Polyurethane foam used when installing windows, without additional protection, quickly deteriorates under the influence of adverse environmental factors and loses its water and heat insulation properties. To prevent deformation of assembly seams and additional sealing of joints, special-purpose compounds are used: Stiz A, Stiz B, Stiz D.

The use of Stiz A, B, D sealants in combination when installing windows in accordance with GOST

Products have been manufactured by the domestic company SAZI for 20 years. During this time, the product has earned high positive reviews from professionals and confidently holds a leading position in its niche. After treating the installation seams with Stiz sealants, the room will be better protected from drafts, the appearance of fungus and mold.

STIZ-A sealant for plastic windows

When installing plastic windows, it is important to ensure their reliable tightness; sealants are additionally used for these purposes.

With their help, gaps between the frame and the window sill, the frame and the slopes, etc. are sealed. There are several types of sealing compounds on the domestic market, one of which is Steez sealant.

It is a vapor-permeable one-component composition based on acrylic, completely ready for use. Stiz sealant is produced by the Russian company SAZI and is very popular in our country and neighboring countries.

Is it possible to use “Stiz-B” instead of “Stiz-A” and vice versa?

These products are not interchangeable. "Stiz-A" is considered vapor permeable, which allows moisture to easily leave the seams. “Stiz-B,” on the contrary, prevents water from penetrating into the room, reliably sealing internal joints. It is better to use both products together with each other.

Combined use of "Stiz-A" and "Stiz-B"

Features of Stiz sealant

- Excellent adhesion to any materials, and also fits well on a wet surface;

- Resistance to moisture, ultraviolet radiation, atmospheric influences and temperature changes;

- Can be painted and plastered after drying;

- Vapor permeability, due to which the microclimate in the room is not disturbed;

- Durability and strength of the material, service life is up to 20 years;

- The composition contains antibacterial substances to prevent fungus from occurring;

- The polymerization time of the sealant is about 2 days;

- The shelf life of unopened packaging is 6 months.

Storage recommendations

During storage, it is allowed to freeze and defrost the sealant several times (no more than 10 cycles). In a closed container, the composition is stored at a temperature of –5 degrees for a year. After opening, it is advisable to immediately use the sealant, as it may dry out.

If immediate application is not possible, there are a number of methods that will help preserve the product remaining in the tube. Here is one of them:

- Press the composition so that the top of the tube is empty.

- Remove the piston, melt the plastic and press with pliers to seal the top of the package.

- Place the sealed storage container in a cool place.

Window sealant in various packages

You can also transfer the sealant into a glass jar, leaving as little air space as possible on top. After rolling up the jar under an iron lid, place it for storage in a place where there is no access to the sun's rays.

How to use Stiz-A

First of all, it is necessary to thoroughly clean the working surface from dust and dirt, and it is not necessary to dry it, since Steez sealant has good adhesion to a wet surface. To ensure that the edges of the sealant are even, it is worth sticking masking tape to the window frame and the wall.

Then the sealing composition is applied to the prepared surface (into a crack or gap) using a gun, spatula, or squeezing out of a tube, depending on the shape of the package. Then the tape is removed, and when the sealant has completely hardened, it can be painted to match the color of the walls or window frame.

Source: everything-for-windows.rf

Advantages

The advantages of the Stiz-A material will be its excellent characteristics, especially when working with plastic frames. The mixture strictly meets quality criteria. This sealant can be used in conditions of high humidity and temperature changes. It is also suitable for premises in regions with harsh climatic conditions.

Stiz-A is a vapor-permeable composition that interacts well with metal, plastic, concrete, plaster and other surfaces. It can be applied even to a damp coating, which will not affect the quality of the work performed.

The sealant also has low shrinkage and excellent ductility. After drying, the surface of the composition can be coated with various varnishes and paints. Another advantage is that the sealant does not deteriorate under the influence of UV rays and the sun. It also withstands mechanical loads. The formation of the primary film occurs within 2 hours. The manufacturer provides a guarantee for its products for more than 20 years.

