Sooner or later, a household may need to replace glass on its own. But working with such fragile material is very dangerous. Therefore, in order to avoid injuries and unnecessary consumption of material, you should know the basic rules for working with this material and the selected tool.

Cutting ordinary glass is very simple and will not cause any difficulties for a person. You can cut such glass with a special glass cutter or even ordinary scissors.

If you have no idea how to properly handle this tool, you can watch numerous videos on this topic on our website. They will help you cut out the desired shape and provide the necessary information on working with a rather complex and fragile material like glass.

Safety regulations

When starting the procedure for cutting glass, be sure to keep in mind that working with this material requires compliance with safety rules, which are not recommended to be neglected. When untreated, glass has sharp edges that can easily cut the skin and cause infection. To avoid cuts, protect your hands with gloves and wear clothes with sleeves. Since glass tends to crumble into small, sharp fragments, we strongly recommend cutting with glasses.

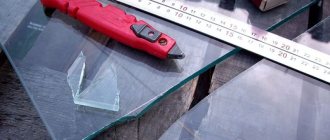

The glass cutting area must be level and stable. It is strictly not recommended to perform this operation on a knee, a rickety stool, or other questionable surfaces. Compliance with this rule will minimize the risk of glass falling onto the floor, and will also make the work more convenient and improve the quality of the cut.

If you have not previously had experience in handling glass, and do not yet know how to cut with a glass cutter, we do not recommend neglecting the above recommendations. Perhaps some experienced craftsmen can do this work with their eyes closed on their knees, but for beginners everything usually does not go so smoothly. Due to inexperience, you can make many mistakes: grab a sharp edge, drop the glass on your foot, or crush the cut site and get a piece of glass in your eye. If you are working with glass for the first time, and have not yet experienced this process, it is best to be fully prepared.

How to use a glass cutter correctly?

In order for cutting to be of high quality, adherence to technology and sequence of actions is required:

- The points where the beginning and end of the cut will be are marked on the glass sheet.

- The glass cutter is placed at the starting point, and a ruler is attached to it.

- In one smooth movement, the cut is made with force. Under no circumstances should it be repeated.

- The cut piece breaks off. To do this, the cutting line is aligned with the edge of the table, you need to lightly tap the cut with a glass cutter, and then break off the unnecessary glass with one sharp movement.

Important! If the chip is uneven, use pliers to remove the excess. To prevent the material from cracking, the edge is moistened with kerosene or turpentine.

Glass selection

One of the key factors for the success of any job is choosing the right material. This belief also applies to glass, which should be selected based on the task at hand. In the following paragraphs, we will give a couple of recommendations on how to determine the quality of glass and choose the optimal thickness. If you already have the material, you can go to the next heading or directly to the instructions on how to cut glass with a glass cutter.

Before we begin the description, we clarify that we are talking about ordinary window glass, which is most common in the construction markets. The first thing you need to pay attention to when buying glass is its end part. The edge of the canvas should have a bluish-green tint. Low quality glass has greener tones due to the higher iron content. This material is more fragile, but usually costs less.

The choice of glass thickness should be made based on the required dimensions. To make working with the canvas more convenient and to minimize the risk of defects, the ratio of width, height and depth should be optimal. Glass with an area of 1 m² and a thickness of only 2 mm is highly likely to crack at the first wrong movement. When using canvases up to 50 cm, a thickness of 2-2.5 mm will be sufficient. From 50 to 100 – 3-4 mm. More impressive sizes should have a thickness of 5-6 mm or more. Take these recommendations into account when choosing glass in a store and save yourself from unnecessary trouble.

How to cut a circle from glass

In order to cut a circle out of glass, you can use several different methods, which may differ depending on the diameter of the future circle and, of course, the thickness of the glass.

The simplest and most common way to cut an even circle is to use a circular glass cutter. Usually, the presence of such a tool in the household is quite rare. But for these purposes you can use a regular tool.

