STATE STANDARD OF THE USSR UNION

WOODEN WINDOWS AND BALCONY DOORS WITH DOUBLE GLAZING FOR RESIDENTIAL AND PUBLIC BUILDINGS

Types, design and dimensions

GOST 11214-86

State Construction Committee of the USSR

Moscow - 1986

INFORMATION DATA

DEVELOPED by the State Committee for Civil Engineering and Architecture under the USSR State Construction Committee

PERFORMERS

I. V. Strokov

(topic leader);

B. A. Filozofovich

;

I. S. Poselskaya

;

G.G.

Kovalenko ;

N. N. Tsaplev

, Ph.D.

tech. sciences; A. V. Tkachenko

;

G. V. Levushkin

;

N.V.

Shvedov INTRODUCED by the State Committee for Civil Engineering and Architecture under the USSR State Construction Committee

Deputy Chairman M.P. Kokhanenko

APPROVED AND ENTERED INTO EFFECT by Resolution of the USSR State Committee for Construction Affairs of November 14, 1985 No. 191

STATE STANDARD OF THE USSR UNION

WOODEN WINDOWS AND BALCONY DOORS WITH DOUBLE GLAZING FOR RESIDENTIAL AND PUBLIC BUILDINGSTypes, design and dimensionsWooden windows and balcony doors of double glazing for dwelling and public buildings. Types, structure and dimensions | GOST 11214-86 Instead of GOST 11214-78 |

By Decree of the USSR State Committee for Construction Affairs dated November 14, 1985 No. 191, the introduction date was established

from 01/01/87

This standard applies to wooden windows and balcony doors with double glazing intended for residential and public buildings, as well as for auxiliary buildings and premises of enterprises in various sectors of the national economy.

TYPES, SIZES AND GRANDS

1.1. Windows and balcony doors manufactured according to this standard are divided into types:

C - with paired wings and door panels;

R - with separate doors and leaves.

1.2. The overall dimensions of windows, balcony doors and the dimensions of openings for them must correspond to:

for residential buildings - indicated on the drawing. 1 and Appendix 1;

for public buildings - indicated in the drawing. 2 and in Appendix 2.

Windows and balcony doors are shown in the devil. 1 can also be used for public buildings.

1.3. Windows sizes 9-13.5; 12-13.5; 15-13.5; 18-13.5 and 21-13.5 modules (module M-100 mm) for filling openings in walls made of non-modular bricks of facing masonry, at the request of the consumer, it is allowed to produce a width of 80 mm more than specified, due to the increase in wide sashes, and the window size is 15-6 modules - the width is 70 mm less than specified, and the marking is changed accordingly to 9-14; 12-14; 15-14; 18-14; 21-14 and 15-5.

1.4. For residential buildings erected in climatic region IV, it is allowed to use narrow sash windows (without a window).

1.5. At the request of consumers, single-leaf windows and balcony doors, incl. with window sashes and transoms, should also be made on the left, and multi-leaf windows with an asymmetrical pattern - in a negative image.

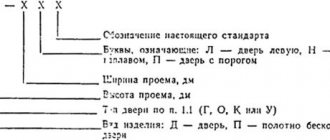

1.6. The following structure of the symbol (brand) of windows and balcony doors is established:

At the end of the brand of windows and balcony doors with single glazing, before the standard designation, add the number 1 through a dash.

An example of a conventional designation for a type C window for an opening 15 dm high and 9 dm wide, with right-hand hinged sashes:

OS 15-9 GOST11214-86

The same, with the left hinged door:

OS 15-9L GOST11214-86

Right balcony door type C for an opening 22 dm high and 9 dm wide:

BS 22-9 GOST11214-86

The same, type P window for an opening 18 dm high and 18 dm wide, with an asymmetrical window pattern (option B):

OR 18-18V GOST11214-86

The same, in negative image:

OR 18-18VNGOST 11214-86

The same, type C windows for an opening with a height of 15 and a width of 13.5 dm, with a window sash:

OS 15-13.5GOST 11214-86

The same for the right balcony door type C for an opening 22 inches high and 7.5 inches wide with a right door hinge:

BS 22-7.5 GOST11214-86

The same for the left balcony door:

BS 22-7.5L GOST 11214-86

Plastic or wooden structures?