Specifications

| No. | The name of indicators | Standards according to STO 034-37547621-2016 | Test results | |

| Technical quality indicators (TPK) | ||||

| 1 | Resistance to vapor permeation with a sealant layer thickness of 5 mm, m²•h•Pa/mg, no more | 0,25 | 0,23 OS Mosstroycertification Appendix No. 1 to certificate No. ROSS RU.MC46.H01873 dated 06/16/2016 | |

| 2 | Strength of adhesion to materials of wall openings and window structures, MPa, not less | 0,1 | PVC | 0,1 OS Mosstroycertification Appendix No. 1 to certificate No. ROSS RU.MC46.H01873 dated 06/16/2016 |

| concrete | 0,42 OS Mosstroycertification Appendix No. 1 to certificate No. ROSS RU.MC46.H01873 dated 06/16/2016 | |||

| painted wood | 0,18 OS Mosstroycertification Appendix No. 1 to certificate No. ROSS RU.MC46.H01873 dated 06/16/2016 | |||

| aluminum profile | 0,1 OS Mosstroycertification Appendix No. 1 to certificate No. ROSS RU.MC46.H01873 dated 06/16/2016 | |||

| 3 | Predicted service life, conventional years, not less | 20 | 20 OS Mosstroycertification Appendix No. 1 to certificate No. ROSS RU.MC46.H01873 dated 06/16/2016 | |

| 4 | Water resistance at a pressure of 600 Pa for, h, not less | 1 | 24 OS Mosstroycertification Appendix No. 1 to certificate No. ROSS RU.MC46.H01873 dated 06/16/2016 | |

| 5 | Heat resistance at (80±1)°C for 8 hours | No leaks, defects or changes in appearance | Absence of drips, defects and changes in the appearance of the OS Mosstroycertification Appendix No. 1 to certificate No. ROSS RU.MC46.H01873 dated 06/16/2016 | |

| 6 | Surface film formation time, h, no more | 2,0 | 1,5 OS Mosstroycertification Appendix No. 1 to certificate No. ROSS RU.MC46.H01873 dated 06/16/2016 | |

| 7 | Dripping, mm, no more | 1,0 | 0,0 OS Mosstroycertification Appendix No. 1 to certificate No. ROSS RU.MC46.H01873 dated 06/16/2016 | |

| 8 | Elongation at break, %, not less | 250 | 500 OS Mosstroycertification Appendix No. 1 to certificate No. ROSS RU.MC46.H01873 dated 06/16/2016 | |

| 9 | Conditional tensile strength on blade samples, MPa, not less | 0,1 | 0,15 | |

| Technical Identity Indicators (TPI) | ||||

| 10 | Dynamic viscosity, Pa•s | 120-350 | 215 OS Mosstroycertification Appendix No. 1 to certificate No. ROSS RU.MC46.H01873 dated 06/16/2016 | |

| additional characteristics | ||||

| 11 | Application temperature range | from minus 25 °C to + 35 °C | ||

| 12 | Operating temperature range | from minus 60 °C to + 80 °C | ||

Flaws

The disadvantages of the composition are offset by its positive qualities. The disadvantages can be found below:

- Does not have a long shelf life. After opening the package: 6-12 months.

- Insufficient elasticity when compared with silicone materials.

- The porous structure causes some difficulties when used indoors.

After some time, the stiz mastic will begin to darken due to the absorption of evaporation of various origins. This worsens the appearance. Coloring will help prevent this.

Instructions for use

Preparing the sealant

The sealant is completely ready for use. At negative air temperatures, before use, it is necessary to warm up the sealant to a positive temperature. It is IMPOSSIBLE to dilute the sealant with water - this may lead to a change in the properties of the sealant (reduced adhesion, dripping of the sealant from the seam, etc.), cracking is possible!

