Platbands, Miscellaneous

The flooring is selected depending on the functionality of the room and your own preferences. Problems may arise not with the choice of material, but with the direct connection of the parts at the joints. After finishing the walls and installing the floor, the question arises of how to join the baseboard to the door casing. It is important to pay attention to the unification of all finishing elements, while skirting boards, trim and door structures should not fall out of the overall style.

How to connect the platband to the baseboard?

What is the best way to join a door casing and a floor plinth?

Where can you clearly see how this is done? This work once again shows how everything is interconnected in construction.

In order for the joining of the plinth and the platband to be of high quality, it is necessary to decide on both the platbands and the plinths before laying the floor covering.

After all, in order for the question “how?” stopped tormenting, it’s enough to buy a plinth of the same thickness as the casing (this is if the doors do not have a high threshold).

People laying the flooring need to be shown the baseboards so that they create an appropriate gap between the flooring and the wall.

And the platband and baseboard fit together differently.

In most cases (there are exceptions), the platbands are attached first, then the baseboards.

You can do the docking like this:

If the plinth is thicker than the casing, then you can join it like this.

The joint itself is straight, and the corner of the casing is cut at 45 degrees, this is not a bad option, the joint looks neat.

Now about the exception.

If your door has a threshold, the threshold is high (such options are often found on doors to toilets and bathrooms), then you can attach a plinth along the threshold, and install a trim with a straight, even cut on it.

If the threshold is low, the plinth is higher, then you can make markings along the threshold and use a plane to remove part of the “body” of the plinth, along the height of the threshold, then the removed part is painted to match the color of the door frame, or rather the threshold.

This option will work with wooden baseboards.

Of course, the door frame should not be adjusted or cut in any way; the door frame should definitely reach the floor; there is no need to cut or sharpen it from the sides!

But the baseboard, depending on what kind of baseboard you are going to install, needs to be adjusted.

Skirting boards and trim made from the same material (for example, MDF) fit together without any problems at all.

Plastic skirting boards have decorative plugs, with their help you can neatly and beautifully join the end of the skirting board and the door casing.

An oblique cut is made on the wooden plinth to align the adjacent side of the plinth with the thickness of the door casing, it looks like this.

And here is a picture of the result that you get if you cut the door casing, I hope now it’s clear why you can’t cut the casing, it looks even uglier in real life!

There are a lot of docking options, one of the most common is to lower the casing to the floor and dock the plinth to it through a plug. But I don’t know about anyone, but I absolutely don’t like it, there is no harmony, especially when the color of the platband and the baseboard with the end cap do not match.

Some join in reverse, complete the baseboard with a cap to the end of the wall, and nail the platband on top. But it also doesn’t turn out so beautifully, although if you cut it not as in the picture, but a little at a bevel, then it will look better from above.

A better option would be to purchase a plinth with a radius at the end, then the whole combination is smoothed out and seems to move from one completed composition to another, especially if the colors of the platband and the plinth match.

But I like this option best, when the corner of the plinth is cut off, but forms one whole, passing into the platband already along the width of the platband itself.

Production of end caps for veneered or solid wooden skirting boards

If the profile of the plinth is thicker than the door casing, the question often arises of how to elegantly design the end. The easiest way is to paint the end in the color of the decor with oil, varnish, wax grout, etc., but for the sake of a couple of ends you need to select the color, and the result is most often far from ideal.

There is a more professional way - to make the end ends yourself. Please note that this method is only suitable for straight profiles without slope. We could tell you how to file the baseboard, but it’s easier to show a photo of the finished end once and everything will be clear.

The concept of floor plinth and platband

Overlay strips, which are designed to hide shortcomings in the installation of a doorway, are usually called platbands. They perform a decorative role, visually hide the imperfections of the box, thereby giving the entrance structure a complete look. A plinth is a horizontal plank on the floor covering, designed to cover the gap that forms between the wall and the floor. Its installation is carried out in order to ensure a smoother transition from wall to floor. Both parts are made of different materials and can have different shapes, textures and colors.

The seam between the overlay strip and the floor plinth must be neat

What are thresholds for?

As you know, laminate flooring needs to be laid indoors with a gap from any enclosing structures - walls, door frames, columns, etc. This is due to the relatively large coefficient of change in the linear dimensions of the flooring material due to temperature and humidity changes. For this reason, experts advise laying laminate flooring separately in each room, and forming a kind of expansion joint between rooms in the doorway. This will allow you to avoid swelling of the coating in the future, compromising its integrity and geometry.

There is one more important note in the instructions for laminated parquet - the area of the solid coating should not exceed 30-100 m2 (depending on the density and size of the slab). That is, every 5-10 m in the room it is recommended to make an expansion gap

Limit laminate area and seams.

