A fire door is an element of protection against fire, high temperature and toxic smoke. People have long been building blank walls, partitions, ceilings from stones, bricks, reinforced concrete slabs or monolithic structures, and fire doors are no exception. The purpose is to divide and fence off premises into fire compartments. The whole problem is that very often it is necessary to arrange and make openings in them: construction openings - for gates, windows, doors, hatches and technological openings - for conveyors, conveyor belts, utilities, pipelines.

Fire resistance limits - E, EI, EIW, EIS, EIWS

This is the period of time (indicated in minutes or hours) from the moment the flame begins to impact the surface until the onset of one or more limiting states.

The fire resistance limit of PD is determined during fire resistance tests in accordance with GOST.

Main limit states of PD:

- E - loss of door integrity, and/or

- I - thermal insulation ability.

Other types of limit states include:

- W - achievement of the maximum value of heat flux density - for glazed PDs with a glazing area of more than 25% of the area of the canvas, and

- S - achievement of the maximum value of smoke-gas tightness - for smoke-gas-tight PD with a glazing area of more or less than 25% of the canvas area.

The fire resistance limit of fire-resistant structures is measured in minutes - 15, 30, 60, etc. minutes and is designated as EI-15, EI-30, EI-60 respectively. The fire resistance limit of fireproof windows is indicated only by the loss of integrity time (E), i.e. E-15, E-30, E-60.

When testing structures for fire resistance, the lowest value for the onset of the limit state is taken.

So, if during testing the structure lost its thermal insulation ability (I) at the 35th minute, and its integrity (E) at the 65th minute, then the product will be assigned a fire resistance limit of EI-30.

It is also important that the fire resistance limit indicators should be read as “no less than (15, 30, 45, 60) minutes”, that is, a design with a fire resistance limit of EI-60 can hold back fire for longer than 60 minutes, but no less can not.

This is interesting: How to choose a fire door and what to pay attention to

Fire resistance

The fire-resistant properties of fire doors largely depend on the size of the glass insert and the filling option for the opening.

For models with a glass surface area not exceeding 25%, there is a separate classification. The markings for this characteristic use the letters E, I, S and numbers.

E characterizes the appearance of cracks on the doors, through which smoke and fire can penetrate.

I is an indicator of a decrease in the thermal insulation capacity of the sheets, accompanied by overheating of the internal part of the structure as a whole.

S – indicator of a decrease in the ability of doors to isolate a room from smoke.

Depending on the type of filling used for doorways with a glass area of less than 25% of the total surface, doors are divided into categories EI-15, EI-30, EI-60.

The number indicates the number of minutes until fire resistance is lost. Doors of the first type have a number equal to or greater than 60 in the marking, which indicates the minimum durability time.

For fire doors of the second type, the maximum time is 60 minutes, and the minimum is 30. Models of type 3 are characterized by the lowest resistance because they can withstand a maximum of 30 minutes of fire, and a minimum of 15.

Smoke-gas-tight door models with a glass insert not exceeding 25% of the total area of the door panels, depending on the type of filling of the openings, are similarly divided into classes EIS -15, EIS -30, EIS -60 and more.

If the duration of reaching the fire resistance limit differs according to different indicators, then the number is placed not just at the end, but after each letter. For example, markings E 60, I30, S15 are possible.

This means that smoke can begin to seep through the iron sheets after 15 minutes, heat will no longer be insulated after 30 minutes, and cracks can appear within an hour.

For a variety of doors with a large glass area exceeding 25%, the letter W is entered into the marking, which characterizes the heat flow entering the room at a distance of up to half a meter.

The marking of fire doors with a large glass area looks like this: EIW. The letters next to them indicate numbers indicating the number of minutes.

When considering doors as an element of building structures, the parameter R is introduced into the characteristics - the duration of the time interval after which the load-bearing capacity is violated.

What is a redevelopment project

Any change in the configuration of the room is a redevelopment, including the installation of a door on the staircase. Redevelopment should be carried out according to a special project. It all depends on the design of the house. Somewhere there is already an opening for installing a door, somewhere you need to build an additional wall in order to install a door in it. All this is done in the redevelopment project: door, installation location, materials, dimensions.

This project can be done before the residents' meeting, or after. However, in order to have a project approved by all kinds of government services, the approval of the general meeting is required; without it, nothing will be agreed upon. The law prohibits redevelopment without a project.

The redevelopment project is prepared, for example, by the technical inventory bureau. You can contact any private design organization that has the appropriate design permits, but it is more convenient to work with BTI, because a private company will still approve this project with BTI. There are even individual organizations that undertake to carry out the entire turnkey approval process from the installation project to coordination with government services.

The project itself for installing and assembling the door can cost from 5,000 RUR and more - it all depends on the city of residence. But the companies’ services for coordination will most likely start at RUB 20,000. Complex work costs from RUR 30,000. The deadlines can be up to 6 months, this does not take into account the time frame for receiving the decision of the general meeting of residents.

