Tapes for window installation according to GOST

High-quality glazing requires serious consideration and is impossible without proper insulation of the gap between the opening and the window. Often, organizations that install translucent structures limit themselves to traditional polyurethane foam, which is subsequently covered with plaster or other finishing materials. This approach has proven itself relatively well and in some cases does not cause any complaints from the consumer throughout the entire service life of the window.

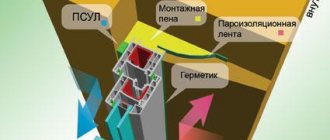

However, glazing with one level of sealing of the opening does not meet the state requirements for the quality of services or goods provided, that is, GOST. To comply with these requirements, additional insulation is required at the junction of the window and the opening both from the street side and from the room side. Such insulation is ensured using special mounting tapes.

Scheme for using mounting tapes on windows

View from above

Mounting tape for windows is a self-adhesive material on a polymer or fabric basis, designed for additional sealing of window or door openings.

What happens if you don't use PSUL tape?

Some installation teams, in order to save money allocated for the purchase of materials and time, ignore the requirement for the mandatory use of PSUL. Failure to use it leads to the fact that the hardened polyurethane foam absorbs and retains moisture in the internal pores for a long time. This triggers the process of destruction of the assembly seam, which entails quite a lot of unpleasant consequences:

- depressurization of window or door units;

- increased heat loss;

- the appearance of condensation;

- rapid development of fungus and mold;

- destruction of internal slopes.

Some unscrupulous installers argue for violation of installation technologies by the fact that anyway, the windows along the perimeter of the external slopes will be puttyed or covered with strips, so the seams will be protected in any case. This information is unreliable and misleads customers, since the specified slope cladding is not capable of providing effective protection against moisture.

Types of mounting tapes for windows

The functions performed by the tapes are different and depend on the location of gluing, the condition of the opening, the features of the future finishing of the slopes, as well as the requirements for the window block. Next, we will consider the most commonly used materials common in the modern construction market.

Pre-compressed sealing tape is used primarily on the outside of translucent structures. Its main purpose is to ensure unimpeded drainage of moisture from the area where the hatch connects to the opening.

Essentially, this is a tape product made of elastic polyurethane foam (looks like foam rubber), usually gray or black. One side of the material is covered with an adhesive composition, insulated with a protective film. The tape is supplied twisted into compact reels or rolls (depending on the size), which need to be unwound only during the installation process, since the material loses its quality over time.

An example of tape expansion over time

The main feature is the ability to fill joints as a result of expansion, which occurs as a result of contact with air. The tape isolates the gap from moisture and external influences from the outside, while simultaneously allowing excess liquid to evaporate from the inside.

Scope of application of PSUL:

- Additional sealing of interfaces between elements of prefabricated structures;

- Sealing the gap between the frame and the opening when installing windows and doors;

- Insulation of joints between small-sized moving units of building facades;

- Filling the external seam between the slope and the frame during the installation of PVC windows.

It is important to understand that to fill the gap efficiently, you need a tape of the appropriate size. For example, if the task is to seal a joint with a maximum width of 40 mm, you will need a PSUL with a nominal size of 45-50 mm.

Water vapor barrier (GPL)

This type of tape product is most popular when installing window blocks. Among its main features it is worth highlighting the following:

- Water vapor barrier mounting tape is designed to seal joints on the room side.

- Polyethylene film is most often used as the basis for self-adhesive material. On one side the tape is equipped with a foil coating, and on the other - with an adhesive composition.

- The adhesive used provides reliable fixation on most surfaces (concrete, brick, cinder block, wood and others). The products of some brands have poor adhesion to foam blocks and aerated concrete, so before purchasing you should consult with the seller or read the attached instructions.

- The structure of the material prevents the penetration of moisture or air both through the tape itself and through the gluing points. This ensures the maximum possible tightness of the joint of the opening and, as a result, the structure as a whole.

- In addition to insulating from moisture, the tape does not deteriorate during prolonged contact with ultraviolet radiation and is not subject to destruction from exposure to aggressive environments (household acids, alkalis and other reagents).

GPL is used for waterproofing installation gaps that arise when installing window and door units, as well as for sealing structures made of metal, wood, concrete and plastic.

