Stiz-A is an acrylic window sealant designed to seal the outer seam of a window block.

Scope of application: sealing plastic, wooden, aluminum windows, as well as balconies and stained glass windows. The sealant is intended for the installation of the outer layer of the assembly seam in the junction points of window blocks (including balcony ones) to the wall openings of heated buildings of civil and industrial construction with permissible deformation of the assembly seam of no more than 15%.

Peculiarities

Its main features are the following aspects:

- After drying, the surface is painted or plastered.

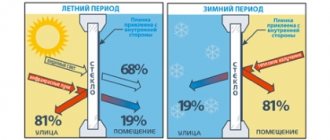

- High level of vapor permeability.

- Resistant to deformation, ultraviolet radiation, weather conditions such as rain and snow. This is especially important if the sealant for window seams was used from the street.

- Can be used even on a damp surface.

- Takes on a matte finish after vulcanization.

Suitable for use with concrete and metal surfaces, not only with wooden bases. Due to the presence of antibacterial additives in it, it prevents the formation of mold and fungal deposits.

Types of sealants, how to choose the right one

On the building materials market you can see a large selection of window sealants. They have different characteristics and purposes. Let's look at the main types of insulating materials for PVC windows, as well as the features of each of them.

Silicone

This is a popular sealing material that is durable and strong. Silicone sealant can be used for external or internal finishing of seams. It can also be used for restoration of old wooden frames and other works.

The advantage of this sealant is that silicone is resistant to negative weather factors: snow, rain, icing, hail. This material is not afraid of ultraviolet radiation, is quite durable, resistant to aggressive environments, and has good adhesive properties.

However, silicone sealants have their drawbacks. Due to their high toxicity, the room must be thoroughly ventilated when working with them (after drying it is safe). The composition must be applied very carefully, since after drying, excess silicone does not look beautiful. It is worth noting that silicone releases acids that cause rust, does not allow moisture to pass through (which disrupts air exchange in the room), and cannot be painted.

Acrylic

An inexpensive building material that can be used to seal a window slope or be used for other work. It has high adhesive ability, is used for interior and exterior work, is non-toxic, and can be used for painting. But at the same time, it is practically not plastic and after hardening it can become deformed if the air temperature is too low, which will lead to depressurization of the window.

Polyurethane

This is a universal composition that is often used to seal window seams. It is suitable for working with any type of surface - wood, plastic, metal. Polyurethane sealant is resistant to moisture and ultraviolet radiation, is highly elastic, quite durable, dries quickly, and can be used for painting.

The disadvantages of polyurethane sealant are its short shelf life (9 months), high toxicity and humidity requirements during installation (the maximum permissible value is indicated by the manufacturer).

Acrylate

This type of window seam sealant is the most durable. It is often used to insulate windows, as it rubs well after hardening. This sealant has a high level of moisture and frost resistance. In stores you can find two types of acrylate material: for internal and external insulation work. The only noticeable disadvantage is the high cost.

When choosing a sealant, you must follow the following algorithm:

- Determine where the seam is located (outside or inside). This is the main criterion on which the choice depends.

- Determine the type of surface and ensure that the selected sealant is suitable.

- Select the color of the sealant or paint with which it will be painted over.

Before you start sealing the window, you should make sure that the weather conditions are suitable for the planned work. Only after this can you proceed directly to sealing the windows, following the sequence of actions and following the advice of professionals.

Specifications

Let's look at what technical characteristics sealant “A” has:

- Vapor permeability at a thickness of 5 mm = 0.25;

- Adhesion strength with PVC = 0.1, concrete = 0.42, painted wood = 0.18 MPa;

- Polymerization time is 1.5 hours;

- Elongation at break: 500%;

- Tensile strength = 0.15 MPa;

- Moisture resistance at pressure 600 Pa: 24%.

It goes on sale in the following packages: from 0.44 grams to 7 kg.

Features of Stiz-A sealant

Stiz sealant is a domestic product that has been known for more than 20 years. The solution is available in the form of a viscous, one-component paste. The composition includes acrylic polymers, elastomers, which gives the material additional elasticity and hardeners. Fully complies with GOST 30971.

The products are easy to apply and can be used in areas with limited access. After hardening, the paste forms a durable waterproof layer. In addition to white, in the Stiz line of sealants you can purchase solutions of different shades.

The insulating solution has the following technical characteristics:

- The material does not require additional mixing and is produced completely ready for use.

- Does not flow down when applied to vertical planes.