Dimensions, materials for manufacturing

The type of fire-resistant doors is determined by national technical regulations, which consider them as types of fire barriers.

The document strictly indicates the required compliance of dimensions, weight, and other characteristics with the purpose of the premises, the thickness of the walls, the height of the ceilings and the width of the openings in it.

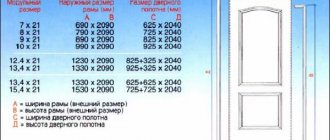

The following parameters are common:

- height from 2030 mm to 2200 mm;

- width from 800 mm to 950 mm for single-leaf models, 1200 mm for double-leaf models.

Particular attention is paid to the design of emergency exits, the width of which should be more than 0.8 m; height – minimum 2 m.

The dimensions of fire doors in rooms without constant presence of people, according to the standard, may be somewhat smaller. The minimum height is 1.9 m, and attic fire exit doors can be up to 1.5 m high.

In addition to standard sizes, many manufacturers offer the production of fire-resistant door structures according to individual drawings, which can specify any shapes and parameters.

With large dimensions, products have greater weight, require additional effort during delivery and installation, and differ from conventional products at a higher price. Models with a large area of translucent insert and a high degree of fire protection are characterized by maximum cost.

Steel sheets are used to produce fireproof products; wood with a high degree of impregnation with fire retardants, which is protected on both sides by non-flammable coatings; special heat-resistant plastic.

Polymer outer layers can have different colors and beautiful decorative elements; harmoniously complement the interior of the room. In models made of fire-resistant glass, metal profiles are used as a base.

What happens if we don’t agree?

As a result, if you do not receive all these documents (consent of the owners, redevelopment project, coordination with firefighters), any resident of your house can file a lawsuit, and the court will oblige you to dismantle the door, although usually such disputes arise only between neighbors in the stairwell.

Here, for example, are the court decisions that I found: In 2022, the Volzhsky District Court of Samara ordered the apartment owner to demolish an unauthorized partition in the common corridor, because there was no consent of all apartment owners, and the door prevented neighbors from accessing the apartment. A similar decision was made by the Sterlitamak District Court of the Republic of Bashkortostan in 2014. Judicial practice across the country is clear. If there is no agreement, dismantle it, especially if it disturbs the neighbor.

In addition, unauthorized installation of a door without permits and approvals is considered an administrative offense. For this, a small fine of 100-300 R is provided. But for violating fire safety standards (since the door can block access to fire exits and create an obstacle for fire crews to access the apartment), the fine will be higher: 2000-3000 RUR.

Building regulations and markings

Fire doors are installed both in residential and any other premises.

Some models can be constantly open, but must have an automatic closing device.

To prevent crowding, the doors are equipped with an Anti-Panic system, which allows you to easily and quickly open the doors from the inside, while closing from the outside is done using a key.

The ability to open indoors by pressing or turning a handle is very important for people under stress and can save many lives.

All fire barriers must have a metal marking, which is called a nameplate. It contains information about the engineering features, dimensions, and characteristics of the barrier. The presence of markings is evidence that the door has passed tests and meets the standards.

If the door was installed a long time ago, maybe not even you

If you installed the door, the approval procedure is the same. We'll have to collect signatures and make a project. There is no need to legalize the installation through the court; it is enough to collect all the documents in case one of your neighbors sues you with a demand to dismantle the door.

It may be that you bought an apartment and there was already a door. Then you are not responsible for it. Recently, the Supreme Court supported tenants who were trying to be forced to dismantle a door installed by the previous owner of the apartment. The court explained that it is necessary to identify a specific person responsible for unauthorized redevelopment, and not thoughtlessly oblige residents to eliminate other people’s alterations at their own expense.

Therefore, you can safely refuse to do anything if you did not install this door. You can even say about your door that it is not yours. But then one fine day the management company or a neighbor may simply cut down this door, and you won’t do anything to them for it - the door is not yours.

Products class EI60

Among the wide variety of fire doors available from suppliers, products with the EI60 marking attract deserved attention.

The product has an affordable price and can be installed in residential buildings, as well as in the following premises:

- dangerous production workshops with the threat of fires;

- cable and ventilation sections;

- pumping stations;

- warehouses with flammable products;

- technical rooms, basements, attics, ground floors.

- emergency exits of all types.

EI60 doors are manufactured in different design options and can be made with or without a glass insert.

This is interesting: Fire hatches: types, characteristics, types of fire resistance

Lock system

There are several types of locks used on fire doors in various premises. In public institutions, a locking system of three main elements is often installed, which includes a locking unit with a horizontal beam on the left; the same block on the right; a long-shaped handrail connecting both locking fragments.

It is very easy to open such a door; to do this, you need to push or press the handrail, when it goes down, the mechanisms are activated and the doors open.

The handrails of many types of fire-resistant door structures are covered with heat-resistant plastics that are not subject to heating and destruction.

