Any plastic structure has its own maximum dimensions - a responsible manufacturer must take this parameter into account. Thus, the maximum sizes of REHAU windows depend on the type of profile and the method of its reinforcement; they cannot exceed strictly defined values. Exceeding them is fraught with the collapse of the structure, which may not withstand heavy wind loads combined with sudden changes in ambient temperature.

Width and Height Options

The maximum dimensions are calculated according to GOST, taking into account the type and thickness of the profile system, the method of its reinforcement and the installed double-glazed window. Maximum dimensions of a plastic window according to GOST for a solid structure without sashes:

- Height - 2755 mm, while the width should not exceed 1770 mm.

- Width - 2670 mm, but permissible only with a height of 1160–2060 mm.

Today's fashionable floor-to-ceiling structures for 2–3 floors in a private cottage or a two-story studio apartment can be made from several double-glazed windows. When determining dimensions, the type of glass matters.

- Tempered glass (thickness 10–15 mm). The maximum size of a plastic window is 5900 x 3150 mm.

- Triplex on thick, tempered glass (13–48 mm). Dimensions 4700 x 2800 mm.

- Non-tempered glass (4 mm). Let's say the size is 3400 x 2800 mm.

It should be noted that transporting and installing non-tempered glass of small thickness is quite problematic. They are fragile and can crack.

+7

Call

Order windows at a profit!

Until the end of the week, 30% discount on windows and balconies!

I want a discount

Decoding the formulas of double-glazed windows for plastic windows

The formula of a double-glazed window reflects its design features. The symbols indicate the characteristics of the glass, spacers and the gas mixture filling the chambers. The decoding of the glass unit formula comes from the outer glass sheet located on the street side. The first symbols are graph paper and the brand of glass, the second value is written through the line - this is the width of the internal frame, the third value is the properties of the second glass, then the width of the second frame comes again, and the third glass (subject to a double-glazed window), located with the “home”, completes the marking sides. Classification of double-glazed windows by the number of chambers and their designations (abbreviations) A formula entry may begin with an abbreviation indicating the number of chambers. If SPO appears at the beginning, this means that the double-glazed window has one chamber. Formulas for double-glazed windows begin with the abbreviation SPD. Here SP is an abbreviation for “double-glazed window,” and O and D are, respectively, “single-chamber” or “double-chamber.”

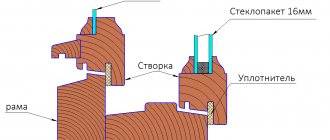

Double-glazed windows A single-chamber double-glazed window is a double-glazed window consisting of two glasses located parallel and hermetically connected by one spacer frame. A double-glazed window is a design consisting of three glasses connected by two frames. For example, this is what the formula for a single-chamber double-glazed window with a width of 24 mm will look like: 4M1-16-4M1 (4 mm is the thickness of the glass, 16 mm is the width of the spacer frame, M1 is the type of glass). If, instead of conventional float glass, energy-saving glass is used, then the formula will look different: 4M1-16-4i (here the internal glass ensures heat retention indoors and protects the space from drafts, resistance to heat loss reaches 0.59 m2 C/W, according to compared to the previous formula - 0.32 m2 C/W). But the calculation of the formula for a two-chamber double-glazed window, 32 mm wide, looks different: 4M1-10-4M1-10-4M1 (the formula already takes into account three glasses and two spacer frames, each 10 mm wide, the thermal insulation is 0.47 m2 C/W) . If we replace ordinary glass with energy-saving glass, we get the following formula: 4M1-10-4M1-10-4i (the principle is the same, the inner glass is indicated by a different marking inherent in energy-saving glass, the thermal insulation increases to 0.64 m2 C/W) . The total thickness of the structure may be indicated in parentheses after the chamber designation. For example, the formula for a 32-mm double-glazed window is SPD(32) 4M1-10-4M1-10-4M1. Here you can see that the product is made up of three 4 mm glasses and two 10 mm frames, totaling 32 millimeters. GOST R 54175-2010 “Glued double-glazed windows. Technical Specifications” also describes double-glazed windows with special properties, which are then displayed in the formula. Their properties can also be included in the abbreviation in the form of letters:

- UD - shock resistant;

- E - energy saving;

- C - sun protection;

- Ш - protected from noise;

- M - frost-resistant.