GPL-S and insulated GPL

- GPL-S its structure is identical to the GPL described above. The main difference is an additional strip of double-sided tape on the side that is not covered with adhesive. Due to this, the area of fixation of the material on the window block expands. Unlike traditional water vapor barrier tape, GPL-S can be glued to the inner surface of the profile using an additional strip, and the adhesive side to the slope.

- Insulated hydro-vapor barrier tape is an improved modification of conventional GPL. Main features: thickened base layer based on polyurethane foam or cellular polyethylene; a more durable foil component, usually made from high-quality polyethylene. As a result, the tape, in addition to its high waterproofing qualities, significantly prevents heat loss at the joints of the frame and the opening. In addition, the material is quite durable, which ensures the safety of the structure, preventing mechanical damage.

VM (VM+) tape

- VM . Vapor barrier tape designed for sealing joints indoors. It is used in cases where wet finishing of slopes is planned (plaster or tiling). Provides protection from moisture entering the joint of the opening and reliable fixation of the finishing coating.

- VM+ . A modified analogue of the previous product with similar properties. It has the best waterproofing qualities, which allows it to be used in rooms with high humidity (kitchens, showers).

VS (VS+) tape

- Sun. Material with one-sided adhesive coating on a non-woven base. Used indoors for waterproofing window and door openings. Intended only for dry finishing of slopes. For example, plastic, wooden or MDF lining, plasterboard and other sheet materials.

- BC+. Similar to the previous product, also used for dry slope design. Distinctive features: adhesive layer on one side and the presence of an additional strip of double-sided tape on the back; There are modifications with foil coating for additional thermal insulation of the seam.

Diffuse (vapor-permeable waterproofing tape)

It is used outside structures in conjunction with pre-compressed tape or in situations where it is impossible to use the latter. Traditionally, diffuse tape is used to isolate the area where the molding profile is attached, since PSUL cannot be glued to the place where it is fixed, but there are also frequent cases of use along the entire perimeter of the window block.

Butyl rubber, used as the base of the tape, is a fairly elastic material with high adhesion to most surfaces. It is equally firmly fixed on stone, wood or plastic. It is also worth noting that it is environmentally friendly and almost completely harmless to the consumer. The main disadvantage is the flammability of butyl rubber, which requires compliance with appropriate standards for installation and subsequent operation.

Used as an insulating material on the inside of the structure. It is glued to the bottom of the window sill profile as additional protection against blowing from the outside and penetration of steam into the installation seam from the room side.

Types of vapor barrier and waterproofing tapes for seams

Types of vapor barrier tapes

Waterproofing windows ensures their long-term operation, therefore, according to SNiP and GOST, tapes for sealing them are installed on the outside and inside with the mandatory installation of slopes. But external conditions are always harsher than internal ones. From inside the premises, the main load is considered to be moist air vapors that tend to escape outside. As soon as they penetrate the structure of the seams (joints), they will begin to condense. And this simply cannot be allowed. Although the application of slopes serves as a certain protective barrier against high humidity.

Therefore, the external waterproofing of plastic windows must ensure the tightness of the seams from precipitation with high humidity. This is where waterproof but vapor-permeable tapes, or polyurethane, are most often installed. And this is waterproofing. On the inside, it is necessary to install only vapor-proof tapes, that is, a vapor barrier.

True, the building materials market does not stand still. Recently, a sealing mounting tape has appeared on it, which combines all three main characteristics necessary for sealing window openings. Let's look at two of its types:

- GPL – hydro-vapor barrier tape (self-adhesive) with a foil layer.

- PSUL – pre-compressed sealing tape.

This window waterproofing tape consists of three layers:

- External – metallized polyethylene film, which performs the functions of vapor barrier and waterproofing.

- Medium - foamed polyethylene that performs thermal insulation functions.

- The bottom layer is a waterproof adhesive composition based on rubber (synthetic) for fastening, covered with a protective silicone film.

Tape width: 90, 120, 150 and 200 mm, thickness 20 microns. It can be cut into pieces of the required length. The installation process is quite simple. It is necessary to remove the protective film from the back side and lay the tape itself to waterproof the seams of the window without tension. After which it is recommended to roll it with a roller, thereby removing air bubbles from under the strip. Next, the slopes are installed.

Advice . Manufacturers recommend carrying out work related to installing the tape at a temperature not lower than +10C. Window sealing with this vapor barrier can be carried out both from the inside and from the outside.

