Many people have to face this problem, since redevelopment of residential premises, and even more so major renovations in a house, is far from uncommon. The need to reduce the height of the doorway is due to the fact that often the door model you like does not fit it in size. There are several simple techniques that allow you to level out this discrepancy between the linear parameters of the frame and the passage.

Acceptable work technology, as well as appropriate materials, are selected based on an assessment of the following factors:

- difference between the dimensions of the opening and the block;

- required strength (depending on the location of the door);

- condition of the wall.

Is it possible to make an interior door smaller?

An interior door consists of a frame and a leaf. The box is firmly attached to the wall, and the canvas opens and closes the passage. You can reduce any door and any opening. It is important to take correct measurements and prepare the necessary tools.

Reduce the size of the door in cases where it is installed in a joint with a wall or blocks off a large area of the room. Large, heavy doors sag over time. In some cases, the dimensions of the opening are reduced due to large heat losses. You will also have to work with the dimensions of the canvas if the floor level rises, or the wooden house settles and the door jams.

Preparation stage

- “Exposure” of a section of the wall at the site of installation work

This is necessary in cases where the doorway is reduced in an already inhabited room. For example, when moving into a purchased apartment with an old layout, during a major renovation, and the like. This will allow you not only to take all dimensions of the passage with maximum accuracy, but also to assess the condition of the wall. It may be necessary to first expand it slightly, and then artificially reduce it while simultaneously strengthening it.

- Changing the Communications Trace

Also one of the typical situations. For example, if the internal electrical wiring was previously laid close to the door block. It is clear that during the installation of the new structure it will be a hindrance; you'll have to change the line.

- Taking measurements

Based on the results, a conclusion is drawn on how to reduce the doorway. That is, the most acceptable of the methods practiced in everyday life is selected.

Differences in working with different types of doors

There are quite a few types of doors: from light plastic to heavy steel.

Aluminum or iron doors are rarely installed in the interior space, and other types are easily processed with hand tools. Almost any door made of wood, MDF or veneered canvas can be sawed to narrow or make it shorter. Except for glass. You can, of course, cut off an extra piece from a glass sheet, but it is, as a rule, made of tempered, thick glass. For this type of work you will need a special machine.

If the door is combined, for example, glass elements are inserted into a wooden frame, then such a door can be narrowed or shortened by the thickness of the wooden frame without touching the glass.

Laminated, veneered, laminated doors are very easy to saw, because they are wood processed in a special way. The same goes for plastic.

Carrying out calculations and creating a layout

For a reduced opening, the following measurements are required:

- length and width of the door leaf;

- size of canopies;

- threshold height;

- door frame parameters.

To get this data, you need to understand:

- the depth of the opening should be the same as the thickness of the adjacent walls;

- the height of the opening corresponds to the height of the door frame;

- the distance between the opening and the ceiling is 1.5 cm;

- To calculate the width of the opening, you need to sum up the thickness of the frame and the width of the door leaf. Double the resulting figure;

- The gaps between the box and the wall are made equal on each side - 1 cm.

Materials and tools

First of all, you need to decide on the material. Drywall is easy to work with, saw it and adjust it to the desired size, but it is fragile and easily breaks under light load. In this regard, plywood is much stronger, but also more expensive.

The tools you need to reduce the height of the opening are available at any hardware store:

- a knife for cutting drywall or a jigsaw for plywood;

- screwdriver;

- ruler;

- hydraulic level

GOST requirements for door and opening heights

The standard height of doors and openings and for their installation is specified in GOST 6629–88. However, one must keep in mind that imported door leaves may differ slightly from domestic samples.

The optimal height of the door is 200 cm. The opening under it should be higher, since it includes not only the door leaf, but also the door frame with technical gaps.

The optimal door height is considered to be 2000 mm, as it allows you to leave the necessary technical gaps in the opening

Table: standard dimensions of door leaf and opening

| Door size (mm) | Doorway size (mm) | ||

| Width | Height | Width | Height |

| 550 | 1900 | 630–650 | 1940–2030 |

| 600 | 660–760 | ||

| 600 | 2000 | 660–760 | 2010–2060 |

| 700 | 770–870 | ||

| 800 | 880–970 | ||

| 900 | 980–1100 | ||

| 1200 | 1280–1300 | ||

| 1400 | 1480–1500 | ||

| 1500 | 1580–1600 | ||

Operating procedure

The opening for any type of door is reduced in the following way:

- First of all, it is noted at what height the top edge of the door should be.