Surface preparation

The surfaces on which the sealant is applied must be cleaned of dirt, dust, grease, cement mortar residues, ice, frost, etc. The sealant can be applied to both dry and wet surfaces. The presence of dripping moisture on the surface is unacceptable. It is IMPOSSIBLE to apply sealant during rain and snow!

Applying sealant

In order for the edges of the sealant layer to look even, first apply construction tape to the window frame and wall opening, which determines the width of the contact area, then apply a layer of sealant, after which the tape is removed.

The sealant is applied to the surface of the mounting foam using a spatula, brush, syringe or other device.

The thickness of the sealant application layer should be from 3.5 to 5.5 mm. The thickness of the sealant application layer should be from 3.5 to 5.5 mm.

The thickness of the layer after shrinkage is from 3 to 5 mm. The sealant should be applied evenly, without breaks. The width of the sealant contact strip with the surfaces of openings and block boxes must be at least 3 mm on each side.

It is NOT ACCEPTABLE to use at humidity levels above 90%.

Review of manufacturers

Stiz a sealant for plastic windows is produced by Russian industrial. This is the largest domestic enterprise in its industry. Stiz a is available in various types and volumes of packaging:

- In a hermetically sealed plastic bucket weighing 3 and 7 kg. Costs from 560 rubles. Suitable for a large volume of external work, mainly when repairing cracks and filling gaps in facade cladding. On average, packaging is 3 kg. With standard seams it is enough for 6 window blocks. After completing the work, the material is stored in a plastic bucket for no more than a day. If it is possible to store it airtight after opening, then the mixture is suitable for use until the end of the shelf life.

Dilution of Stiz A sealant with water is not allowed. In this case, the composition delaminates and loses its technical characteristics.

- In folic tubes (file packages) of 0.9 kg, price from 120 rubles. The packaging is intended for use with a closed type mounting gun. After completing the installation, without waiting for it to dry, the mounting gun must be cleaned of any remaining sealant.

- In plastic tubes (cartouches) of 0.44 kg. This package costs from 85 rubles. The tube has a cone dispenser. With its help, it is convenient to apply the solution into thin cracks and gaps of 1.5–2 mm. To squeeze out the solution, you need to trim the edge of the nozzle. The closer to the edge of the spout you make the cut, the thinner the seam will be. The volume is suitable for small installation areas of window and door openings.

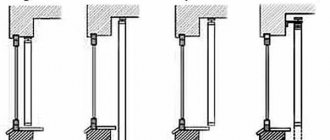

Application technology

Step 1 of 5

We apply a protective composition. The protective composition is applied with a brush in 1-2 layers, depending on the porosity of the wall material, along the opening area in the area of the planned installation seam.

Step 2 of 5

We stick construction tape onto the wall panel to keep the work area clean and reduce the time it takes to remove excess sealant.

Step 3 of 5

We apply the material. The sealant is applied to the surface of the polyurethane foam using a spatula. The thickness of the sealant application layer should be from 3.5 to 5.5 mm.

Step 4 of 5

Remove the tape after application. We do not wait for a film to form on the surface of the sealant.

Step 5 of 5

The final view of the outer layer of the assembly seam. The installation seam fully complies with GOST 30971.

How to apply

Application is carried out on pre-fixed slopes.

Tools:

- construction tape;

- putty knife;

- sponge and piece of fabric;

- stationery or regular knife;

- container with water.

If special packaging is available, you must prepare a mounting gun.

Step-by-step work:

- Prepare the coating. Clean from dust and dirt.

- Apply masking tape around the joint.

- Squeeze the sealant directly into the gap and smooth it out. The layer is no more than 5.5 mm. Remove excess with a wet sponge.

- Remove the tape and wait for the layer to dry completely.

- Paint the seams.

Work should be carried out at a temperature within +25 degrees, but not higher than 35. The mastic hardens in about 48 hours.

Sealant consumption

Average consumption of stiz "A" per 1 linear meter = 120-150 grams. With a layer thickness of 2 mm and a seam width of 20 mm, the consumption will be 80g/linear meter.