Particularly valued are lock products with automatic indicators that record an increase in temperature and smoke concentration; appearance of flame. When there is a threat of fire, they independently open the fire doors.

What should the author of the question do?

You write that your neighbor put locks on the common doors in the entrance. You can make the same claims against him. The neighbor breaks the law in the same way by blocking the passage to the fire escape. There is definitely a fine for this, and the fire department will certainly require you to dismantle the lock, or even the entire door.

In this situation, you need to complain about your neighbor to the housing inspection, fire supervision and police. But it’s better to try to find a compromise: in this case, both you and your neighbor are breaking the law.

Source: journal.tinkoff.ru

Requirements for fire doors: according to the letter of the law

The requirements for limiting the spread of fire (namely, this is the function that fire doors perform) are established in Federal Law No. 123-FZ of July 22, 2008 “Technical Regulations on Fire Safety Requirements” (hereinafter referred to as Federal Law No. 123). According to this document, parts of buildings, structures, fire compartments, as well as premises must be separated from each other by enclosing structures or fire barriers.

A more complete idea of what a fire door is is given by GOST R 57327-2016. Fireproof metal doors. General technical requirements and test methods". This national standard was first introduced on July 1, 2022; it establishes the classification of doors, technical requirements and test methods, requirements for components and materials, as well as general rules for the acceptance, installation and operation of this type of fire-fighting equipment.

A fire door in this document is described as a structure of moving and fixed elements with locking mechanisms, self-closing devices and fastening elements. The purpose of this design is to prevent the spread of fire and combustion products.

The regulatory framework for fire doors is also supplemented by:

- “GOST R 53303–2009. Building structures. Fire doors and gates. Test method for smoke and gas permeability", with change No. 1, effective from September 1, 2014;

- "GOST R 53307–2009. Building structures. Fire doors and gates. Test method for fire resistance."

These documents explain how to properly test and evaluate the quality of a finished fire door.

Despite the fact that, as a general rule, standardization in Russia is voluntary, the application of the above national standards may be mandatory for the manufacturer. We are talking about cases when he publicly declares the compliance of his product with national requirements and records the corresponding designation in the labeling. In other words, if a manufacturer declares compliance with GOSTs, he is obliged to certify his products; in our case, he is obliged to certify the door as fireproof.

As for the buyer (the head of the organization), it is he who is responsible for compliance with fire safety requirements, including, for example, for the good condition of fire door mechanisms (clause 37(1) of the Government of the Russian Federation of April 25, 2012 No. 390 " About the fire safety regime"). That is why purchasing doors that meet state standards is no longer a luxury, but a vital necessity.

How to understand the types of door blocks and their characteristics? We will try to answer this question in the next section.

Types and characteristics of fire door blocks

According to Article 37 of Federal Law No. 123, fire barriers are divided into seven types. In turn, filling openings in fire barriers (for example, fire doors), depending on the fire resistance limits, are divided into three types (first, second and third). Each type of opening filling has its own fire resistance limit (Table 24 of Federal Law No. 123), which for doors has several designations depending on the glazing area and the presence of smoke-gas-tight properties.

As a result, markings such as “EI 60” or “EIS 30” are available to the manufacturer and buyer, where the letters indicate a certain parameter (limit state):

- "E" - loss of integrity;

- “I” - loss of thermal insulation ability;

- “S” - loss of resistance to smoke and gas permeation.

And the numbers indicate the time period in minutes during which the limit states are observed.

Example

The door marking “E 60/ I 30/ S 15” means that the product will lose its integrity after 60 minutes, its thermal insulation capacity after 30 minutes, and will lose its resistance to smoke and gas penetration 15 minutes after the start of exposure to fire.

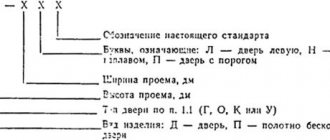

In addition, depending on the design of the door, it can be:

- deaf;

- glazed;

- single-field and double-field;

- with and without a threshold;

- right and left opening.

The modern market offers a wide variety of fire doors, which can not only perfectly perform their main function, but also be easy to use and aesthetically pleasing in appearance. At the same time, the buyer’s main task is to correctly assess their needs and choose the best quality product that suits them. We'll tell you how to do this in the next section.

How to choose a high-quality fire door: step-by-step instructions

Despite the existence of national standards regarding fire doors, products that do not meet basic quality requirements still continue to enter the domestic market. In such a situation, the possibility of becoming a victim of counterfeiting is very high. How to distinguish a fake from a quality product that complies with GOST R 57327–2016?

It is necessary to begin studying the product by confirming three main factors:

- availability and compliance of markings;

- completeness of delivery;

- presence of all necessary documents.

Any fire door must be marked in such a way that even after a fire its characteristics can be determined. That is why responsible manufacturers most often use a metal nameplate where they write the following information:

- about the model;

- about technical conditions;

- about the date of production;

- manufacturer's contact information.