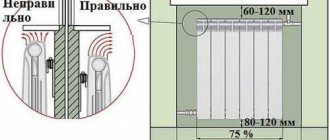

- Then, along the perimeter of the marked area for installing drywall, a metal profile is attached to the wall. It can be replaced with a wooden beam with a cross-section of 5x5 cm, so the structure will be stronger and in the future it will be possible to install not only drywall, but also plywood on it. The lower beam is attached only after it has been leveled using a hydraulic level.

- After securing the support frame above the door, a pre-cut piece of plywood or drywall is attached to it with screws. After installing the plywood or plasterboard panel on the frame, the gaps between it and the wall are covered with putty. To prevent it from cracking over time, reinforcing tape is first glued to the gap.

- Next, the door leaf is adjusted to the desired height. Having measured the exact distance from the bottom edge of the doorway to the top edge with a tape measure, you need to mark the same distance on the canvas. To make the door close easily, this distance is reduced by 2–4 mm.

- Using a regular or electric jigsaw, the excess part is cut off from the canvas. It doesn’t matter what material the door is covered with - a jigsaw can easily cut veneer or laminate of any thickness.

- The cut edge on the door is sanded and painted.

You can lower the door using a wooden beam. This method is often used in houses with wooden walls. In this case, the timber is sawn off to the width of the doorway and fixed at the required height. If its thickness is not enough to reach the specified height, another one is added, etc. The last beam is processed with a plane or sawed off with a hacksaw for an accurate fit.

How to widen a doorway?

To increase the doorway, you will have to remove part of the wall. You can widen the passage in concrete and brick partitions from 0.7 to 2 m. In an apartment on the first floor, they adhere to the recommended width of 1 m and carry out additional reinforcement of the structure. It is allowed to increase the height of the doorway up to 2.1 m.

Widening the passage in the wall begins with dismantling the door block. The sash is removed from its hinges. The box is cut with a hacksaw and removed with a pry bar. The expansion of the interior doorway is done to install a larger door. According to the dimensions of the new block, markings are drawn on the wall.

The excess area is removed in two ways:

- Gentle. To cut openings, a grinder with a diamond wheel is used. There is a lot of dust, but the possibility of cracking the entire partition is excluded.

- Aggressive. When removing pieces of the wall, a sledgehammer, hammer, chisel, or hammer drill is used. If you overdo it, you can damage the integrity of the entire partition.

An enlarged doorway must be strengthened. It is especially important to strengthen the pier where the old lintel is removed when the passage is expanded in height. The main methods of reinforcement are welding metal corners, channels, tires made of thick sheet steel along the ends of the walls, or installing tie beams with bolts.

Brick house

A feature of expanding a doorway in a brick wall is accuracy. In order not to disturb the masonry, it is better not to hit the partition with a sledgehammer. You can widen a doorway in a brick wall with a minimum amount of dust using a hammer and chisel. Bricks are knocked out one by one on the marked area. You can get the job done faster and get the smoothest edges possible by using a grinder, only after cutting there will be a lot of dust left.

The transfer of the block lintel is carried out by increasing the height of the old doorway. Additionally, the top masonry is reinforced with welded channels or tie beams.

Panel house

To expand an interior doorway in a concrete wall, use a grinder with a diamond blade in the same way. The panel is cut in turn on each side. If the diameter of the disk is not enough to cover the entire thickness of the concrete, slots are made on both sides of the partition.

You can widen a doorway on a concrete wall without dust using an impact drill. Through holes are drilled along the contour of the marking in frequent steps, and only the reinforcement is cut with a grinder. Pieces of concrete can easily break off with a sledgehammer. If it is necessary to increase the height of the passage in a concrete wall, the old lintel is similarly dismantled.

Large openings are widened in squares, removing sections of the concrete panel from bottom to top. The ends are reinforced with a frame, welding on sheet steel tires or metal corners.

When changing the dimensions of the passage in the interior partition, it is important to carefully carry out the dismantling work, install a reliable new structure and coordinate the redevelopment with the BTI.