The popularity of plastic windows is due to their tightness and long service life. Wooden structures manufactured in accordance with the requirements of regulatory documents are in no way inferior to plastic ones.

Double glazing:

- Provides soundproofing characteristics of the structure. Even if the windows/balcony overlook a busy street, a properly installed structure will prevent extraneous sounds from penetrating into a public or residential building.

- Guarantees a high level of thermal insulation of the room and energy saving.

- Reduces the amount of condensate formed during operation.

Plastic construction

The wood used to make the frame is treated to ensure long service life of the installed structure. There is no need to fear that after some time the box will lose its shape or change size due to exposure to precipitation.

Wooden structure

Considering that natural material is used for production, the design is safe for humans. Wooden frames fit harmoniously into any room.

LOCATION OF DEVICES IN WINDOWS AND BALCONY DOORS (examples)

1 — hinge PV1-100 for internal sashes and leaves of types C&R; 2 — hinge PV2-100-1 for external doors and leaves of type P; 3 — loop PV3-1 for type C; 4 — ST coupler for type C; 5 — stop OU for type P; 6 — wrapping ЗР2-1

Crap. 1

1 — hinge PV1-100 for internal sashes and leaves of types C&R; 2 — hinge PV2-100-1 for external doors and leaves of type P; 3 — loop PV3-1 for type C; 4 — loop PV2-100-2 for transoms; 5 — transom device PF2; 6 - clamp FK1 for type C or FK3 for type P; 7 wrapping ZR2-1; 8 — ST coupler for type C; 9 — stop OU for type P; 10 — PC80 handle.

Crap. 2

Notes damn it. 1 and 2

1. Devices for windows and balcony doors must comply with GOST 538-78, GOST 5087-80, GOST 5088, GOST 5090-79 and GOST 5091-78.

2. External sashes must be hung on type PV2 hinges with removable rods.

3. The screws are shown in the open position.

4. PC80 handles are installed on external doors on the outside of the building at a height of 1000 mm from the threshold.

5. The transom device is shown conditionally.

6. Squares are installed in accordance with clause 2.13 of GOST 23166-78.

7. ST ties are placed on the doors from the side of the room.

8. The clamps are installed on narrow sashes of windows in residential and public buildings.

9. In the case of using wrappers with removable handles of type P2, the number of handles per product is established by agreement between the manufacturer and the consumer, but not less than one.

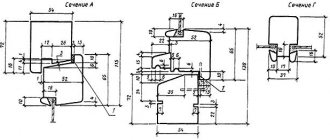

Technical requirements

The product manufacturing standard must comply with the requirements of GOST 23166 (from 1999). The technological part contains architectural drawings of the manufactured product, requirements for the dimensions of all elements forming the structure. For example, when the doors swing open, it is necessary to install a special device that provides tilt or tilt-and-turn opening.

Depending on the chosen design solution, the standard prescribes the procedure for hanging the sashes. If we are talking about a single system, the fastening is carried out directly to the box. In this case, loops that are suitable in size and characteristics are selected. This option is applicable when glazing an internal opening, when performing repairs in an unheated room.

With a large number of sashes, but separated, separate hinges are used to fasten each leaf. Installation of locks and handles is also carried out on each sash separately. Regulatory documentation allows for the installation of a removable handle or the connection of blades using special connectors. This option involves installing handles only on the inner panel.

If we are talking about paired sashes, hinges of various types are used, allowing you to hang the outer leaf on the inner one. To ensure stable operation of the structure, additional fastening of the canvases is provided through a number of elements, which are latches, screws or screws. Handles and latches are installed only on the inner panel.

