The vast majority of customers perceive the installation seam only as a gap filled with foam around the perimeter of the window, which is subsequently sealed with putty or other building materials. Therefore, when checking the quality of installation, many do not pay due attention to this important element due to its apparent insignificance, which in the very near future may lead to not the most pleasant consequences. In order for the windows to be guaranteed to last a long time, and no alterations are required, it is recommended to treat this structural element as seriously as the profile, double-glazed windows and fittings.

Requirements for translucent structures of residential buildings

According to the above GOST R 56926-2016, design solutions for window and balcony blocks, assemblies adjacent to external wall openings must ensure water and air tightness of the building when exposed to precipitation and wind, as well as combinations of these loads.

Translucent structures must provide natural lighting of the premises at a standard level (in accordance with SP 52.13330 “Natural and artificial lighting”). Therefore, the total area of light openings should be at least one-eighth of the floor area of living rooms and kitchens.

Plaster

Sealing external seams after installing plastic windows using the plastering method also requires compliance with certain rules. First of all, this relates to the choice of material suitable for these purposes. The most convenient to use is elastic acrylic plaster. The only thing I want to warn you about is: before purchasing, pay attention to the manufacturer’s recommended thickness of the seam to be applied. There are compositions intended strictly for decorative work and they are laid in a thin layer (5-10 mm).

If it is necessary to seal a seam whose depth is 3 centimeters or more, I recommend using proven cement-based plaster. It can be used for sealing deep seams.

Source usetips.ru

Why do you need window sealant: installation solution

If we consider the design of a window or balcony glazing in a simplified way, it consists of the following main elements:

- an opening in the wall for installing a window or balcony block;

- window or door balcony block.

It is impossible to ensure that the linear dimensions of the blocks perfectly coincide with the linear dimensions of the opening. You also need to take into account that with temperature changes, the linear dimensions of the opening and the window block will change differently due to differences in the characteristics of the materials from which they are made, so a gap must be provided between them.

This gap breaks the tightness of the structure, becoming a “cold bridge”, an area through which precipitation and drafts will penetrate into the room. The result will be a decrease in room temperature (and high heating costs), humidity, and mold in the corners of the windows.

Areas of application

Modern manufacturers have come up with many different products for processing and insulating windows. ZhP is able to cope with the cracks that form during the installation of slopes. Installing such elements allows you to cope with several construction defects:

- It is the slopes that allow you to transform the window structure, due to which it will acquire an improved and harmonious appearance.

- During dismantling of old panels, deformation of the opening may occur. It can be easily removed using slopes.

- The level of lighting in the room is significantly improved. The desired effect is achieved due to the fact that the opening is equipped with an additional reflective surface.

- High-quality slopes allow you to increase the level of thermal insulation, due to which you can ensure the most favorable microclimate in the room.

- The penetration of dust and extraneous noise is prevented.

All these factors influence the fact that a window structure cannot do without installing plastic slopes of suitable size. But in order for such products to fully cope with the obligations assigned to them, their connection with the main fabric must be as strong as possible. To solve this problem, the ZhP was developed. The craftsman must carefully close the technological seams, as well as fix some auxiliary elements (plates, drains, protective strips). This is precisely what explains the need to use universal sealants.

Places for applying sealants on translucent structures. Window sealant requirements

The following areas require sealing:

- gaps between the window block and the window opening;

- gaps between the frame and slopes;

- gaps between slopes;

- cracks in window frames;

- window sill connection;

- from the outside - the junction of the cornice to the wall.

Thus, sealing is required both indoors and outdoors.

These areas must be filled with material that meets the following requirements:

- high adhesion to the materials from which window blocks are made and to the wall material;

- thixotropy (so that it does not flow when applied along the upper horizontal and ceiling surface of the seam connecting the window and opening structures);

- elasticity;

- resistance to various adverse environmental factors (precipitation, aggressive chemical compounds, solar radiation, high and low temperatures and sudden temperature changes, vibration);

- antiseptic properties;

- aesthetic qualities (white, transparent or another color that matches the color of the frame or the possibility of painting);

- durability while maintaining all characteristics.

Sealing of windows is carried out both during the installation of window blocks and during repairs, when the old seal or sealant has ceased to perform its functions. The need for repairs can be determined by the following signs:

- draft;

- condensation on glass;

- water on the windowsill;

- mold on slopes.

