The main purpose of fire doors is to provide conditions for the rapid evacuation of people from a burning building and the effective work of Emergency Situations Ministry employees to localize and extinguish the fire. Based on this, the places for mandatory installation of such structures are determined. In accordance with the rules established by the current regulatory framework, fire doors must be installed in two main cases - on escape routes in crowded places and at the entrance to premises or buildings with a high level of fire danger.

Mandatory installation locations for fire doors.

According to SNiP 2.01-85 “Fire safety standards”, the installation of fire doors is provided for:

- elevator shafts, as well as technical rooms of elevators.

- balcony openings on common staircases;

- main exit from the building;

- corridors, if they are connected

by flights of stairs; - on objects (structures and buildings) no more than 15 meters high, if they have the only exit for evacuation;

- evacuation routes;

- in preschool institutions, if they are located in three-story buildings

. - vestibule-gateways;

- doors to garbage chambers;

- electrical panels;

- residential premises with built-in non-residential premises;

- communication routes between production workshops, if the technological processes in them are different from each other.

Additional Information

When installing a door leaf, an important indicator is a door with the necessary markings for a given type of room, as well as having confirmation that the model is certified. The certificate serves as a quality indicator; it indicates the name of the manufacturer, the legal and actual address of the organization, the fire resistance coefficient, and the batch number of the product. Only after the fire door passes the necessary tests will it receive a certificate of conformity. Markings are indicated on fire-resistant glass.

A fire door can be produced using various technologies. Even materials such as wood are used in the manufacture of fire doors. As a rule, to prevent doors from letting in smoke and fire, they are equipped with special seals. Whole tree species are used in the production of door frames.

When making a steel door, mineral wool boards are chosen for the fireproof material, which have the properties of sound insulation and insulation. Fire doors are filled with mineral wool, which creates heat and sound insulation.

Fire doors have a wide range of models. For example, they can be with built-in fireproof glass, with regular or special fittings, as well as ventilated or vice versa.

In some rooms you can install a door with a single or double leaf system. If the doorway is non-standard or of an unusual shape, then horizontal and vertical hatches, which are quite large in size, both in length and height, are used.

Which door should I install?

Each location where fire doors are installed requires a certain “fire resistance” class. Fire resistance is a fundamental criterion when choosing a fire door depending on its purpose. It is marked as EI with an indicator of 15, 30, 60. What does this mean? E is the loss of fabric integrity, I is the heat-insulating qualities. The numerical designation indicates the time that the door can withstand the onslaught of fire.

What kind of barrier should be installed at what object is regulated by technical regulations (123 Federal Law). Information in accordance with this law is mandatory included in project documentation.

Fire safety requirements

The basic documents regulating the rules for installing fire doors include the Technical Regulations on Fire Safety Requirements. It was put into effect by Federal Law No. 123-FZ, which was signed by the President of the country on July 22, 2008. The legislative act has been adjusted many times, so the version adopted on December 27, 2018 is currently in effect.

Important. The main objective of the Technical Regulations is to create conditions for the safe construction and operation of buildings of any type and purpose.

The requirements of the document apply to all stages of the existence of a building, from design to possible disposal. The Regulations complement and expand the provisions of the documents listed above, including GOSTs, SNiPs and Codes of Rules.

Fire barriers.

Not only the installation location and the type of fire resistance are important, it is important to install the right type

. What are fire barriers:

- walls are barriers located vertically along the entire height. The walls separating parts of the building are fire compartments;

- partitions - enclosing structures separating rooms on the same floor;

- partitions with glazing - the same enclosing structures, only with the installation of fire-resistant glass;

- ceilings - ceilings and floors that do not allow fire to pass from one floor to another.

Tables No. 23 and 24 of the above-mentioned Federal Law will help determine which fire door to install and where in order to comply with the regulations. Here, depending on the type of barrier (wall or partition), the appropriate door class

.

The right to choose the material remains yours. This can be a metal structure (DPM) or a wooden door (DPD). Pay special attention to the installation of the fire door. If it is installed incorrectly, even if all legal requirements are met, this may result in liability in the form of a fine.

Need fire doors? Contact ADC. The most famous companies trust us

Call ☎ or leave a request

Where is the PD placed?

That is, where exactly fire doors are placed in the above-mentioned places, in general, is quite simple to determine - the door must be installed in the opening available in the fire barrier of the required type.

The types of barriers are determined according to table No. 23, and according to table No. 24 of the Technical Regulations (Federal Law No. 123), we find out which door (what fire resistance limit) should be installed in a particular room, building/structure.

