In any apartment you may be faced with the need to replace glass in a window, door or closet. It is very rare to find ready-made glass of the required size. Of course, you can turn to a specialist for help, but this will take time and money. All the necessary work can be done with your own hands at home if you know how to cut glass correctly.

How to choose the right glass

Glassmakers advise when choosing glass to pay attention to the following points:

- One of the signs of high-quality glass is a blue or greenish tint to its ends.

- Scratched sheets should not be used.

- If all the rules are not followed during the process of rolling glass or cooling it, then such sheets may have defects in the form of stripes. These stripes will significantly distort the image, so it is better not to use such sheets to replace glass in a window.

- The thickness of the glass depends on the size of the frame into which it is inserted. If its width and height are less than 600 mm, then you can get by with glass 2–2.5 mm thick. And if one of these parameters exceeds 600 mm, then the thickness of the glass sheet increases to 3.5–4 mm.

- When doing glazing at home, you need to cut a piece of glass 3–5 mm smaller than the size of the frame, because the slightest distortion will not allow the glass to be inserted into the opening.

Subtleties when carrying out work

- The diamond glass cutter is operated without pressure along the entire line. When using a roller glass cutter, apply light pressure.

- Pressure should be measured, as too much pressure may create excessively deep grooves, the edges of which will crumble and chip.

- At least 5 mm from the edge of the sheet, the pressure should be reduced. This will eliminate defects and prevent damage to the instrument.

- It is forbidden to cut the same line twice with a glass cutter.

- Before starting work, the surface of the glass roller is lubricated with a pre-soaked sponge. Diesel fuel, oil or paraffin can be used as impregnation.

- It is necessary to break the glass immediately after the material has been cut.

- The size of the cut plane should not be less than the thickness of the sheet itself. For example, if the thickness of a glass sheet is 6 mm, and it is necessary to cut 5 mm from the edges, then this will be quite difficult to do.

- When working with ordinary glass smaller than 5 mm, tapping is not required.

- Tapping can be replaced by heating the cut line with a blowtorch.

- You should break a sheet of glass correctly; to do this, you need to place a ruler under the glass, the thickness of which is 5 millimeters or more.

Glass preparation

Often many people simply forget about this important point. But high-quality glass cutting with your own hands is impossible without preliminary preparation. New glass should be wiped with a damp cloth. After it dries, wipe dry.

Some experts recommend using newspaper rather than a rag. It will not leave lint on the glass that could interfere with the movement of the glass cutter.

Glass that has already been used cuts much worse and requires more careful preparation. They are washed using special detergents, and after drying, degreased with turpentine or kerosene. During the drying process, it is necessary to prevent dust from entering the sheet.

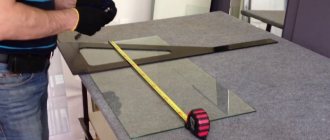

Correct marking is already half the battle

The markings can be made on a regular table, the main thing is that it is level and the surface does not slip,” continues Mikhail. – To do this, felt or linoleum is fixed on it with the terry side up.

Marking for round glass using a marker and compass

To make the markings correctly, measure all sides of the window sash. Then take a large piece of cardboard and mark the cuts on it. Remember that the glass should be 4 mm less than the distance between the frame folds. After all, if the frame shrinks in the cold or swells from moisture, the glass will crack.

Next, cut out a template from cardboard, attach it to the glass and outline it with a marker. You will cut according to this marking. Afterwards, be sure to check with a ruler - maybe the line has moved to the side? If so, then erase and draw another, correct line.

Checking tools and arranging the workplace

Before discussing how to properly cut glass, you need to decide on the tool that will be used for this specific job. In order to cut a glass sheet with your own hands, a glass cutter is most often used. There are three types of glass cutters:

- roller;

- diamond;

- oil

The last two are used mainly by professionals. The cheapest and most common option is a glass cutter with replaceable rollers.

Regardless of the model used, before cutting glass, it is better to check the sharpness of the glass cutter. To do this, you can try cutting some unnecessary piece of glass. Ideally, the glass cutter should move with a slight rustle, leaving a thin, continuous line. If it moves with a creak, the cut line is interrupted or looks like a white scratch, then either the cutting element is dull or errors were made in the cutting technique.

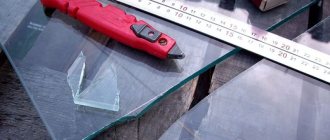

It is also necessary to prepare a flat surface, the dimensions of which must exceed the dimensions of the sheet being cut. At home, this could be a table covered with a soft cloth. If the table is not large enough, you can put a sheet of plywood or chipboard on top of it. You will also need a marker and tape measure for marking. If the glass will be cut with a glass cutter, then you need to prepare a thick metal ruler. Its thickness should be 8–10 mm - this is the only way you will create the necessary support for the cutting tool.

Features of glass cutting technology

Before cutting glass, it is necessary to properly prepare the material. The glass should be washed from dust and thoroughly wiped with a dry cloth. If there is debris in the path of the cutting tool, the cutting angle may change, which will not only lead to defects, but may also damage the tool. The debris can be completely unnoticeable particles of glass chips or fragments. Even ordinary dust can significantly affect the quality of the cut.