Window mounting seam: according to GOST or not

Today, when glazing houses, most construction companies require the installation of windows in accordance with GOST. When installing windows, private consumers do not always think about the importance of a high-quality installation seam and are not ready to overpay for it. Why is a high-quality and protected installation seam in a window so important and what materials can it be used to make it?

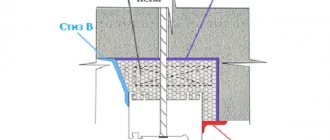

Photo: 3 protective layers of window assembly seam according to GOST

A regular window installation seam differs from a GOST installation seam in the number of protective layers. In a regular seam there is only 1 thermal insulating layer of polyurethane foam.

According to GOST, the installation seam must have 3 protective layers:

- external vapor-permeable and waterproofing to remove excess moisture to the outside and protect the seam from the sun, rain and wind, which is done using mounting tapes or sealants;

- medium – thermal insulation using polyurethane foam;

- internal - vapor barrier (vapour-tight), protects the seam from the penetration of steam from the room into the seam, using tapes or sealants.

What materials are windows made from?

If the translucent filling of a window or balcony block is usually made of glass, the profile material may be different:

- PVC;

- metal with or without thermal bridge;

- tree.

PVC is most often used for windows. Balcony blocks can be plastic or metal. Wooden windows are now available in two versions:

- expensive wooden double-glazed windows;

- simple wooden frames (found in old houses, and can also be used in country houses and outbuildings as an inexpensive window option).

Thus, the sealant for window seams must have adhesion to glass, plastic, wood, metal, as well as to the materials from which the walls of buildings are made - concrete, brick, stone.

The advantage of processing joints with liquid plastic for windows

The liquid plastic material used to fill the seams is also used for the manufacture of slopes and windows.

Since both parts are made of rigid PVC and have the same density and structure, a perfect combination of the parts to be glued is ensured. When liquid plastic hardens, it forms a monolithic base in which the window and the slope are combined and create the appearance of a single whole. In places of gluing, diffuse welding occurs, that is, the interpenetration of parts.

Also, fungus or mold does not appear on such a seam, and the seam itself is mechanically stable and environmentally safe.

Choosing a sealant for sealing window seams

Sealant is a material for filling, sealing and sealing seams, abutments and joints. It can take the form of self-adhesive tapes, sheets, and is also available in the form of polymer-based pastes or so-called liquid plastic.

Paste-like polymers can be single-component or consisting of several components. While the former are ready for use, the latter are mixed from separate components, which complicates the work.

Sealants are also classified according to the type of active substance. Depending on it, the sealant has certain characteristics, therefore, for each type of material and work, its own type of sealing material is used. Of course, the more versatile the sealant, the better.

Important!

Sealant on windows is used not only inside, but also outside. Therefore, you need to use different sealants for different types of seams or choose a universal sealant that is suitable for both external and internal work.

What sealants are not used for plastic and other types of windows

Let us first list the types of sealants that are not the best choice for windows made of PVC and other materials.

Bitumen sealants

Although today there are already non-black bitumen sealants that are resistant to high temperatures, in general they are not used for windows.

Acrylic sealants

The downside to acrylic sealant is its tendency to darken or yellow over time. When used for external seams, its low resistance to moisture becomes critical. Even waterproof and frost-resistant types of acrylic sealants begin to deteriorate when constantly exposed to high humidity.

However, acrylic window sealants are still used on external seams, but with subsequent treatment with a fungicidal compound.

What sealant to use to seal the seams of window blocks

Let's look at the sealants that are most often used for plastic, wooden and metal windows.

Thiokol sealants

Thiokol or polysulfide sealants are high-quality materials that penetrate even the smallest cracks and cracks, filling them reliably.

The advantages of thiokol sealants include:

- strength and durability;

- resistance in a wide temperature range from –55°С to +130°С;

- chemical inertness;

- water resistance;

- resistance to organic solvents;

- excellent adhesion;

- Possibility of use at low temperatures.

Thiokol sealants are used in hydraulic engineering construction and are even more suitable for windows.

The disadvantages include the need to mix sealant from 2-3 components.

Butyl rubber sealants

One-component butyl rubber sealants have good adhesion and can be applied to wet and oily surfaces. The advantages of these sealants also include:

- strength;

- stability in the temperature range from –50°С to +90°С;

- elasticity;

- water insolubility.

However, these sealants are applied only at positive temperatures. In window blocks they are used mainly for sealing seams and cracks in double-glazed windows, and for processing the joints of the frame and slopes it is better to choose a different type of sealant.

