High-quality window structures should work flawlessly after installation. However, many owners begin to experience a draft with the onset of cold weather, blowing from under the windowsill of a plastic window. What to do if a crack appears under the frame causes inconvenience. If double-glazed windows have been installed recently, the warranty period has not expired. If the breakdown was not your fault, then it is reasonable to contact the manufacturer. Employees will fix it for free. If this is not possible, there are several options for independent dismantling, but after finding out the reasons for the blowing.

Blowing from a crack under the windowsill: solving the cold problem

Conversation between two friends:

– I installed new “breathable” double-glazed windows.

“Yesterday, in 20-degree frost, they inhaled and exhaled so much that my cat was frozen to the radiator.

A life anecdote, isn't it? Many consumers face the problem of draughts coming from slopes or blowing from under the sill of a plastic window. The causes of the defect must be clarified and definitely corrected, otherwise in the cold season the street will be heated, and not the living space.

Why does water accumulate on the windowsill of plastic windows?

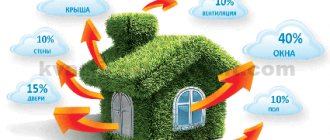

Often, after the blowing has been eliminated, users are faced with the fact that complete tightness leads to water accumulating on the windows and sills of plastic windows. This is condensation that forms for various reasons, in particular:

- due to lack of ventilation,

- due to the significant width of the window sill. It protrudes beyond the heating radiator and the warm air does not have time to warm up the glass and prevent the appearance of moisture;

- high indoor humidity. The appearance of condensation is typical for the kitchen or for rooms in which renovation work is being carried out;

- low temperature in the rooms;

- defects in window installation and slope insulation.

How to get rid of condensation on a windowsill:

- install a convection valve;

- remove all unnecessary things from the windowsill, in particular potted indoor plants;

- replace the heating radiator or replace the window sill with a narrower one;

- Ventilate the room periodically.

How to eliminate condensation on PVC windows is shown in the video

Types of materials and results

Liquid plastic

Liquid plastic is most often used to fill cracks and seams between the frame, slopes and window sill. This composition is widely used among professionals. Available in a tube or as a cartridge for a pistol. The color of liquid plastic can be white or transparent.

The kit usually includes a special nozzle that allows you to apply the strip into the seam as thinly as possible. One of the well-known brands that produce these materials is Cosmofen.

After drying, the mass becomes hard, resembling plastic.

Silicone sealant

Silicone sealant is also a means for grouting joints, but many reject its candidacy because of its elasticity. In fact, softness after drying will not affect the performance in any way, so you can safely use it.

By the way, after several years of service, such material can be easily removed from the surface of the window sill and slope panels. This line of products has many shades, so this material is perfect for the owner of textured and colored windows.

Acrylic sealant

Acrylic sealant also has a wide color palette, but the classic white color is also available in almost every store. After drying, it becomes more rigid, but not as hard as liquid plastic. It has a lower percentage of elasticity, but this is its advantage for many buyers. You can also use this product, but it is better to choose from sanitary representatives with special additives. Well-known and high-quality sealants: “Tytan”, “VGT”, “Makroflex”, “Moment”, etc.

Adhesive/cold welding

Adhesive/cold welding can also be used to seal seams on window units, but their properties differ from sealing materials. These compounds glue one part to another, which eliminates the possibility of their easy replacement if they lose their properties after some time. At the same time, the slope panels may be slightly deformed when the cold weld dries, despite the fact that it was originally intended for PVC; this occurs due to the strong adhesion, given that the panel and frame are perpendicular to each other, creating an angle of 90 degrees.

You can purchase any of the above products, but the results will be different, so you must initially decide which product is more suitable in a particular case.

General information

How to find the problem area?

Before you begin insulation, you should reliably identify all weak points. Otherwise, you will need to redo the work, and possibly more than once.

To be able to find a specific place of blowing, it will be enough to run the back of your hand along the entire perimeter of the frame, sashes, slopes and under the window sill. In places where there is depressurization, air circulation will be felt. If you wet your hand, your sensitivity will increase and you will be able to easily notice even small cracks that need to be sealed.