The delivery package of a fire door necessarily includes a product passport and operating instructions. In addition, such a product is accompanied by a certificate of compliance with fire safety requirements.

After an external inspection of the received product and the documents attached to it, you can proceed to the next stage - assessing the quality of the main structural elements:

- door frame;

- seals;

- accessories;

- thermal insulation filling of the sashes (thermal package).

When inspecting a door frame, you need to pay attention to the type, profile and fire resistance solution. The buyer should remember that GOST R 57327–2016 offers several optimal solutions on this issue. If the manufacturer has not used them, it is advisable to ask yourself why this is happening.

When we talk about seals, we first of all mean thermal sealing tape, which ideally should be located in a special groove in the door frame. The tape is made of a substance that foams under the influence of temperature and fills the gaps between the sash and the frame. That is why at the time of purchase and during operation it must fit tightly to the structure. It is important that the door also has a rubber seal, which can protect the room from smoke penetration at the initial stage of the fire before the tape is activated.

High-quality fittings for a fire door are a guarantee of its functionality. Skimping on these additional elements may result in the product's inability to fulfill its primary purpose - temporarily preventing the spread of fire.

Fire door fittings include:

- lock;

- loops;

- anti-removable bolt;

- additional locking devices;

- end bolts.

These elements must be made of quality materials that allow the fire door to meet fire resistance requirements. Often, non-flammable plastic is allowed to be used as part of the fittings, but complete with metal components or heat-insulating structures (for example, a heat-insulating box for the lock body).

Of great importance for the functionality of a fire door is the design and thermal insulation of the frame, as well as the filling of the sash. Unfortunately, it is impossible to establish compliance of these elements with GOST requirements without damaging the door itself. However, a competent buyer can ask the manufacturer for a demonstration sample, which will give an idea of the composition of the door being purchased.

The frame of a metal fire door is made of cold-rolled metal sheet with a thickness of 1.2 mm. The design of the box can be corner, end or covering. The thermal package of the sash must be made of dense heat-insulating material. As a rule, for fire doors with a fire resistance of more than EI-30, the thermal package must be composite.

A fire door, like any other product offered for sale, must satisfy not only the functional needs of the client, but also correspond to his aesthetic ideas. Experts highlight the following aesthetic properties of such doors:

- type and method of packaging;

- marking order;

- condition of fasteners;

- quality of powder coating (in particular, color uniformity).

As a rule, manufacturers who do not care about the aesthetic appearance of the product make more serious errors, so sloppy packaging or primitive labeling can serve as a signal for the buyer to be more attentive.

Choosing a fire door is a serious and responsible undertaking. You can carry it out yourself, using the recommendations described above, or you can seek the help of specialists in this matter. At the same time, by turning to trusted suppliers of high-quality fire-fighting equipment, the head of the enterprise, on the one hand, minimizes the risk of a fire hazardous situation, and on the other hand, prevents liability for possible fire safety violations.

Kinds

Fire door sizes

Types and types of fire doors vary not only from the fire resistance limit for which they are maximally designed before losing load-bearing, heat-insulating capacity, smoke and gas resistance, but also from the main material of manufacture. The last parameter affects a lot, so it’s worth taking a closer look at the main manufacturing options.

Wooden

Wooden fire doors

- Material for production – wood. They are intended for installation in residential and public buildings. The general requirements for their types, design, and dimensional characteristics are classified by the Soviet GOST 6629-88. A small nuance - it doesn’t say anything about fireproof products.

On this topic ▼Determination of the fire resistance limit of building structures

Tables for wood, metal and other building structures

- In the USSR, a standard fire door, also resistant to burglary, was usually a familiar wooden structure, only upholstered with thin sheet iron, with the obligatory laying of asbestos cardboard over the entire area of the door, less often - under the upholstery of the frame, to increase the fire resistance limit. It was a completely usable, working thing, tested by time and fire. During perestroika, it, like many other things, for example, the Soviet Union, was “rejected” and they began to invent something new, preferably in a Western manner.

- Modern with a base of wooden structures made of solid solid rock, or knot-free timber and boards; Usually, frame elements that are more powerful in frame, thickness of the canvas, than for ordinary interior ones, are made in two different ways.

- The first technology is based on deep fire-retardant impregnation of well-dried wood with special compounds, usually in autoclave baths under pressure, with a certain temperature regime of the process, which gives it the necessary characteristics to withstand fire and high temperatures. Plus - it turns out to be the lightest of all types, which makes it necessary and effective to use it in residential and public buildings, where it will be opened by people of different ages, physiques, body weight and physical strength. The downside is the need for repair/replacement, since this technology for protecting wood of any species from fire gives a maximum service life without loss of necessary properties of 5–10 years.