How to use these tables is discussed below.

First, we must find out what fire barriers are and what function they perform?

SNiP for fire doors, norms and requirements according to GOST of the Russian Federation

In which premises are fire doors installed according to SNiP? According to SNiP 21 01 97, the following installation locations for fire doors are distinguished:

social institutions where people stay temporarily or permanently: kindergartens, residential buildings of boarding schools, homes for the disabled and elderly, hospitals;- hotels, boarding houses, sanatoriums, hostels;

- multi-apartment and single-apartment buildings;

- crowded places: theaters and cinemas, clubs, sports complexes, libraries, concert halls;

- enterprises serving the population, where the number of visitors is higher than the number of staff;

- shopping centers, train stations, clinics;

- buildings of organizations providing utility and household services;

- educational and scientific institutions;

- banks, offices, agricultural buildings.

Fire doors are installed in warehouses if explosive or flammable substances are stored in them.

What are the requirements for fire exits?

SNiP says that an evacuation exit is leading:

- from the first floor of the building directly to the outside or through the vestibule, hall, corridor and so on;

- from rooms on floors other than the first to the staircase, corridor or hall. Doors on staircases must be fire resistant;

- to the adjacent room, from which you can go to the staircase, hall or corridor, from where there is access to the street.

Basements and basements should have exits directly to the street. Openings in which sliding or lifting doors or turnstiles are installed are not considered escape routes.

In kindergartens, hospitals, nursing homes, where more than 10 people live, there must be at least two emergency exits. Two emergency exits on each floor are provided in hotels, hostels, cultural institutions, and retail establishments. In basements and basements with an area of more than 300 sq. m., where there are more than 15 people at the same time, two evacuation routes are also made.

The number and width of emergency exits depend on:

- number of storeys of the building;

- the number of people simultaneously staying in it;

- distances from the most remote location of people to the nearest evacuation route.

Fire doors, according to GOST 53307-2009, must undergo fire resistance tests. The following fire resistance limits are distinguished:

Related article: Which manufacturer’s entrance doors are best to choose?

In most buildings and structures, EI 30 and EI 60 doors are installed. The marking (designation) of fire doors means that they can contain a flame for 30 and, accordingly, 60 minutes without losing their integrity and heat-insulating ability. Thus, doors to the electrical room, server room, and doors for archives must have a fire resistance rating of at least 45 minutes. EI 60 steel blocks can be installed in these rooms.

The following types of fire-resistant doors are distinguished:

- Type 1: doors with a fire resistance rating of more than 60 minutes;

- 2nd type: doors with EI 30;

- 3rd type: doors with EI 15.

Manufacturers mainly produce doors of the 1st and 2nd types, which are suitable for installation in most premises.

Door Features

Depending on the installation location, the requirements for fire doors may vary slightly. Thus, the doors to the electrical room must be equipped with a ventilation grille.

Fire door sizes may vary from manufacturer to manufacturer. The following standard door sizes are available: 2030 by 860, 2030 by 880, 2050 by 950 mm and so on. The Moscow Metal Door Plant produces single-leaf doors with dimensions ranging from 2200 to 800 mm and double-leaf doors with dimensions ranging from 2200 to 1200 mm.

SNIP stipulates that evacuation routes must be at least 190 cm in height, and their width is from 80 cm. If we are talking about kindergartens, sanatoriums, boarding houses with the number of evacuees of more than 15 people, as well as premises with the number of people more than 50 people (except for apartment buildings), the width of the openings is determined to be 120 cm. According to GOST 53303-2009, the dimensions of sample structures that are tested for fire resistance may differ from those indicated in the certificates in the range from +10 to -30%.

The design of doors is not regulated by law; the main thing is that the doors have a fire resistance limit confirmed during testing. The product package from the Moscow Metal Door Plant includes:

- frame and sash made of steel 1.2 mm thick;

- hinges with bearing:

- mineral wool;

- anti-removal blockers;

- handle and lock.

The glazing of fire doors, according to standards, should not exceed 25% of the area of the door. Fire-resistant doors on staircases must be equipped with closers. The exception is structures that lead into the apartment or directly outside.

Fire doors are installed using special polyurethane foam. It must comply with the standards established in GOST 30402-96 (flammability index - B1).

Nameplates on fire doors

GOST 31173-2003 states that each door must have a label or waterproof designation, which indicates the product manufacturer, product brand, date of manufacture of the door and a stamp indicating acceptance of the design by technical control. Typically, labels (nameplates) are made of metal. Like the door, they must meet fire safety requirements.

