Features of Stiz-A sealant

Stiz-A is a sealant designed specifically for plastic windows. It is a one-component composition, ready for use immediately after purchase. It is not diluted or mixed, but the finished product looks like a viscous mixture.

The sealant has been popular among professional craftsmen for 20 years. It receives good reviews regarding its properties and ease of use. It is made on the basis of acrylic, and after drying it retains high strength, at the same time with excellent elasticity. The good protective properties of this composition are also noted.

Stiz-A sealant is available in different colors, but when installing plastic windows, a white mixture is most often used. There are brown and different shades of gray, which allows you to choose the most suitable material for a particular job.

A sealant for working with plastic frames must meet a number of technical requirements:

- Good strength.

- Sufficient elasticity.

- Ability to withstand humid environments and atmospheric conditions.

- Resistant to different temperatures and frost.

- The ability of strength to adhere to vertical surfaces.

- Long service life.

The sealing composition Stiz-A adheres perfectly to various types of polymer surfaces, which is why it is ideal for installing plastic windows. This composition is also good for outdoor work, when you need to isolate street joints. It also adheres to metal, wood, and concrete surfaces. Antibacterial components in Stiz-A sealant help prevent the appearance of fungus and mold.

Products are available in containers of 310 and 600 ml; you can purchase formulations in buckets when performing large-scale work. The latter can be 3 and 7 kg.

The main purpose of using an acrylic composition is to protect the polyurethane foam. It was found that due to fluctuations in temperature outside, its volume decreases, as a result of which the window frame ceases to be securely fixed and can shift. This leads to damage to the locking elements, and also becomes a factor in the destruction of the plaster that is adjacent to the window frame.

To avoid such problems, it is important to seal from the outside and inside, which is what the Stiz-A composition does. If low-quality materials are used for this, the polyurethane foam will begin to deteriorate over time under the influence of ultraviolet radiation and sunlight. Foam is also negatively affected by precipitation and temperature changes.

As practice shows, not everyone is engaged in high-quality sealing, and many do not even remove excess polyurethane foam, let alone protect it. And this is an absolutely wrong approach if you ultimately need to get high-quality sealing with a long service life. The outcome of choosing poor compounds is also the appearance of mold and mildew. In addition, ice may appear in winter. Without sealing, installing even the highest quality windows will be a cause for many worries and frustrations in the future.

Content:

- Introduction

- Requirements for working conditions

- Application surface requirements

- Materials, tools and devices used

- Incoming materials inspection

- Preparatory operations before application

- Operations for installing an additional layer of construction seam

- Operations for constructing the outer and inner layers of the construction seam

- Control of work progress

- Packaging, transportation and storage

- Safety regulations

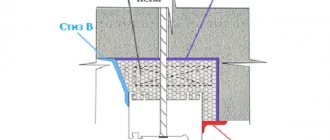

- Application. Construction diagram of the assembly seam

- Terms and Definitions

Advantages

The advantages of the Stiz-A material will be its excellent characteristics, especially when working with plastic frames. The mixture strictly meets quality criteria. This sealant can be used in conditions of high humidity and temperature changes. It is also suitable for premises in regions with harsh climatic conditions.

Stiz-A is a vapor-permeable composition that interacts well with metal, plastic, concrete, plaster and other surfaces. It can be applied even to a damp coating, which will not affect the quality of the work performed.

The sealant also has low shrinkage and excellent ductility. After drying, the surface of the composition can be coated with various varnishes and paints. Another advantage is that the sealant does not deteriorate under the influence of UV rays and the sun. It also withstands mechanical loads. The formation of the primary film occurs within 2 hours. The manufacturer provides a guarantee for its products for more than 20 years.

Mechanical method

This involves using sharp objects to help remove the physically dried silicone sealant stain from the plastic.

Mechanical cleaning method

This method is usually used when a stain has dried on plastic. The thicker the layer of dried sealant, the greater the effectiveness of the mechanical method.