Reduce Width

The main problem of reducing the width of a doorway is maintaining structural strength. Even if the door is not secured from the installation side, the load on the opening will be distributed evenly throughout the frame. That is why the frame for the structure must be very reliable; it is better to use foam blocks or bricks for this.

In this case, the tool is selected depending on what material will be used to narrow the opening. If it is drywall, then you will need a jigsaw, a ruler, a level, and a screwdriver. If it is a brick or foam block, then you need a trowel and a container for concrete mortar. As for the order of work, it also depends on the selected material.

Is changing the dimensions and location of the passage considered redevelopment?

Reducing, expanding, or moving entrance openings is legally considered redevelopment. Current legislation regulates the mandatory approval of these actions. If the location of the entrance in the supporting structures changes, approval of the redevelopment is carried out according to the sketch and reflects the changes in the BTI plan. Additionally, an expert opinion will be required confirming that the redevelopment work is safe.

Please keep in mind that unauthorized changes in the dimensions and location of doorways are an administrative offense. The culprit faces a fine and an obligation to return everything to its original state.

Using drywall

The algorithm of actions when using drywall is as follows:

- The first step is to mark the existing opening.

- Further along the perimeter of the marked area, a beam or metal profile is attached.

- To strengthen the structure, you need to make at least two horizontal crossbars at the same distance.

- A pre-cut piece of drywall is attached to the frame with screws.

- A layer of basalt wool or other soundproofing material is laid between the drywall panels.

- Finally, the gaps between the drywall and the wall are sealed with mounting tape and puttied.

Finishing a doorway (portal) in an apartment

If you don’t want to install an interior door, you can install a portal instead. Arches are outdated, and this solution increases the space in a small apartment, so this is a win-win option for visually combining adjacent rooms: hall and living room, corridor and dining room, living room and small kitchen. A doorway without a traditional door surprisingly transforms a room:

Preparing the flooring before installing doors

A common mistake made by repair teams when laying floor coverings is when the gap between the floor covering and the wall in the area of the platbands exceeds the thickness of the platband. And you just need to remember to make it no more than 3 mm. in the area of platbands.

A recess (groove) can be made in the wall near the floor to compensate for possible expansion of the floor covering.

Storing doors after purchase

To avoid deformation under the influence of gravity, the canvas, box beams and platbands must be stored on a flat surface before installation. Doors can be placed on their side against the wall.

After a cold spell, doors, trims and frames increase in size due to increased humidity, so doors and moldings must first be stored indoors for several days. Do not remove the packaging from the doors in advance until the temperatures have completely equalized.

Failure to comply with these rules may cause cracks at the joints of platbands and boxes a few days after installation!

With the help of timber

Timber is used in wooden houses. This is structurally more convenient and more harmonious from an aesthetic point of view. First you need to adjust the timber to the required parameters.

- Width of the beam - trimming must be done so that the workpiece fits into the opening as tightly as possible. Then you won’t need to “wedge” it.

- The thickness of the timber - if it protrudes beyond the plane of the partition, it is enough to process the excess part with a plane.

Work order:

- The timber is measured, cut at the required distance and installed in the doorway.

- If its tire is not enough to narrow, then the next beam is installed, etc. - up to the size that suits the owner.

- To increase the strength of the structure, the timber is attached to the top crossbar of the opening, to the floor and to each other.

- Upon completion of the work, it is advisable to decorate the timber with plywood or plasterboard.

Standard opening sizes

Recommendations of state standards and requirements place emphasis on such dimensions of the door portal as height and width. The depth of the opening for an interior door is proportional to the thickness of the walls, which differ in materials of manufacture and finishing, and therefore does not matter as such.

The dimensions of the passage can be characterized by different qualities of the room's functionality. For example, doorways to the kitchen, bathroom or pantry are equipped with a smaller width than to living rooms.

The standard opening height for an interior door, according to recommendations, is 2.05 -2.06 m.

Standardized aisle width:

- 0.7 – 0.71 m for door leaves 600 mm. It is recommended to install in bathrooms, toilets, pantries;

- 0.8 – 0.81 m for 700 mm sheets. Recommended for installation in the kitchen;

- 0.9 – 0.91 m for 800 mm sheets. It is recommended to install in bedrooms, living rooms, children's rooms;

- 1.0 – 1.01 m for 900 mm leaves; such doors are installed similarly to 800 mm leaves.