- The second technology involves a minimum amount of wood - a frame sheathed with non-combustible / fire-resistant materials - sheets, slabs. The inside is filled with rolled mineral wool and basalt insulation, which both withstands thermal effects well and does not emit volatile, gaseous substances dangerous to people. Mineral materials in the form of rigid sheets or a combination of both are often also used.

- Exception: WHO and the Russian Ministry of Health have long ago categorically prohibited the use of asbestos in any form - sheets, cords, as a strong carcinogen. Products in which it was previously used, including obsolete ones from the Soviet period, are subject to mandatory replacement.

- The second option for internal filling is the use of heat-sensitive materials similar to modern fire-retardant paints. They foam when exposed to heat, filling the volume with durable mineral foam.

- The fire resistance limit of high-quality factory-made wooden products in compliance with production technology corresponds to EI 30; 60. A mandatory condition is the presence of an industrial safety certificate.

- They are made so that the vestibule is as dense as possible.

For additional protection against the penetration of fire and toxic combustion products into the protected room, several layers of different sealants are installed/mounted in the box: against cold smoke - rubber tapes, against hot smoke - heat-sensitive, intumescent gaskets.

Note: this sealing method is used in all types, types and modifications of modern products.

The advantage of using wooden models is that, due to the physical properties of wood, they do not deform in the opening, which is possible when using metal ones.

Metal

Double-leaf metal fire door

- Fire-resistant metal doors, the characteristics of which correspond to EI 30 and 60, are made of metal corners, sheets of both steel and heat-resistant aluminum alloys. Sheet thickness – from 1 mm. Quite new is the use in the production of complex cross-section cold stamping profiles for the manufacture of frames and boxes, which have higher characteristics than angles.

- Metal ones have more weight than wooden ones, but have better technical and operational parameters - strength and wear resistance.

- For production, the plant/company develops and approves separate technical regulations depending on the type, modification, compliance with which guarantees full compliance with the requirements of regulatory documents. They must be tested. The internal filling is similar to wood.

- Each product must be labeled indicating all the main characteristics.

Conclusion: metal manufacturing options are more reliable, have a longer service life, and require repair or replacement less often. Therefore, they are most often used not only in industrial enterprises/productions, but also in public and residential facilities.

Glass

Glass fire door swing

- Quite a new type of product. In the past, even glazed wood/metal modifications were not used as often as standard blind models.

- The frame is usually made of heat-resistant aluminum alloy, the filling is laminated safety glass or translucent composite material that can withstand regulatory fire/heat exposure.

- Advantages - attractive appearance, aesthetic appearance, which is important for rooms with increased requirements for design and interior decoration, excellent insolation from window openings; possibility of inspection inside when closed, lighter weight than metal ones.

- The main area of application is office and business centers, shopping malls, art galleries and museums.

Extremely important! All fire doors and gates with wickets must be equipped with self-closing devices - hydraulic, gas, lever closers; springs, blocks with counterweights. Why this is needed is quite clear, because an unlocked door will not fulfill its functions; and one should not rely on the attention, memory of employees, engineering and technical personnel, maintenance personnel working in protected objects.

Canvas materials

This refers to the material from which the structure is made. Based on the type of material, the following types of PD are distinguished:

- Metal (FDM) - the leaf, like the frame of such doors, are made, as a rule, of steel with a thickness of 1 mm, hence their other name - steel (iron) fire doors;

- Wooden (WPD) - the canvas consists of wood, processed in a special way, and/or fire-resistant wood-based materials. The box can be either metal or wood;

- Glazed - metal or wooden PD with glazing less than 25% of the area of the canvas;

- Glass doors and partitions - the door leaf of such structures is made of more than 25% of translucent material, as a rule, it is fire-resistant glass or fire-resistant glass with gel-like non-flammable filling. The frame and frame of the door leaf of such doors most often consist of aluminum.

There is a myth that there are plastic PDs, but this is nothing more than fiction. Although a fire door can be lined with plastic (this is especially true for wooden fire doors), the technology for making a plastic fire door does not yet exist.

This is due to the fact that PVC products, in principle, cannot withstand prolonged exposure to fire - plastic not only has very low fire-resistant properties, but is also extremely toxic when burned, which is unacceptable for this type of structure.

Construction standards (SP and SNIP)

The most important fire safety requirements for fire doors and other fire-resistant structures are contained in SNiP 01/21/97. The document came into force at the beginning of 1998 instead of the partially canceled SNiP 2.01.02-85. It was adjusted twice - in 1999 and 2002, and in 2011 it was registered with Rosstandart as SP (Code of Rules) 112.13330.2011.

The building codes introduced by SNiP regulate the fire safety rules during the construction of various buildings, as well as their subsequent operation. The key requirements are as follows:

- when developing design documentation for construction, including PPR, it is necessary to provide for the structural and technical solutions necessary to comply with fire safety rules;

- One of the basic requirements is the installation of fire doors on escape routes and in rooms with a high level of potential danger. The latter include social institutions, hotel-type facilities, places of mass gathering of people, enterprises with large staff, etc.;

- fire-resistant door structures are selected taking into account the minimum dimensions and the required fire resistance limit;

- Fire doors must be installed by licensed contractors, and the products themselves must be certified.