Note! The use of sharp objects can negatively affect the smooth glossy surface of the plastic - if used carelessly, scratches, abrasions and other damage appear that irreversibly spoil the appearance of the coating.

Sharp knife

A well-sharpened kitchen or shoe knife will do an excellent job of cutting through a thick layer of dried silicone on plastic.

Sharp kitchen knife

It is important that the blade is as smooth as possible, without minor damage, chips or protrusions - every small blemish will immediately begin to scratch the plastic, even with the most careful use. A thin, sharp blade can pry a stain of sealant right under the base, and the task is greatly simplified by the smooth, non-porous surface of the plastic

With a precise movement, you can remove all the contamination entirely in one go, while minimizing the impact of a sharp object on the plastic

A thin, sharp blade can pry a stain of sealant right under the base, and the task is greatly simplified by the smooth, non-porous surface of the plastic. With a precise movement, you can remove all the contamination entirely in one go, while minimizing the impact of a sharp object on the plastic.

Using a sharp knife, you can also remove silicone from stained tiles.

Glass scraper

To remove a silicone sealant stain, you can resort to using a special scraper, which is used to clean dirty glass in windows. Plastic and glass have similar types of surfaces, so this scraper will be very effective when cleaning any type of sealant, including acrylic.

Glass scraper

The very thin plastic or metal blade is combined with a comfortable handle, thanks to which no special skills are required in cleaning smooth surfaces. This scraper does an excellent job not only of silicone stains on plastic, but also on smooth plastic panels, as well as glass surfaces.

Wooden or plastic spatula

When leveling surfaces in construction, spatulas of different widths are used. They are designed to smooth out freshly applied plaster or poured screed. To do this, they are equipped with thin wooden or plastic blades, which are as sharp as knives and scrapers.

Plastic mounting spatula

They also have very comfortable handles that allow you to apply the right amount of force for the most effective removal of sealant from PVC surfaces.

Advice! To remove sealant from smooth surfaces, it is advisable to use new scrapers and spatulas. If the tool has already been used, the blade may be worn to the point of becoming rough and chipped.

Napkins and rags

The above methods are usually used when the sealant on the plastic or plastic has already dried. If it is still in a gel-like state, you can use a clean cloth or napkin to wipe off the stain.

A paper towel is effective for removing fresh silicone

This must be done very carefully so as not to smear the sealant that has not yet hardened onto a clean surface - this can significantly increase the amount of cleaning in the future.

Attempts to immediately wash off a silicone sealant stain from plastic may fail if the sealant is quick-drying - at the point of contact between the stain and the plastic, it dries very quickly, and it is no longer possible to remove such a stain with a rag. A knife or scraper is also unlikely to help - the layer is too thin. If this has already happened, you should resort to chemical cleaning methods.

It is advisable to use rags immediately after sealing

Cons of Stiz-A

The composition from the SAZI company also has some disadvantages. The first is a short shelf life. According to the information on the package, it lasts from six months to a year, while many others can be stored for more than 1 year. Some craftsmen note that the elasticity of Stiz-A is not as good as that of silicone compounds.

This sealing compound has a simple structure, which can cause some problems during interior work. Over time, the sealant begins to absorb various fumes, which affects its appearance. But this can be easily prevented if, after drying, you paint with water-based paints or varnishes.

Application

Working with acrylic sealant does not require special skills. However, to obtain a high-quality result, you need to take into account some points. In order for the composition to bond well with the surface, it must first be thoroughly cleaned and dried. The composition can be applied directly from the tube, by pressing, with a pistol or with a spatula. Before application, pay attention to the depth of the seam.

If the seam depth is sufficient, it is recommended to first place a special cord or seal in it. This will save the amount of sealing mixture. After applying the composition, the surface is cleaned and degreased.

The main area of application of Stiz-A is sealing plastic windows. However, its use is not limited to this.