Selection rules

To fill the door leaf, basalt fibers are used, which contain mineral wool slabs or silicon dioxide. The door leaf is made of a solid bent steel profile that can withstand high temperatures for two hours.

The main criteria for choosing a design are:

- Fire resistance limit is the period of time in minutes during which a door can withstand fire. The indicator value ranges from 15 to 120.

- The quality of locks and other components that allow you to leave the premises in case of fire.

- Thickness and surface of the door leaf. The thickness of the structure should be within 2-6 mm. The door can be made of galvanized metal or powder coated.

- Availability of glazing. Typically, fire-resistant glass is used for these purposes, but solid doors are the most fire-resistant.

- An enclosing structure that matches the wall of the room where the fire doors are installed.

- Manufacturer's reputation. A reliable design can only be purchased from a manufacturer that uses high-quality materials and provides a guarantee.

According to the GOST 30247.0-94 standard, the marking of fire doors has a special mark on the fire resistance indicator. This is the EI index, in which E is an indicator of structural strength, I is the thermal insulation properties of the door. The numbers indicated next to the index show the period of time during which the product will not allow the flame to penetrate the room. On the marking of some structures you can see additional indices:

- W is a designation that shows how long a glazed product can prevent the flow of hot air from entering the room.

- S is an indicator of the tightness of the door block and its ability to prevent combustion products from entering the room.

- J, G – explosion safety index, indicating that the product is manufactured in accordance with the requirements of a separate state standard.

Fire doors undergo a mandatory certification procedure.

Requirements according to GOST

Regulatory requirements for fire doors are being developed depending on the area of application, so strict compliance is provided for at all stages of production and during installation of structures.

The quality and correctness of the door structures and the use of fittings will ensure the protection and rapid evacuation of people by firefighters in the event of an emergency.

The main documents that stipulate standards, norms and rules are specially developed by GOST, SNiP and SP.

It is these documents that secure the national standardization of control testing methods, according to which fire doors are tested for resistance to direct contact with fire, and the fire safety of construction projects (buildings and structures for various purposes) is determined.

GOST R 53307 2009 “Fire doors and gates. Fire resistance test method" provides for the determination of a time indicator measured in minutes. During this period, the door structure is able to hold the flame.

The second important indicator is the temperature, under the influence of which the fire door undergoes significant changes.

The starting point is the unilateral effect of heat on the prototype, and the final moment is the onset of a critical state of the prototype. The destruction category is provided for by fire resistance standards.

Fire doors are tested based on the standards. GOST regulates:

- equipment for the stand - a special oven and related parts;

- measuring equipment;

- test samples, which are selected according to quantity, parameters and design features, fully equipped in accordance with technical documentation;

- complete with passport, drawings, technical specifications for the product and descriptions, installation instructions;

- input control;

- preparatory process;

- placement of a prototype;

- initial check;

- assessment of the information received about the loss of door integrity and thermal insulation properties;

- designation of the maximum fire resistance indicator;

- area regulated for testing;

- reporting;

- safety precautions.

Related article: How to remove the handle from a plastic balcony door

Box installation

Fastening the door frame is one of the important stages. In appearance, it is a metal frame onto which a fire-prevention fabric is subsequently hung. Therefore, its strength is given special attention in the provisions of GOST and SNiP.

In the event of a fire, the frame must, along with the door leaf, prevent the spread of fire. If the frame is made of low-quality materials or errors were made during installation, then the fire safety functions will not be fully performed, and you will not be insured against the entry of combustion products.

Installation of the frame begins with markings and determining the dimensions of the parts of the beam. The measurement follows a standard scheme for all types of doors, so we will not dwell on it. The differences lie elsewhere - in the fastening details. In the case of fire-resistant structures, fire-resistant fasteners are used for fastening.

The joints are treated with a special sealant that is not afraid of high temperatures. Its properties make it possible to protect premises from the penetration of fire or smoke.

Door frame installation

When installing fire doors, there are many nuances and standards that must be observed to the nearest millimeter. According to the Construction Norms and Rules (SNiP), the installation of doors must ensure unhindered passage of stretchers and persons providing their transportation; the minimum width must be 1 meter. This will allow people to be evacuated without difficulty in emergency situations. If these conditions are not met, the fire inspector may simply not accept the object.