How to correctly cut a circle from glass with a glass cutter video

First of all, you will need to mark the central part of the future product and attach a special suction cup to it. Then you need to tie a strong thread or fishing line to this suction cup with a length equal to the radius of the planned circle. The glass cutter itself must be tied to the end of this rope. Pull the rope as tight as possible and then draw a line with the tool in a circle around the suction cup. When the circle is drawn, it is very important to additionally make ray lines that will eliminate excess pieces of glass around the finished product.

Preparatory activities

In order for the cut to be of high quality, it is necessary to first prepare the material for work. If the glass is new, then just wipe it. Newspaper is best suited for these purposes; it mainly wipes the surface dry and also does not leave lint or stains behind.

If the glass has been used before, then before cutting the material with a glass cutter, you will need to spend a little more time preparing it. First of all, such a surface will need to be washed thoroughly using special glass cleaning products. A thorough degreasing process should then be carried out. Alternatively, you can use kerosene. To do this, use a rag soaked in kerosene to thoroughly wipe the glass and wait until it dries completely.

At the same time, the glass preparation stage also includes cutting it. There is no doubt that you will be able to achieve the final result without waste, especially if you need to cut a product of irregular geometric shape. But if you make the calculation as correctly as possible, you can reduce the amount of waste several times.

Also, make sure that the working surface is fairly flat and without slopes, but not too hard; it is advisable to make the working surface from plywood or fiberboard, and cover the top with oilcloth or soft cloth.

Glass processing at home

Many people are wary of working with glass and limit themselves to simple operations like repairing a broken window. But glass is an amazing material, and not all craftsmen know that at home it can be processed no worse than in production. Oleg Abramov shares his secrets.

The molecular structure of glass allows it to be cut, sawed, drilled, sanded, glued, engraved, bent, and even drawn into threads!

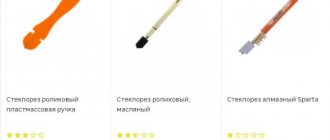

A glass cutter is required to cut glass. Roller glass cutters are most often used.

A - glass cutters with such a handle were produced forty years ago. Their advantage is a heavy head, which is convenient for tapping the cutting line.

B and C are cheap Chinese glass cutters. Sold under the brands Jobo, Kraftool, Stayer. They are difficult to use for cutting glass due to the poor quality of the rollers and glass cutter head. On Kraftool, the damaged teeth of the head are clearly visible after breaking off the glass.

D - professional roller glass cutter Silberschnitt. My favorite model. A universal and reliable tool.

The professional oil glass cutter Touo TS-17 is good for curved cuts. If you need to regularly cut glass, you shouldn’t skimp on a glass cutter. Although professional glass cutters are not cheap, it will cost more to damage glass. And the most expensive part in a professional glass cutter is the roller.

READ How to Cut Tempered Glass at Home

The rollers are made of alloyed stainless steel. They vary in sharpening angle, usually 130-165 degrees. Rollers with a sharpening angle of 130 degrees are used for cutting glass with a thickness of 1 to 3 mm, and those sharpened at an angle of 140-150 degrees are used for cutting glass with a thickness of 4-10 mm. For glass thicker than 10 mm, use a glass cutter with a 155-165 degree roller.

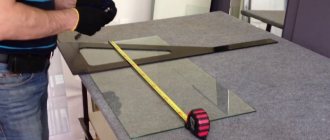

This is how glass is cut. The cutting table must be level and stable. The surface is covered with thin insulation, but ideally a thin carpet or felt is glued onto the table. This makes cutting more convenient, and the underside of the glass will not be scratched by fragments that inevitably form during cutting. The glass is placed on the table surface, marked, and a ruler is pressed against it.

Faithful friends of the glazier. ruler, kerosene and hammer

A ruler for cutting glass is a ruler with a strip of thin rubber glued to the bottom so that the ruler does not move when cutting. Or it is a special ruler with suction cups embedded in it. You can make this yourself.

So, we use a glass cutter to cut the line. Important! This line cannot be interrupted and repeated. It must be drawn in one pass.

Then we move the glass from the table and carefully tap the cutting line with a small hammer - here is another faithful friend of the glazier. Next, we lay the glass along the cutting line on the edge of the table and break it off, pressing it with a board using clamps. Clamps are especially important if the glass is thick.

With some skill, you can stretch the cutting line with your fingers, especially if the glass is thin.