- It has a high degree of adhesion to concrete, plaster, aluminum, wood, brick, PVC, foam concrete.

- Suitable for both plastic and wooden structures.

- Resistant to vibration and static loads.

- Creates a vapor-permeable seam, which allows condensation to escape.

- Complete curing time is 48 hours.

- Slight shrinkage of Stiz sealant up to 20%.

- Application temperature from -10°С to +35°С; Operating temperature from -60°С to +80°С.

- The declared service life of the treated areas is 20 years.

- High elasticity: at least 250% elongation to break.

- Repeated freezing and storage for 30 days is possible.

Advantages

Stiz sealant for PVC windows takes a leading position due to the following advantages:

- Complies with all GOST parameters;

- Vapor permeability. This means that it can be used at high humidity. Withstands temperatures from -60 to +80 degrees;

- Frost resistance. Used even in areas with harsh climatic conditions;

- Adhesion to plaster, metals, brick, plastic, concrete;

- Plastic. And this despite its shrinkage, which can be 20%;

- The warranty is more than 20 years, as the manufacturers assure.

Paint and varnish materials ideally lie on the hardened layer of hermetic composition. The primary film begins to form after 1.5 hours.

Scope of application

The area of use is largely determined by the type of composition.

Acetate or acidic materials (relative to the scope of application) require the following subtleties:

- cannot be applied to metal and stone, as surface damage may occur;

- poor adhesion to gypsum and concrete walls is also noted;

- It is not recommended to use such compounds for processing plastic frames, since the adhesive properties in this case also leave much to be desired;

- Sealing of glass can be carried out successfully, since in this case the adhesive properties are at a high level.

Neutral silicone compounds are recommended to be used to solve the following problems:

- can be used to treat window sills and blocks made of materials that are sensitive to acids (such materials are limestone and marble);

- Silicone-based sealants can be used for metal openings, since they do not provoke the development of corrosion;

- such compositions exhibit good adhesive properties relative to plastic outer frames and non-porous (glazed) materials, which are often found between the facade and the window structure;

- silicone materials are good for sealing and insulating seams on the outside;

- for interior work they are better than acetate materials, since when they harden they do not emit an unpleasant and persistent odor.

Sealants have a huge range of applications.

Many compositions are universal and can be used without restrictions to implement the following tasks:

- protection of seams in PVC structures and window openings from the negative effects of atmospheric phenomena;

- fixing window frames and glass;

- insulation of openings for the winter, which must be done periodically before the heating season;

- fixing window sills;

- filling cracks and processing external and internal seams that form between walls and windows when installing or resealing aluminum, wood or plastic frames;

- performing work on processing seams in structures made of concrete or reinforced concrete, subject to deformation not exceeding 25%;

- glazing and sealing of balconies;

- installation and insulation of ventilated warehouses.

Flaws

The disadvantages of the composition are offset by its positive qualities. The disadvantages can be found below:

- Does not have a long shelf life. After opening the package: 6-12 months.

- Insufficient elasticity when compared with silicone materials.

- The porous structure causes some difficulties when used indoors.

After some time, the stiz mastic will begin to darken due to the absorption of evaporation of various origins. This worsens the appearance. Coloring will help prevent this.

Acrylate sealants

They are used for making external and internal assembly seams when installing plastic windows. There are two most famous formulations on sale, which complement each other - “Stiz A” and “Stiz B”.

p, blockquote 33,0,0,0,0 —>

p, blockquote 34,0,0,0,0 —>

Pros of acrylate sealants:

p, blockquote 35,0,0,0,0 —>

- the compositions can be applied at sub-zero temperatures;

- have good adhesion to concrete, plastic, wood, brick surfaces, aluminum profiles;

- UV resistant;

- applied in any convenient way - spatula, brush, syringe, gun.

"Stiz A"

A vapor-permeable sealant intended for sealing seams between the opening and a window or balcony block on the outside of a building in accordance with GOST 30971. The vapor permeability of the outer layer is necessary so that moisture from the polyurethane foam is removed outside and the thermal insulation properties of the material are not reduced.

p, blockquote 36,0,0,0,0 —>

p, blockquote 37,0,0,0,0 —>

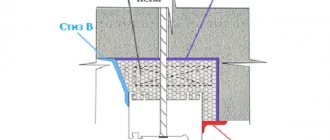

"Stiz B"

Vapor barrier acrylate sealant for the seam between the slopes and the window block indoors. Prevents moisture and steam from entering the seam from the room. Used in combination with the composition "Stiz A".

p, blockquote 39,0,0,1,0 —>

p, blockquote 40,0,0,0,0 —>

How to apply

Application is carried out on pre-fixed slopes.