Preparing the opening

According to the rules, the installation of a fire door should begin with measurements of the opening, since there are certain standards for installation, and some buildings, for example, houses with brickwork, require the installation of a reinforced frame. It is imperative to free the opening from traces of the old door structure. A fire door should only be installed in a prepared opening.

Installation of the box

Next, a team of craftsmen installs the frame of the new door. It is best to assemble the box in a horizontal position, after which the already assembled box is mounted in the opening. This is done as follows: the door frame is placed in the prepared opening and, after alignment, is secured in it using special fire-resistant anchors (at least three on each of the four sides). It is important to ensure that the gaps between the opening and the structure are the same. Next, they are filled with a special sealant, which, when heated, turns into foam, filling all possible voids, thereby preventing smoke from penetrating.

Installation of the canvas

It is produced in almost the same way as with ordinary doors. In this case, the hinges must be installed in such a way as not to interfere with the full opening of the door. Next, the hinges are adjusted, and the closer is installed and adjusted.

Final stage

After all the above steps, further adjustment of locks, handles and locking mechanisms is carried out. This is followed by the installation of platbands (it is recommended to treat them with a fire-fighting compound in several layers), a painstaking check of the quality of installation work, and a call to a fire inspector to accept the work.

And finally...

This whole process requires knowledge and experience in several directions at once, so it is best to entrust it to a company specializing in such services. It is worth noting that according to SNiP there is a clear description of the tools that can be used during installation work, and according to GOST this work must be performed by a contractor with at least 6 years of experience.

After installation, the customer must check:

- the presence of a closer, with the help of which the door must close independently;

- the presence of pink sealing foam inside the structure;

- the passage of one person through an open door and the closing time;

- tight fit of the door to the frame, painting and all installation work to finish the structure.

The procedure for filling out an application for the installation of fire doors must be strictly according to the protocol and with the availability of supporting documents, signing an agreement, taking into account unforeseen situations and breakdowns on the part of the contractor.

SNiP requirements

SNiP 2.01.02-85 “Fire standards and rules”, based on this document, the classification of construction projects, structures and materials according to fire and technical characteristics is regulated.

The norms and rules provide for general fire safety requirements for planning and design solutions for structures, premises, and buildings for various purposes. SNiP is used at the project development stage.

When choosing fire-resistant door structures, one should take into account their main characteristics that indicate resistance to fire - these are:

- level of flammability of materials. There are 4 groups: G1 - low flammability; G2 - low flammability; G3 - normal flammability; G4 - highly flammable;

- fire danger level. Classification - non-fire hazardous (K0), low fire hazardous (K1), moderate fire hazardous (K2) and fire hazardous (K3).

- fire resistance limit. The standards are regulated by SNiP (time is calculated in minutes). The letter designation “E” is an indicator of the moment when the integrity of the material is lost - cracks appear on the surface of the door and minor deformations of the leaf occur.

The letter “I” indicates the time of loss of the thermal insulation properties of materials. The designation “R” is the ultimate indicator of the integrity of the entire structure. After the specified time period, the fire door becomes deformed and destroyed, resulting in the lock jamming and smoke leaking through the resulting cracks.

It is during this period of time that people need to get out of the burning room. For example, if a door structure is designated E-30, then its fire resistance is designed for half an hour, respectively E-60 - for an hour, E-90 - for 90 minutes.

! The requirements for fire doors provide a minimum fire resistance time of 30 minutes.

The installation of door structures is also regulated by SNiP. Fire doors are installed for safety purposes in factories, warehouses, shops, service stations, as well as in other non-residential and residential facilities where there is an increased risk of fire.

In addition to SNiP and GOST, fire doors must comply with the Code of Rules, which provide for the prevention of the spread of fire at protection facilities.

The current regulations determine the type of fire doors. SPs are used at the design stage, during the construction and reconstruction of construction projects.

Prototype testing

To obtain the necessary readings, a sample of a fire-rated door is taken. GOST defines the main results of limit states.

Loss of integrity (E) occurs when:

- stable flame on an unheated surface for 10 seconds;

- smoldering, accompanied by the glow of a cotton swab, or ignition under the influence of fire or flammable gases that penetrate through the resulting cracks, crevices, holes, or porches;

- slots with a size of at least 150 mm, through-type holes with a diameter of 6 (±2) mm, probes with a length of over 500 mm in door samples;

- the prototype falling out of the door frame or the frame itself from the enclosing structure of a standard type.