So, we learned how to cut straight lines with mowing line. What about curves? To do this, first, instead of a ruler, we cut out a pattern - for example, from thick linoleum. The remaining operations are similar.

You can even cut a circle out of glass. To do this, you will need a circular glass cutter or a round template of a suitable diameter. If you have a compass, then attach a suction cup to the glass and draw a circle. Of course, without interrupting the cutting line.

Then we draw rays from the circle to the edges of the glass.

We turn the glass over and use the handle of a glass cutter to carefully press through the cutting line and rays. If everything is done correctly, the workpiece itself will disintegrate into a circle and side fragments.

If you only have a template at hand, you can fix it on the glass with double-sided tape to prevent it from shifting, and then run the cutting line around it in the same way.

Not only flat glass. For example, you can cut bottles. They make interesting vases or shades for lamps. To do this, they usually assemble an improvised workbench from a base and three blocks. The bottle is placed between the bars and rotated with the left hand, while the cutting line is drawn with a glass cutter in the right hand.

Then the cutting line is tapped from the inside with a pin with a weighting agent and the cut part is separated from the bottle.

If it is impossible to tap the cutting line from the inside, gently warm it up with a portable gas burner. The main condition is that the bottle must have a smooth surface, preferably cylindrical. Bottles of complex shape, angular for example, are more difficult to cut.

We have learned how to cut, now we need to process the cutting line. Those involved in stained glass use portable diamond machines Inland or Krištáli 2000, which quickly sharpen even uneven cutting lines.

If you need to dull the edges of window glass, you can use a diamond-coated sponge or a whetstone to sharpen knives, after moistening it.

If more sanding is required, a sanding attachment on a drill with waterproof sandpaper will come in handy.

Drilling glass Glass often has to be drilled. For example, to fix a handle on a glass door or hang a mirror.

Drills for glass are tubular with diamond coating or carbide spear-shaped.

It is advisable to use a drilling machine, because the drill is difficult to install strictly vertically, which is why the glass may burst when pressed. Place the glass on a soft pad - for example, rubber or carpet. Drill in a water bath. To do this, attach a plastic or rubber ring around the drilling area, then pour water into it and carefully drill. Do not press hard on the glass. First, drill halfway on one side, then turn the glass over, align the drill and the drilling point, and drill further on the other side.

Engraving on glass To apply a pattern to glass, processing the edges of small parts or markings, you can use drills. They are produced by Dremel, Prokhop, Bort, Kalibr, Energomash and other manufacturers.

It is important to choose the right drill and attachments for it so that the power and speed correspond to the operation being performed. For some work, carborundum grinding attachments are suitable, and for fine and precise work, diamond-coated attachments are used. You won’t be able to save money on attachments: cheap ones are poorly aligned and wear out quickly because they use low-quality abrasive compounds.

Good advice: how to cut glass at home

Frosting of glass Glass can be frosted completely or locally. In the first case - for the manufacture of a lampshade, vase, stained glass element or for subsequent painting. In the second case - to apply a pattern, because you still need to practice drawing on glass with a drill. What about those who cannot draw? We cut out a pattern on the Ogasai film, glue it to the glass surface, and then subject it to local matting.

Matting methods. The simplest is in a sandblasting chamber, which can be found in glass shops and auto repair shops. There are glass matting pastes based on ammonium fluoride - Glassmoze and Glassmat. The paste is applied to the surface of the glass with a spatula, left for some time, and then collected back into the container or washed off with water.

Gluing It's amazing, but a properly glued seam between two pieces of glass is stronger than the glass itself. The industry produces dozens of types of glass adhesives. Here are the main ones.

Superfluid adhesive is used for: bonding polished surfaces - for example, glass furniture. It is this kind of seam that is stronger than the glass itself, because gluing occurs at the molecular level. An example of such glue is Bohle Verifix LV 740. For household purposes, Spanish glue CristalCeys is more accessible.

Viscous adhesive is used if it is not possible to create perfectly adjacent glass surfaces, as well as when gluing ground but not polished surfaces. For example, UHU or DoneDeal.

Two-component epoxy compounds are well known for bonding other materials. The most popular are Kilto or Rohiroi.

