ABS glass production » Glass processing » Glass cutting

Glass materials have a wide range of applications. A large assortment of types of canvases allows you to make an excellent choice for decorating items, zoning, and creating original, extraordinary interiors. The material has excellent technological characteristics, but is fragile, requiring careful cutting. It is advisable to trust this process to professionals in order to eliminate damage and minimize the amount of waste. Professional cutting of glass to size is carried out in. We employ experienced craftsmen, have the latest processing equipment, and offer a wide range of fabrics.

Qualified cutting of glass to size

Not all glass sheets can be cut. If you plan to install elements made of hardened material, it is necessary to create elements of the required shapes and dimensions before the hardening process. For standard materials, optiwhite, lacobel, such restrictions are not provided. You can create elements of any configuration from them.

Glass sheets are used for various purposes. They can be used in creating panels and mosaics, making doors, and are an important element of furniture designs and effective finishing. When cutting glass to order, we take into account the purpose of the material and choose the optimal technology. You can order from us:

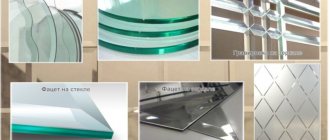

- straight and figured cutting;

- production of parts for mirrors, countertops, doors, panels, furniture facades;

- edge processing, hole creation.

The operations are carried out using modern equipment equipped with computer control programs. This guarantees accurate dimensions and shapes. You can use bevels in the design of edges, give design elements a finished look, and improve aesthetics.

Moscow offers professional cutting of glass to size in several companies. But you need to take into account that to obtain an impeccable result, the necessary conditions are the availability of professional equipment and appropriately qualified specialists. An ordinary household glass cutter will not allow high-quality cutting of multilayer canvases that have a specific structure.

Our company specializes in working with glass sheets. We offer these products in a wide range. We produce tempered glass to order in sizes for interior doors, partitions, etc.

What tools to use?

Many of us are accustomed to thinking that glass can only be cut correctly and efficiently with a glass cutter. But what to do if you need to cut a piece of glass urgently, but you don’t have this tool at hand? There is another unusual, but no less effective method that helped our great-grandfathers get out of this situation. Such a tool is ordinary scissors, available to any owner. Let's look at each method in detail.

Option 1: glass cutter

The technology for cutting glass with a glass cutter is quite simple. To do this, you must comply with certain conditions and choose the right glass cutter. Today, the choice of this tool is quite wide, which allows you to turn work into pleasure.

- Diamond glass cutter, time-tested and remains a leader in its field to this day. Glass cutters with a beveled cutting edge are suitable for home use. This tool is designed to cut glass up to ten kilometers and is suitable for any thickness of the material used. From time to time, such a glass cutter needs to be sharpened on a special whetstone.

- Roller. As the name suggests, the cutting part of such a glass cutter is made in the form of a roller made of a durable cobalt-tungsten alloy. The number of rollers can be from one to six.

- Oil. This tool works on the principle of a roller glass cutter, with the difference that a reservoir with oil is built into its handle, which is automatically supplied to the roller. Suitable for cutting thick glass.

To learn how to choose a good glass cutter, watch the video:

So, having dealt with the glass cutter, place the glass on a flat surface. Mark the glass and get to work. To make the task easier, you can use a ruler. It is worth considering the point that the line must be drawn the first time, otherwise a repeated attempt will lead to cracking of the surface. When cutting glass with a glass cutter, you need to apply equal force along the entire length of the line.

Option 2: ordinary scissors

Cutting glass with scissors like paper is not a fairy tale, but a completely everyday reality. For this purpose, you will need the scissors themselves (sewing scissors are best for this) and a tank of water (preferably hot). It is necessary to apply markings on the glass in advance, and then elementary physics comes into play: scissors create a microcrack, and the capillary effect completes the process. Of course, the result obtained will differ from that achieved with a glass cutter, but if necessary, this method can help out significantly.

Triplex processing

| Grinding triplex (trapezoid) rub/m.p. | Polishing triplex (trapezoid) rub/m.p. | ||

| 3+3mm | 4+4mm | 3+3mm | 4+4mm |

| 180 | 210 | 230 | 270 |

Our company has been working in this field for more than 20 years. Processing and cutting glass to size in Moscow is carried out by experienced, qualified craftsmen who know all the nuances of working with this material. Professional service guarantees:

- exact observance of dimensions and shapes of elements;

- high-quality processing;

- waste minimization;

- cost savings.

The use of specialized equipment allows us to achieve perfect accuracy. Edge treatment ensures safety. Our significant advantage is the affordable cost of glass. Moscow offers the best conditions in ours!

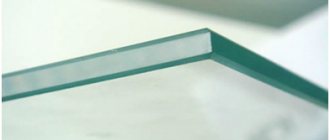

Features of manufacturing and cutting triplex

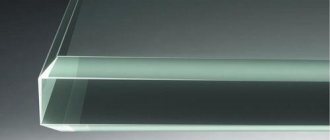

Triplex is essentially multilayer glass, the glass sheets of which are connected to each other through a polymer base. This material has a high level of strength. There is also an effect of increased sound absorption. Another equally important advantage is the increased flexibility, which is maintained even with a thickness of 40 mm. Thanks to these properties and technical characteristics, triplex is a safe and reliable glass, the options for its use are almost limitless. The main technical characteristics of such glass are:

- High impact resistance;

- Increased penetration protection;

- Armored glass.