For a visual assessment, try using a lighter or matches. If there is a draft in some place, the flame will begin to deviate from the vertical. To avoid fire, you should never bring fire near curtains or other flammable objects.

Please note that the intensity of drafts may always vary. The strongest air will blow from the cracks in windy weather, as well as when there are large temperature differences between the room and the street.

For this reason, it is worth starting to look for problem areas at this time.

Why do drafts appear in the window?

To know exactly what should be done if it is blowing from a plastic window, you should understand in detail all possible malfunctions:

- The rubber seal is worn out. This reason is the most popular, and therefore probable. The service life of new tires will be 10 years, provided that regular maintenance is carried out. Without maintenance, rubber bands will last no more than 5 years.

- The fittings are worn out. The axles will have a “Winter” and “Summer” position, which are designed for seasonal deformation of the material. If you leave them on the porch to the maximum, the service life of the mechanism will decrease. At the first stage, such a distortion can be eliminated through adjustment.

- Violation of installation technology. A draft often appears when a foam seam breaks. If the composition was applied to a dusty wall, then after a short period of time it will begin to come off. If the material is not covered with a cover, it will crumble in the sun. The most serious violation of technology is the absence of a closed loop from the insulation layer.

- Shrinkage of the building. If you have a draft between the window and the sill, then perhaps the problem lies precisely in shrinkage. This situation is more typical for new buildings. In the first years after construction, the foundation will always sag a little, and if this happens unevenly, then distortions will begin to appear.

- Blowing slopes. Adjacents to window blocks should create a single heat-insulating contour. It is better to entrust their installation to real professionals, as otherwise there is a high risk of cracks and cracks.

When the cause is established, it is worth talking about how to deal with the problem.

What to do if there is blowing from the gap?

In cases where the gap is small and only cold air enters through it, minor repairs can be limited.

To carry out the work you will need the following materials and tools:

- silicone window sealant;

- gun for applying sealant;

- profile for tiles “internal corner”;

- construction knife;

- masking tape.

The profile is sold in standard lengths of two meters. This is too much for a regular window. To work, you need a piece that exceeds the length of the frame by 1.5-2 cm.

The perforated part of the corner is cut off. The edge along the cutting line is slightly sharpened with a knife. This is necessary to facilitate the installation process. It is much easier to drive a wedge into a narrow gap.

The joint between the window sill and frame is cleaned of dust and dirt. Using a knife, the gap is slightly widened. Small holes are made in the slopes to install the profile.

In order not to create unnecessary problems for yourself, strips of adhesive tape are glued to the frame and window sill. They will protect the surface from excess silicone.

Then, using a gun, a layer of sealant is evenly applied along the entire length of the joint. This must be done so that the maximum amount of it gets inside the gap. The pointed wedge of the profile is also covered with a layer of sealant.

The most important and difficult operation is installing the corner. First, it is inserted into the holes in the slope. Then it is carefully tucked into the slot and pressed for a few minutes.

After the sealant has set slightly, remove the tape. Silicone that gets on the corner is carefully removed with a rag soaked in alcohol.

Let's start with insulation

Insulating the window sill of plastic windows will provide additional thermal insulation and eliminate blowing. The materials used are polyurethane foam and acrylic sealant . If you find a gap between the window sill and the wall, you cannot do without dismantling it.

Dismantling

Arm yourself with a hammer, hammer drill, chisel, hacksaw, knife. Dismantling can be done in two ways.

Method No. 1

First of all, remove the wallpaper. Then, using a chisel and hammer, beat off the plaster under the window and in places where there is a junction between the side parts of the window sill and the slopes.

Cut off the mounting foam and carefully pull the canvas towards you, tilting it down a little.

To insulate the window sill you will need to dismantle it

Method No. 2

Using this method, you will not need to beat off the plaster. Run a long-bladed knife under the window sill and cut away the foam and sealant near the slopes. The blade should not come into contact with the plastic. After getting rid of the fastening elements, pull out the canvas.

