Home |GOSTs and SNiPs |GOST 948-2016. Reinforced concrete lintels for buildings with brick walls. Specifications

Date: January 11, 2018

Comments: 0

Reinforced concrete factories produce various types of products, including reinforced concrete lintels. They are used to increase the load capacity of openings in brick and block buildings. Beams are made from heavy grades of concrete, reinforced with steel reinforcement and are able to maintain integrity under the influence of bending loads. Previously, products were manufactured in accordance with the requirements of the standard registered under number 948 84. GOST was updated in 2016 with the assignment of number 948-2016. Let's consider the main provisions of the standard.

GOST for jumpers - structure of the standard

The updated version of the interstate standard contains information on the following issues:

- area of product use;

- terminology used;

- product classifications;

- sizes of reinforced concrete lintels for windows and doors;

- main product parameters;

- technical requirements;

- acceptance and control methods;

- marking features;

- organization of transportation and storage.

Let us dwell in detail on the main points of the regulatory document.

Reinforced concrete has found widespread use in modern construction

Reinforcement of reinforced concrete products

The choice of reinforcement type and rod diameter depends on the type of lintel. According to GOST, for reinforced concrete lintels used in private construction, prestressed reinforcement with a diameter of 6 to 8 mm is used. For floors designed for heavy loads, reinforcement of a larger diameter is used.

For longitudinal reinforcement the following is used:

- heat-strengthened steel type At800 or At600C, hot-rolled steel rod of class A800 or A600 can be used as prestressing reinforcement;

- non-prestressed reinforcement is made of steel A400 or A500, heat-strengthened steel At-IIIC, wire B500 or BP500.

For the manufacture of transverse parts of the frame for reinforced concrete, hot-rolled steels A240, A400, A500, reinforcing wires B-500, BP500 are used. When making bar or slab elements of standard sizes, it is necessary to take into account that with a thickness of 12 cm a flat steel frame is made, and with a thickness of 25 cm a spatial frame is made.

When stressing the reinforcement, it is necessary that the actual deviations in the reinforced concrete do not exceed the values indicated in the table:

Name Geometric parameter Limit deviation, mm

| Deviation from linear size | Length: up to 2500 inclusive over 2500 up to 4000 inclusive over 4000 Width and height: Size that determines the position of: protrusions, recesses and holes of embedded products: in the plane of the lintel from the plane of the lintel | ±6 ±8 ±10 ±5 5 3 |

| Deviation from straightness | Straightness of the front surface profile: up to 2500 long at a given length 1000 long over 2500 to 4000 over the entire length over 4000 long over the entire length | 3 ±3 ±4 |

Before pouring, steel reinforcement rods are laid along the formwork and secured with wire to form a strong reinforcing mesh. The cells of the resulting frame should be 20-50 mm, this is the optimal indicator for ensuring the required strength.

Concrete lintels - purpose of products

In its main sections, the standard classifies products by type, contains information on the main parameters, technical requirements, and also regulates the dimensions of reinforced concrete lintels.

The high strength properties of crossbars reinforced with a reinforcing frame allow them to withstand bending loads in the openings of various buildings made from the following building materials:

- baked brick;

- natural stone;

- concrete blocks.

Purpose of reinforced concrete beams:

- compensation of existing loads;

- strengthening of various openings;

- formation of a supporting plane during the construction of walls;

- installation of jumpers over doors and windows.

The increased strength of reinforced concrete crossbars, due to the use of durable concrete, allows solving a wide range of problems in the construction industry.

When constructing buildings from piece materials (brick, cinder block, aerated concrete blocks), it becomes necessary to block door and window openings

Formwork and its strengthening

The technology also makes it possible to fill beams directly above the opening.

To ensure the strength of concrete structures reinforced with steel reinforcement, formwork from the following materials is assembled in the opening area:

- metal sheets;

- wooden boards;

- moisture-resistant plywood;

- particle boards.

The height of the lintel is selected based on the calculated load on the opening.