Silicone sealants

Silicone sealants in everyday life are also referred to as “plumbing” sealants, because, due to their high adhesion, elasticity, strength and water resistance, they are popular for sealing joints in bathrooms.

Silicone sealants are available in a wide range of colors, as well as in a transparent version. They are also suitable for narrow joints up to 5 mm wide.

Silicone sealants are also used for windows, but there are some limitations to their use:

- acidic varieties of silicone sealants are not suitable for window blocks with a metal profile, as they cause corrosion of the metal;

- Silicone sealants are not suitable for windows with wooden profiles because, unlike wood, they do not work well under compression (bubbles may appear);

- on external seams, silicone sealant lasts no more than 5–7 years;

- For plastic windows, silicone sealant is suitable, but the seams filled with silicone quickly become covered with dust, which is difficult to clean because it sticks to the sealant, and the appearance of the window becomes sloppy.

Siliconized sealants

These are inexpensive, durable, vapor-permeable sealants (a mixture of acrylic and silicone components), but they are not used for metal work.

Alkyd sealants

One-component sealants based on alkyd resins are available in several versions.

These are inexpensive sealants that are suitable for exterior and interior use and can be painted. With high water resistance, they retain vapor permeability, have good adhesion to wood, brick and PVC profiles, and allow work at low temperatures.

Polyurethane sealants

The most important advantage of polyurethane sealants has always been their durability.

New generations of polyurethane sealants can be considered as truly universal materials, suitable for external and internal use and compatible with any building materials.

General information about the product

The sealant for metal-plastic structures is a kind of mass that has plasticity and a self-leveling effect; the product contains a polymer. Thanks to this component, all the smallest excesses that arise after installing the frame can be quickly and easily eliminated.

We are talking about blocking cracks and minor voids; window sealant is often purchased in a white shade so that the mixture, after hardening, completely merges with the frame, and the appearance is as attractive as possible; if the seams are manipulated correctly, the material is quite difficult to notice.

The compactor is capable of solving problems such as:

- Helps the master achieve ideal noise and heat insulation.

- Provide reliable protection against seasonal temperature changes.

- The plastic component of the repair makes the appearance of the slopes more attractive.

When working with the mixture, everyone can notice good adhesion, regardless of the base material; over the years, the high reliability of the adhesion, resistance to mechanical stress and the harmful effects of ultraviolet radiation become obvious.

Adhesive sealant for seams white

CEMMIX Adhesive-sealant for seams is a one-component polyurethane sealant for sealing various seams, junctions of steps and walls, entry of pipes and ventilation systems and rigid-elastic gluing of various materials.

More details

Manufacturers and price

The manufacturer of the adhesive-sealant is the popular German company Weiss, which produces liquid plastic under the well-known brand Cosmofen. Recently, the manufacturer has been quite successfully expanding its product line, adding glue for working with glass, leather, and cellular polycarbonate.

The glue should be stored in a tightly closed container for 12 months at a temperature range of 15 to 30 degrees. If used after the expiration date, it should be remembered that the viscosity of the adhesive may increase and the result of the work will no longer meet the necessary criteria.

https://www.youtube.com/watch?v=rAR70o1hMWQ

The main types can be called:

Cosmofen 345

The sealant is not prone to spreading over the surface. The resulting seam is reliable, weatherproof and does not fade.

Cosmofen Plus HV

The best option for instant connection of rigid PVC. It has found its application when gluing drains, flashings, and closing elements. Has increased viscosity.

White facade adhesive sealant

CEMMIX Facade adhesive-sealant is a special sealant based on hybrid polymers for various joints.

More details

Let's consider one-component sealants based on hybrid MS polymers - weather-resistant Cemmix Facade Sealant and Cemmix Seam Adhesive Sealant:

- sealants are designed for sealing seams up to 20 mm wide, as well as for rigid-elastic gluing of different types of materials;

- have excellent adhesion to a wide range of building materials;

- easy to apply (applied with a spatula or a construction gun, does not bubble, does not spread, and is thixotropic);

- quickly cure when exposed to atmospheric humidity (initial polymerization within 15 minutes);

- allow application at sub-zero temperatures;

- elastic;

- are not afraid of sunlight, high and low temperatures and temperature changes, vibration;

- frost-resistant;

- waterproof and chemically inert;

- mechanically strong;

- allow coloring;

- have antibacterial characteristics;

- safe for humans;

- serve for 10–25 years with preservation of properties.

Important!