After dismantling, clean the work surface of debris with a broom or vacuum cleaner. This will allow you to see all the cracks through which cold air entered.

Polyurethane foam is used to fill cracks

Fill all cracks with foam. And if there are significant deformations, use silicone sealant.

Installation

After completing all the necessary procedures, you can install the window sill. To do this, apply polyurethane foam along the perimeter of the front side, as well as along the diagonals of the product. Lay the canvas on the work surface.

To ensure that the canvas adheres to the base, lightly press it and hold for a few minutes. Use a spirit level to make sure everything is level.

The correct installation of the window sill is checked using a level

For better fixation, place something heavy (for example, books) on the windowsill, as it may warp as a result of foam expansion.

More reliable insulation is achieved through the use of sealant. It is applied to each area where there is a joint .

The final stage in the installation is plastering the slopes. It is made from both cement mortar and ordinary dry mixture.

By insulating a plastic window in this way, you will forever forget about the cold window sill and drafts in the house.

Another option

In this case, the same sealant is used, but a plastic profile is used to insulate it. The work is carried out in stages.

- Prepare the part (it is recommended to use a bathroom profile of a suitable size; it should match the length of the window or be 2 cm longer).

- Remove the perforated area of the profile.

- Holes are created in the corners of the window sill; their size should not exceed 1.5 cm. A profile will be mounted into these holes.

- The area where the frame meets the window sill is cleaned and then dried.

- The gap is “closed” with a hermetic compound (it is recommended to apply it evenly).

- A large seam is cleaned, but a small one is not. A coin is used to remove excess applied product.

- The end of the plastic profile is placed in the inner corner (where there is already a composition), after which the second end is carefully pressed and secured.

Important! If you cannot fix the profile, you need to lightly press it down and wait until the product dries.

It happens that the profile forces out a small amount of sealant. Then the product is carefully removed and the same coin is used. This method of insulation has more advantages: the window acquires an aesthetic appearance, the corner lasts longer and is not exposed to moisture.

A special case

The window is sealed, but it still blows.

Perhaps the apartment has too much forced ventilation, for example, an exhaust hood in the kitchen or bathroom.

By pumping air out of the apartment, it creates a vacuum, and due to the difference in pressure inside the house and outside, air will be sucked into the apartment through micro-holes in the places where handles and fittings are attached.

In this case, you need to adjust the pressure in the apartment (install check valves on the hood).

Blowing from plastic windows

With the onset of cold weather, many owners of plastic windows discover drafts and blowing. And this problem is relevant not only for old windows, but also for those that were installed more recently.

There can be quite a lot of reasons. And the problem does not always lie in the design itself. Let's look at how to tighten plastic windows so that it doesn't blow, and why a draft can appear in general.

How to seal the gap between the window and the sill

Post by igor40in » 16 Nov 2016 00:28

Question about the gap between the window sill and the window

Post by mitbka » 02 Dec 2016 01:23

Question about the gap between the window sill and the window

Post by Ocean+ » 04 Dec 2016 00:18

Question about the gap between the window sill and the window

Post by Technologist » 04 Dec 2016 20:19

Not an option at all. The window sill plastic is quite fragile. In addition, if there is foam there, then it is as if glued to it. It won't attract.

Sent after 1 minute 40 seconds: How was it before? Maybe the profile itself is bent? If not, then you should try to remove the ebb and insert something into the spacer under the window sill. Then foam again.

Question about the gap between the window sill and the window

Post by Ocean+ » 04 Dec 2016 20:48

Question about the gap between the window sill and the window

Post by mitbka » 04 Dec 2016 20:58

Question about the gap between the window sill and the window

Post by Technologist » 04 Dec 2016 21:39

Question about the gap between the window sill and the window

Post by igor40in » 04 Dec 2016 21:58

Question about the gap between the window sill and the window

Post by Lech Kursky » 05 Dec 2016 00:32

During installation about five years ago, this was done quite often. There was even a 7mm cutter. first with a 4mm drill and then with a milling cutter so that the head fits into the groove. But personally I don't like this method. I prefer to make rigid supports from straightening bars or bars.