Stiz-A from SAZI can be used for the following purposes:

- Insulation of cracks in wooden frames.

- Filling voids in concrete, metal and wooden structures.

- Elimination of external cracks in brick surfaces.

A sealing acrylic composition is used to protect polyurethane foam from moisture. The sealant is frost-resistant and does not corrode. It combines well with a wide variety of materials that are often used when installing windows. Surfaces do not need to be primed before applying Stiz-A. The material stretches well, which is extremely important when filling joints in brick or wood masonry, as well as when insulating gaps between the window frame and openings.

On video: Installation of windows. Application of STIZ A

Cooking at home

Previously, you didn’t buy window putty, but made it yourself. You can do the same thing now. The process is not complicated and will save money. But at the same time, there is one feature: it should turn out to be plastic and quick-drying. Stay on treated surfaces and serve for at least 12 months.

Homemade sealant must meet the following requirements:

- Excellent adhesive properties. Grip on any surface it will be used on.

- High plasticity, stretchability. At the same time, it should not crack or tear with slight stretching.

- Fast hardening. After complete drying, no cracks or bubbles should be found on the surface.

- Not critical indicators of response to temperature fluctuations and high humidity.

- Service life is at least 12 months.

Based on these indicators, choose what the sealing composition will consist of.

How to make putty and what components to use will be described in detail in each recipe below. All that remains is to be put into practice.

From chalk and linseed oil

This is one of the most popular compositions for wooden structures. Professional glaziers resort to it, as it consists of two components.

The manufacturing sequence consists of the following aspects:

- Grind the chalk to flour and mix with linseed oil in a ratio of 4:1.

- Knead the dough". If you can roll it into a ball, it's a good consistency to work with. Otherwise, add more chalk powder.

- If desired, add dye. White is required, leave everything as is.

If you don’t have linseed oil on hand, replace it with drying oil, but then the mixture will have a certain smell.

Made from fine sand and flour

Often a situation arises in which there is a need to seal from the inside, but there is nothing at hand except flour and sand.

Mix the indicated ingredients from the recipe name in equal proportions. Add a small amount of water or PVA glue. The result should be a viscous mass that can hold its shape.

From melted lard and rosin

Its peculiarity is that it can be prepared for future use and stored in the refrigerator.

So what you need to do:

- Melt lard in a hot frying pan. From the amount received, take only 1 teaspoon;

- turn rosin into powder, you will need 1 tbsp. spoon;

- mix the previously prepared ingredients with 10 tsp. chalk powder.

You will get a thick mass. Transfer the excess into a tightly sealed container and store in a cool place. Use as needed.

From tar and ash

Boil the tar over moderate heat for a couple of hours and cool. Add sifted ash to it. Stir until the mixture is no longer sticky. The resulting composition is used immediately; it cannot be stored, it loses its properties.

From vegetable oil and talc

From the remains of liquid, vegetable fats, a water-repellent material is prepared for sealing glass.

Separate the resulting precipitate from unrefined sunflower oil. Add talc to it until the required consistency is achieved. It can be replaced with ordinary or decorative cement composition. Then you will have to cook quickly, as well as spend it.

Other building materials can also be used: sand, putty, cement, etc.

Multicomponent

This is the best recipe, after which, after using it, the windows will last for at least three years, retaining heat inside the house and without losing their tightness. Differs from other compositions in complexity.

Components and their ratio:

- Lead white: 11 parts;

- Crushed chalk: 6 parts;

- Flaxseed oil: 8 parts;

- Beeswax: 4 parts;

- Ocher or umber (powder): 4 parts.

First you need to decide on the volume. It is calculated based on the size and number of windows. Take a measuring cup and a container for mixing the putty composition.

Recipe

Melt the wax and, without removing from the heat, add oil. Remove the dishes from the stove and cool the mixture to room temperature. After this, add ocher, pre-mix with chalk powder, stir until smooth. Pour in whitewash, shake with a spoon (or other utensil) and begin sealing.