The flat surface to be processed should be level and without slopes. In addition to the glass cutter, you need to prepare a marker and a thick ruler to mark the cutting line.

When using a diamond glass cutter, no special effort is required. The tool must be pressed with approximately the same force as a pencil. It can be difficult for beginners to set the correct direction to the cutting element and select the appropriate angle of inclination. To understand the principle of operation, you can practice first on a sheet of rough material. After making a thin linear cut, you need to remember what position the glass cutter was in, and use the same principle to do it on a normal sheet. To make the cut easier, you need to move the tool evenly along the length of the ruler without changing the pressure on the tool or the angle of inclination.

Roller glass cutters must be held perpendicular to the plane of the material. Along the edges of the sheet, small linear markings are made with a glass cutter, thanks to which the pressure on these fragile parts can be eased. Otherwise it will lead to chipping. After this, you need to step back with a ruler from the markings to the width of the cutting element and make the cut. The work must be done from the far edges; the glass cutter should be brought towards you, pressing its side tightly against the ruler.

The cut must be done quickly. Thus, it takes about 2 seconds to travel 1 m. When working with a roller glass cutter, it is necessary to apply more force than when working with diamond tools, and the pressure should not be changed along the entire length, except for the edges.

How correctly the instrument is used can be determined by hearing. If there is a steady hissing or crackling sound, we can say that the work is being done correctly, but if squeaks or squeaks occur, this indicates that something is being done incorrectly. This indicates that the tool is dull or the pressure is too weak. The presence of small white fragments on the line may indicate overdoing the pressure, so it should be slightly loosened.

A high-quality cut will make it possible to easily break the glass and obtain smooth edges.

Defective lines or glass that is too thick will need to be tapped on the other side of the sheet. To do this, you need to move the glass to the edge of the working surface so that the linear cut is 5 mm from its edge. Then, using the head of the tool, you need to tap along a line from the top edge of the sheet to the bottom. Due to this, microcracks are formed, which make it easy to break off the material being cut. You can use the side of a glass cutter or pliers to break off small strips of glass.

How to use a glass cutter correctly

To cut glass with your own hands, you must follow the technology and sequence of actions.

- The starting and ending points of the cut are marked on the sheet.

- Place the glass cutter at the starting point and attach a ruler to it.

Note! The ruler should not be located along the cut line, but at a distance of several millimeters from it. This value corresponds to the distance between the tip of the glass cutter and its side surface.

- The cut is carried out smoothly, from start to finish in one movement and with one effort. And only once. If you run a glass cutter over one place several times, the glass will simply crack.

- The cut piece is chipped. To do this, the cut line is aligned with the edge of the table. They cause a crack by lightly tapping the cut with a glass cutter, and then break it off in one motion.

- If the chip is uneven, then excess glass can be removed with pliers or using special cutouts in the handle of the glass cutter. To avoid cracking, the cut line should be lightly moistened with turpentine or kerosene.

- At the final stage, the cut line is processed with sandpaper, a velvet file or a grindstone.

Stocking up on tools

First of all, you will need a glass cutter. Now there are many of them, but most often they choose diamond and roller ones.

We, the craftsmen, often work with diamond ones; there are two types of such glass cutters: those with a tetrahedral pyramidal shape and those with a curved cutting edge.

The diamond glass cutter cuts easily, like clockwork! However, it is more difficult to adapt to. Especially the first type with a pyramidal shape. After all, during the cutting process it must be held at a certain angle. For beginners, I would recommend a diamond glass cutter with a curved cutting edge that is held perpendicular to the glass.

Diamond glass cutters are used for glass up to 10 mm thick

A roller glass cutter will cut glass 4 mm thick

A roller glass cutter is even better for a beginner. True, it does not cut as well as a diamond one. Its design has three cutting rollers, which can be easily swapped with each other when one becomes dull. To do this, loosen the fastening of the brass drum in which the rollers are located, rotate the drum 120° and place another roller in the workplace.

In addition to glass cutters, you need: a flat table and pliers with rubber pads to break the glass after cutting, a long straight ruler, a triangle ruler. And also cloth gloves, a glass marker and thick cardboard.

Frames with one glass on the balcony are classified as cold glazing. What it is, its advantages and disadvantages, see this article. Glazing in Stalin-era houses has its own nuances. If you live in such a house, the article will help you: Glazing a balcony in a Stalinist house, prices and reviews.

Read about the features and prices for glazing a balcony in a Khrushchev-era building here.

How else can you cut glass?

What to do if you don’t have a glass cutter at hand? There are ways in which glass is cut with non-standard tools. This operation can be carried out with a soldering iron, grinder, nichrome thread and even ordinary scissors! Let's find out how to properly cut glass with your own hands using each of these methods.

- Using a soldering iron. First, cuts are made with a file at the beginning and end of the cutting line. Then you need to carefully run a well-heated soldering iron along the entire line. Due to the temperature difference on the sides of the surface, the glass will crack, after which all that remains is to carefully break it off.