Sent after 1 minute 42 seconds: and on the standing window - the best option was suggested by Zhenya. If only the montag would fit under the sweet clover.

Question about the gap between the window sill and the window

Post by mitbka » Dec 12, 2016 11:28

Question about the gap between the window sill and the window

Post by mitbka » 21 Feb 2022 14:19

Question about the gap between the window sill and the window

Post by Egor Tarkov » 12 Feb 2022 17:04

For these purposes (eliminating cracks), mounting tapes are sold. They close cracks, prevent moisture and dust from entering, retain heat, etc. But this tape must be glued immediately at the time of installation of the plastic window. The tape has an adhesive base, so it attaches without problems. Unfortunately, not all companies that install windows use these mounting tapes, as this increases the cost of installation and adds more hassle to the craftsmen, but the thing is actually very smart.

The advertising link has been removed, repeating it will result in a ban. Administrator.

Question about the gap between the window sill and the window

Post by mitbka » 12 Feb 2022 22:45

Non-standard solution to the problem of the joint between the frame and the window sill

Post Window repair Bezenchuk » 06 Dec 2019 19:19

Adjusting the bottom hinge horizontally

Having dealt with the vertical adjustments, you should adjust the hinges in the horizontal plane. This need arises if the sash touches the frame from the side.

The problem can be solved this way: 1. Open the window. If slopes interfere with adjustment, the sash must be fully open. In this case, the hinges are adjusted from the reverse side.

There is also a screw on the back side

2. Turn the hex key. If the sash catches the frame at the bottom left, rotation is performed clockwise. If the fit is too tight to the loop, counterclockwise.

3. Continue turning the key until the door begins to press against the hinge and close normally. Check the tightness of the closure every half turn.

Sometimes a screw is installed on the lower hinges, allowing you to adjust the pressure from below. A key is also used for adjustment. The degree of pressure is selected according to the season.

This screw regulates the pressing force of the lower corner of the sash. Happens not on all windows.

What to do if there is blowing from the gap?

In cases where the gap is small and only cold air enters through it, minor repairs can be limited.

To carry out the work you will need the following materials and tools:

- silicone window sealant;

- gun for applying sealant;

- profile for tiles “internal corner”;

- construction knife;

- masking tape.

The profile is sold in standard lengths of two meters. This is too much for a regular window. To work, you need a piece that exceeds the length of the frame by 1.5-2 cm.

The perforated part of the corner is cut off. The edge along the cutting line is slightly sharpened with a knife. This is necessary to facilitate the installation process. It is much easier to drive a wedge into a narrow gap.

The joint between the window sill and frame is cleaned of dust and dirt. Using a knife, the gap is slightly widened. Small holes are made in the slopes to install the profile.

In order not to create unnecessary problems for yourself, strips of adhesive tape are glued to the frame and window sill. They will protect the surface from excess silicone.

Then, using a gun, a layer of sealant is evenly applied along the entire length of the joint. This must be done so that the maximum amount of it gets inside the gap. The pointed wedge of the profile is also covered with a layer of sealant.

The most important and difficult operation is installing the corner. First, it is inserted into the holes in the slope. Then it is carefully tucked into the slot and pressed for a few minutes.

After the sealant has set slightly, remove the tape. Silicone that gets on the corner is carefully removed with a rag soaked in alcohol.

There are two options for eliminating blowing.

Sealing foam under the window sill The first one is suitable, if the window was installed recently and work on decorating the window opening has not yet been carried out, you can remove the window sill and blow foam over the junction of the wall and the window frame. After this, install the window sill in place.

Window sill repair process on video

Causes

Two main factors are known:

- Defective window design.

- Broken installation technology.

If a marriage is noticed. If the installers are to blame for making mistakes during installation, it is worth notifying the installer about this during the warranty period. Specialists are required to come and reinstall the structure free of charge.

