April 25, 2014

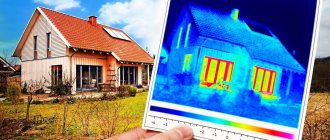

Rising prices for energy resources and utilities pose a challenge to rational owners: how to ensure warmth in the home in winter and pleasant temperature in summer with minimal losses, how to create a comfortable indoor microclimate without drafts and street noise. One solution to the problem is to use a thermal unit in window structures instead of conventional double-glazed windows.

What is Stis heat package

The StiS thermal package is a unique product that was introduced to the Russian market by the group in 2006. It is a double-glazed window made using a special technology and possessing unique properties.

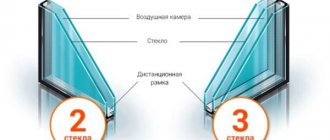

Just like a conventional double-glazed window, the StiS thermal package consists of two sheets of glass connected along the contour using an aluminum spacer frame and sealants. A closed sealed chamber is formed between the glasses, which is filled with dried air or inert gas. The difference lies in the details:

1. Energy saving glass

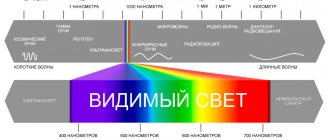

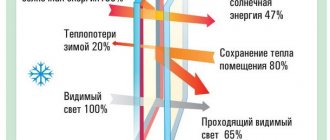

StiS thermal packages use glass with a low emissivity coefficient. In physics, the emissivity of a material is understood as the ability of a material to absorb and emit thermal energy. The lower the emissivity coefficient, the less heat is generated by its surface. To give the glass energy-saving properties, a unique multilayer coating containing silver atoms is applied to its surface. As a result, i-glass allows short-wave solar rays to pass into the room, but prevents long-wave thermal radiation from heating devices from escaping.

Glass in StiS thermal packages performs the function of a thermos. They do not heat the room, but prevent the loss of heat present inside. In the summer heat, i-glass is just as effective at keeping cool air out, allowing you to maintain an optimal microclimate.

Coated glass is exceptionally transparent; externally, double-glazed windows with regular and i-glass cannot be distinguished from each other.

2. Frame with thermal break

Conventional bags use an aluminum spacer. Aluminum is a material with very high thermal conductivity, so the coldest place in the window is considered to be the edge zone. It is along the edge that fogging and freezing of the glass unit occurs. It is impossible to completely abandon the use of aluminum, since this material has the ability to firmly adhere to glass and has the same dimensional parameters as glass when the temperature drops, which prevents the glass block from coming apart.

The StiS thermal package with a combined spacer frame provides absolute protection against fogging and freezing, providing windows with a long service life (guarantee - up to 20 years).

3. Inert gas in inter-glass chambers

To increase thermal efficiency, heat packages are filled not with ordinary dried air, but with an inert gas - argon. The use of gas increases the energy-saving properties of windows by 5-10%, however, as evidenced by expert reviews, it is justified only in harsh climatic conditions.

Comparison of double glazed windows

For the smart ones, a more detailed comparison, with numbers and other coefficients:

| Number of cameras | NAME | FORMULA | Light transmittance LT % | Heat transfer resistance Ro mꙇ2•°С/W | Solar factor SF% | ψ Linear heat transfer coefficient W/m•°С | UV Ultraviolet transmittance % |

| 1-room | Regular double glazing | 4-16-4 | 82 | 0,33 | 78 | 0,06 | 53 |

| 1-room | Lifeglass TM | 4LifeglassClear-16-4 | 75 | 0,56 | 49 | 0,06 | 30 |

| 1-room | Heat package S | 4-16TSS-4И | 82 | 0,56 | 65 | 0,03 | 35 |

| 1-room | Heat package 2.0 | 4SPGU-16TSS-4 | 74 | 0,57 | 45 | 0,03 | 22 |

| 1-room | Heat package DS | 4DSCD-16TSS-4 | 72 | 0,6 | 38 | 0,03 | 13 |

| 2-room | Regular double glazing | 4-10-4-10-4 | 74 | 0,47 | 70 | 0,06 | 45 |

| 2-room | Lifeglass TM | 4LifeglassClear-10-4-10-4 | 69 | 0,65 | 46 | 0,06 | 25 |

| 2-room | Heat package S | 4-10TSS-4И-10TSS-4 | 75 | 0,7 | 59 | 0,03 | 26 |

| 2-room | Heat package 2.0 | 4SPGU-10TSS-4-10TSS-4 | 67 | 0,71 | 43 | 0,03 | 19 |

| 2-room | Heat package DS | 4DSCD-10TSS-4-10TSS-4 | 65 | 0,75 | 35 | 0,03 | 11 |

Thermal package or double glazing. What to prefer?

Installing plastic windows is a serious undertaking, which largely determines the indoor microclimate and the amount of electricity and utility bills. When deciding which package to choose, consider the following.