A form is assembled from blanks, which is fixed with wire or bars against possible deformations during concreting. It is important to think about how the formwork structure will be disassembled after the crossbar has hardened. For this, a polyethylene film is used, which is placed inside the mold or the metal surface is lubricated with oil. A reinforcement cage is placed inside the formwork, which ensures the integrity of the structure and prevents displacement. Vertical supports should also be provided for additional fastening of the form.

Features of the beam device

Reinforced concrete lintels according to GOST 948-2016 include:

- spatial frame made of steel reinforcement, increasing rigidity and strength characteristics;

- branded concrete, the frost resistance of which is regulated by the standard for various climatic conditions;

- sling eyes or holes that facilitate the transportation and lifting of products with increased weight.

The products can be used in harsh climates with outside air temperatures of 40 degrees Celsius below zero. If it is necessary to manufacture beams intended for use in seismically active areas, the technical requirements are specified in the order. It must comply with the design documentation for the building. Products for use in aggressive conditions are also manufactured according to individual customer requirements.

Useful tips

When performing work, pay attention to the following points:

- the height of the beam, which must be at least 5% of the height of the opening;

- the width of the structure, which must rest completely on the surface;

- diameter of reinforcement cage rods, ranging from 10 to 14 mm;

- immobility of the structure, which can be loaded a month after pouring;

- quality workmanship and reliability of installation, guaranteeing the absence of cracks;

- thorough compaction of the concrete mixture to remove air pockets.

In the process of manufacturing and installation of concrete crossbars reinforced with reinforcing mesh, one should be guided by the provisions of the regulatory document. The products are in demand in the construction industry and provide an increased margin of safety, as well as durability of building structures. When designing, it is necessary to focus on the provisions of GOST 948 84. This will avoid problematic situations associated with the formation of cracks and violation of the integrity of building structures.

Reinforced concrete lintels according to GOST 948-2016 – classification

According to GOST 948-2016, jumpers have different markings. They are classified as follows:

- products with the designation PB. These are timber elements having the shape of a parallelepiped with a maximum cross-sectional width of 25 cm;

Lintels are reinforced concrete beams resting on the masonry walls and transferring to them the load of the masonry and floors overlying the opening.

- products marked PP. Externally they resemble a stove. They have an increased width, the minimum value of which exceeds 25 cm;

- crossbars with PG index. A special feature of these reinforced concrete products is a longitudinal groove to facilitate joining with floor slabs;

- façade type lintels, marked with the letters PF. They also have a quarter recess and provide covering of openings from the front of the house.

The standard tables systematize the dimensions, design loads, masses and material consumption of all types of products. Block and slab beams can be manufactured with sloped end planes, as well as side faces, with a slight reduction in the dimensions of the supporting surface.

Types of products

The lintels used for arranging brick walls are different:

- reinforced concrete,

- metal (made from channel and corners),

- brick,

- wooden,

- cellular prefabricated,

- reinforced brick.

Reinforced concrete

Reinforced concrete products are prefabricated and monolithic. Prefabricated ones include the following types:

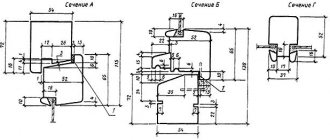

bar (PB) of square or rectangular cross-section (maximum width – 250 mm, length – 1031-5960 mm);- slab (PP), two options in width (1 – 381 mm, 2 – 511 mm), height (141-221 mm) and length (maximum – 2981 mm);

- beam (PG), with a stepped section (a protruding flange for supporting the floor slab), width 250, 380, 510 mm, length - 1550-5950 mm.

There is also a facade type of lintel, but experts often classify it as PG, but with a slight difference - at the ends the shelf is made with recesses, and is clearly visible from the facade.

PP and PB are considered interchangeable . They have identical height and length, but differ only in width. This option is used if there are no slab-type lintels available at the construction site.

Monolithic lintels are installed in the wall itself using formwork. At the same time, they calculate the height of the structure (1/10-1/12 of the opening dimensions), with mandatory reinforcement (metal rods with a diameter of up to 12 mm).

The reinforcement is poured with a concrete composition with a thickness of at least 20 mm.

Metal

For such jumpers, rolled steel is used . They can make floors of 2-5 m, and they can be laid in both load-bearing and non-load-bearing parts. For brick walls, along with reinforced concrete products, this is one of the ideal options.