It should be noted that self-adhesive waterproofing tape for seams of this type is present on the market not only in domestic versions. A large assortment is represented by German companies whose products are of high quality. True, it costs more. After completing the installation of the vapor barrier tape, you need to start installing the slopes.

This is a completely new and unique approach in the window sealing category. Essentially, this is a sealing mounting tape (waterproofing and vapor barrier), which is inserted into the gap between the PVC window frame and the opening wall, where it begins to expand to a certain size, filling the entire volume of the gap. This mounting sealing tape is made from a special material, very similar to foam rubber, which is impregnated with special additives. Upon contact with air, the PSUL begins to expand.

Here are the dimensions of the German sample from:

- Tape width: 10, 15, 20 mm.

- Accordingly, expansion: 3, 6-8, 8-10 mm.

- Maximum extension: 10, 30, 40 mm.

Important . Since the material can expand twice, it is necessary to choose its dimensions in strict accordance with the parameters of the gap between the opening and the window.

If the air temperature is +30C, then the waterproofing (vapor barrier) mounting tape will fully expand in half an hour. At a temperature of 0C – 4 days. But the main selection criterion must be based on water resistance. The higher this indicator, the better. Currently, the maximum water resistance is 600 MPa. By the way, the color of the tape for sealing PSUL seams is either gray or black. If you come across material with a different color, it is a fake.

Of course, the catalog of mounting tapes used to seal windows does not end with these two materials. As mentioned above, the assortment is quite large. And if you choose from other models, then you should pay attention to the conditions for which they are intended. That is, as a waterproofing and vapor barrier sealing of windows from the outside or from the inside.

Installation features

The tape is applied both before fixing the window block in the opening, and on already installed structures. The first option is more convenient in cases with the installation of external insulation.

Let's consider the algorithm for using tape insulation using the example of gluing pre-compressed sealing tape (PSUL) and internal GPL-S with an additional strip of double-sided tape:

- We prepare the opening. If there is an old window unit, we dismantle it as carefully as possible, without causing unnecessary damage. After dismantling, we level the surfaces adjacent to the future structure and clean them of foreign contaminants.

- We perform a test installation of the block in the opening, temporarily fixing it. This is necessary to mark the edge of contact between the walls and the window, so that when gluing the tape is hidden behind the outer slopes.

- We measure the window block. In accordance with the obtained dimensions, we cut PSUL for gluing on the top and sides of the frame; we prepare diffuse tape to isolate the area where the molding profile is attached.

- We do the same with GPL-S (internal slopes) and butyl rubber tape (for the window sill profile). The material is measured for each side with an allowance of 10 cm to form corner joints.

- We apply the tape, gradually removing the protective layer from the adhesive surface of the PSUL.

We glue GPL-S to the inside of the window profile using a strip of double-sided tape (we do not remove the protective film from the main adhesive surface at this stage). - We fix the window in the opening. We wedge it, and then fasten it with anchors or using mounting plates. We fill the seams with polyurethane foam.

- After complete polymerization of the foam and rough preparation of the inner surface of the walls, we fix GPL-S on them (remove the protective paper and glue it to the slopes).

It should be remembered that the tape must be selected in accordance with weather conditions. When working in winter, it is possible to glue only material intended for use in low temperature conditions.

Useful video on the topic:

Dimensions and approximate cost

Diffuse insulating tape for installation outside (under low tide):

- Width -70 mm;

- Length in a skein – 25 m;

- The price of a skein is 436 rubles.

PSUL for use at sub-zero temperatures:

- Width – 20 mm;

- Thickness – 8 mm (40 when uncompressed);

- Length – 5 m;

- Price – 160 rub.

Internal duplicated tape:

- Width – 100 mm;

- Length per skein 25 m;

- The price of a skein is 377 rubles.

Inner metallized tape:

- Width – 45 mm;

- Length – 24 m;

- Price for 24 m – 523 rub.

Tape for window sill profile:

- Width – 200 mm;

- Length – 12 m;

- Price – 600 rub.

Vapor barrier tape and its types

Replacing windows in a house is always accompanied by the installation of protection for the junction of the frame and the wall. Polyurethane foam is applied between the opening and the frame - traditional and proven thermal insulation. The foam performs its role properly, but if exposed to extreme moisture or ultraviolet radiation, its quality may change for the worse.