- Bulgarian. This tool is found in almost every home, so it is not surprising that it has also been adapted for working with glass. In order to cut glass with a grinder, you will need a thin diamond disc. With its help, a thin groove is made along the entire cutting line, along which later chipping occurs. But when cutting with a grinder, you need to make sure that the glass does not overheat, and be sure to use coolant. You need a good tool, otherwise the glass will simply shatter from its vibration. When working with an angle grinder on glass, it is imperative to protect your respiratory organs and eyes. Getting the smallest glass dust into them will not lead to anything good. Therefore, if you cut a sheet of glass with a grinder, you need to stock up on glasses and a respirator.

- Using heating and cooling. A thread soaked in a flammable substance is laid along the cutting line and set on fire. Immediately after it goes out, the cutting line is cooled with water. A sudden temperature change will cause the glass to crack. Another option is to heat the glass with a nichrome thread through which an electric current passes. In this case, no water is required, the temperature difference between the two surfaces of the sheet is sufficient.

- Scissors. Thin glass up to 3 mm can be cut with ordinary tailor's scissors, if this operation is performed by immersing the scissors and glass in a container of hot water. The process feels like cutting thick cardboard.

Bottom line

The above methods have the right to life and give good results when handled skillfully with glass.

Perhaps, without experience in glass work, you will not be able to get an even chip the first time. Before you start processing the main material, we recommend that you first get your hands on unnecessary fragments. If you want to get a high-quality cut without much practice, it would be better to purchase a roller or oil glass cutter. article from the Rating section

- 80

Hand Tools DIY & Crafts

Save this page on your social media. network and return to it at any time.

ADD A COMMENT

Tempered glass processing

The question often comes up on forums: how to cut tempered glass? The answer is simple: tempered glass cannot be cut or drilled. Whenever you try to do this, it loses all its properties and simply shatters into small pieces. Tempered glass was used in cars before triplex technology was invented. During the accident, glass fragments should not have injured passengers. So you shouldn’t even try to cut tempered glass with any tool.

To understand how to cut glass with your own hands, you just need to take it and try it. The choice of method depends on individual skills and the availability of the necessary tools. But all these options are quite feasible at home.

How to replace a glass cutter

Not only professional tools will help when cutting glass, but also not quite ordinary ones, for example, such as scissors or a grinder. They can easily cope with such work under certain conditions.

Scissors cannot cut glass in the air, but you can cut glass with scissors in water.

In a liquid, gravity is less and the scissors make not a cut, but a microcrack. This crack plays the role of a capillary into which water will enter. Capillary water has a wedging effect at weak points of crystallization and the glass breaks off in pieces. Interesting! If it is necessary to cut out shaped parts, the glass is placed in cold water and then boiled for several hours.

After cooling, the tension inside is relieved and the material becomes soft. There are several ways and options for cutting thick glass. The simplest one is to use an oil glass cutter if the thickness is no more than 20 mm. But as an option, you can use a grinder. The dimensions of the tool should be small and convenient. The diameter of the circle is the smallest, then it will be easier to work with.

How is heat-resistant glass cut?

By cooperating with us, you will have the opportunity to obtain high-quality products at the most affordable prices.

Glass ceramics or tempered glass should not be processed after tempering, otherwise the stress distribution will be disrupted and the glass will break. All types of mechanical processing (milling of cutouts, drilling of holes, processing of edges) are carried out before the hardening process.

As a rule, glass is associated with fragility, but this is unacceptable when using glass ceramics or tempered glass.

Read also: How to start a floppy drive on a computer

Compliance with safety regulations

To avoid injury, you should work with gloves. Pay attention to shoes that should be durable so that accidental glass does not cut your feet. It is necessary to dress in thick overalls made of thick fabric.

Sources

- https://vopros-remont.ru/obshhie-voprosy/kak-rezat-steklo-pravilno-uchimsya-rezke-svoimi-rukami/

- https://stroypomochnik.ru/kak-rezat-steklorezom-01/

- https://domsdelat.ru/instrumenty/kak-pravilno-rezat-steklo-v-domashnix-usloviyax.html

- https://HouseDiz.ru/kak-prosto-rezat-steklo-v-domashnix-usloviyax-svoimi-rukami-steklorezom/

- https://FB.ru/article/264894/kak-otrezat-steklo-bez-stekloreza-poshagovaya-instruktsiya-sposobyi-i-rekomendatsii

- https://setafi.com/lajfhaki/kak-bez-stekloreza-razrezat-steklo-v-domashnih-usloviyah/

- https://2lzz.ru/ruchnoj-instrument/steklorez/7-sposobov-kak-bez-stekloreza-razrezat-steklo

- https://izobreteniya.net/kak-razrezat-steklo-bez-stekloreza/

What will you need?

A special cutter was invented for cutting glass. Previously, a diamond cutter was used, but nowadays they prefer to use a cutter whose wheel is made of steel.

The choice of tool depends on the intention of its use. If you will use it regularly, then you need to purchase a professional cutter that has a wheel change function. If you intend to use the cutter up to ten times, buy an inexpensive one; this is the number of times it can be used, but after which it can be thrown away.

Attention, if there is no need for regular use, you must purchase a disposable cutter to avoid unnecessary costs