Cemmix adhesive-sealant for seams is available in 4 shades, Cemmix facade sealant - in 8.

Cosmofen: instructions for use

Clean the surface to be glued from dust, degrease and wait until it dries. The glue must be applied to only one surface of the bottle using a dispenser located directly on the lid. Combine both parts of the product and hold for some time, pressing them against each other until the surfaces stick together. This is approximately 15-20 seconds. Final hardening depends on ambient temperature and humidity.

COSMOFEN CA 12 adhesive has a low viscosity, so it cannot be used with a gap of more than 0.1 mm between the surfaces to be bonded. For larger gaps, COSMOPLAST 516 and COSMOPLAST 564 can be used. In order to speed up the hardening time, the catalyst COSMOPLAST 583 is used. Careful preparation must be carried out before gluing. Namely:

- aluminum parts are treated with a special chemical composition or varnished;

- silicone and plastic surfaces must be tested first, since the range of materials is quite wide, and it can be difficult to immediately select the gluing mode and speed.

Glue consumption varies and depends on the material. The viability of the glue and the holding time of parts under pressure vary. They can be determined experimentally, since all these processes are influenced by the structure of the material, the volume of the surface to be bonded, as well as air temperature and humidity, the thickness of the applied layer, compressive force and other criteria.

Uncured COSMOFEN CA 12 can be cleaned using COSMOPLAST 597. Cleaning with acetone or removing the hardened film mechanically is possible.

When working, precautions must be taken. The basis of COSMOFEN CA 12 adhesive is cyanoacrylate - ethyl cyanoacrylic acid

This is a toxic substance that also has a high bonding rate.

When it comes into contact with the skin, it immediately sticks together, and the eyelids can also instantly stick together. This happens within a few seconds. Avoid direct contact with the glue. Inhaling vapors sometimes causes nausea and even dizziness. If COSMOFEN CA 12 adhesive gets on your skin, immediately wash off the cyanoacrylic composition with soap and water. If it gets into your eyes, under no circumstances should you close them; you need to wash off the glue under running water, the rinsing duration is several minutes. After the procedure, you should immediately consult a doctor. If glue vapors are inhaled, it is necessary to ventilate the room. Access to fresh air will prevent poisoning.

It should be stored in places where small children have no access. The glue has a shelf life of six months, provided that the contents are kept in a container from the manufacturer in places that exclude humidity. The temperature should be in the range from +15°C to +25°. Exposure to direct sunlight is destructive and leads to drying out of the polymer. At lower storage temperatures, for example, in the refrigerator (about plus six degrees), the shelf life is extended to 12 months.

This is interesting: Contact glue “Moment Crystal” - instructions for working with the product, its composition and characteristics - we reveal the essence

Adhesive sealant for seams white

CEMMIX Adhesive-sealant for seams is a one-component polyurethane sealant for sealing various seams, junctions of steps and walls, entry of pipes and ventilation systems and rigid-elastic gluing of various materials.

More details

Rating of quality acrylic products

Profilux Acrylic 300 ml

A quality product that is sold in cartridge form and is suitable for sealing windows. The main feature of the product is the ability to be painted in any color. The maximum temperature that the product can withstand is 80 degrees.

The average price is 170 rubles.

sealant Profilux Acrylic 300 ml

Advantages:

- Good seal;

- Durability;

- Safe composition;

- Efficiency;

- Price.

Flaws:

- Not detected.

TYTAN PROFESSIONAL

A one-component product suitable for use in various structures. Surface hardening time is 25 minutes. Can be used to connect glass, concrete, aluminum, steel, wood, etc. Cartridge volume – 310 ml.

Sold at a price of 270 rubles.

sealant TYTAN PROFESSIONAL

Advantages:

- Durability;

- Efficiency;

- Good composition;

- Rapid hardening;

- High-quality sealing of joints between glass and aluminum.

Flaws:

- Price.

MASTERTEKS PM

A quality option designed for filling joints around window spaces. The product guarantees excellent adhesion to almost all smooth materials. The main feature of this sealant is its high elasticity after hardening. To give a beautiful appearance, the seam is painted over in any color. The product is completely safe for health and environmentally friendly.

The average price is 220 rubles.

sealant MASTERTEKS PM

Advantages:

- Aesthetic appearance;

- Contains a fungicide that prevents rotting;

- Painted in any color;

- Non-toxic.

Flaws:

- Not found.

White facade adhesive sealant

CEMMIX Facade adhesive-sealant is a special sealant based on hybrid polymers for various joints.