The specified SNiP introduces important concepts for the classification of fire doors: the level of fire hazard, the degree of flammability of materials and the fire resistance limit. The document provides a detailed definition of each of them, and also provides links to regulations governing the rules for conducting relevant tests.

Fire safety requirements

The basic documents regulating the rules for installing fire doors include the Technical Regulations on Fire Safety Requirements. It was put into effect by Federal Law No. 123-FZ, which was signed by the President of the country on July 22, 2008. The legislative act has been adjusted many times, so the version adopted on December 27, 2018 is currently in effect.

Important. The main objective of the Technical Regulations is to create conditions for the safe construction and operation of buildings of any type and purpose.

The requirements of the document apply to all stages of the existence of a building, from design to possible disposal. The Regulations complement and expand the provisions of the documents listed above, including GOSTs, SNiPs and Codes of Rules.

Design Features

The following design features of fire-resistant structures are distinguished:

Number of door leaves

There are two main types:

- Single-field (in technical documentation, as a rule, they are not designated at all or are designated by the number 1);

- Double-field (indicated by the number “2”, for example G2 - deaf double-field right).

In another way, such doors are called single-leaf and double-leaf, respectively.

In turn, double-leaf fire doors are divided into equal-floor - when both door leaves are the same size and opposite-floor - when the door leaves are of different sizes.

There are active and passive doors. An active sash is one on which there is a handle for opening and closing, a passive sash is one without a handle. The active leaf can be either right or left;

Opening direction

Fire doors, like any other, can be right-handed (usually not indicated in technical documentation) or left-handed (indicated by “L”, for example GL door is a solid single-leaf left door).

Often the direction of a door is mistakenly determined by the opening side - if the door opens to the left, then it is left-handed.

This is not true, in fact, the side of the door is determined by the outer door hinges on the side of the active leaf.

Those. if you stand facing the door so that the door hinges of the active leaf are on the outside (or on the side of the door frame closest to you, if the hinges are hidden), and if they are on the right, then the door is right, if the hinges are on the left, then the door is left;

Door leaf type

There are two main types:

- Blind canvas - in technical documentation it is designated “G”, for example GL - blind single-field left;

- The glazed leaf is designated “C”, for example S2L – glazed double-leaf left; in another way, glazed fire doors are called translucent.

When choosing a fire door, it is important to remember the following:

ENGLISH AND METRIC MEASUREMENT SYSTEMS

Today the market puts forward products labeled in two measurement systems:

1. English, the unit of measure of which is the foot (30.48 cm). The system is widespread mainly in the United States, but its convenience makes feet very popular among manufacturing brands of various product categories, including entrance doors.

2. Metric, based on the meters and kilograms familiar to Russia and serving as a recognized international system of units. Domestic and foreign companies often offer entrance doors in this measurement system, putting forward the following standard values:

- 2040 x 826: ordinary wooden doors;

- 2050 x 860: metal reinforced structures.

Separately, the presence of one or two doors should be taken into account.

Installation and installation

Can only be carried out by an organization licensed for this type of work.

If you do not have a license to install fire doors, installing such doors yourself is strictly prohibited. Liability for such a violation can be very serious, even criminal.

When purchasing, you need to check with the seller whether he has a license to install doors.

If the seller is not involved in installation, you will have to look for a third-party organization (one that has a license for this type of work), which means you will have to spend your time and money finding a licensed installer.

How to legally install a door on a staircase?

Many years ago, we fenced off part of the public corridor that leads from the elevator to the apartments with a separate entrance door. Now the neighbor who lives opposite is demanding that it be dismantled. The door leads only to our apartment; it does not block the neighbor’s passage. Usually we don’t even lock the door, we just close it. Is it possible to somehow legalize it? Maybe this is not required?

By the way, the neighbor put a lock on both doors that all residents use: on the entrance from the elevator and on the door leading to the fire escape.

It so happened that residents of apartment buildings throughout the country fence off “vestibules” for several apartments with a common door. In 90% of cases this is done without approval. In the nineties, such doors were installed to protect against thieves. Utility and supervisory services turned a blind eye to this.

Now they have begun to monitor this a little more strictly, although no one specifically goes and forces them to dismantle the doors. But both management companies and fire departments respond to citizen complaints.

It is quite difficult to legally obtain permission to install such a door, although it is possible.

Let's figure out how to get permission to install a common door in the corridor, if you really want to, or how to legalize an already installed door that suddenly began to bother the neighbors.

Fire resistance parameters and dimensions

The standard technical characteristics of fire doors and gates most commonly used in civil and industrial construction are as follows:

Dimensions of fire door elements

Dimensions:

- single-leaf - from 2.03 x 0.86 to 2.1 x 1 m, double-leaf - from 2.03 x 1.3 to 2.1 x 1.5 m;

- gates - from 2.2 x 1.75 to 3-4 m, with a wicket in them - from 2.2 x 2.3 to 2.5 x 3 m.

