice. 3.11.

Single-tier aeration lantern

1

— load-bearing elements;

2

— opening mechanism;

3 -

frame sash element;

4 —

light-transmitting filling;

5

- coating;

6 -

protective mesh

3.3.2. Light aeration lamps should be located along the axis of the building spans. The length of the lanterns should not exceed 120 m. The distance between the ends of the lanterns, as well as from the end of the lantern to the outer wall, should be at least 6 m.

The opening of the lantern shutters must be mechanized (with the inclusion of opening mechanisms from the premises) and duplicated by manual control.

To open the lanterns, it is recommended to use rack-and-pinion mechanisms (series 1.464.2-25.93, issue 5).

3.3.3. A protective metal mesh with cell sizes of no more than 50´50 mm made of galvanized wire with a diameter of 2 mm should be installed on the inside of the glazing of light-aeration lanterns. The mesh should be positioned vertically along the inside of the supporting pillars of the lantern to a height of at least 1/3 of the height of the light opening.

3.4. Fire safety requirements for lanterns

3.4.1. Rooflights with light-transmitting elements made from materials of groups G3 and G4 (in terms of flammability) are allowed to be used in industrial buildings of I, II and III* fire resistance classes of fire hazard class C0 in premises of categories B4, G and D with coatings made of materials with fire hazard NG and G1 and roll roofing covered with gravel (7.8 SNiP) or coarse-grained topping.

The total area of light-transmitting elements of such lamps should not exceed 15% of the total coverage area.

________________

* Determination of the degree of fire resistance and class of structural fire hazard of a building - see SNiP *.

3.4.2. The opening area of one lantern should be no more than 12 m2 with a specific weight of light-transmitting elements no more than 20 kg/m2 and no more than 18 m2 with a specific weight of light-transmitting elements no more than 10 kg/m2. In this case, the rolled roofing must have a protective coating of gravel or coarse-grained topping.

3.4.3. The clear distance between the lanterns must be at least 6 m for openings with an area of 6 to 18 m2 and at least 3 m for openings with an area of up to 6 m2.

When combining lanterns into groups, they are taken as 1 lantern, to which all the specified restrictions apply.

3.4.4. Between lanterns with light-transmitting fillings made of materials of groups G3 and G4 in the longitudinal and transverse direction of the building's roof, gaps with a width of at least 6 m should be made no more than 54 m apart. The horizontal distance from the fire walls to the lanterns should be at least 5 m.

3.5. Heat transfer resistance

3.5.1. The main thermal technical characteristic of lanterns is the reduced heat transfer resistance - R

0 (reference values of

R

0 elements of light-transmitting filling of lamps are given in Appendix 1). The required value of the reduced resistance to heat transfer is determined depending on the degree-day value of the heating period (DHD) based on the conditions for ensuring energy saving according to table. 3.3 and sanitary and hygienic conditions according to formula (2). Fulfillment of the condition according to formula (2) makes it possible to eliminate the formation of condensation on the surface of the elements of the translucent filling of the lanterns on the room side during the winter period of the year.

The degree-day of the heating period (DHD) is determined by the formula

GSOP = ( t

in –

t

from. per)Zot. lane, (1)

where t

c - air temperature in the working area of the room (determined according to Appendix 2);

from. per and Zot. per - average temperature, °C, and duration, days, of the period with an average daily air temperature below or equal to 8 °C, are taken according to Appendix 3.