There are also multifunctional products that combine several properties, for example, energy-saving and noise-proof. These characteristics can be determined by the properties of the glass. Types of glass for double-glazed windows and its markings The formulas of glass in a double-glazed window reflect the thickness of the glass, their brand and characteristics. The belonging of a material to a specific type is indicated by letters, abbreviations or words. Sheet glass

Standard double-glazed windows are made from M1 glass. The characteristics of this type are considered sufficient to ensure the required quality; the use of lower grades is not recommended by GOSTs. This material is transparent, it has a minimum of bubbles and optical distortions. This type of glass product is produced by drawing. In addition to M1, there are M0, M2, etc. The decoding of the glass unit formula includes the thickness of the glass indicated in front of the brand. Glass sheets are used for 4, 6, 8, etc. millimeters. The sheet type also includes float glass, designated by the symbol F or the word float. Float glass is flat and colorless; it differs from ordinary glass in the way it is made: a mixture of silicates is continuously cast onto liquid tin, followed by cooling. When deciphering a double-glazed window, you can see the inscription 6Fjumbo. She's talking about 6mm thick float glass with larger dimensions. Jumbo is a type of architectural glass, the polished sheets of which reach record sizes of 6000x3210 millimeters. Reinforced glass Identified by the letter A. Wire mesh is inserted into the reinforced glass sheet at the production stage. It is made from low-carbon steel and serves to give the finished product safety and fire resistance. In the formula of a reinforced double-glazed window, the glass will come with the prefix “A”. For example: 4A-8-4M1. Self-cleaning glass is also marked with the letter A. Although they are often labeled as Active Clear, there are other properties to keep an eye on to avoid confusion: Wired glass comes in clear, colored, flat, wavy and ribbed - and they all have a mesh inside. Triplex Another name is laminated glass. The material consists of three glass layers, bonded with a special film or specific polymers. Thanks to this, it is able to withstand enormous loads, which classifies it as an impact-resistant product. In the formula for a double-glazed window, triplex is designated as:

- — 3.3.1 (two 3 mm glasses and 1 mm film);

- — 4.4.1 (two glasses of 4 mm each and a film of 1 mm);

- — MS 33.2 (two 3 mm glasses and 2 mm film);

- — Stratobel Clear 3.3.1 (4.4.1);

- — Optilam Clear 3.3.1 (4.4.1).

Depending on the characteristics, triplex can withstand impacts from a hard or soft body and exposure to fire. There are varieties that can protect not only from noise, but also from radiation interference. Tinted glass It is also called colored glass. It is divided into two subtypes: mass-tinted or reflective. Tinted glass is classified as float glass. During production, metal oxides are added to the liquid glass raw material, which gives the finished product the required shade. The most common colors are blue, grey, green and bronze. Designations:

- — Planibel Gray (instead of Gray (gray) there may be a different shade, for example, Bronze (bronze));

- — 4Ton (4T, 4 ton.mass., 4Ton) — thickness and toning without specifying color.

The reflex type has a characteristic mirror effect. Metal oxide is applied to its surface on one side using a pyrolytic method. Example of designation: Stopsol Classic Bronze, where another shade may be indicated instead of Bronze. This type also applies to solar control glass.

Tempered glass To give the glass additional strength, it is tempered in three ways:

- — thermal hardening;

- — heat strengthening;

- - chemical hardening.

Thermal hardening increases safety: when glass breaks, it breaks into small fragments with blunt edges. Hardening takes place in special furnaces. The sheet heats up to 680 degrees Celsius and cools evenly. A product processed in this way is marked with the abbreviation ESG. The heat strengthening process is similar. The main difference is that the cooling stage lasts longer. The resulting material is no longer considered safe: when broken, large sharp fragments are formed that can cut you. Marked as TVG. For chemical tempering, a sheet of glass is placed in a salt solution and heated to a temperature of over 380 degrees Celsius. Under such conditions, sodium ions on the glass surface are replaced by potassium ions, which increases fracture strength and fire resistance. Tempered glass can be marked with the symbols Zak or Z. Solar control glass This type is characterized by an increased ability to reflect or absorb solar radiation. Divided into:

- — tinted in mass;

- - reflex;

- — with a soft coating (has a nanocoating applied by the magnetron method).

Markings found:

- — SunStop;

- — StopSol;

- — ANTELIO;

- - 4SGSolar.