Tools:

- construction tape;

- putty knife;

- sponge and piece of fabric;

- stationery or regular knife;

- container with water.

If special packaging is available, you must prepare a mounting gun.

Step-by-step work:

- Prepare the coating. Clean from dust and dirt.

- Apply masking tape around the joint.

- Squeeze the sealant directly into the gap and smooth it out. The layer is no more than 5.5 mm. Remove excess with a wet sponge.

- Remove the tape and wait for the layer to dry completely.

- Paint the seams.

Work should be carried out at a temperature within +25 degrees, but not higher than 35. The mastic hardens in about 48 hours.

Sealant consumption

Average consumption of stiz "A" per 1 linear meter = 120-150 grams. With a layer thickness of 2 mm and a seam width of 20 mm, the consumption will be 80g/linear meter.

Features of structural glazing

Structurally, structural facades are very similar to the mullion-transom glazing system; the main difference is the absence of a visible clamping profile from the outside.

Let's consider the main characteristics of structural glazing:

- The frame consists of vertically installed racks and horizontal jumpers (crossbars);

- The profile is made mainly of aluminum, sometimes stainless steel, light alloy metal elements or titanium are used.

- The frame is fastened between the floors, and the structure is visible only from the inside of the room. From the outside, only double-glazed windows are visible, the seams between which are filled either with a special sealant of a suitable color or with a thin decorative profile.

Visually, the structure of the system can be seen in our video:

Double-glazed windows for structural facades

The outer glass in such double-glazed windows is 10-15mm larger than the inner glass. This is necessary to minimize the external seam and securely attach the glazing to the frame. There are designs in which the spacer frame is slightly recessed into the glass unit. This allows you to insert a metal profile into the resulting groove and fix the glass unit through it on the supporting frame.

External and internal glass also differs from those used in traditional PVC structures. The outer part is made of thick tempered glass - triplex is mainly used for the inner part.

Another important point that needs to be taken into account when installing double-glazed windows is the installation seams between them. It is impossible to assemble a completely seamless structure, since the structure will lose its integrity due to temperature deformations of the glass and the supporting profile. The minimum gap between the outer glasses is 1 cm. However, it is also undesirable to make seams larger than two centimeters - a façade with such gaps does not look entirely monolithic.

Structural glazing sealant

Methods of mechanical fixation of double-glazed windows to the supporting frame vary depending on the profile manufacturer. However, in most cases, the outer glass of a double-glazed window is held in place by silicone sealant. In addition, this material seals all joints and junctions of the structure, compensates for temperature changes in dimensions, preventing damage to glass and deformation of the structure as a whole.

In structural facades, sealant is used for the following reasons:

- Reliable fixation of glass, metal, ceramics and most plastics.

- You can choose a material that matches the color or use a transparent one.

- You can work with silicone sealant at temperatures from -30 to +40.

For glazing structural facades, either neutral or acidic sealants are used. The use of the latter together with glass coated with decorative or energy-saving coating has a number of features. This type of spray typically contains metals, and the acid in the sealant can react with these metals. Therefore, the contact points between the acid composition and the glass must be pre-cleaned.

Nuances in application

The sealant is completely ready for use, but you need to be aware of some nuances:

- The viscosity will increase if you keep it warm for 2-3 hours.

- Do not dilute with water, it will reduce adhesive properties.

- To ensure perfectly smooth edges, construction tape must match the width of the seam. After this, fill the gap with sealant and remove excess. Otherwise, it’s difficult to do after it dries. Don't forget to remove the tape.

The sealing compound is applied to the joint surface of the panels with a brush, gun or other device. Fill the mouths of the joints with an even layer, without breaks. Smooth out with a spatula.

Manufacturers

Moment brand sealants are available in a wide variety. You can choose the right option for a specific task. There is also a universal putty on sale, which is popular and allows you to solve problems of various types. Moment products are attractive due to their high quality, which allows them to maintain their leadership position.

Stiz putties are the choice of professionals. They completely trust these sealants because they are a high-quality, reliable product that does not fail and always performs its functions. The sealing agent is available in different containers and different volumes.

The Bauset company produces a large number of products for window systems, including sealants. This brand produces many neutral putties, many of which are universal. The quality of the products is at a high level, the cost is affordable, and the performance characteristics are maintained for a long time.