These sizes comply with building standards, making them easy to install on site.

- Software – EI 30; 60.

A simple explanation of the EI 60 marking: the letter E indicates loss of integrity, i.e. the formation of holes through which fire and smoke begin to penetrate into the adjacent, protected fire compartment;

- I – loss of the ability to not transmit heat, therefore, strong heating of the surface inside;

- 60 – guaranteed time of flame and high temperature resistance, determined by calculations and full-scale fire tests.

Advertising brochures from some manufacturers offering a product with a limit of several hours (!) are at the very least meaningless, since this contradicts the requirements of the norms and common sense - the content should not have more software than that of the barrier in which it is installed. It turns out that the wall will burn/collapse, but it will proudly stand at the site of the fire.

There are also curious cases of installation in walls or partitions that are not barriers - structurally made of logs, timber, plywood sheets, or non-fire-resistant gypsum sheets.

Where are PDs installed?

These places are strictly regulated by regulatory documentation. In general, we can distinguish the following main places where PDs are installed:

- In places with large crowds of people - shopping and business centers, cinemas, hotel complexes, hospitals, schools, libraries, museums, etc.;

- Technical rooms, as well as rooms with electrical, gas and other fire-hazardous equipment - electrical switchboards, production rooms, boiler rooms, warehouses (especially warehouses with fire-hazardous and explosive substances), kitchens of canteens and restaurants, etc.;

- On the routes for evacuating people from a building (premises) there are exits to emergency staircases, exits from elevator halls, emergency and fire exits.

Cost and approximate prices

When purchasing PD, you need to be guided by the rule - “the bigger and better, the more expensive.”

That is, the larger the area of the door leaf and glazing, the higher quality and more expensive the finishing materials and fittings, the more additional equipment installed on the leaf (chips, transoms, ventilation grilles, etc.) - the more significantly the price will increase.

Remember!

If a door is called fireproof, it means that similar designs from a particular manufacturer have been tested for fire resistance.

This means that this type of structure meets the requirements of GOST and they must have a certificate of conformity, and in any case, they are required to contain fire for the stated time.

That is, a door that costs 10 thousand rubles will hold back fire in the same way as a door that costs 20 thousand rubles - that’s a fact. And if the seller assures you otherwise, this is nothing more than a marketing ploy.

The thing is that an expensive door will most likely look more expensive and elegant. And what kind of fire-resistant construction is needed for your specific situation is up to you to decide.

Commissioning and use

Video - 60 minute test of EI-60 doors:

Before commissioning, the installer provides documents - passports, certificates for the structure itself and its fittings. During operation, the following requirements must be observed:

- the door can only be opened using the installed handle;

- when opening doors, it is forbidden to make great efforts; it is enough to move the door evenly in the required direction;

- It is prohibited to place household waste and workplaces in the door leaf movement area;

- it is necessary to maintain the cleanliness of the floor area over which the door leaf moves;

- It is forbidden to hit the door and place obstacles to close it;

- It is prohibited to make changes to the modifications and fittings of doors that affect the level of fire resistance of the structure.

Door opening side

The effectiveness of the practical use of a fire door is influenced by a large number of operational and design characteristics. One of them is the opening side of the product. The current regulatory framework does not regulate mandatory requirements on this issue. However, when choosing a fire-resistant entrance structure, it is recommended to adhere to several principles:

- in the open position, the shutter should not interfere with the opening of other doors, which is especially important for multi-apartment residential buildings;

- if there is a vestibule, it is recommended to open the doors in different directions;

- for residential premises, the optimal direction for swinging the sash is inward, for public buildings - outward;

- doors installed on escape routes must, in most cases, open in the direction of travel, unless this conflicts with other regulatory requirements.

Design decisions taken during the development of design documentation regarding the opening of fire doors and ordinary doors must be agreed upon with regulatory authorities. The latter are the relevant units of the Ministry of Emergency Situations and construction control departments of local authorities.

Rules for installing entrance doors in apartment buildings according to SNiP 2022

Installation of entrance doors to an apartment (vestibule, entrance) must be done correctly. There is a certain set of norms that regulate this point. It is called SNiP 2022 (this is an updated version with some changes). In 99% of cases, the average person is unfamiliar with building codes and regulations, and, therefore, will install entrance doors to an apartment with violations. This is fraught with a fine and a requirement from the supervisory organization to dismantle the structure and install it again.

Installation site regulations

The level and quantity of requirements for the installation of fire doors is seriously influenced by the functional purpose of the buildings and premises at the entrance to which they are installed. For some categories of buildings, special rules have been developed to ensure their safe operation. Some of them should be considered in more detail.

Staircases and elevator halls

The need to install fire doors at the entrances to staircases and elevator halls is easily explained. The fact is that these parts of the building are mandatory for evacuating people.