Glass painting The industry produces paints with good adhesion to glass. But when making vases or lampshades, it is easier to frost the surface of the glass - and then any paint from an aerosol can will adhere well to it.

Polishing glass We do not recommend polishing large glass items at home: it is quite a messy task. But miniature surfaces are polished with drills with polishing attachments and polishing pastes based on crocus, polyrite or zirconium oxide.

Products manufactured by the methods described above.

Sources:

https://givewhereyoulivehamptons.org/steklo/kak-razrezat-tolstoe-steklo-v-domashnih-usloviyah.html https://don-krovlya.ru/dacha/kak-razrezat-tolstoe-steklo-v-domashnih-usloviyah .html https://www.umeltsi.ru/hitrochi/4198-obrabotka-stekla-v-domashnih-usloviyah.html

How to cut glass with a glass cutter: detailed instructions

If you are planning to cut glass, then first of all you should decide which glass cutter is best suited for your case. At the moment, there are two types of tools - diamond and roller.

How to cut glass at home

The diamond model is rightfully considered the leader among tools of this type. If you are going to use it at home, then the perfect model is one that has a beveled edge, which is very convenient for breaking off cut pieces. You can cut glass with such a glass cutter, almost ten kilometers of material, with a thickness of up to one centimeter. But at the same time, it should be taken into account that there are also cheap types in which an artificial diamond is installed, which allows cutting glass with a thickness not exceeding 5 mm.

Unlike a diamond cutter, a roller glass cutter has a working element in the form of a small roller, usually made of carbide materials, usually a tungsten-cobalt alloy, which is capable of cutting material up to 4 mm thick. The advantage of this type of tool is that the roller can easily move along the glass, without putting much effort into making a furrow.

The work process is carried out in the following order:

Clean and dry glass is placed on the surface of the work table. The necessary markings are made with a marker. Next, small cuts are made at both ends along the marked line. Please note that the material used must be in close contact with the surface of the desktop.

Afterwards, you need to put a ruler on the glass and draw a line along it with a tool. Holding a diamond glass cutter in your hands is exactly the same as a regular pencil; when passing along the marked line, you should only apply a little force. As a result, only a barely noticeable mark remains on the glass, which looks like a scratch. If the instrument is in good working order, then there must be a characteristic sound reminiscent of crackling. If the sound is creaking, then this means that its cutting element needs to be sharpened on a special block for this purpose.

During operation, such a tool should be held at a slight angle, the correctness of which is determined experimentally. Please note that a tool that is in the correct position relative to the glass will leave a colorless thin line.

A roller glass cutter, unlike a diamond one, must be held strictly at right angles to the surface of the glass, while pressing it with the middle and thumb, and pressing on it with the index finger. Please note that the roller tool is pressed a little more than a diamond tool, and the cut itself should turn out white.

In order to get a high-quality and, of course, even cut, remember a few simple rules that must be followed when working with glass using a diamond tool:

- Do not press on the glass while moving the glass cutter, otherwise the cut will be too deep and the edges will be uneven.

- Under no circumstances should another cut be made along the resulting line. Otherwise, the glass may break. The cut must be made as quickly as possible. For example, if we are cutting a length of a meter, then you need to spend no more than two seconds on it.

- In order for the workpiece to break quickly and accurately along the cut line, you need to lightly tap on the back side of the glass. After which you will not need any effort to break it off.

If you are just a beginner, it is best to practice on small pieces; this will help you determine the correct angle of inclination of the tool, gain experience, reduce losses, and also avoid mistakes in the future.

Plexiglas: glass or plastic

Not all types of glass can be cut with glass cutters. There are materials on the construction market that either cannot be cut at home at all, or to cut them you need to familiarize yourself with certain rules, and some are cut very simply.

One of the most flexible materials for cutting is plexiglass. It is a transparent plastic with thermoplastic properties. The material is very easy to process, but there is one feature: low thermal conductivity, due to which the edges of the cut immediately heat up. Therefore, before cutting acrylic glass, you need to think about how to cool it.

Basic tools for cutting plexiglass:

- hand saw for metal;

- a circular saw;

- cutter;

- milling machine;

- stationery knife.