Even a small gap can be the cause of blowing

If the warranty period has expired, but the double-glazed windows were purchased from a reputable company and defects are excluded, then we can only assume that siphonitis is due to:

- poor sealing of tides;

- insufficient number of frame attachment points;

- poor-quality installation of the structure or interface unit (window sill-window opening-frame);

- subsidence of the polyurethane foam (destruction of the seam) in the case of using low-quality adhesive and sealant;

- savings on foam by unscrupulous installers;

- distortion of the glass unit against the backdrop of shrinkage of the building;

- wear of the seal;

- making spacer pads from the wrong material.

Attention! It is important to approach the purchase of plastic products responsibly. Otherwise, under the influence of cold winds, the seal will quickly wear out and the profile will lose strength.

How to cover it up

The fastest way is to seal the gap with sealant. It only works if the joint is separated by a small distance.

- Wash the window from dust and dirt, degrease and dry.

- Take a transparent composition with a special nozzle and place it exactly at the junction of the frame and the window sill.

- Pour in as much sealant as possible.

This putty will last for 1-2 years. It's not much, but the method is cheap and fast.

Advice! To make the sealant seam look beautiful, immediately after pouring, go over it with the edge of a large coin, for example 10 rubles.

What to do if a defect is discovered is up to you. If you are not satisfied with the short-term result, arm yourself with knowledge and begin dismantling. If in doubt, this process should be entrusted to specialists.

Dismantling

If there is a strong blow in the window, it is better to immediately begin global measures, namely, reinstalling the window sill.

How to do it right:

- First you need to dismantle the canvas: carefully run a sharp knife under the window sill, cutting off the mounting foam, and cut off the sealant on the slopes. Do not touch the plastic.

- Carefully pull out the window sill.

- Use a vacuum cleaner to clean the entire work surface. This will reveal all the cracks.

- Fill the cracks with sealant or foam. The method with sealant is more reliable, the substance fills defects better.

- Apply polyurethane foam to the canvas. Return it to its place and press down for better fixation. It is most convenient to control an even angle using a mounting level.

- While the foam dries, it is recommended to strengthen the position of the window sill with heavy objects so that it does not warp.

All that remains is to plaster the slopes. If everything is done correctly, improvements will be noticeable immediately.

Draft protection for wooden windows

The problem of drafts is relevant not only for plastic windows, but also for wooden structures. In the case of wooden windows, you can get rid of drafts using platbands. This element of the system serves as decoration and is a reliable protection against the penetration of cold air into the room.

Wooden windows insulated with platbands

How does the platband work:

- Covers the gaps between the window opening and the wall.

- Protects rooms from penetration of cold and moisture.

- Reduces noise levels.

- Reduces heat loss.

Before installing the platband, determine its style. If there are several wooden buildings on the site, it is recommended to decorate the windows in the same style.

You should also pay attention to the material used to make the window structure. Platbands are also installed on plastic windows

In this case, the decorative protective element should be white in order to avoid differences between the texture of wood and plastic.

An option for platbands is double-glazed windows made of natural wood or PVC windows laminated to look like wood.

The design for the platbands is selected taking into account the characteristics of the architectural ensemble or the taste of the home owner. The decorative element may be without thread. But the traditional platband is always decorated with carvings:

- Deaf. The drawing lies in one plane. This type of carving includes bas-relief.

- Through. Openwork pattern consisting of through cuts. The openwork carving method allows you to make complex large-scale patterns.

- Invoice. It is a contrasting background (dark, light), onto which cut out pattern elements are applied (glued).

For carved platbands, soft, dense wood species that are resistant to moisture, temperature changes, and ultraviolet radiation are used.

Pine is considered an inexpensive, strong, durable material. The material lends itself well to processing and is not afraid of mold.

Oak, linden, and cherry are durable, but expensive. Such wood requires special processing techniques.

Important. The higher the grade of wood, the better it is suitable for carving and making trims

The boards do not contain knots or chips. Lumber with a moisture content of 10-12% is also used.