Therefore, the following requirements are imposed on such fire protection structures:

- door width - at least 80 cm, and for some categories of buildings - 120 cm;

- construction height – from 190 cm;

- fire resistance limit is at least 30 minutes, for individual buildings and structures - 60, 90 or even 120 minutes.

Important. The list of requirements is determined for each specific building. It depends on the functional purpose of the building, its area and number of floors, as well as the number of people who can be inside at the same time.

Electrical switchboards

The operability of the building's power supply system is one of the prerequisites for the prompt evacuation of people and the effective use of elevators, smoke removal and fire extinguishing systems, as well as other utility networks. Therefore, fire doors must be installed at the entrance to electrical switchboards, which are responsible for the proper energy supply of the building.

Requirements for them will be determined according to the scheme described above for staircases and elevator halls. They depend on the purpose of the building, the area of the electrical panel and other similar parameters.

Schools and preschool educational institutions

Most of the educational facilities are places where people gather. Particularly high requirements in matters of fire safety are imposed on schools and preschool institutions. This approach is explained by the need for an increased level of protection of the life and health of children.

One of the prerequisites for ensuring this is the installation of fire doors. It is carried out in accordance with several standard rules:

- installation location - escape routes;

- requirements for the dimensions of fire-resistant structures are traditional: height – at least 190 cm, width – from 80 cm;

- The fire resistance limit is determined depending on the scale of the building, but not less than 30 minutes.

Project documentation for the construction of preschool educational institutions, schools and other educational institutions undergoes mandatory state examination. One of its stages is to check the compliance of the decisions made by the designers with the current rules in the field of fire safety.

Warehouses

The need to install fire-resistant door structures at the entrance to warehouse premises is determined depending on the type and characteristics of goods, substances and materials stored inside. Depending on this parameter, all objects are divided into several categories:

- “A” - warehouses with increased fire and explosion hazard. Example – stations for storing flammable liquids, stationary battery installations, etc.;

- “B” - fire and explosion hazardous warehouses (workshops for the production of wood flour, stations for the production of diesel fuel);

- "B" - fire hazardous premises. They are divided into 4 groups - from B1 to B4. Examples are peat storage facilities, auto repair shops, transformer substations and similar buildings;

- “G” and “D” are warehouses with a moderate and reduced level of fire hazard.

For warehouse and industrial premises of the first three categories, increased fire safety requirements are provided. One of them is the installation of fire-resistant doors. The minimum characteristics of structures are determined depending on the parameters of a particular building. For example, for warehouses of categories B3 and B4, the installation of fire doors with a fire resistance rating of at least 30 minutes is required.

Evacuation routes

Installation of fire-resistant doors on evacuation routes of any buildings that belong to crowded places is one of the mandatory rules in the field of fire safety. Such structures are subject to standard requirements, including:

- opening in the direction of people moving towards the emergency exit from the building;

- minimum dimensions – width from 80 cm and height from 190 cm;

- fire resistance limit – 30 minutes and above.

Important. A specific set of operational and fire safety characteristics of doors is determined at the building design stage. It depends on the functional purpose of the building, number of floors and area, as well as other similar factors.

Requirements of a competitive Russian market

When choosing an apartment entrance door, a potential buyer is guided by several of the most important criteria that describe the requirements that a quality product must meet. Their number is relatively small. Firstly, strength characteristics and safety level. They are determined by the grade and thickness of the steel used in manufacturing. In addition, the burglary resistance class of the installed locks is of serious importance for the parameter under consideration.

Based on the provisions of GOST 31173-2003, when manufacturing a door frame, a solid-bent profile must be used, the thickness of which is at least 1.5 mm, and the cross-section is 40 * 50 mm. In this case, it is allowed to install locking devices of 3-4 classes of resistance to burglary.

Secondly, the insulation parameters of the product. Requirements for heat and noise protection are contained in the above SNiPs. In practice, they are formulated as follows. To obtain a high-quality product, it is necessary to use progressive insulation materials, for example, polyurethane foam, polystyrene foam or mineral wool, the thickness of which is at least 4-5 cm. The specific value depends on the climatic characteristics of the region of operation.

It is important to note that not all requirements for modern apartment entrance doors are included in regulatory documents. For example, today reputable manufacturing enterprises produce metal structures that have two or three sealing circuits. In fact, the first of these options is already considered a standard, and one formed precisely by market conditions.

Thirdly, the requirements for the installation of apartment entrance doors. They are most fully formulated in SNiPs, which establish standards for the construction of multi-apartment residential buildings. Among the most important requirements is the need for a vertical location of the metal structure. It is allowed to deviate from the plane of the opening by no more than 3 mm. The second prerequisite for proper installation is the use of anchor bolts, the minimum diameter of which is 10 mm. In this case, the distance between the fasteners closest to each other cannot be more than 70 cm.

Source: door-met.ru