The resulting compensation gaps are decorated in several ways. The most famous of them are transition profiles or thresholds. Their purpose:

- Smoothing out differences in floor level or creating a neat transition from one type of coating to another;

- Protection of the ends of the laminate from dirt, chipping, burrs and other damage;

- Leveling seams at joints with a decorative effect;

- Creating a zoning effect.

Thus, thresholds are useful finishing profiles that can be used both for their intended purpose and for the implementation of various design ideas. Available in the following sizes:

- Width from 1 to 12 cm;

- Length from 0.9 to 3 m;

Why is it important to do the docking beautifully?

The joining of the plinth and the platband is an important point in the renovation, without which it is impossible to create a holistic look for the interior. A beautifully designed doorway, correctly installed floor planks and a well-made connection are all an integral part of creating a beautiful room design.

They help not only to hide defects after repairs, but also allow you to give the interior greater aesthetics, as well as emphasize the chosen stylistic direction.

Docking options

There are two ways to make a neat joint. The classic connection is based on bringing the plinth to the platband and then cutting it off. It is better to make such a connection without a decorative side. It can be made to order to make the joint. In this case, the connection will be able to perfectly match the thickness of the element to the door trim. A non-standard connection involves a connection with a cut at an angle of 45˚ to the floor. Such a joint must be made if the thickness of the casing is less than the door lining.

Related article: How to open a metal door if the lock is broken

The joint option is selected depending on the thickness of the casing and the wall

Decorative panels

If other analogues of the plinth are small in size and height, then the decorative panels are mounted on part of the wall. Therefore, in this case, it is important to carefully consider the combination of design, texture, color, and so on. Fortunately, stores now sell decorative panels for every taste and color.

You can even find premium decorative panels with a three-dimensional pattern, although their price is several times higher. The panels are easy to install; just use special glue or screws.

Features of joining in corners

The question of the correct connection of skirting boards to platbands in the corners is considered the most important. If the angles are right, then this joining option is considered the simplest. The floor part of the device will need to be placed on the base, and the side part, which will be fixed to the wall, to its side part. On the side scale you need to find a groove with an angle of 45˚ and make a cut in the desired direction.

If they are indirect, then making the correct seam is more difficult. Here, successful joining of products directly depends on correctly performed measurements. In this case, you should bring the plinth on both sides and outline the outer floor border of the product. The result should be a rhombus, the cut line in which will be the diagonal drawn outward.

It is necessary to install the plinth in the corners after making calculations

Ceramic border

Initially, this technology was used in places where the bathtub adjoined the wall to seal the cracks. But then someone suggested using a ceramic border instead of a baseboard for the floor. As a result, this technology quickly spread throughout Russia and Europe.

Since the ceramic border has an attractive appearance and a number of useful properties: long service life, resistance to almost all external factors and high tightness.

If you are already tired of the classic option of framing the transition between the floor and the wall, then you can use one of the unusual analogues to the baseboard. This way you will get a more original and attractive interior, thereby spending not much more money.

Harmony of color and material

To create the perfect design, the choice of products for joining should be made in accordance with the tone and texture of the doors and floor. The combination of linoleum and carpet with wooden trim and baseboards will not be the most successful. In this case, plastic options will look much more advantageous. If the apartment has laminate or parquet, then wooden lining of the door and floor will look much more impressive. Moreover, regardless of the material of the selected products for joining, their color and texture should preferably match. This way the overall picture looks more harmonious.

Rope

A cord, or rope in other words, is a budget analogue of a plinth. The thick designer rope looks very original and unusual. In stores you can now purchase any type of edging cord, which differ in design, thickness, material of manufacture, and so on.

At the same time, to attach the rope to its rightful place, you do not need to call specialists. This interior element is attached with glue. The only task is to glue the rope evenly.

How to join the plinth and platband with your own hands during installation?

Since achieving an excellent result in joining structures is not so easy, it will be useful to learn how to join the plinth and door casing correctly. At the same time, you should initially understand that the connection and design of the joint can be done only after finishing the work on the floor covering and installing the door structure.

The design of the joint can be done after finishing work on the floor covering.

Tools and materials

Before connecting structures, you should prepare the following:

- hacksaw;

- miter box;

- roulette;

- goniometer;

- pencil.

Before carrying out work, it is important to prepare tools and materials

Docking process

There may be several connection options. Moreover, under no circumstances should the platband be cut or filed away from the sides. It is better to perform all these manipulations with a plinth. The junction of the plinth and the platband will be hardly noticeable if the edge of the floor plank is cut at 45˚. When the thickness of the plinth is greater than the casing, the joint can be made straight and the casing can be cut by 45˚. In addition, if the height of the plinth is greater and it is wider, then the connection can be made through a heel or shoe. This connection looks more interesting and is especially relevant for the design of rooms in a classic style.