More details

Important!

For polyurethane sealants on joints requiring elasticity, the third contact surface must be eliminated. To do this, a cord made of foamed polyethylene is installed at the mouth of the seam.

Watch the video : Plastic windows. Quick sealing of joints and seams

The choice of materials for sealing windows and balconies is very wide, but each sealant has its own characteristics. Cemmix facade sealant and Cemmix adhesive-sealant for seams are universal materials that can be used when installing window units. You can buy Cemmix sealants wholesale and retail in construction networks, as well as online.

You can buy CEMMIX products without leaving your home, with discounts from 5 to 33%!!!!

Buy on Ozon

Buy on Yandex.Market

Buy on Wildberries

Buy at Leroy Merlin

Or you can find the nearest official dealer in your region on our map

← Sealant for blind areas

Waterproof and frost-resistant metal sealant for exterior use →

Return to list

Comments

TOP-best

The following brands deserve attention:

- Cosmofen - produced specifically for sealing joints. The composition of the mixture allows it to resist the formation of moisture, fungus, and external factors. One-component product, low viscosity. The sizing is instant, since it contains ethyl cyanoacrylate, there is no creation of flaws. Complete drying and hardening occurs after 15 hours. Heat resistance is guaranteed. It conducts heat poorly, so it does not release heated air from the room. Country of origin: Germany.

- Tytan is a sealant for PVC (liquid plastic) windows. Made on the basis of vinyl mastic. Designed for gluing and sealing cracks and joints on polyvinyl chloride. The use of this material ensures the strength of the formed seam, its water-thermal resistance, and is not susceptible to the influence of solar radiation or other street influences. Work should be carried out at temperatures from 15 to 25 degrees. The hardening time depends on the thickness of the applied seam, so with a thickness of 1 mm, complete hardening occurs within a day. Country of origin: Poland.

- Fenoplast is a white liquid plastic. Used for repairing window structures. The seams are strong and reliable. The first setting period is up to 4 minutes. Complete hardening occurs within a day. Country of origin: Germany.

- Enamel “Liquid plastic” DUFA Kunststoff flussig is used as a sealant for wooden windows and PVC. On two planes it forms a strong, durable, moisture- and chemical-resistant coating. It does not resist mechanical stress. There is no smell. One coat is enough to cover the base color. The composition does not spread when applied, as it has a viscous consistency. German quality.

- Greenteq – white hard plastic. It has a one-component composition. Fast polymerization, quality gives frost-heat resistance, impact resistance. Also unaffected by solar radiation. The production is based on diffusion adhesive, vinyl chloride polymer in a solvent. The first setting occurs in a minute at a temperature of 20 degrees and a humidity of 50 percent. Complete hardening, subject to the same conditions, will occur within a day. The minimum temperature at which work with trains is permissible is 5 degrees. To clean excess liquid plastic, cleaners of the same brand are used, and from metal objects it is enough to remove the frozen film, since setting with the metal does not occur.

News

We are always ready to help

Cemmix has opened a free hotline

to help you with any questions related to construction using concrete additives. Call and ask, our consultants are always ready to help!

Hyperplasticizer

Hyperplasticizers are a new type of plasticizing additives for concrete, ensuring the mobility of the mixture above P5. In addition to plasticity, they increase the water resistance and frost resistance of concrete by 2-3 times.

Silicone sprays

For ease of use, it is better to take window sealant in spray form. Because if you take the standard packaging, you will also have to buy a mounting gun.

Please note that the following factors are significant for achieving a good seal:

- the reliability of your seal;

- correctness of its application;

- compliance of its composition with the scope of application.

The main advantages of the spray are:

- you can stop plumbing leaks without disassembling;

- significant savings in time and money;

- perfectly seals and protects;

- Suitable for sealing window blocks.

Conclusion

So, let's summarize. We have already found out that sealing is a reliable means of sealing windows and increasing their thermal insulation properties . When choosing a suitable substance for sealing, it is necessary to take into account its scope of application, what material we will work with, what will subsequently affect it, whether further painting of the sealed area will be necessary or not.

The answer to the question - how to insulate windows for the winter - is very simple. Here are our tips:

- sealing agents are applied between the frame and the window sill, or between the frame and the glass.

- To insulate wooden windows, we need to remove the glazing beads from the frame, clean them of dust and dirt, paint residues, and then apply a sealing agent to the seat.

- After the final hardening, we put the glazing beads in place, but we recommend replacing the old glazing beads with new ones for reliability.