Using a brick

Narrowing a doorway using bricks is quite simple:

- The bricks are laid out along the required width of the opening and secured together with cement mortar. To make the masonry strong and even, the bricks are laid plumb in a checkerboard pattern. It is also advisable to drive anchors into the slope of the opening so that they are sandwiched between the bricks. This will create additional adhesion between the brickwork and the wall.

- In another option, a metal corner is installed in the doorway at the required distance from the wall. Bricks are laid into the resulting opening. The corner itself is secured at the top and bottom of the opening with long nails or anchor bolts.

- You can lay an opening made of foam blocks in exactly the same way. They will rest against the wall and the metal corner, which will make the wall monolithic.

- At the end of the masonry, the wall is plastered with a special mortar or a simple cement mixture.

After completing the work to reduce the width of the doorway, the door itself narrows. This is done using an electric jigsaw. The canvas is carefully measured, and cutting line marks are applied to it. In order for the door to close easily, the door leaf must be 2–4 mm narrower than the opening.

After sawing off the excess part, the door is processed with sandpaper and decorated.

Ways to reduce a passage in a wall

Narrowing an old doorway during redevelopment involves reducing the size of the door in height or width, as well as in both parameters at the same time. The procedure can be performed in three ways: using timber, drywall or blocks.

The most reliable method to reduce an opening in a wall is to partially block it with blocks. The option is ideal for the front door. Suitable materials include brick, cinder block, and cellular concrete blocks. It is better to use foam block or aerated concrete for interior partitions. The material is light, easy to cut, but absorbs moisture. It is slightly less durable than brick.

The work consists of the following actions:

- to reduce the height of the passage in the wall, prepare a jumper from a beam or a metal corner;

- the workpiece is cut off larger than the width of the passage, and landing nests are made under it at the ends of the wall using a grinder;

- After fixing the lintel, the space above it and the sides of the passage in the wall are filled with blocks.

When choosing this method, take into account the weight of the blocks. The heavier the material, the stronger the jumper will be needed. If the whole block does not fit into the gap above the jumper, it is sawed with a grinder or wood, polystyrene foam, or polyurethane foam are used for filling. The disadvantage of porous blocks is the absorption of moisture. To prevent fungus from appearing, the structure is treated with protective impregnation.

How to reduce a doorway with timber?

It is easier for an apartment dweller who does not have construction experience to reduce the width of the doorway with timber, and also to lower it. The work order consists of the following stages:

- The thickness of the timber used to narrow the doorway is adjusted with a planer so that the workpiece does not protrude beyond the plane of the wall. The surface is treated with a grinder. In this case, the finishing material will fit better.

- The dimensions taken from the opening are transferred to the timber. Use a saw to cut the pieces to the required length and fix them to the ends of the wall. The thickness of the beam should not protrude beyond the plane of the wall, and the upper lintel should be cut to such a width that it fits tightly into the ends of the side walls.

- When drilling mounting holes on the beam, recesses are provided to allow the heads of the fastening elements to be hidden flush.

- The posts and lintel are fixed to the wall with anchors, bolts or other parts.

- Large gaps between the frame and the end of the wall are filled with polyurethane foam. Small cracks are sealed with putty.

- The finished structure is impregnated with a primer. After drying, they are covered with gypsum board, chipboard or other sheet material.

When reducing the doorway, the frequent dynamic loads acting on the door are taken into account. To prevent the structure from becoming loose, the timber is attached to the wall as often as possible.

After you have managed to lower the door opening with timber, the question arises of how to close the space from above. The easiest way is to cover it with plasterboard, plywood or chipboard. A small gap is hidden with wide platbands. Before finishing, the cracks are filled with foam.

The advantage of this method is the ease of installation of the timber. The downside is the installation limitation. In humid rooms, the wooden frame becomes deformed and cracks due to temperature changes. The method is not suitable for the bathroom and kitchen.

Reducing the span with plasterboard

To build up an interior doorway with plasterboard, on the installation side of the profile frame, the wall is cleaned of various materials and treated with a primer.

- Having taken measurements of the entrance opening, cut the guide profile into the required pieces. The upper lintel is fixed with hangers, and the side elements are fixed directly to the ends of the wall.