Varieties by type of design

In this case, two classifications are taken into account. The first involves dividing the thresholds into curved and straight ones. In essence, these are flexible plastic and rigid wooden elements. Aluminum can only be bent in the longitudinal plane along the length, but not sideways. Another classification involves division into collapsible and solid elements. Collapsible ones consist of two parts - the lower one is laid under both sides of two floor coverings, and the upper one covers the outer side. The coupling is formed by special groove clamping systems. But this option is allowed only during the initial installation, when the main flooring material is also laid. The one-piece element involves only external masking of the joint, but can be installed at any time without requiring intervention in the structure of the laid flooring. It is also worth noting the multi-level threshold between the tiles and the laminate, which is designed for an organic connection of coatings located at different heights. For example, if you need to technically level the gap between thick tiles and thin laminate, then a multi-level threshold of the appropriate standard size is suitable.

Installation of platbands

The design of the doorway is an important moment of every renovation. Without attractive doors, fittings and trim, any interior seems unfinished. The process of decorating a doorway is simple, so you can install decorative strips yourself.

Important! Before direct installation, the edges of the parts should be lubricated with glue to ensure a strong connection.

The installation process consists of the following points:

- Measure the distance from the lower end of the additional component to the floor covering. About 5 mm is added to the resulting figure;

- The acquired result is measured on the platband and the excess is taken away;

- If the platband comes with fastening in a groove, then measurements are taken along its hidden part;

- Mount the element on the door;

- According to the installation technology, fixation is performed in increments of 50 cm;

- After the manipulations, the upper casing is prepared. The part is filed along the edges at an angle of 45 degrees.

Important! To do everything correctly, after cutting down the first corner, the workpiece is applied to the structure. If necessary, adjust it and only after that file the second one.

- The top part is fixed in the same way as the side parts.

Related article: How to remove a lock from a metal door

Sometimes novice craftsmen make a number of inaccuracies during installation, which lead to the formation of gaps between the joints of the platband. To fix this, you will need a special sealant.

How to choose the right skirting board

It is often possible to hear the judgment that the baseboard has no effect on interior design, but designers believe that this is incorrect.

When choosing this element, pay attention to a number of criteria:

| Room dimensions | 1.Light shades are suitable for small rooms. They visually expand the room. 2.To achieve a visual separation between walls and flooring, the baseboard can be used as a dividing line. If it is chosen to match the wall, this solution also helps to expand the area. |

| Product texture | If the flooring is made of solid wood, an identical baseboard is selected for it. |

| Skirting configuration | 1. Plays a role when choosing a shade; 2. In most cases, this part acts as a frame. But sometimes it’s worth deviating from generally accepted principles and choosing a model in a bright, contrasting color. |

| Color spectrum | Decorating details should not stand out against the general background; their main function is to harmoniously fit into the style of the room. |

Shadow seams

A shadow seam is an interior detail that is most often used in plasterboard structures. Visually it looks original and unusual. After all, from the outside it seems as if the wall is floating in the air and is not attached to the floor in any way.

This effect is achieved due to the fact that this type of hidden plinth has the shape of the letter “L”, and the floor covering extends under the plinth by at least 3-6 millimeters.

Variety of floor skirting boards

To decorate the premises, skirting boards are used from the following materials:

- Wood. Such details are a traditional option for decorating a room. The products have an outer relief surface, and on the inside there are special grooves for mounting electrical wires or cables in them. Fixation of such skirting boards is carried out using self-tapping screws, less often nails.

Wood product, photo

Important! If you plan to use self-tapping screws to attach a wooden plinth, then dowels are installed in the walls in advance.

Among the positive properties of wooden parts are their environmental friendliness and the possibility of reuse. After installing the wooden plinth, it is additionally puttied and coated with varnish, paint, and stain. Wooden baseboards are not cheap.

- Plastic skirting boards are also well suited for covering flooring. In such products, everything is thought out to the smallest detail. Such skirting boards are distinguished by ease of installation, a variety of shades, and the presence of additional elements (plugs) for sealing joints. Once installed, no additional processing is required. However, plastic is a fragile material. Under strong mechanical stress, cracks or chips may form on the surface of the product. After such deformation, it will require complete replacement;

A variety of plastic skirting boards will allow you to choose the right option

- Products made from MDF. Their advantages include durability, ease of installation, environmental friendliness, cost-effectiveness, and a wide range of colors. Before joining such a plinth, you should remember that MDF has increased fragility, so all manipulations must be performed extremely carefully.