The number of hinges directly depends on the dimensions of the sash. If the height and width exceed 1.4 m and 0.7 m, you will have to use three loops. The door leaf has three hinges for any size.

Three hinges are required for a door leaf

Attention! The standard limits the maximum design weight of opening elements to 80 kilograms. If this indicator turns out to be higher for a particular window before installation, you will have to perform calculations to confirm the strength characteristics of the manufactured product or conduct laboratory tests.

To ensure strong fixation of glass in the frame, waterproof sealants are used. If you give preference to other materials, you may encounter serious difficulties during operation. Direct exposure to precipitation will cause the structure to lose its tightness over time.

There are requirements for the connection of individual frame elements. Regardless of where the joint is formed, in the corner or in the middle, the elements are connected using straight tenons. The use of other connection options is permissible only when they do not reduce the strength characteristics of the corner connection and do not reduce the service life of the product as a whole. Requirements for connection parameters must be specified in the design documentation developed for a specific product.

Proper care

The service life of the installed system largely depends on the correct care of all structural elements. Attention should be paid to:

- accessories;

- window surfaces;

- seal.

Maintenance of structural fittings

The condition of the fittings affects the smoothness of opening and ease of locking. In order for the sash or door leaf to function correctly, do not forget about the rules:

- Lubricate moving parts annually with machine oil, adding a small amount between rubbing parts.

- For washing, use only delicate detergents, since aggressive compositions, including those containing solvents, reduce the service life of the fittings.

- Check that there are no foreign objects between the frame and the sash.

- Avoid hanging heavy objects that can increase the weight of the sash and the load on the installed fittings.

- Entrust the adjustment of fittings to professionals or carefully prepare for the work.

Hinges require periodic lubrication

Surface care

Considering that the structural elements are made of wood, it is recommended to take care of the frame responsibly. When cleaning you should:

- use water and soap solution;

- stop using solvents and compounds that can damage the decorative coating;

- choose a soft cloth and avoid hard brushes.

To ensure a long service life of the installed structure in the event of minor damage, it is recommended to use varnish and polish to treat wooden surfaces. The composition is applied to a completely dried surface, which must be degreased. It is recommended to promptly update the condition of the paintwork. Windows are painted every 10-15 years. However, it is recommended to constantly monitor the condition of the coating. If, after visual inspection, it is determined that the coating requires updating, it is worth doing this without waiting for a ten-year period.

Timely care

Seal care

Silicone or rubber material is used for sealing. It ensures the required tightness of the installed structure. To ensure that the seal lasts as long as possible, it is recommended to promptly remove dirt with a soft cloth. If the contamination is severe, use a soap solution. After cleaning, lubricate the seal with a substance containing glycerin.

Installation of the structure

The installation sequence depends on the characteristics of the opening and the material used in the construction of the walls. All work begins with the installation of the window sill. To ensure the correct spatial position, prepare a cement pad that will level the base under the window sill in a horizontal plane.

If it is decided to make the window sill attached, then its installation is carried out at the last moment. The feasibility of installing such a window sill needs to be carefully analyzed. The design is less durable, especially with relatively small wall thicknesses. In this case, the installation speed will not be reduced.

The standard thickness of the window sill is 3-5 cm. If it is decided to give preference to a thicker material, this fact is taken into account when determining the height of the mounted structure. For fixation, 3-4 nails or 6 mounting nails are used. When using mounting nails, mounting holes are drilled in the window sill, the diameter of which is equal to 3/4 of the diameter of the fastening element. 15-20 cm retreat from the edge of the opening.

The window sill is installed so that its outer edge of the frame coincides with the edge of the board being mounted. The fasteners are placed at a distance equal to 1.5 times the thickness of the board being installed. Before installation, the structure to be mounted is prepared: the sashes with glass and hinges are dismantled, leaving only the frame.