This product will withstand very heavy loads, as it is durable. Since such jumpers can be of any length, there are no questions when arranging openings of non-standard width.

Steel corners have a number range; numbers 10-12 are especially recommended .

Brick

They can be arranged in a straight line or curved (arch). The rectangular version is laid on the formwork, according to the rules for laying and tying bricks. Here you can create a wedge shape along the vertical seams of the masonry.

It is necessary to ensure that the seams are inclined and there is no vertical movement of the bricks. The work must take into account the width of the opening.

The curved lintel is laid using a wedge method, with emphasis on compression. Arched segments are obtained due to special laying with an edge, where the seams of the laid bricks open up.

The lifting booms are located in the range of 1/6 - 1/10 of the opening width. Curvilinear arches are laid out on a specially made circle - an arched device made of metal or plywood.

In practice, a metal circle for arches is more preferable, since its shape is easy to align or bend.

Wooden

This type of lintel is made from good quality boards, special plates and logs with edging and timber.

The ends of such structures are embedded into the wall, no less than 25 cm. Wooden lintels are easy to build with your own hands. They can last for many years (more than 50 years), but must be insulated from moisture penetration.

Therefore, when installing them, the products must be wrapped in insulating material (made of polypropylene, rubber, roofing felt, polyethylene). In modern construction, such floors are used less and less, despite their most affordable cost, since products made of reinforced concrete and metal are more durable.

Cellular prefabricated

Such products are made from cellular concrete , which can be reinforced and arched. The height of such a lintel is 125 mm, and the depth of its support is 200-250 mm. This type of lintel for brick walls is not yet very common.

Many experts believe that this material is more suitable for a wall built from the same cellular concrete.

Reinforced brick

They are made of brick and reinforcing metal components - hence their name. They are created according to the same principle as brick ones - straight or arched.

The reinforcement used in their arrangement is 6-10 mm. It is laid in formwork, filled with concrete solution. This protects them from corrosion.

There is another way of laying this type - in the form of a collapse vault. Only a professional can perform this method.

Each of the listed types of jumpers is good in its own way . Which one is suitable in each specific case depends on the time of construction (renovation of an old building, new building), additional materials used, in addition to bricks, the existing plan and structure diagram (drawing), the wishes of the customer and the material component.

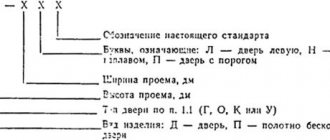

Marking of reinforced concrete lintels

All products manufactured in accordance with the requirements of the standard are marked with paint on the top surface or on the end surface. Marking is carried out by the manufacturer in the form of an alphanumeric index.

It contains the following information:

- serial number of the section corresponding to certain dimensions;

- type of reinforced concrete product according to classification;

- the length of the crossbar, expressed in decimeters, rounded to the nearest whole number;

The main parameters of prefabricated products are determined by GOST “Reinforced concrete lintels for buildings with brick walls”

- calculated load value given in kN/m;

- class of reinforcing bars used (for stressed structures);

- data on sling eyes and fastening elements;

- information about the possibility of using beams in special conditions.

Additional information about sling elements and anchor outlets is indicated by the following letters:

- the lowercase letter “a” confirms the presence of protruding rods for fixing the balcony slabs;

- the designation “b” indicates the presence of sling eyes attached to the embedded elements.

A number of capital letter indices confirm the possibility of long-term operation of reinforced concrete structures in extreme conditions:

- “C” – carries information about the possibility of use in earthquake-prone areas;

- “P” - denotes high density concrete used for aggressive environments.

Using the example of a reinforced concrete beam with the designation 5PB 21-27 A800-a, we will determine the main characteristics of the product:

- 5 – profile section number corresponding to dimensions 220x250 mm;

- PB - designation of a block-type structure;

- 21 – length expressed in decimeters, actual size is 2070 mm;

- 27 – rounded value of the design load in kN/m (according to the table 27.46 kN/m);

- A800 – classification of longitudinally located prestressing reinforcement;

- a – the presence of protruding parts of reinforcement for fastening reinforced concrete elements.