- GKL sheets are screwed to the finished frame with self-tapping screws, maintaining a pitch of 150 mm;

- The cracks are sealed with putty. The plasterboard structure is primed, and a metal perforated corner is glued to the corner joints.

Seal the opening above the door and along its width with plasterboard if the difference in size between the opening in the wall and the door frame does not exceed 100 mm. To fix the gypsum boards, a frame is made from a galvanized profile. The frame turns out to be quite weak and is easily deformed if there is a large gap when opening the sash. It is better to use a plasterboard structure for an arched passage. To strengthen the gap between the profile and the ends of the wall, fill it with pieces of timber or polyurethane foam.

How to reduce a doorway with foam blocks?

Working with aerated concrete and foam blocks is easy. The material is not heavy and can be easily cut even with a regular hacksaw. Blocks are usually used to narrow passages in thick walls and panel houses.

It is easier to reduce the width of the door opening. The blocks are laid out in a column from the floor to the top crossbar. If it is additionally necessary to reduce the height of the passage, a lintel made of wooden beams is cut into the ends of the walls. The gap is sealed with pieces of foam blocks.

The laying out of blocks begins from the floor. It is important to initially prepare a flat and durable surface. Pieces of reinforcement are embedded between the rows. One end is driven into the wall. This strengthens the structure. The rods will not allow the foam block pillar to move away from the wall.

A cement-based adhesive composition is used as a mortar for laying blocks. It is sold dry in bags and to prepare it, just add water and then mix well. The solution is applied to the blocks with a notched trowel.

The finished structure is impregnated with an antifungal compound, plastered, puttied or sheathed with plasterboard. After finishing, the door frame is installed.

Narrowing the opening with brickwork

When reducing a wide opening with bricks, the work requires similar construction actions as in the case of a foam block. The difference is the heavy weight of the material. Instead of timber lintels, it is better to use metal corners.

They begin to build up a new doorway from the side, not forgetting to reinforce the rows. The masonry is carried out using a solution prepared from three parts sand and one part cement. Water is added until a homogeneous thick mass is obtained. The mortar is applied to the brick with a trowel.

How to reduce a passage with concrete walls?

To reduce the interior doorway with concrete walls for a new door, any of the considered methods will do. The best option is to use blocks. In a lived-in apartment, work begins with exposing the wall. Removing finishing materials will allow you to assess the condition of the concrete structure. If there are severe defects, the wall will have to be partially destroyed, and the resulting widened passage will have to be narrowed again.

To build up an interior doorway with blocks from above, the wall is partially destroyed to insert a lintel. If there was electrical wiring or other communications near the old door frame, they need to be moved.

Common mistakes

When working to reduce interior doors, people make a number of common mistakes that lead to weakening of the opening structure and deformation.

- When narrowing a doorway using timber, you should use only dry wood, the so-called planed timber. It is more expensive than undried. As a result, many people, trying to save money, buy raw wood. As a result, the timber cracks and deforms in the opening, sometimes completely jamming the door.

- When working with drywall, it is advisable to lay a layer of sound insulation between the walls. After all, the purpose of an interior door is to cut off sounds from the room. Basalt wool is well suited for sound insulation. Its randomly arranged fibers perfectly stop sound waves.

- When installing brick or foam block masonry, many do not install a vertical corner to support and strengthen the structure. Again for reasons of economy. You need two such corners; they are installed so that the bricks are inside the “U” shaped opening. If there are no corners, then the heavy brickwork may crack and collapse when the door slams.

- Between bricks or foam blocks it is necessary to lay steel wire with a cross-section of at least 4 mm. Even if the width of the opening being laid is less than 20 cm. If you skimp on this point, the wall will crack over time.

- You only need to cut the door leaf with a jigsaw. Moreover, the markings must be applied with a marker that is noticeable in color, and the jigsaw must have guides. The fact is that the door leaf can be up to 220–240 cm in length. It is almost impossible to manually make a straight cut of such a length.

- Before starting work on narrowing and lowering the doorway, you need to draw a sketch of the project, prepare all the necessary materials and tools. The drawing will help you carry out all installation work correctly, and timely purchase of everything you need will allow you to stay focused on the process.

The doorway can be completely reduced with your own hands. With proper preparation, this can be done easily with minimal material and physical costs. In addition, such an opening will become the pride of the owner of the house or apartment. The main thing is not to be afraid to work with your hands and head and treat everything as a creative process.