The choice of tool directly depends on the thickness of the glass: the thinnest - with a knife, the thickest - with a circular saw or on a machine. Electric saw blades are special for plexiglass, but are suitable for copper and aluminum.

You need to work quickly with a hacksaw or stationery knife. Unlike window glass, the cut line can be drawn several times. During cutting, the blades are cooled so as not to melt the edges of the cut. The resulting cut will have roughness, which can be removed when processed with sandpaper.

The low melting point makes it possible to cut plexiglass with a jigsaw and obtain a wide variety of shaped products. In a jigsaw, the file is replaced with nichrome wire. which connects to a transformer with an operating voltage of up to 4 V. The heated wire easily and softly passes through the plexiglass along any trajectory. the cut is smooth and even, requiring no additional processing.

How else can you cut glass?

What to do if you don’t have a glass cutter at hand? There are ways in which glass is cut with non-standard tools. This operation can be carried out with a soldering iron, grinder, nichrome thread and even ordinary scissors! Let's find out how to properly cut glass with your own hands using each of these methods.

- Using a soldering iron. First, cuts are made with a file at the beginning and end of the cutting line. Then you need to carefully run a well-heated soldering iron along the entire line. Due to the temperature difference on the sides of the surface, the glass will crack, after which all that remains is to carefully break it off.

- Bulgarian. This tool is found in almost every home, so it is not surprising that it has also been adapted for working with glass. In order to cut glass with a grinder, you will need a thin diamond disc. With its help, a thin groove is made along the entire cutting line, along which later chipping occurs. But when cutting with a grinder, you need to make sure that the glass does not overheat, and be sure to use coolant. You need a good tool, otherwise the glass will simply shatter from its vibration. When working with an angle grinder on glass, it is imperative to protect your respiratory organs and eyes. Getting the smallest glass dust into them will not lead to anything good. Therefore, if you cut a sheet of glass with a grinder, you need to stock up on glasses and a respirator.

- Using heating and cooling. A thread soaked in a flammable substance is laid along the cutting line and set on fire. Immediately after it goes out, the cutting line is cooled with water. A sudden temperature change will cause the glass to crack. Another option is to heat the glass with a nichrome thread through which an electric current passes. In this case, no water is required, the temperature difference between the two surfaces of the sheet is sufficient.

- Scissors. Thin glass up to 3 mm can be cut with ordinary tailor's scissors, if this operation is performed by immersing the scissors and glass in a container of hot water. The process feels like cutting thick cardboard.

How to cut: instructions

First, prepare the glass surface. It should be washed well, removed from grease and dried. If stains or streaks remain on the surface, the cutting tool may slip, resulting in a crooked chip. It is better to choose a table or a piece of chipboard as a working surface. You can lay a piece of thick fabric (tablecloth, sheet) or linoleum on it.

After preparing the surface and materials, markings should be carried out. If you need straight edges, it is better to draw them using a thick ruler; for smooth lines, you can use patterns. To prevent the item from slipping, you can secure it with pieces of electrical tape from the inside out. Then, using a file, grinder or other cutting tool, a smooth, clear line is drawn.

When the cut is ready, you should break the glass. Place a small object (match, nail, pencil) under it and lightly press with your hands on both sides. You can also split the mirror on the edge of the table, or tap it from below with a small hammer.

Important! If you can't break the glass, you don't need to use brute force or push very hard. It is better to make a second cut at a distance of 2 cm from the first.

Tempered glass processing

The question often comes up on forums: how to cut tempered glass? The answer is simple: tempered glass cannot be cut or drilled. Whenever you try to do this, it loses all its properties and simply shatters into small pieces. Tempered glass was used in cars before triplex technology was invented. During the accident, glass fragments should not have injured passengers. So you shouldn’t even try to cut tempered glass with any tool.

To understand how to cut glass with your own hands, you just need to take it and try it. The choice of method depends on individual skills and the availability of the necessary tools. But all these options are quite feasible at home.

Glass preparation

Often many people simply forget about this important point. But high-quality glass cutting with your own hands is impossible without preliminary preparation. New glass should be wiped with a damp cloth. After it dries, wipe dry.