In terms of its ability to retain heat, a single-chamber heat package is superior to a two-chamber one. At the same time, it is lighter than the latter, which means it places less load on fasteners and fittings, thereby increasing the service life of window structures.

If you decide to order plastic windows to reduce the noise level in your home, it is better to install a two-chamber package with internal energy-saving glass. Sound absorption is affected not so much by the thickness of the glass as by the number of cameras in the package and the different widths of the spacer frame.

The thermal package allows:

- reduce heating costs by up to 70%

- use air conditioners less often in the warm season, which is especially valuable in regions with a continental climate (cold winter, hot summer)

- create a favorable microclimate without convection drafts and dampness

- turn the cost of installing windows into investments - the warranty period for thermal packages is 4 times longer than the warranty for conventional windows (20 versus 5 years)

StiS heating packages are the best solution for those who know how to count money!

Services and service Warranty

- Guarantee

- Payment Methods

- Production time

- Calculator

- Order from A to Z

- Certificates and licenses

- 08 May 2014

Accessories for plastic windows

Behind the external simplicity and elegance of a modern plastic window lies a high-tech product, the performance characteristics of which largely depend on what components are used for plastic windows. A window system is a structure that includes profile systems, double-glazed windows, fittings and finishing elements. Each element performs a specific function, but they are all equally important.

- April 29, 2014

Modern plastic windows

The demand for modern plastic windows in Russia continues to increase. An increasing number of people have appreciated their advantages - heat preservation, noise protection, safety and ease of use, reliability, beauty and durability. How long a window will last depends on correctly selected components, accurate measurements, and professional installation. You can independently understand the intricacies and nuances of the window business, spending energy and precious time on it. The alternative is to trust professionals, such as the specialists of the “Window Continent” campaign.

- April 22, 2014

Elite plastic windows - a fusion of technical and aesthetic perfection

Plastic windows have gained national recognition due to their reliability, strength, durability, ease of use and optimal price-quality ratio. At the same time, “massive” does not mean “monotonous”. An example of this are elite plastic windows, which combine the functionality of modern German PVC windows and unlimited design possibilities.

- April 21, 2014

STiS

STiS products

News

Like

STiS Group of Companies is the leader of the Russian double-glazed window market. Our company produces window glass

for glazing the facades of buildings, offices, houses, cottages. The holding's products are used in their work by the largest window companies in Russia. Windows with STiS double-glazed windows can be found in residential buildings, public buildings and country cottages from the Black Sea coast to the Arctic Circle. And thanks to modern equipment that makes it possible to produce large-sized window glass, and rich experience in working with complex types of glass, STiS Group actively cooperates in the architectural glazing market with the largest construction companies, taking part in the construction of modern hotel, retail, office and entertainment complexes.

The quality of a modern window equally depends on three components - double-glazed windows, profiles and fittings - each of which carries certain functions and is responsible for various consumer characteristics. Only by combining them into a single translucent structure

You can offer the consumer a finished final product - a window. At the same time, we should not forget that each of the components is a separate product, produced at completely different enterprises, and can be used by window manufacturing companies in all sorts of combinations.

The Group’s strategy is to offer the most optimal solutions to assigned tasks, in strict accordance with the requirements of Clients, through strict business specialization and concentration of its efforts exclusively in its areas of interest.

- Work for the client, guided solely by his interests;

- Form long-term mutually beneficial relationships with partners;

- Produce products today, according to tomorrow's standards;

- Introduce new and improve existing working methods.

- We strive to take a leading position in the industry in the production and sale of double-glazed windows of any shape and configuration;

- Constant expansion of the product line, quality control, impeccable service and attraction of highly qualified specialists - these are the ways by which we achieve our goals;

- The main values of our company are stable production, responsibility to partners, respect for the interests of clients;

- We invest in development, build production facilities, create new jobs, apply the latest technologies - We want society to be proud of us.

was formed in the late nineties of the last century. Initially, it was created as a trading company, but in 1999 a decision was made to change the direction of activity, and the first plant for the production of double-glazed windows was opened in Saratov. By the end of 2000, STiS became the undisputed leader in the production of double-glazed windows in the Volga region.

To implement ambitious projects, the company required not only active expansion of production, but also access to new markets. In 2001, the first production line of the plant was launched in the Moscow region - in Elektrostal, and a central office was opened in Moscow. In 2002, the company managed to double production volumes, which strengthened its position in the regions and laid the foundation for large-scale regional expansion, which began in 2003. In 2004, a new plant was opened in Krasnodar. The company has taken a leading position in the double-glazed window market throughout the European part of Russia. During the same period, two new divisions appeared in the holding structure. To improve customer service, our own transport and logistics system was created. And new equipment and acquired experience in working with complex types of glass formed the basis for the creation of an architectural and design glazing division. In February 2005, the plant in Voronezh was put into operation. A new automatic assembly line was launched in Krasnodar, thanks to which Krasnodar has become the largest technological complex for the production of double-glazed windows in the south of Russia. At the same time, the company invested in the creation of a unified IT infrastructure, the implementation of which made it possible to significantly improve the quality and level of service. In 2006, STiS Group of Companies began construction of Europe's largest complex for the production of double-glazed windows in the city of Serpukhov. During the same period, the company’s share in the market for architectural and design glazing in the Central region of Russia amounted to more than 10%, and the total production volume of double-glazed windows exceeded 3 million square meters. meters. This means that every third window in the European part of the Russian Federation has a double-glazed window

"STiS".