Under the brand name "Vilatherm" a sealing harness is produced, which is widely used for sealing seams. In combination with a sealant, the harness allows you to achieve an excellent result, protect the room from noise from the street, prevent the ingress of moisture and the penetration of cold.

Tytan Professional is a wide range of sealants, which contains options for solving a variety of construction and renovation problems. You can choose a universal putty that will help you cope with a number of minor household problems. It will also not be difficult to choose a special option to solve a specific purpose. The cost of Tytan Professional products is in the middle segment, but the quality corresponds to the premium level.

Isocork and Bostik make cork sealant, which was mentioned in this conversation. There are other manufacturers, but these two produce the most worthy products.

Storage recommendations

Mastic in a closed container should be stored at a temperature not lower than - 5 degrees. It is allowed to freeze and thaw the composition about 10 times. Use damaged packaging immediately.

If most of the unused composition remains, it can be used as follows:

- Seal the installation seams of window and door openings, as well as interpanel joints or restore the walls.

- Carry out restoration and finishing work.

You can find many uses for it. Otherwise, close the container tightly so that air and moisture do not get inside and put it in a specially designated place until required.

Application area

Stiz A sealants are used for the installation of window and door units on residential, administrative and industrial buildings, as well as in private construction, namely:

- External insulation of cracks in wooden frames around the perimeter of the box and in places where mechanisms are attached, including balcony ones.

- Filling voids in concrete, metal and wooden structures of heated rooms.

- Restoration of cracks and damage in walls inside and outside buildings.

- Protection of polyurethane foam from humidity, temperature changes and UV rays.

- Formation of an additional layer of assembly seams at the junction points of window blocks.

In addition to Stiz A sealants, for repair work, Stiz B can be used for processing internal seams and Stiz D for pre-treatment of openings before installation in order to create additional moisture insulation.

Control of work progress

The presence of an additional layer of the installation seam is checked by visual inspection - on the surface of the window opening there must be a solid white film no less wide than the width of the installation seam.

The quality of the additional layer of the assembly seam is controlled using a water resistance test. A Karsten tube (straight or angular, depending on the location of the application surface) is installed on the Stiz D layer, cleared of polyurethane foam, and secured with plasticine. Pure water is poured into the tube so that the height of the liquid column is 30 mm. The upper part of the tube is closed to prevent water evaporation. Leave the tube in this state for 30–60 minutes. If the additional layer of the assembly seam is made with high quality, the height of the water column in the tube will not change during this time.

The thickness of the sealant layer during the application process is measured with a ruler with a division scale starting from the end of the ruler. To do this, the narrow end of the ruler is recessed into a freshly applied layer of sealant perpendicular to the surface of the seam until it touches the cut surface of the foam. Then carefully remove the ruler and use the trace of sealant on it to determine the thickness of the layer. After this, the seam measurement area is leveled with a spatula. The ruler itself is cleaned of sealant using improvised means.

The quality of the sealant application is assessed after it has cured by visual inspection, checking the absence of gaps in the foam insulation, as well as monitoring the continuity of the sealing and the thickness of the layer.

To measure the thickness of the layer of cured sealant, a U-shaped cut is made in it with a construction knife, after which the cut out part of the sealant is bent outward (Figure 2). The designated U-shaped section of the sealant is separated from the base of the mounting foam and the thickness of the sealant layer is measured using a caliper or ruler b.

The minimum thickness of the sealant layer after curing should be: for Stiz A and Stiz B – 3 mm; for Stiz PU – 2 mm. It is permissible for the sealant to flow into the pores of the polyurethane foam, provided that the minimum layer thickness is maintained.

To measure the width of the strip of contact of the sealant with the opening and the material of the translucent structure lcont (Figure 1), in the area of the U-shaped cut with a construction knife, continue the cut to the wall opening and the translucent structure. Using a ruler, measure the width of the uncut section of the seam located on the surface of the opening or translucent structure. The cut area in the sealant layer and additional cuts are sealed again. The width of the contact strip must be at least 3 mm.

If necessary, the technical characteristics of the assembly seam are checked using the methods recommended by GOST 30971-2012.

Nuances of work

For maximum sealing of plastic windows, there must be a certain thickness of the sealing material, optimally 3.5 mm. This is difficult to adjust, so using a ruler is recommended. A thin layer of material will be of lower quality, which will affect the sealing strength.