If there is a lot of unused mixture left, do not rush to get rid of it. It can be stored in the refrigerator or other cool place, after transferring it to a plastic bag or tightly sealed container.

Recommendations for application

When working with sealant for plastic windows, recommendations from professionals will not be superfluous. Helpful tips will help you do everything right from start to finish.

The first thing that is important is to apply a sealing compound to the already fixed slopes. Before work, you need to prepare a spatula, knife, tape, sponge, a bowl of water and a piece of cloth. First, the coating is prepared. To do this, you need to remove excess mounting foam and clean the surface so that it is smooth and with minimal porosity. The maximum pore size should be no more than 5 mm.

The coating is also well cleaned from various contaminants and dust. The surface around the joint should be covered with tape so as not to accidentally damage it. You can then apply the sealant directly into the seam, smoothing it out with a spatula. Afterwards, you need to check the thoroughness of filling the cracks. Excess product is carefully removed with a wet sponge or rag.

What else is important to know when working with a sealing compound from the SAZI company:

- After applying the product, remove the mounting tape.

- Once the sealant has dried, it can be painted.

- It is best to work with a sealant that is sold in special packaging that allows you to immediately squeeze the product into the seam.

- If the cracks were previously insulated with another means, it must be removed.

- To degrease the surface, it is best to use gasoline or white alcohol.

- It is better not to use acetone, it can cause streaks.

You can apply Stiz-A in several ways: straight from the pack, with a gun or with a spatula. However, you need to work with it under certain conditions. The air temperature must be at least 25 degrees. Complete hardening of the composition occurs within 48 hours. Professionals recommend applying the product in small areas, immediately correcting all errors, since after polymerization it will be difficult to eliminate them.

Review of manufacturers

Stiz a sealant for plastic windows is produced by Russian industrial. This is the largest domestic enterprise in its industry. Stiz a is available in various types and volumes of packaging:

In a hermetically sealed plastic bucket weighing 3 and 7 kg. Costs from 560 rubles. Suitable for a large volume of external work, mainly when repairing cracks and filling gaps in facade cladding. On average, packaging is 3 kg. With standard seams it is enough for 6 window blocks. After completing the work, the material is stored in a plastic bucket for no more than a day. If it is possible to store it airtight after opening, then the mixture is suitable for use until the end of the shelf life.

- In folic tubes (file packages) of 0.9 kg, price from 120 rubles. The packaging is intended for use with a closed type mounting gun. After completing the installation, without waiting for it to dry, the mounting gun must be cleaned of any remaining sealant.

- In plastic tubes (cartouches) of 0.44 kg. This package costs from 85 rubles. The tube has a cone dispenser. With its help, it is convenient to apply the solution into thin cracks and gaps of 1.5–2 mm. To squeeze out the solution, you need to trim the edge of the nozzle. The closer to the edge of the spout you make the cut, the thinner the seam will be. The volume is suitable for small installation areas of window and door openings.

We recommend watching the video review:

Nuances of work

For maximum sealing of plastic windows, there must be a certain thickness of the sealing material, optimally 3.5 mm. This is difficult to adjust, so using a ruler is recommended. A thin layer of material will be of lower quality, which will affect the sealing strength.

When installing plastic windows, it is rational to use two types of compositions - Stiz-A and Stiz-B. The first one is perfect for protecting the outer layer. Stiz-B will provide protection against moisture penetration from the room. For external joints, it is best to use Stiz-A, because Stiz-B after application reduces the heat-insulating properties of the polyurethane foam.

Do-it-yourself waterproofing of a plastic window

Before starting repair work, it is necessary to establish the cause of condensation. In practice, this is facilitated by the following factors:

- the windows are located on the north side of the house;

- the wrong glass unit has been selected;

- the areas where the frame meets the wall are poorly processed.