Cutting triplex, unlike monolith, is a rather labor-intensive process. Everything is explained by the presence of adhesive tape; it is for this reason that high-quality cutting requires high-tech equipment. Of course, the modern generation of machines allows us to do this faster and with better quality.

| Triplex cutting | Price |

| Triplex 3+3 | from 1300 rub. per sq.m. |

| Triplex 4+4 | from 1400 rub. per sq.m. |

| Triplex 5+5 | from 1500 rub. per sq.m. |

Selecting a glass cutter

On the market, the consumer has a wide choice of equipment for cutting glass. They are called glass cutters. They differ from each other in design, working body and cutting method. The abundance of offers allows you to make the optimal choice of tool.

Diamond glass cutter

This tool is most often used by professionals. In order to cut this material, this tool uses technical or natural diamond. To secure it in the holder, silver-based solder is used. A tool with natural diamond can work with glass whose thickness reaches 10 mm. If the tool uses technical diamond, then the maximum thickness of the glass sheet should not exceed 5 mm. But a glass cutter with natural diamond is quite expensive.

Glass cutter with diamond cutter

There are several types of diamond glass cutters on the market, some with a curved edge. The cutters, and there may be several of them, are installed on the same axis with the glass cutter and this makes the life of the cutter, especially a beginner, easier. Some glass cutters are equipped with a diamond shaped like a pyramid. It is fixed at an angle of 20 degrees. Such fastening requires certain skills from the master, and only professionals can cut with it.

Intensive use of a glass cutter leads to the fact that the diamond becomes dull after some time, and to restore it, a block with a layer of diamond dust applied to its surface is used.

Roller glass cutter

Perhaps this is one of the most common tools used both at home and by professionals.

Roller glass cutter

On the market you can find glass cutters with different numbers of rollers - 1, 3, 6. The quality of the cut and its cost depend on the number of rollers. A roller with a diameter of 6 mm can cut glass up to 4 mm thick. With its help, you can make cuts with a total length of about 350 m.

A cutting roller that has become dull is simply replaced with a new one. If this is not possible, then it can be refilled using a fine-grained disk.

Oil glass cutter

This tool is similar in appearance to a classic roller tool. But there is one significant difference - it is equipped with a lubrication system. Lubricant poured into the handle is supplied to the working area through a special wick. This cutting method reduces friction and reduces tool wear.

Glass cutter with oil

This glass cutter can be equipped with several heads that allow you to cut material of different thicknesses. To work with a thickness of 10 mm, rollers with a sharpening angle of 135 degrees are used; glass up to 20 mm thick can be processed with a roller with a sharpening angle of 150 degrees.

Using one head you can cut up to 6,000 linear meters. To increase efficiency, both permanently fixed and rotating rollers are used. Heads that have reached the end of their service life must be replaced.

This tool is a professional one, and therefore there is no point in buying it for one-time work. At the same time, if there is a large amount of work to be done, then its acquisition becomes advisable.

Circular glass cutter

This is a special tool that allows you to cut circles and ovals. Its design includes a measuring scale that sets the size of the cut, a suction cup and the glass cutter itself, and rods for cutting ovals. Usually an oil tool is used.

Circular glass cutter

note

Regardless of the type of glass you are going to cut, do not forget about safety precautions and be sure to take precautions.

- During work, small fragments often bounce off, which can injure your eyes; this happens especially often when working with old glass. A prerequisite for glass cutting work is the presence of safety glasses.

- Gloves will protect your hands from cuts. If you don't have gloves at hand, at least wrap your fingers with adhesive tape. Gloves must be clean so as not to leave marks on the glass.

- If you do cut yourself while working, do not suck the blood from the wound under any circumstances. There may be small glass left there, the entry of which into the esophagus can cause big problems. Rinse the wound under a strong stream of cold water to remove any possible debris, then treat it with iodine or brilliant green.

- Also take care of the arrangement of your workplace. When working with glass, it is assumed that there will be fragments, so lay any material on the work surface that you won’t mind throwing away later.

After finishing cutting and processing glass, it is necessary to thoroughly clean the work area.

Cutting triplex: basic methods

In industrial conditions, the cutting process is carried out on both sides, after which breaking occurs. The resulting ends must undergo infrared heating. Any company engaged in cutting such glass has this equipment. However, there is a more modern method by which triplex can be cut without preheating, which provides higher quality indicators.

has a range of technological equipment to carry out such operations. Glass cutting is carried out only by highly qualified specialists of our company. Laminated glass is quite widely used in interior design of various premises. In particular, in the manufacture of interior items, the manufacture of partitions for various purposes, glass interior and exterior doors, as well as in the manufacture of double-glazed windows. When using modern technologies and equipment, in addition to its protective functions, triplex can be used as a decorative element.