Table 3.3

| Heating season degree-day (HSD), °C day | Reduced heat transfer resistance of overhead natural lighting structures, not less, m2 °C/W | |

| Anti-aircraft lights | Light aeration lanterns | |

| Premises of public, administrative and domestic, medical and preventive, children's institutions, schools, boarding schools, attic floors of residential buildings, industrial buildings with excess sensible heat up to 23 W/m3 | Industrial premises with excess sensible heat from 23 to 50 W/m3 | |

| 2000 | 0,3 | 0,20 |

| 4000 | 0,35 | 0,25 |

| 6000 | 0,4 | 0,30 |

| 8000 | 0,45 | 0,35 |

| 10000 | 0,5 | 0,40 |

| 12000 | 0,55 | 0,45 |

| Notes 1. Intermediate values are determined by interpolation. 2. The reduced resistance of the blind part of the overhead light devices (support contours, side elements, etc.) must be no less than 1.5 times higher than the required reduced heat transfer resistance of the translucent part. |

3.5.2. The required heat transfer resistance of lanterns that meet sanitary and hygienic conditions is determined by the formula

, (2)

where is the temperature of the internal air under the lantern, determined by the formula

(3)

where t

c - estimated air temperature in the working area of the room during the cold season (Appendix 2);

N -

room height, m;

t

n is the average temperature of the coldest five-day period (accepted according to Appendix 3);

tр - dew point temperature, taken depending on relative humidity and values according to Appendix 4;

aв is the heat transfer coefficient of the fence, taken equal to 9.9 W/(m2 °C).

3.5.3. Of the two required values of heat transfer resistance according to 3.5.1 and 3.5.2, when choosing a design solution for a lantern, the largest value is taken.

3.5.4. If possible design solutions for lanterns do not satisfy the requirements of formula (2), the design should include measures for blowing or heating the inner surface of light-transmitting elements during the cold season.

3.6. Breathability resistance

3.6.1. Actual resistance of lanterns to air permeation Ru

there must be no less than the required air permeation resistance, m2 h Pa/kg, determined by the formula

, (4)

where G

n

-

standard air permeability of the lantern, kg/(m2 h), is taken equal to 10.0 kg/(m2 h);

K

=10 Pa - air pressure difference at which the air permeation resistance

Ri

;

Dp— _

difference in air pressure on the outer and inner surfaces of the lantern, Pa, determined by the formula

, (5)

where N

— height from the floor surface to the bottom of the lantern, m;

gн and gв - specific gravity of external and internal air, N/m3, determined by the formulas, m:

; (6)

, (7)

where t

n is the average temperature of the coldest five-day period, taken according to Appendix 3;

t

c - design temperature of internal air, taken according to Appendix 2;

n is the maximum wind speed by direction for January, the frequency of which is 16% or more, adopted according to Appendix 3.

3.6.2. Actual air permeability values of lanterns G

n are accepted based on test results.

The design of the lantern in terms of resistance to air permeation must satisfy the condition

. (8)

3.7. Natural lighting of premises

3.7.1. The main value characterizing the indicator of natural lighting of premises is the natural illumination coefficient (LFC).

The normalized value of KEO in a room is determined by the formula

(9)

where e

n is the KEO value, determined depending on the category of visual work performed indoors (Table 3.4);

mN

— light climate coefficient, taken taking into account the orientation of the light opening and the area according to the light climate resources (Appendices 5,6).

3.7.2. The categories of visual work performed in the premises of public and administrative buildings and attic floors of residential buildings should be taken according to Appendix 7.

The categories of visual work performed in the premises of industrial buildings should be adopted in accordance with industry regulations on the construction design of buildings and structures, approved in the prescribed manner.

3.7.3. In the event that, due to the peculiarities of the space-planning decisions of public, administrative and residential buildings or economic considerations, it is not possible to ensure the required value of KEO in the premises, it is allowed to provide for their combined lighting, with the exception of living rooms and kitchens of residential buildings, premises for stay of children, educational and educational-industrial premises of schools and educational institutions, sleeping quarters of sanatoriums and rest homes.

3.7.4. When designing combined lighting, the KEO value should be taken according to table. 3.4 depending on the categories of visual work performed indoors (Appendix 7).

3.7.5. The normalized values of KEO for combined lighting of premises in industrial buildings should be taken according to table. 3.4:

a) in cases of lighting installations for premises in which visual work of categories I, II and III is performed;

b) for industrial premises in which, due to the conditions of technology, production organization or climate at the construction site, space-planning solutions are required that do not allow for the provision of standardized KEO values, as well as in cases confirmed by appropriate calculations of the technical and economic feasibility of using combined lighting;

c) in accordance with approved industry regulations.