Non-standard doorways

If the height of the doorway has non-standard dimensions, there are two solutions: purchasing custom-made interior door designs and elements for it, or adjusting the existing passage to the standard.

The first will cost more than purchasing standard products, and in the future when replacing doors you will have to overpay again.

The second option will require that the height and width of the door opening be increased, or that the passage be reduced around the perimeter. Increasing the passage is not always possible due to structural or planning restrictions, for example, if the wall is load-bearing or the opening is too close to the wall. In addition, installation work to expand the opening is quite labor-intensive and expensive. It is possible to carry out such work on your own, but it is worth considering that you will most likely have to update the wall decoration. It is possible to trim a door leaf that is too high for the opening, but not all door models are suitable for this. It is better to find out about the possibility of reducing a particular door from a sales consultant or on the manufacturer’s website.

Reducing the opening can also be difficult, since in the case of a large gap it will be necessary to decide how to close it if the width of the platband is not enough.

Non-standard openings are often an expression of the owners’ desires when designing and building a private house. This is explained by the fact that people are trying to bring more functionality and comfort into their homes, as well as create a unique individual interior. Particularly popular are widened living room openings with the installation of two door leaves. This solution gives the room a visually freer, more voluminous space. In addition, the increased passage, more than a meter wide, is quite practical, as it easily passes large-sized furniture and interior items. It is possible to create a meter-long opening and save space around it by installing a compartment-type door.

How to prepare the entrance opening for reduction

Preparatory algorithm of actions:

- dismantle the old opening - disconnect the hinges, remove the frame and trim;

- remove the remaining plaster from the working wall - the one you plan to narrow. Keep in mind that the plaster is removed completely - down to the concrete or brick;

- attach an aluminum profile to the wall;

- draw lines on both sides of it;

- take two plumb lines and draw two vertical lines;

- cut the profile into the required lengths.

Application of telescopic structure

The problem of beams protruding beyond the wall can be solved by using a door frame with grooves and telescopic platbands. When installing, the platband can be turned over, and then its shelf will hide the seam attaching the tray to the wall and the protrusion beyond it.

Increasing wall thickness with plasterboard

You can apply additions to the box. These are special boards made of any type of wood or special plywood (used in aircraft development). This plywood does not crack, does not delaminate during edge processing, and does not swell from moisture. Standard board sizes are in the range of 8-60 cm. When installing a door frame in an opening of less thickness, install an additional board of the required size between the wall and the platband.

Ways to seal an opening above a door

Making repairs with your own hands is doubly pleasant. After all, this allows you to enjoy the process and gives you the opportunity to really get what you want. And independent actions are an opportunity to save money. As a result, this approach is very popular among us, but many suffer from it. After all, any repair involves certain difficulties that have to be overcome. And very often unforeseen circumstances or unusual situations arise. For example, there is a space above the door that needs to be filled. What is the best way to do this? What tools and materials should I use? How to properly lay the opening above the door?

Let's try to answer all these questions, using photos for clarity.

Increasing wall thickness

Laying tiles around a doorway

To achieve the required wall thickness for installing a door frame in a bathroom or toilet, you can trim the walls of the rooms with tiles. This will add a centimeter and a half, this is enough to install the frame without significant gaps between the wall and the platband. This option will take up some useful space in an already small room, but will make it easier to install the doors. When installing the hole, you can secure it by making holes with a regular drill - the concrete will not split.

On the outside, you can build up the wall using regular plaster - the thickness of the opening will increase and the wall will be leveled. You can glue drywall to the surface and make a decorative cladding - this will provide the missing centimeters for installing the door frame.

Features of trimming a box to fit a narrow wall

When trimming beams, there is always an unsightly appearance. The painting of the sawn part will be of a different shade, quality and different from the remaining part. The cut line cannot be completely hidden, although there will be a platband on top.

It is not advisable to cut off the excess part from a veneered box, since the part of the veneer that remains will certainly delaminate after a certain period of time under the influence of humidity.

Attention! Veneered doors are not suitable for installation in a bathroom - the material deteriorates under the influence of an aggressive environment (steam).

You cannot cut softwood beams covered with plywood hardboard (MDF), as they easily crumble. Therefore, it is better not to touch them, but large gaps between the platbands and the wall will have to be sealed - for example, with plaster.