Loss of thermal insulation properties (I) as a result of:

- increasing the temperature without heating the surface of the prototype by an average of 140°C or at any point on the tested surface by 180°C compared to the temperature indicators of the structure before testing;

- increasing the temperature to 300°C on the prototype box, regardless of the initial indicator before testing.

Test parameters

The construction market offers a large selection of fire-resistant doors, which are manufactured by different manufacturers.

In accordance with standards and requirements, fire safety doors are subject to certain parameters. For testing, one standard size is taken, which is reflected in the protocol.

The results obtained apply to products with permissible deviations that vary from +10% to -30%, both in width and height. In addition, rounding is provided, if upward - up to 5 cm, downward - up to 10 cm.

All about fire doors: where they are installed, selection criteria, installation recommendations

Fire doors prevent the rapid spread of fire and help delay smoke for some time. But it is worth remembering that such a design is not a fire prevention measure, but is considered a good precaution that can protect people from trouble. There is a certain category of premises that must be equipped with fire doors. Requirements and rules are regulated on the basis of building codes and regulations - SNiP. In this article we will look at where fire doors are installed, the requirements and GOSTs for them. Photos and videos will help you make a choice and make installation.

Current regulatory framework

Today, there are three main documents that define the rules in the field of fire safety. These include:

- SNiP 21-01-97;

- Federal Law No. 123-FZ;

- SP 1.13130.2009.

It is these regulatory and legislative documents that clearly regulate in which premises, buildings and structures fire doors are installed. In addition, they contain basic requirements for the fire resistance of such entrance structures. No less important information is the minimum and maximum dimensions of products, which must also be observed by the owners of buildings.

Where is it mandatory to install fire doors?

The material of fire doors is resistant to high temperatures. At the same time, they are able to fully maintain their functionality, preventing jamming of the lock and other blocking of the passage. SNiP regulates which buildings, with which fire safety class, must, on the basis of the law, be equipped with fire protection enclosing structures with a certain level of fire resistance.

According to SNiP, premises and places that must be equipped with fire doors are:

- exit from the stairs to the attic;

- ventilation chambers;

- storerooms with flammable materials;

- through corridors and elevator shafts;

- children's educational buildings, hospitals, houses on stylobates;

- vestibules, emergency stairs, fire exits;

- entertainment centers, cafes, restaurants.

Related article: How to shorten a plastic door with your own hands

All of the above locations and buildings must include fire safety doors. The standards have been especially tightened for premises and buildings that are permanently or periodically a place of mass gathering of people. According to fire safety standards, the fire inspector draws up an assessment report of the building, which is subsequently the subject of installation of a fire protection structure.

Requirements for a fire door when choosing

This design is regulated by GOST standards, and clear standards govern the subsequent installation of a specific door. The list of requirements includes: the quality of the construction material and the location of the partition. Let us further consider the criteria on the basis of which you should choose a high-quality fire door that complies with all norms and standards:

- Fire resistance limit of the material. The long service life of the door and increased resistance to high temperatures depend on the quality of the material. Therefore, when choosing a high-quality door, you should not skimp on this characteristic. A good fire door is made exclusively from high-quality fire-resistant material.

- Level of resistance to deformation. A good fire-resistant door should also be resistant to fire for the maximum amount of time. High quality fire doors are capable of creating a reliable barrier to fire for a long time.

- Sealing quality. The partition must have a high level of smoke insulation and heat non-conductivity. To ensure that the structure does not allow combustion products to pass through the cracks, special attention must be paid to insulating the joints during installation.

These are the main criteria. Next, we will focus in detail on the material from which the structure should be made.

Attention! The fire door must be at least 1 meter wide. The requirement is based on the fact that the opening must allow the full unimpeded removal of victims on stretchers.

Fire resistance parameters and dimensions

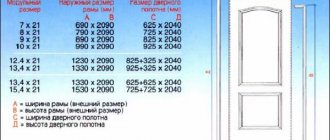

The standard technical characteristics of fire doors and gates most commonly used in civil and industrial construction are as follows:

Dimensions of fire door elements

Dimensions:

- single-leaf - from 2.03 x 0.86 to 2.1 x 1 m, double-leaf - from 2.03 x 1.3 to 2.1 x 1.5 m;

- gates - from 2.2 x 1.75 to 3-4 m, with a wicket in them - from 2.2 x 2.3 to 2.5 x 3 m.

These sizes comply with building standards, making them easy to install on site.

- Software – EI 30; 60.