Table 3.4

| Building view | Characteristics of visual work | Smallest size of discrimination object, mm | Visual work category | Sub-sequence of visual work | Normalized value of KEO, e n, | |

| in natural light | with combined lighting | |||||

| Residential, public and administrative | Distinguishing objects with a fixed and non-fixed line of sight: | |||||

| very high precision | From 0.15 to 0.30 | A | 1(70*) | 4,0 | 2,4 | |

| 2(<70) | 3,5 | 2,1 | ||||

| high precision | From 0.30 to 0.50 | B | 1(70) | 3,0 | 1,8 | |

| 2(<70) | 2,5 | 1,5 | ||||

| medium accuracy | More than 0.50 | IN | 1(70) | 2,0 | 1,2 | |

| 2(<70) | 2,0 | 1,2 | ||||

| Review of the surrounding space with very short-term, episodic discrimination of objects: | ||||||

| with high light saturation of rooms | No matter the size | G | — | 3,0 | 1,8 | |

| with normal light saturation of the premises | object | D | — | 2,5 | 1,5 | |

| at low light saturation of rooms | E | — | 2,0 | 1,2 | ||

| General orientation in interior space and movement areas with large and small crowds of people | Same | AND 3 | — — | Not regulated | ||

| Production | Highest precision | Less than 0.15 | I | — | — | 6,0 |

| Very high precision | From 0.15 to 0.30 | II | — | — | 4,2 | |

| High precision | From 0.30 to 0.50 | III | — | — | 3,0 | |

| Medium accuracy | Over 0.5 to 1.0 | IV | — | 4,0 | 2,4 | |

| Low precision and rough (very low precision) work with luminous products in hot shops | Over 1.0 | V, VI, VII | — | 3,0 | 1,8 | |

| General monitoring of the production process: | ||||||

| permanent | VIII | — | 3 | 1,8 | ||

| periodic with constant presence of people in the room | 1 | 0,7 | ||||

| periodic with intermittent presence of people in the room | 0,7 | 0,5 | ||||

| general supervision of utilities | 0,3 | 0,2 | ||||

| * Relative duration of visual work, %. |

3.7.6. In industrial premises of buildings constructed in areas with an average temperature of the coldest five-day period minus 27 ° C and below, as well as in premises in which work of I-III categories is carried out, it is allowed to take the values of combined lighting according to Table. 3.5.

| Due to the large volume, this material is placed on several pages: 2 |

Reviews about light domes

The roof windows are now new. they are very environmentally friendly and economical, and if you have the money to install such lamps, then take a bet and you will not regret it.

Trainee

https://wt-forum.com/index.php/topic/6627/

roof windows. This is a luxury item that gives the design a unique flavor and originality. There are savings on electric lighting, but they pale in comparison to the cost of materials and maintenance that are required for skylights.

Nasta

https://www.interior-design.club/threads/277/

The popularity of roof windows is only gaining momentum, and you can be one of the first to appreciate all the benefits of this technology. The main thing is to find professionals who can qualitatively satisfy your desires.

Source – https://legkovmeste.ru/stroitelstvo-i-remont/kryisha/zenitnyie-fonari-promyishlennyih-zdaniy.html

Device

The main design elements of a spot skylight:

- The base is a “glass” made of rigid, durable material, mounted in the opening on the roof.

- A layer of thermal and waterproofing around the base.

- Frame with thermal break contour - installed on the base.

- A sash filled with light-transmitting material is mounted to a subframe.

- The hinged window is equipped with an opening mechanism.

The following can be additionally installed in the opening:

- A protective grille made of metal rods that protects against accidental falls or intentional entry into the room.

- A protective mesh that protects against splinters. It is installed when the sash is filled with double-glazed windows.

Panel and strip lights are designed similarly. Elevated structures are systems that require special design. They consist of a light-transmitting fence enclosed in a complex frame.