When installing plastic windows, it is rational to use two types of compositions - Stiz-A and Stiz-B. The first one is perfect for protecting the outer layer. Stiz-B will provide protection against moisture penetration from the room. For external joints, it is best to use Stiz-A, because Stiz-B after application reduces the heat-insulating properties of the polyurethane foam.

Preparatory operations before application

Before using Stiz D, all operations for the preparation and acceptance of wall openings must be completed.

Before using Stiz A, Stiz B or Stiz PU, perform the following set of operations.

Remove the protective film in the area of contact between the sealant and the window block, since after the sealant has completely cured, it will be impossible to remove the protective film from the window block without damaging the assembly seam layer.

The surfaces of the wall opening and window frame located in the area of contact with the sealant are cleaned of:

- mud;

- dust;

- fat;

- cement mortar residues;

- ice;

- frost, etc.

Foam insulation that extends beyond the plane of the window block and wall opening is trimmed with a construction knife.

To create the necessary contact strip of the sealant with the window block and the surface of the wall opening, as well as to improve the aesthetics of the installation seam, masking tape is glued to the surface of the window frame and wall opening at a distance of at least 3 mm from the border of the foam insulation parallel to the direction of the window profile.

To organize a layer of assembly seam at negative air temperatures, SMS materials are preheated to a positive temperature for at least 24 hours.

Safety regulations

When working with materials from the SAZI installation system, it is necessary to comply with the basic rules of occupational safety and health in accordance with SNiP 12-03-2001 “Occupational safety in construction. Part 1. General requirements."

Avoid contact of SAZI mounting system materials with eyes and unprotected areas of skin. Do not use internally. In case of contact with skin, wash off with warm water and soap; in case of contact with skin, Steez PU is a pre-cleaner with a solvent such as white spirit. When cured, remove mechanically. In case of contact with eyes or ingestion, consult a doctor immediately. Keep away from children.

Operations for installing an additional layer of construction seam

Stiz D is applied in even stripes using long, wide brush strokes. The composition is applied in such a way that the surface is not visible through the applied layer of Stiz D.

When using highly porous materials to create a wall opening or in the presence of irreparable defects in the wall surface, it is necessary to apply another layer of Stiz D on top of the dried layer to prevent problems associated with the possible absorption of the composition into the wall material or its flow into surface unevenness.

After applying the finishing layer of Stiz D, you can immediately begin installing the window structure. The construction of the central layer of the assembly seam is carried out after the formation of a stable surface film Steez D.

The maximum duration of formation of the surface film of Stiz D is 30 minutes at a temperature of 23 ± 2 ° C and a relative air humidity of 60 ± 10%. During the formation of the surface film, it is necessary to ensure ventilation of the applied composition and prevent rain and snow from entering it.

You can check the layer of the Composition for the formation of a stable surface film by touching its surface. If the layer does not smear or get dirty when touched, then you can begin further work on organizing the installation seam.

Operations for constructing the outer and inner layers of the construction seam

Mixing components (in case of using Stiz PU)

The ratio of components A and B when mixed should be 100 parts by weight of the main paste (component A) to 10 parts by weight of the hardener (component B).

Mixing is carried out by pouring the contents of the container with the hardener into the container with the main paste. The remaining hardener is removed from the walls of the container with a spatula and added to the main paste.

Both components are mixed using a low-speed drill (no more than 350 rpm) with a spiral mixer until a homogeneous one-color paste is obtained, but not less than 10 minutes.

To organize a layer of assembly seam at subzero air temperatures, before mixing components A and B, it is necessary to keep them at a positive temperature for at least 24 hours. The recommended temperature of the finished sealant mixture at negative air temperatures is 20 ± 5 ° C.

Applying sealant

Stiz A and Stiz B sealants are applied with any tool suitable for this purpose. The most common options are using a spatula, a paint brush, or squeezing the sealant directly onto the foam insulation from a cartouche (tube) or a file package using a special gun.

It is recommended to apply Stiz PU sealant to the surface of the foam insulation with a spatula.

Treatment of the applied sealant layer

After application, the sealant is leveled with a spatula. In order to avoid sticking of the material to the tool, the spatula is moistened in a soapy water solution (at negative air temperatures - in an unsaturated solution of table salt in water). The thickness of the layer of sealants Stiz A and Stiz B after leveling should be 3.5÷5.5 mm. The thickness of the Stiz PU sealant layer is 2÷4 mm.