Floor plinth made of MDF, photo

What types are there

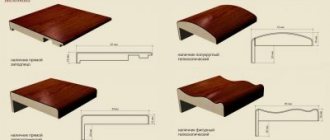

There are various options for overlay strips. They differ in functions (to support the structure or for decoration), color palette, installation method (telescopic or overhead), shapes (rounded, flat, curly), sizes, materials (wood, metal, aluminum), texture (simple, carved elements, made according to a template). The finish is selected according to the style of the interior, the installation location and the volume of hidden elements (for example, a lot of cables and wires).

Made of wood

The wooden panel is made from soft linden, spruce, pine raw materials (budget models), from hard (expensive products) - ash, oak, Karelian pine, walnut, beech. They are suitable for any door materials, easy to install, environmentally friendly, adapt to any interior design, have a long service life (with proper care) and can be repaired in case of minor damage.

They are mainly used for interior door frames because they are not resistant to changes in room humidity and temperature. Strong changes lead to swelling or drying of the material.

If the surface is poorly processed, it may darken and lose its original shade. The cost of a wooden plank may be more than a door leaf if there are brass or copper elements. They are present only in designer products, but even without them the cost is higher than other types of cash.

From MDF

MDF paneling is almost no different from wooden types, so it often replaces its competitor. MDF panels are laminated with PVC film or covered with veneer, obtaining a good imitation of the structure of wood. MDF is safe for humans, because it is environmentally friendly. Wear-resistant, resistant to mechanical damage. But it can swell from high humidity. For example, in the bathroom. Materials laminated with PVC film are not expensive, but those covered with natural veneer are the opposite.

Made of plastic

Plastic paneling is made from a strong plastic mass that does not change under various negative conditions. They do not require special care products or frequent cleaning (once a week is enough), they do not melt and do not fade in the sun. The cost is low, so paneling is often used to complete repair work on installing door panels.

Don't miss: Installing hinges on a door

The disadvantage of the material is the small palette of colors and models. Usually ready-made ones are available in white and brown, other colors are made to order. In addition, plastic trims must be secured carefully, because they cannot be repaired and are easily scratched.

Made of metal

This type is used for installing steel doors. Usually they are placed on the side of the street or corridor, then they are combined with the box. This allows you not to worry about how to install the panel, because the installation is carried out simultaneously with the box. But there are also separate metal racks, because there are interior steel and aluminum doors that require a metal design.

It has many advantages: resistance to moisture, sunlight, and mechanical stress. They can also be used forever, because they do not wear out like other types.

Important! People without experience may have difficulty sizing. To get everything straight, they hire craftsmen.

How to properly connect the plinth and platband

In most cases, the edge is installed at the stage of laying the floor covering and is intended to mask the seams in the covering near the wall. The cross-section of the plinth is thin at the top and wider at the floor.

The junction of the floor edge with the platband

Important! This configuration causes some difficulties when joining the baseboard and door frames.

Door frames are usually thinner than the bottom of the side. Such a difference does not look very aesthetically pleasing. As an option, you can use thicker bars in the lower part of the structure, and thus successfully connect the plinth and platband. However, this solution is not suitable for ultra-modern styles.

Rice. 5 Direct joining of the plinth to the platband

The way out is to abandon the classic decorative side and make it to order. Then it will be possible to adjust the thickness of the part to the platbands as much as possible.

You can purchase a narrow decorative edge, but in this case it is important to ensure that the installation of the floor covering is done to the highest possible quality. The gap between the wall and the ceiling should not exceed 1 cm.

Backlight

Every person has seen LED lighting on the floor or ceiling in at least one movie or TV program. It goes well with any design and looks great.

The only disadvantage we can highlight is that the monthly payment for electricity will increase (the backlight does not consume a large amount of energy, so the increase in the amount will be insignificant). In addition, you can install an LED strip that will respond to movements in the room and turn on at that moment.

The lighting can be installed inside the shadow seam or built into special baseboards. Alternatively, you can install a special neon cord along the transition of the floor to the wall. And if you want to install a backlight that will turn on when you move, you also need to connect a motion sensor.

Skirting boards. Subtleties of joining and joining.

Sometimes joining the plinth and door casing becomes a difficult task for people doing repairs on their own. The thickness of these decors is rarely the same and very often, especially for economy class doors, the trim is made of thin MDF. Towards the end of the renovation, when the doors and moldings have already been installed and the turn of the baseboards comes, it turns out that the joining of the thin platband and the thick baseboard turns out to be ugly. In cases like these, people sometimes come to me asking me to suggest a way out of the current situation.

I RULE: Buy doors whose platbands have a heel (shoe). The thickness of the heel is usually greater than the thickness of the door casing and the wider end allows the baseboard to fit the heel as expected.

II RULE: Choose a plinth of less thickness than the door casing!