Some experts recommend using newspaper rather than a rag. It will not leave lint on the glass that could interfere with the movement of the glass cutter.

Glass that has already been used cuts much worse and requires more careful preparation. They are washed using special detergents, and after drying, degreased with turpentine or kerosene. During the drying process, it is necessary to prevent dust from entering the sheet.

Tips for cutting glass

Professionals always have in their arsenal tricks and secrets that they have gained from their own experience. Use them to make the process easier.

- Use your ears, the sound of cutting glass will help you determine whether you are doing everything correctly. A steady hiss is what you should hear. The appearance of a squeak indicates the need to sharpen the instrument.

- Increasing pressure does not mean doing it better. A roller tool requires more force than a diamond one, but if white splinters appear along the seam, ease the pressure to avoid crumbling the cut.

- Do not add pressure at the edge of the glass, but, on the contrary, reduce it 5 mm before the edge. This will protect the instrument from damage.

- Using a glass cutter, draw one confident line, without repetitions or secondary cuts. Break the glass immediately, without delaying it until later.

- You can make the task of the glass cutter easier and extend its service life by using oil or paraffin. Apply oil to the roller or glass before cutting.

- To make breaking the glass easier, place the ruler you used for drawing under it. A marker or pencil placed exactly along the cutting line will also work.

What properties does silicate glass have?

Types of glass

How to prepare glass batch?

Glass mat - what is it, types, application photos, pros and cons

Choosing a glass cutter

In order to make the cutting process as easy as possible, they use special tools - glass cutters. They are represented by three main types:

- A glass cutter, the cutting tool of which is made of natural diamond. This device is the most popular. Thanks to its tip, you can cut glass whose thickness is less than 10 mm. The cut is perfectly smooth, without defects.

- Roller cutting tool. In this case, the working tool looks like a roller. Diamond in this version is replaced by a special alloy of hard metals, most often tungsten and cobalt.

- Oil glass cutters, which differ from roller versions by supplying a special oil lubricant to the cutting tool. Thanks to this, the service life of the roller mechanism is extended.

Cutting material - a detailed algorithm for beginners

To cut the glass evenly, it will need to be annealed. This process involves uniform heating of the surface of the material. In this way, it will be possible to eliminate the stress that was formed as a result of hardening. It is the stresses that become the main obstacles to accurate cutting of the material. Annealing must be performed in a certain order. First, heat the water and maintain its temperature. After this, you dip the glass into the liquid until it heats up to a certain temperature. Different brands require specific cutting temperatures.

Proper glass cutting

Thus, Effetre and Bullseye brand material must be heated to 504°C. Borosilicate material requires a higher temperature, which must be immersed in water to a temperature of 567 °C. Satake brand glass requires less heating - approximately 470 °C. To soak small beads, on average it will take no more than 30 minutes. Larger beads should be kept in water for about an hour. The paperweight already requires 12 hours of soaking. The largest products, whose weight exceeds 50 kg, sometimes need to be kept in boiling water for several months.

Once the desired temperature is reached, cool the material slowly. The final temperature of the finished glass should be slightly below the temperature limit at which the glass deforms. This figure averages 1014.5 Poise. Do all the work very slowly to avoid the slightest tension. For cooling, you will need an oven in which the temperature of the material must drop to room temperature. After the glass has cooled, put on your glasses and start cutting it. To do this, take a square and mark a cut line.

Hold the tool along the line you left. Use a glass cutter to cut along this line. We press the material with medium force and make a shallow scratch along the marking line.

Be extremely careful, as you can only run the glass cutter along the line once. At the next stage, you need to take the rod, place it exactly under the cut line and make a sharp push on both sides of the glass. If you did everything exactly according to the algorithm, the material will break into two neat, even parts. To ensure safe cutting lines, they need to be treated with a grinding stone.

If you have time and desire, the glass can be re-tempered. However, it is best to trust a specialist who has both the skills and equipment for this. Due to the fact that the process of cutting tempered glass is quite lengthy and complex, many people take a different route. They buy ordinary glass, cut it into the required pieces, and then take it to professionals for tempering.