A simple explanation of the EI 60 marking: the letter E indicates loss of integrity, i.e. the formation of holes through which fire and smoke begin to penetrate into the adjacent, protected fire compartment;

- I – loss of the ability to not transmit heat, therefore, strong heating of the surface inside;

- 60 – guaranteed time of flame and high temperature resistance, determined by calculations and full-scale fire tests.

Advertising brochures from some manufacturers offering a product with a limit of several hours (!) are at the very least meaningless, since this contradicts the requirements of the norms and common sense - the content should not have more software than that of the barrier in which it is installed. It turns out that the wall will burn/collapse, but it will proudly stand at the site of the fire.

There are also curious cases of installation in walls or partitions that are not barriers - structurally made of logs, timber, plywood sheets, or non-fire-resistant gypsum sheets.

Material for making fire-resistant doors

GOST standards allow several materials that meet all fire resistance requirements. The large assortment today is dominated by designs made from the following materials:

- refractory metal - a design on this basis provides reliable protection at critical temperatures;

- wooden doors on a fire-resistant basis. Due to the treatment of MDF canvas with a special composition and coating, wooden elements can efficiently withstand thermal loads;

- Fire-resistant alloys and steel parts make even glass structures fire-resistant.

In terms of their design features, fire protection products are similar to conventional entrance doors. The only difference is that the fire-resistant elements are modified using special technologies. Such structures are also frost-resistant and sometimes bulletproof. Therefore, today it is not uncommon for people to install such doors in ordinary apartment buildings.

Before installing the door, you must carefully prepare all the necessary tools and the installation site itself. This will be discussed further.

Opening and its preparation

In order not to violate SNiP standards when installing a door block, it is necessary to properly prepare the doorway. The procedure itself does not involve unfamiliar actions; everything is done as in the case of a conventional design. It is necessary to remove the previous box and clean the surfaces.

The adjacent area is also cleared of foreign objects. When attaching the door, you will have to open it several times to check how correctly it was installed, so foreign objects will interfere with this. In addition, they can create an additional ignition source.

If the fire box is not very reliable, it is reinforced with a special frame. It will also take away part of the load.

Self-installation of a fireproof door: step-by-step instructions

The thickness of the partition, according to GOST and SNiP, must be at least 12.5 cm. If the wall thickness is less than this indicator, then before direct installation the indicator must be brought to the appropriate standard. It is worth remembering that the door must open freely to its full width, so it is worth clearing the surrounding area of foreign objects.

Advice. In some cases, it will be necessary to install a reinforcing frame if the wall is not particularly strong.

Next, we will determine the complete list of tools that will be needed to carry out all the work:

- Drill with a pobedit type tip.

- Hammer.

- Hammer, knife, masking tape.

- Polyurethane foam.

- Tape measure, level, bolts.

First of all, the box is assembled. All the work consists of fastening the corners with screws. After which the door frame is installed in the opening and secured with pegs. The element is aligned using a tape measure and a level. It is necessary to maintain the level of gaps - they must be the same on all sides. For anchor bolts, holes are drilled in the wall through the door frame. The door frame is secured with bolts - at least 3 bolts on each side. The joints are filled with fire-resistant sealant.

The width of the gap between the leaf and the door frame should be within 3 mm, but no more. The leaf itself is installed like a regular entrance door. There is only one nuance here - the hinges should not prevent the door from fully opening. The platbands are treated with a special solution, which will give the elements fire-resistant properties. It is best to apply three layers, then let them dry before installing.

After completing the work, make sure that all elements are securely attached and functioning correctly. Check the operation of the lock, it should work without interruption. The door itself should open smoothly, without applying much effort. When opening there should be no extraneous sounds: creaks, clicks, tapping. If everything works properly, call a fire inspector, who must make sure that the installation is correct, and record the result of the check in the protocol with all the necessary signatures and seals.

Installation of the canvas

The last stage is the installation of fire door leaves. Its class is selected according to GOST and SNiP. The hinges must ensure full swinging of the doors. The rules state that the gap between the box and the canvas should not be more than 3 mm. The door closer is also installed.

Upon completion of installation work, the remaining gaps must be sealed. For this, mineral wool and fire-resistant plaster are used. The rough finish is covered with platbands. In appearance, fire doors may be no different from ordinary ones, but in an emergency situation they can save more than one human life and the building itself from the destructive power of fire.

The final stage is the installation of the door leaf

Installation of fire doors must be carried out exclusively under a license.

Thus, high-quality installation of a fire protection structure in a doorway will allow you to increase the safety indicators of being in the building, as well as significantly facilitate the elimination of a fire if it occurs.