Final operations

Before the sealant cures, remove the masking tape. If, during the process of removing the tape, damage occurs to the contact area of the sealant and the window block or wall opening, the integrity of the layer should be restored. To do this, apply sealant to the defect area using a spatula.

After completion of work, tools should be cleaned of residues of Stiz A and Stiz B with hot soapy water before the sealants cure. If the sealant has already hardened, the tools are cleaned mechanically.

When using Stiz PU, after finishing work, the tool is washed to remove any remaining sealant with white spirit or solvent grade 646 or 648.

The maximum duration of formation of the surface film of Stiz A and Stiz B sealants is 2 hours at a temperature of 23 ± 2 ° C and a relative air humidity of 60 ± 10%. Under other conditions, the formation time of the surface film may change.

During the formation of the surface film, it is necessary to ensure ventilation of the applied layer of sealant and prevent rain or snow from entering it.

The viability of Stiz PU sealant after mixing the components at an air temperature of 23 ° C is about 6 hours (it increases with decreasing temperature).

Packaging, transportation and storage

Materials The SAZI installation systems are supplied in sealed plastic buckets of 3 kg, as well as 6.6 kg and 7 kg, in plastic tubes (cartouches) of 0.44 kg, folic tubes (file bags) of 0.9 kg .

Each product unit is equipped with a label indicating:

- name of the country, legal address (telephone) of the manufacturer and/or trademark;

- product designation;

- Customer's trademark;

- batch number and date of manufacture;

- Net weight;

- number of the Standard to which the material complies;

- warranty period of storage.

The guaranteed shelf life of SMS materials is 6 / 12 / 18 months (depending on the brand), starting from the date of production, while maintaining the integrity of the original packaging and observing the rules of transportation and storage in accordance with the requirements of STO 028-37547621-2016, 034-37547621-2016 , 004-88928000-2015 and 150-37547621-2020.

Transportation of materials is allowed by all types of transport in covered vehicles. Temperature for transporting materials:

- Stiz A and Stiz B – from -13°C to +35°C;

- Stiz D – from -5оС to +35оС;

- Stiz PU – from -20°C to +30°C.

SMS materials supplied to the site are stored in closed warehouses.

Storage temperature for SMS materials:

- sealants Stiz A and Stiz B – from -13°C to +35°C;

- composition Stiz D – from +5оС to +35оС;

- Stiz PU sealant – from -20°C to +30°C.

Transportation and storage of Stiz A and Stiz B sealants is allowed at temperatures from -20°C to -13°C, while the total time of transportation and storage of the sealant should not exceed 30 days, and the number of material temperature transitions through -13°C should be no more than 20.

Short-term (no more than a day) transportation of SMS materials is allowed at a temperature not exceeding +50°C (not applicable to Stiz PU).

During storage and transportation, violations of the seal of the packaging, as well as contact of SMS materials with vapors of aggressive substances and solvents, are unacceptable.

Stiz PU sealant must be protected from moisture and direct sunlight.

Open containers with remnants of unused material are hermetically sealed for further use throughout the entire shelf life of the material (not applicable to Steez PU).

Incoming materials inspection

Before using SMS materials at a construction site, the following is checked:

- shelf life of the material;

- tightness and type of original packaging;

- complete set of delivery (in case of using Stiz PU): component A (container with the main paste) and component B (container with a hardener located inside the container with component A).

After the expiration of the guaranteed storage period, SMS materials can be used for their intended purpose after a request to the manufacturer and his letter about the positive result of checking the compliance of the material with the requirements of the Standard of the organization according to which the material was manufactured.

Materials, tools and devices used

Standard tools for applying sealants are a putty knife or a paint brush.

When using sealants packaged in cartouches (tubes) or file packages, a special closed or skeleton-type gun is required for application, depending on the type of packaging.

To mix the components of Stiz PU sealant, use a low-speed drill (no more than 350 rpm) with a spiral stirrer. Mixing is done in a container with the main paste (component A).

It is recommended to use a spatula to level the sealants and give the layer the desired shape.

To form the required contact strip of sealants with application surfaces, it is recommended to use masking tape.

When glazing with window blocks made of aluminum profiles, to organize the outer and inner layers of the assembly seam, it is recommended to replace a regular spatula with a plastic one to prevent damage to the protective coating of the aluminum profile of the window block.

To control the progress of work, you need a caliper, a construction knife and a ruler with a division scale starting from the end of the ruler.

When applying the Stiz D composition, a paint brush is used. The size and type of brush are selected based on the width of the additional layer specified in the project and the working conditions at a particular site.