To eliminate the possibility of such a situation in advance and save yourself from replacing polyurethane foam in the future, you should think about sealing the seams. To do this, you need to install additional insulation.

Window butyl vapor barrier tape as an element of additional insulation

A complete set of insulation allows you to avoid freezing of the room and minimize the penetration of moisture and noise.

Vapor barrier

The insulation between the wall and the window consists of three layers:

- Outer. Its function is waterproofing, which means protecting the room from any weather conditions - snow and rain.

- The load-bearing insulation layer is located in the middle of the joint and is responsible for heat and sound insulation. Protection from frost is provided by a porous material resembling polyurethane foam. The waterproofing agent prevents moisture from getting inside.

- The inner layer is also considered thermal insulation. Here the mechanism of heat conservation is different. This layer does not allow heat to escape from the inside, unlike the outer layer, which protects the premises from cold air flows from the street.

Window insulation layers

The vapor barrier of windows refers to the inner layer, but is not always included in the insulation system. Single-sided self-adhesive vapor barrier tape or double-sided vapor barrier tape is additional protection. The need to use tape increases if the window is installed in a room with a high moisture content: kitchen, sauna, bathhouse.

Installing vapor barrier tapes is no more difficult than installing other types of seam insulation. However, a vapor barrier can help avoid subsequent serious problems with the entire window protection system. When installing a vapor barrier, in some cases you may need a couple of additional accessories, for example, vapor barrier tape. This is worth considering.

Features of the material

Modern window insulation technologies include the installation of three layers of the product:

- External. Waterproofing is the main function of this layer. The coating provides reliable protection of the room from climatic conditions.

- Basic. It is located between two additional layers and is responsible for ensuring good performance in terms of sound and heat insulation.

- Interior. The process of preserving heated air is carried out using a slightly different method. The layer does not release heat to the outside when the outer insulation does not let in cold air from the street.

The use of vapor barrier tape for windows is used at the stage of creating the inner layer. In this case, the material acts as additional protection.

Also, the need to use vapor barrier tape increases if the window installation is planned in a room with a high level of humidity. These rooms include a bath, kitchen, sauna and bathhouse. Installing vapor barrier tape for windows is no different from its analogues.

Classification of vapor barrier tapes

In the construction market, according to their design features, there are two types of adhesive tape for vapor barrier of windows:

- one-sided;

- double sided

The first option is mounted directly on the window frame. The second, in turn, is installed between the frame and the opening, fixing these elements at the same level.

Varieties - single-sided and double-sided

In addition to the distinctive feature of the adhesive substance, adhesive tape is also divided according to the parameter of use in a certain climatic environment:

- if the electrical tape is planned to be used in warm regions of the country, then the summer series is suitable;

- in areas where the average temperature is in the sub-zero category, winter insulating tape is used.

VIDEO: Correct installation of PVC windows, using mounting tapes, according to approved construction GOSTs

Sticky layer

All vapor barrier strips for plastic windows have a special adhesive layer, which eliminates the need to apply glue yourself and create poor adhesion. Also, the sticky layer increases the level of protection against moisture penetration into the heat-insulating multilayer structure.

The adhesive layer is made on the basis of butyl rubber with the addition of metal components. Rubber variations are great for almost all types of surfaces - metal, brick, concrete, wood, plastic.

For vapor and waterproofing and generally for fastening sheets, you should not use office tape. Due to the textured side of the membrane, it will fall off within a day. The fastening of the waterproofing tape is ensured by a special adhesive composition.

Types of vapor barrier tapes

There are several groups of vapor-permeable tapes for windows, differing in the material from which they are composed.

- Butyl rubber PSUL - used for external vapor barrier, high-quality fixation of frames to walls and processing of joints from the outside of the building. The product is distinguished by its large mass, which is at least 5 times greater than the reinforced type, and this is with the same width parameters.

Classification of vapor barrier tapes

Vapor barrier tapes are manufactured in two versions:

- tapes with one adhesive side;

- double-sided vapor barrier tapes.

Butyl vapor barrier tape for window

The first type of tape is attached to the window frame of the window. The second allows you to choose the mounting location: both on the frame and in the opening.

In addition to differences in adhesive structure, tapes are divided into two types according to climatic design:

- for predominantly warm average annual weather, “summer” vapor barrier films are suitable;

- in the presence of sub-zero temperatures, “winter” tapes are used.