In the first case, the formation of condensation is almost impossible to eliminate, however, there should be a minimum amount of moisture. As a rule, this does not interfere with the normal operation of the window and does not cause discomfort.

In the second case, it is important to correctly take into account the climatic features of the region. For northern latitudes, it is mandatory to install 3-5 chamber double-glazed windows

In the southern regions, a two-chamber one is sufficient.

In the first two cases, it is impractical to carry out repair work. The entire glass unit needs to be replaced. But if the problem is that moisture penetrates through the cracks formed where the window frame fits, it is necessary to perform comprehensive waterproofing. This, firstly, will eliminate leaks, and secondly, it will cost much less than a full window replacement.

Rice. 1. Do-it-yourself waterproofing of a plastic window

Specifications

Description of the properties and characteristics of the composition of Stiz-A:

- Designed for plastic, metal, brick, concrete, aluminum.

- Maximum shrinkage is no more than 20%.

- Withstands temperatures from minus 60 to plus 80 degrees.

- The material dries within 48 hours.

- Produced by the Russian company SAZI.

- Refers to one-component acrylic mixtures.

- The main color is white.

- Deformability up to 50%.

- Consumption – from 120 g per meter.

- Service life – 20 years.

There are some restrictions when working with this composition. It must not be diluted with water or other liquids. Do not allow contact with water until completely dry. It is forbidden to work with the sealing compound in rainy and snowy weather. Do not use the mixture indoors where humidity exceeds 90%. After using the composition, the container must be tightly closed with a lid.

Key features of the sealing composition Stiz-A:

- Ready to use after purchase.

- Can be applied without using a gun (from the packaging).

- Safe for humans and the environment.

- Economical, convenient, has low shrinkage.

- Relatively inexpensive.

- Can be painted or tinted.

- Has high vapor permeability.

It is safe to work with sealant. It is harmless, non-flammable and non-explosive. It can be applied without the use of protective equipment. It is easily washed off with soap and water, and when frozen, it can be removed mechanically.

Transportation and storage

The shelf life of Stiz B sealant is no more than 6 months, provided the product is stored in undamaged packaging from the manufacturer at a temperature above -13 degrees. During transportation, when the temperature drops to -20 degrees, the sealant can be stored for 1 month (the number of freezing/defrosting cycles is 10).

How to save sealant from an open tube

Method 1. There are situations when, after completing all the work, you still have half (or more) of a tube of sealant left. It's financially stressful to throw away a good product every time. To preserve the remaining sealant, you need to remove the piston from the pipe, placing the remaining sealant in the middle of the pipe. Then lightly melt the plastic ends on both sides and press them firmly with pliers. Now you can put the sealant in a convenient place for storage. A little later, simply cut the melted side of the tube and use the sealant for its intended purpose without spending money on buying a new one.

Method 2. You can choose another, simpler method of storing sealant. To do this, you will need a regular empty jar, a lid and a seaming machine. Move the remaining sealant into an empty jar and preserve it, as grandmothers do with compotes or pickles. Try to choose the smallest jar for this so that there is little oxygen inside it in the future.

Using a knife, cut off the threaded portion of the pipe. Carefully squeeze all contents into the jar. Remove the piston from the can if it fell there along with the sealant. Without wasting time, roll up the lid on the jar. Make sure the cap you are using is not expired and has a rubber seal.

Like all methods, this one has its pros and cons. The main advantage is that you can roll the remaining sealant into a jar in a few minutes and not worry later that the material may dry out. Moreover, the procedure is very simple.

Material consumption

With a layer width of 20 mm and a thickness of 2 mm, the material consumption is 60 g/linear m.

SAZI is a leading manufacturer of sealing compounds that offers high-quality products for various works. Stiz-A Sealant is ideal for sealing windows, as well as for application to other surfaces, including metal and concrete. By following all the rules for working with it, you can get high-quality sealing that will last at least 20 years.