In 2007, the Group will expand its presence in the Central region by opening a plant in Vladimir. Thanks to this, the company’s position in the architectural and design glazing market will be significantly strengthened, and new services for tempering and glass processing will be available. In the third quarter of 2007, the plant in Serpukhov will reach its design capacity, providing a production capacity of 340,000 square meters. m of double-glazed windows monthly. One of the important stages will be the launch of branded products on the market, which will radically change the approach to the sale and promotion of double-glazed windows in the domestic market.

"STiS" today is the largest private manufacturer of double-glazed windows in Europe:

- Six factories in the European part of Russia;

- 22 lines for the production of double-glazed windows;

- Six million pieces double-glazed windows annually;

- The largest transport company in Russia for the transportation of jumbo glass;

- Own brand “Heat packages”;

- 1200 highly qualified specialists and industry professionals.

Failure to comply with the requirements during the production of double-glazed windows entails a violation of the characteristics of the finished product, and as a result, the lack of possibility of an engineering design solution for the project.

Manufacturing of double-glazed windows

This is a multifaceted and complex matter, like any production process; it can be conditionally divided into several stages.

At the first stage, after processing and preparing the order for production, glass is cut to the specified type and size in the appropriate area. In parallel with this, the preparation of a spacer frame of the appropriate size is underway. In the production of double-glazed windows, the group abandoned the use of outdated technology of assembling an aluminum frame on the corners, almost completely switching to a bent frame. In addition, in double-glazed windows “STiS”, brand TEPLOPAKET™, a plastic frame is used, which eliminates the cold bridge in the double-glazed window and significantly improves the aesthetic qualities of the product. When preparing the spacer frame, a molecular sieve is poured inside, which is necessary to absorb moisture from the inter-glass space of the glass unit. This eliminates the possibility of condensation between the glass panes during further use of the product. The appearance of condensation on the surface of the glass inside the glass unit indicates gross violations committed during its production - incomplete sealing or the absence of a desiccant.

At the second stage, onto the end surface of the spacer frame

, after connecting it, the first sealing layer (butyl) is applied.

In parallel with this, automatic glass washing is carried out. After these operations, preliminary assembly of the double-glazed window

: connecting the glass and the spacer frame. In the manufacture of double-glazed windows of the TEPLOPAKETA™ brand, the STiS Group uses glass with a so-called “soft” coating, which significantly increases the energy-saving characteristics of the product and increases its light transmission, due to the applied layer of silver. Processing i-glass requires special equipment and technology, since the low-emissivity coating is very unstable to external influences. Therefore, during assembly, the “soft” coating must face the inside of the inter-glass space, and immediately before connecting to the spacer frame, the glass edge must be cleaned around the entire perimeter.

At the final stage, after preliminary assembly, the glass unit enters a press, in which the inter-glass space can be filled with argon and the process of primary sealing occurs. The final work of manufacturing double-glazed windows

is to apply sealant to the end part of the product to provide greater tightness and rigidity.

At the Group’s production facilities, all production operations: cutting, frame preparation, gas filling are automated and controlled by specialized software. Because each double-glazed window

is individual, its production requires not only strict adherence to technology, but also time. The product, depending on the complexity and type, can be manufactured and delivered within 24 hours to 4 days. The use of such an important component of a window as a double-glazed window provides sound insulation, energy and heat savings, increases the protective characteristics of the window, and gives an aesthetic appearance to the room and the building as a whole.

Today the Group is the largest private manufacturer in Europe, owning seven factories in the central part of Russia with 22 lines for the production of double-glazed windows, with a supply geography from the Black Sea coast to Vladivostok.

All our factories are equipped with the latest equipment, which significantly expands our capabilities and allows us to use the most modern technologies. The management models and unified IT system we have introduced solve the issues of operational management of production processes, minimize the dependence of the volume and quality of products on the human factor at all stages of work. An automated method for organizing the processing, placement and control of order execution allows us to constantly reduce the number of defective products (currently this is about 0.4% of total production).

Despite what has been achieved, investments in the capital construction of production facilities remain the main priority of the overall development strategy and will continue the chosen policy of investing in the modernization of existing equipment, the acquisition of the latest IT developments in automation systems, and the opening of new factories in various regions of Russia.

Source: www.stis.ru

Search: STiS