Classification of vapor barriers for windows

To install a PVC window, vapor barrier tape in a wide variety of varieties and diffusion vapor-permeable tape are used.

Tapes can have one or two adhesive surfaces. The first ones are installed on the frame itself, the second ones can be installed in the window opening, gluing them to both the wall and the window profile. The range is divided into winter and summer options. Summer ones are intended for installation at temperatures from +5 degrees to +35 degrees, winter ones - for installation at temperatures of +5 degrees and below. Moreover, when installing in winter, it is necessary to warm up the surface of the window opening.

The tape should be approximately 5 cm larger than the width of the mounting seam.

Based on the material used, there are two types of tapes:

- Butyl rubber tape with a reinforcing layer of non-woven fabric, designed for sealing joints.

- Metallized tape, intended for installation in damp rooms.

Adhesive surface of vapor barrier tapes

All vapor barrier films are equipped with an adhesive strip. The absence of the need to apply glue yourself eliminates the possibility of poor-quality fastening of the tape, as well as moisture getting into the thermal insulation environment.

The material for the adhesive layer of the vapor barrier tape is butyl rubber or, in cases with high humidity, metal. Tapes containing rubber film are used for windows, balconies and doors in almost all types of premises. The basis of such a vapor barrier is non-woven fabric.

Types of vapor barrier tapes

The most common types of tapes, depending on the material:

- One of the most popular butyl rubber tapes is PSUL (pre-compressed sealing tapes), which are responsible for external vapor barrier, finishing of external joints and tight connection between frame and wall.

- GPL polyethylene tape is made from foam material. On one side it is treated with lamination. The strip contains metal inserts and an adhesive part along the entire length and width. Thanks to its well-thought-out composition, it is almost universal and is recommended for insulating all types of door and window frames.

- Vapor barrier tape for aircraft windows. Suitable for insulating joints if a subsequent dry method of finishing slopes is planned. Typically used on plastic or plasterboard elements. The connecting tape protects surfaces from condensation. The wide adhesive strip makes the installation of the vapor barrier strip simple and quick.

- Vapor barrier tape VM. Just like other types of tapes, it attaches perfectly to window and door frames. Installation is carried out in sequence from the frame. The strips of tape are attached overlapping in order to avoid possible heat leaks during operation of windows or doors.

Butyl rubber tape has a high specific gravity. PSUL tape weighs approximately 5 times more than tape made with reinforced aluminum foil with the same width. The differences between the types of tapes also lie in the surfaces for which they are usually used. The thick rubber tape can be firmly attached to the wall, and there is no need to use heavy insulating materials for gluing to slopes. For this case, lightweight foil-reinforced strips are preferred.

Properties

The maximum level of protection of seams from moisture and other unfavorable factors is determined by the technical characteristics of the psul tape, which characterizes wear resistance.

So, the properties:

- does not collapse under the influence of UV rays;

- solvent resistance;

- retains elasticity after use;

- counteracts the deformation process;

- does not absorb water;

- high percentage of vapor permeability;

- withstands temperatures from -45 to +85 degrees Celsius;

- fire safety.

Thanks to these parameters, window insulation tape can be used under previously stated temperature conditions. The service life is from 20-50 years, as the manufacturers assure.

After purchase, use immediately; you do not need special tools, experience or equipment (a hair dryer will come in handy). But there is one fundamental condition: clean the surfaces from dirt and treat them with a dust-repellent solution.

If it is wood, it absorbs water, cover it with a primer.

When gluing, do not bend, compress or stretch, this will lead to disruption of installation and reduce the effectiveness of self-expanding insulation.

If necessary, use a butt joint, pressing the ends tightly together.

GPL tapes

GPL are vapor-waterproofing tapes that perform moisture protection as the main task. These tapes form the outer layer of insulation with an additional vapor barrier function . Self-adhesive vapor barrier tape is made of polyethylene foam.

Polyethylene foam has a porous structure, has good thermal insulation properties and almost zero hygroscopicity (does not absorb moisture). The presence of this material in the tape makes it elastic and provides high-quality sealing with any surface, including uneven ones.

Vapor barrier tape for PVC windows

Joints and seams are always the most unprotected places, including when installing windows. Moisture can seep through them, condensation can form, heat can escape and sound insulation can be impaired. Mounting tapes will help eliminate these problems. Waterproofing tape for PVC windows will not only improve the climate, but also simplify installation.