Energy-saving glass Equipped with a soft or hard coating that reflects infrared radiation. Thanks to this feature, white sunlight passes freely into the room, but heat waves remain outside, which keeps it cool in summer. Home heat is also reflected from windows and remains inside, which protects against heat loss in winter. Hard-coated glass is marked with the letter K. The coating is tin or indium oxide applied to a hot glass sheet. Another designation option is Pilkington K Glass. The soft coating is applied using the vacuum-magnetron method. It is a silver oxide that reflects heat waves. This variety is designated by the letters I, I, E, or the words Top, Low-e, Top-N. Other marking options:

- — Pilkington Optitherm S1 and S3;

- — ClimaGard N;

- - CLGuN;

- - ENplus;

- — ZERO (ZERO-E);

- — Futur-N.

The formula for an energy-saving double-glazed window may look like this: 4i-14-4-14-4i where, 4 is the thickness in mm And is the type of glass, in this case it is energy-saving 14 is the width of the internal space The heat transfer resistance coefficient when using such an energy-saving double-glazed window is 0. 92 m2 C/W. Multifunctional glass Or highly selective. Such glasses combine the characteristics of energy-saving and sun protection. This property is achieved through the multi-layer application of special coatings, which completely transmit useful light but reflect heat. Designations:

- — MF;

- — SunCool;

- — ClimaGard Solar;

- - GuSolar;

- — StopReyNeo;

- - SELEKT;

- — LifeGlassGear.

Marking of spacer frames and inter-chamber space in double-glazed windows Spacer frames separate the glass sheets in a double-glazed window. If they are made of aluminum (the most common case), then this is not noted in any way; the formula then reflects only the thickness in millimeters.

If a frame is made with thermal inserts to enhance its protective properties, it is labeled TP or TD, which stands for "thermal distance" or thermal break. They can also be designated by the name of the manufacturer:

- — Termix;

- - TPS;

- - SwiggleStrip;

- — SuperSpacer, etc.

Decoding the marking of a double-glazed window may also include the gas that fills the space between the glasses - the air chamber. If this space is filled with dried air, then no designations are used. If the sealed cavity is filled with an inert gas for better thermal insulation, then the type of substance is indicated:

- — xenon — Xe;

- — krypton — Kr;

- — argon — Ar or A;

- - sulfur hexafluoride - Sf.

Examples of decoding and a table of formulas for double-glazed windows The marking is applied on the product label - this is required by GOSTs. It is also applied to the visible part of the inner frame. The simplest example of decoding: 4M1-16-4M1 is a single-chamber double-glazed window consisting of two 4 mm glasses and a 16 mm aluminum spacer frame. The chamber is filled with air.

Variant of the formula for a 52-mm double-glazed window: SPD (52) 4MF-20Ar-4M1-20Ar-4i - a two-chamber double-glazed window consisting of an external 4-mm multifunctional glass, two chambers filled with argon and separated by simple aluminum frames, an internal simple 4-mm glass and energy-saving 4mm on the home side. The same example of the formula can be demonstrated on a double-glazed window with a width of 40 mm: 4M1-14-4M1-14-4M1. In the formula of a soundproofing double-glazed window, the width of the internal space (distance frame) and the thickness of the glass themselves play an important role; there are no special markings here: 4M1-12-4M1-8-4M1. In this formula of a sound-absorbing double-glazed window, its main quality is achieved by different distances of glass, shifted closer to the “home” glass - 12 mm and 8 mm. With such a double-glazed window, sound insulation reaches 39 dB. There is another option to achieve high soundproofing characteristics of a double-glazed window, for example: 6M1-10-4M1-6-4i. Here we see that glasses of different thicknesses are used (6 mm and 4 mm), as well as types (M1 and I-glass, energy-saving), the distance is also different - 10 and 6 mm.

Why know the permissible size of plastic windows?

You need to know the approximate parameters of window units when planning glazing in a house or industrial premises, wanting to install plastic partitions with doors, as well as for those who are considering the option of panoramic French glazing of a loggia. It is important that the maximum sizes of REHAU windows are quite large and largely depend on the profile used. In general, the largest window cannot be a structure with a height of more than 6000 mm and a width of more than 3210 mm. At the same time, when glazing high-rise buildings, this value is less - the presence of strong wind affects it.