Knowing the meaning of the label, it is easy to determine the main performance characteristics of the product.

When pouring lintels, use heavy concrete with a density of 2200-2500 kg/m3

Rolled steel lintels

An alternative to precast concrete lintels are rolled steel lintels. They allow you to cover openings with a width of 2 to 5 meters, and can be laid in a load-bearing or non-load-bearing wall. At the same time, the wall material is any small-sized: brick, small blocks, ceramic stone. Lintels made of rolled steel are not heavy, they can be delivered to a construction site without the use of lifting and transport mechanisms, unlike reinforced concrete products. Also, the advantages of lintels made of rolled steel include the fact that they can be of any length, and, therefore, the issue of openings of non-standard width is easily resolved. In addition, such lintels are selected for any section of the masonry wall.

Schemes for installing lintels made of rolled steel: 1 - brickwork; 2- corners.

Corners are most convenient as jumpers. For example, corners No. 10-12 are suitable for a 1.5-meter opening. Based on the idea shown in the figure, it is not at all difficult to develop design solutions for other sections or wall materials.

Lintels made of rolled steel are durable, but their durability is lower than reinforced concrete lintels. Another question is that if the technology for laying steel lintels is violated, cold bridges can form, since the thermal conductivity coefficient of steel is quite high.

Concrete lintels - dimensions, weight and loads

Regulates the dimensions of the jumper GOST 948-2016. Dimensions in comparison with GOST 948 84 are completely the same. So when selecting beam sizes, you can be guided by the old and new versions of the standard. The standard tables show the dimensions and weights for each type of beam.

Characteristics of PB beams:

- length – 1.03–5.96 m;

- width – 12 and 25 cm;

- height – 6.5–58.5 cm;

- weight – 0.02–2.175 t;

- load – 1-51.5 kN/m.

Parameters of PP products:

- length – 1.16–2.98 m;

- width – 38 and 51 cm;

- height – 6.5–22 cm;

- weight – 0.072–0.835 t;

- load – 3-71.5 kN/m.

For lifting, the structure has sling holes or holes, as required by GOST

The dimensions of the PG jumpers with a weight of 0.357-2.465 tons are:

- length – 1.55–5.96 m;

- width – 25, 38 and 51 cm;

- height – 29–58.5 cm;

- load – 8-72.5 kN/m.

Products with the PF index at a constant width of 25 cm are characterized by the following parameters:

- length - 0.77–4.28 m;

- height – 14–29 cm;

- weighing – 0.045–0.458 t;

- load – 2–12 kN/m.

Correctly selected jumpers, thanks to the increased safety margin, can maintain integrity under the influence of bending forces. Using the standard tables, you can select a product to solve specific problems.

Tips and secrets

Recommendations for performing installation work:

- beams are selected taking into account the size of the opening, their height corresponds to 5% of the height of the window or door;

- the diameter of the frame rod is selected taking into account the intensity of the load, it can vary between 10-14 mm; for the construction of low-rise buildings, the average value is used; to strengthen internal openings, the thinnest reinforcement is used;

- you cannot use beams that correspond to the width of the opening or slightly overlap it; the margin along the length of the lintel must be significant; they often create a concrete belt around the perimeter of the object;

- it is impossible to continue work until the cement has completely hardened, vibrations, constant damage to hardening products - these negative factors will contribute to a decrease in the quality of the finished beams;

- It is important to install the supports correctly; several pieces are used, since concrete creates a load of more than 2 tons per 1 m³.

The welding method should not be used when installing the reinforcement cage. This may cause a reduction in the service life of the structure. If beams are made when air humidity levels are high, there is no need to additionally wet them.

Products are sprayed with water in the summer when the heat is intense. Starting work before the concrete in the formwork has dried will lead to the loss of properties of the material.

General technical requirements

The regulatory document regulates the following technical requirements for products:

- the possibility of reinforcing concrete with stressed and unstressed thermally strengthened, as well as hot-rolled reinforcement of various classes;

Brands of serial products consist of two or three groups and fully characterize reinforced concrete lintels: dimensions, load-bearing capacity, cross-section, etc.