Water vapor barrier mounting tape for PVC windows

Mounting tape is a polyethylene foam material with an adhesive composition on both sides. Designed to improve the sealing of window structures. The use of water vapor barrier tapes is used quite rarely due to their high cost. When installed, they increase the cost of windows by 15-25 percent.

Experts often neglect their use and risk the quality of the work done, or find other methods. For example, they can install a plastic slope, use polyurethane foam, and cover the installation gap on the outside with plaster and paint it. This method is widespread and has virtually no negative reviews, due to the high efficiency of the materials used. However, it does not meet industry standards.

The use of vapor-permeable or vapor barrier tape for windows when installing a window mechanism is a mandatory requirement according to GOST. Since they provide additional insulation of the joints between the window and the opening from the outside and inside.

- The purpose and sealing of the window seam with the window opening is created by polyurethane-based polyurethane-based polyurethane foam. However, it is vulnerable to ultraviolet rays and therefore self-adhesive tape is used to protect it. It covers the installation seam from the outside;

- vapor barriers - necessary to improve ventilation and protect against moisture. When temperature changes in the rooms, condensation forms, due to which moisture forms in the installation seams. Tapes help to avoid this and improve the quality of heat conservation;

- vapor-permeable - used for exterior decoration and guarantee good air circulation. That is, they promote the release of moist air from the assembly seam.

Tapes perform various functions, depending on the place of their application, the condition of the window structure, the finishing of the slopes and the materials used.

Types of water vapor barrier tape

Based on the requirements for installing PVC windows, various materials are used. Due to the different features, it is possible to combine different materials to achieve a better effect:

- Water vapor barrier tape (GPL) is the most common when installing window structures. Its main features: it is a sealing material for joints on the inside of the room;

- The component of the self-adhesive material is polyethylene film. On one side, the GPL is covered with a thin foil layer, and on the other, with an adhesive composition;

- strong fixation is ensured by the adhesive composition. It is suitable for almost all materials. However, when choosing a material for foam blocks and aerated concrete, you should pay special attention to the instructions. Since not all formulations may be suitable;

- the composition of the material guarantees complete tightness of both the tape itself and the glued areas;

- GPL not only insulates from moisture, but is also not afraid of exposure to aggressive substances.

The main distinguishing feature is the ability to fill joints due to expansion that occurs from contact with air. But there are other positive aspects of using PSUL:

- seals the seams between the components of the window structure;

- seals the joint between the frame and the window opening;

- isolates gaps of small-sized moving parts of the structure;

- fills external seams between the window slope and frame.

- In addition to the listed varieties, for finishing the room side, internal tapes are used: VM made of vapor and waterproofing material, to seal the joints of rooms. It is used in cases of damp finishing of slopes (with plaster or tiled decoration). Guarantees protection from moisture in the seams of the opening and reliably fixes the finishing coating;

- VM+ is a modified analogue of the previous material, with increased resistance to humidity;

- BC - also used for interior decoration, but in a dry way (plastic, drywall and other sheet material);

- BC+ is a modification of the previous product with greater thickness due to an additional adhesive layer. They are also available with a foil layer, which provides additional thermal insulation of the seam.

Material Dimensions

For convenience, practicality and efficiency, mounting tapes are produced in rolls of various widths and lengths:

- diffuse insulating material for exterior decoration of premises: width 7 cm, length 25 m;

- PSUL used at subzero temperatures: width 2 cm, length 5 m;

- internal duplicated (width 10 cm, length 25 m) and metallized (width 4.5 cm, length 24 m);

- material for window sill profile 20 cm wide, 12 m long.

Attention! In order to properly seal joints, it is necessary to select the correct size of the material. As a rule, the width of the mounting tape should be 5-10 mm larger than the width of the gap.

General installation information

You can use GPL or PSUL both before and after installing the window structure. The sizing algorithm is quite simple:

- Preparing the opening. If available, the old structure is dismantled, very carefully so as not to damage the edges. Next, all surfaces are leveled, cleaned of dirt and dried.

- The window block is temporarily fixed to mark the edges and determine the dimensions of the required material. It is desirable that the PSUL be completely hidden behind the external slopes.

- In accordance with the measurements, mounting tapes (GPL, PSUL, diffuse) are cut. The length margin for corner joints must be at least 10 cm.

- They are glued to the window frame, and at the same time the protective film is removed from one of the adhesive strips.

- The window is installed in the opening, fixed with anchors or mounting plates, and the seams are filled with foam.

- The protective strips are removed from the GPL and glued to the opening.

- To improve the sound insulation of the external window sill, PSUL is glued under the ebb.

Attention! When installing in winter, it is necessary to use special materials that are not afraid of low temperatures.

If the main goal when installing window structures is not to comply with GOST requirements, then mounting tapes do not need to be used. However, they can improve waterproofing, avoid the appearance of moisture, and therefore mold in the joints. In general, they increase the service life of the window structure and make the indoor microclimate more comfortable.

Technical characteristics of PSUL and its properties

There is a wide variety of PSUL vapor barrier sealing tapes on the market; all of them have the following properties and technical parameters:

- an adhesive layer that prevents the product from moving on the surface of the opening;

- resistance to external factors such as ultraviolet radiation, moisture and others;

- various expansion rates (from 2 mm when compressed to 80 mm when expanded);

- chemical neutrality;

- absence of significant deformation (within 15%);

- vapor permeability during compression;

- the ability of the material to maintain elasticity throughout its entire service life;

- good sound, steam and heat insulation characteristics;

- resistance to the formation of fungus and mold;

- resistance to a wide range of temperatures (the operating temperature of the PSUL tape ranges from minus 50°C to plus 80°C);

- thermal resistance (up to +1000°C);

- flame retardant material;

- different product densities.

| PSUL | Size of the sealed gap, mm | Width, mm | Expansion in the uncompressed state, mm |

| 10x2 (10)x12.5 | 2-4 | 10 | 10 |

| 10x4 (20)x8 | 4-6 | 10 | 20 |

| 12x4 (20)x8 | 4-6 | 12 | 20 |

| 15x4 (20)x8 | 4-6 | 15 | 20 |

| 17x4 (20)x8 | 4-6 | 17 | 20 |

Frost resistance and water resistance values according to GOST

According to GOST R 53338-2009, which contains the technical characteristics of self-expanding PSUL vapor-permeable sealing tapes with an adhesive layer, they are divided into types of execution depending on their resistance to negative temperatures:

- I – use of the material in an area with an average air temperature in the coldest month of minus 10°C, the minimum temperature at which strength and reliability tests are performed is minus 25°C;

- II – use of the product in an area with an average air temperature in the coldest month from minus 10°C to minus 20°C, with the minimum durability testing temperature being minus 45°C;

- M (frost-resistant version) - the use of material for the production of products in areas where the prevailing air temperature in the coldest month is below minus 20°C, the minimum testing temperature for reliability and strength parameters is minus 55°C.

Table 1, presented in GOST R 53338-2009, shows the division of the material into three classes according to the value of the limit of water permeability or moisture permeability. According to this table, seals are divided into the following groups:

- Class A – the value of the moisture permeability limit when the seal is compressed in operating mode more than 600 Pa;

- Class B – the value of the above parameter in the range from 400 Pa to 600 Pa;

- Class B – the value of the maximum moisture permeability parameter during compression in operating mode in the range from 200 Pa to 399 Pa.

Composition (structure) of the seal

The basis of the self-expanding strip is polyurethane foam or butyl rubber. In addition, such products differ in the type of impregnation - acrylic compounds, paraffin and oil plasticizers. In addition, manufacturers of PSUL tapes use various technological additives. An adhesive is applied to the base layer, and then a protective film is installed.

Dimensions and thickness

Products made from self-expanding sealing material are manufactured in lengths from 4 to 13 m; the selection of product length depends on the perimeter of the protected opening or structure. The width of a self-expanding PSUL has different values. The thickness of the tapes ranges from 8 mm in a compressed state to 80 mm in an expanded state, the average thickness is within 40 mm. The greater the thickness of the strip, the higher the technical parameters and reliability characteristics it has.

When marking strips of sealing materials, indicate the trade name of the product, its class according to the limit value of water permeability, as well as the numerical values of the width of the PSUL strip and the size of the space for sealing.

For example, PSUL tape Bauset ST-III 20/8 (40) is a product of the Bauset trademark, class B in terms of the maximum water permeability value, 20 mm wide with a working expansion of 8 mm. PSUL 20/40 is a product with an adhesive layer width of 20 mm and a maximum expansion index of 40 mm.