- use for the manufacture of heavy concrete mix products with a density of 2.2–2.5 t/m3;

- maximum deviations in product dimensions are no more than 1 centimeter in length and 0.5 cm in height and width;

- the use of concrete marked for frost resistance from F50 to F200 depending on the operating temperature conditions;

- ensuring the required thickness of the protective layer to prevent corrosion of the reinforcement cage.

All products manufactured by reinforced concrete enterprises are tested according to the current GOST for strength, frost resistance, moisture resistance, water absorption, and rigidity. The probability of crack formation under the influence of control loads is also controlled. Tests are carried out after the final hardening of the concrete and its operational strength. Products that have been tested and accepted by the technical control service are given a special mark.

How to make a jumper yourself

Sequencing:

- Creating a sketch of the bar and shape.

- Polyethylene is placed in the finished form. This material has a smooth surface, is not a porous coating, and therefore is easily separated from the concrete during the extraction process.

- Rods are prepared (diameter 10-12 mm), the length is determined by the dimensions of the beam.

- A frame is created from reinforcement: you need to make a lattice of 4 longitudinal rods, they are connected with wire.

- The metal structure is installed in the finished form, but it must be placed on pads from below, which will ensure the same distance from the frame to the top and bottom edges of the beam.

- A solution is prepared (the ratio of components is standard).

- The form is filled with concrete.

- The top of the structure is covered with polyethylene.

- The concrete is periodically moistened.

It will take 1 month to harden, after which the product can be removed from the mold.

Laying formwork, reinforcement

The molding structure performs the function of formwork. Boards are prepared for this. If you plan to fill at height, it is better to use metal, but it is acceptable to use plywood, wood and particle boards. The structure must be strengthened. For this reason, you need to create a mold with walls at least 20 mm thick.

Nails are used to secure wood; the metal is secured with self-tapping screws. When the formwork is created in weight, the lower shield is first installed (it extends beyond the opening); horizontal - supported by supports.

To reduce heat loss from the room, it is recommended to insulate the lintel. Mineral wool, expanded polystyrene or polystyrene are considered as thermal insulation materials. Recommended thickness is 100 mm.

Pouring concrete

To prepare the solution, use concrete M200 or M250. The proportions of crushed stone, sand, cement are 2:5:1. It is better to mix the components in a concrete mixer. This creates an even mixture. When mixed independently, the solution is compacted to eliminate air. When the reinforcement frame is installed on the bottom of the formwork (on supports up to 200 mm high), the container is filled with mortar.

How to properly store and transport beams

The storage conditions of finished products, the specifics of storage, as well as proper transportation determine the possibility of using beams at a construction site.

Certain conditions must be met:

- store and transport beams, ensuring their immobility, in a position appropriate for the worker;

- stack products in compliance with the maximum height, which should not exceed 2 m;

- avoid contact of beams by installing wooden planks more than 2.5 cm thick between them;

- transport beams with lifting devices using sling eyes.

Only with products that have achieved operational characteristics can loading and unloading operations be carried out and transported.

General characteristics

Products based on concrete and steel are widely used in private housing construction, due to their strength, durability and performance characteristics. The weight of the product depends on its dimensions.

Despite the weight, the finished product can be used in the construction of houses from:

- monolithic concrete;

- foam concrete;

- bricks

The supporting length for load-bearing lintels varies between 17-30 cm, for non-load-bearing lintels – 10-15 cm

Installation

To install lintels over openings, certain rules must be followed to avoid distortion and cracking. In private construction, elements less than 2 m long can be installed manually; for large openings a truck crane will be required. Installation depends on the type of jumpers:

- PB - used in openings of load-bearing walls, since they have increased bending strength and take on the load of the upper floors.

- PP are less durable, so they are placed on a self-supporting wall, taking the load only of the wall against which they rest.

Installation is carried out after completion of the masonry, at the marks approved in the project. Before this, the reliability of the surface and the level of the exposed masonry are checked.

During installation, it is important to correctly determine the depth to which the lintel is supported. This figure for a load-bearing wall must be at least 250 mm on each side, and for self-supporting walls 120 mm is sufficient. To cover the entire width of the masonry, several reinforced concrete bars are laid, but they should not extend beyond the plane of the wall.