When building a house from timber, an integral attribute is windows, which can be made of wood, various kinds of polymers and metal structures. Despite the fact that installing a window in a house made of timber seems simple, it can bring many restrictions if you do not take into account some regularities when working with wooden products. And below we will look at this process in detail, providing useful videos and photos.

Important installation details

When starting the installation, you need to prepare the equipment you will need: a building level and a plumb line, and also know how to insert a plastic window. The installation of a PVC window must be carried out strictly observing the placement in a level plane . This will ensure the correct operation of all elements, the doors will not open or close spontaneously.

The technology for installing a PVC window involves its correct placement in a level plane

When purchasing plastic structures, you need to buy additional special fasteners for installation. The frame is secured in the frame of a wooden structure using self-tapping screws and special fasteners. By following the technological process and correctly installing plastic windows in a wooden house, you are guaranteed to receive window units that will last for a long time.

The window frame is secured using anchor plates

If you dismantle the sashes, the structure will become much lighter and it will be easier to move it, however, installing metal-plastic windows in a wooden house alone is still not recommended. To remove the doors, you need to remove the pins from the hinges.

Preparing the window opening

Before installing the box, you should prepare the window opening. The opening must be rectangular in shape without cracks, recesses, distortions or other defects. Construction debris, dirt, dust and deposits must be removed from all surfaces.

In order to avoid distortions in the future, it is necessary to take accurate measurements of the external, internal and lateral sides of the opening.

In cases where the skew of the opening is significant and it is not possible to correct it, it is recommended to expand the window parameters in such a way that the highest level of the external opening exceeds the width by 2.5-4 cm and the height by 1-2 cm.

Extension can be achieved by installing an additional profile on the window. This will prevent the appearance of gaps between the box and the hole in areas of maximum distortion.

In addition to the option of expanding the size of the opening to correct the distortion, there is such an option as increasing the parameters of the window frame.

How to install PVC double-glazed windows

Do-it-yourself installation of plastic windows in a wooden house is carried out in stages:

- preparatory activities before installation;

- installation of PVC windows;

- control and verification of location in space;

- blowing with foam.

To understand how to install plastic windows both in a wooden house and in a timber or log house, let’s look at each stage in more detail.

Carrying out preparatory work

First of all, you need to take exact dimensions by measuring the opening and order the window structure from a trusted manufacturer . To do this, most often they invite a representative of a company that produces plastic frames. You can take measurements yourself. After this, they determine the color of the structure and the completeness of the fittings necessary for the functioning of the window.

When the manufacturer delivers the product to the site, the following steps must be completed:

- if a decision is made to replace the installed windows in the old opening, first of all, it is necessary to dismantle the structure;

- after which they clean dust, dirt and remove debris that got into the opening from dismantling;

- It is worth aligning the opening if its geometry is broken.

Having completed the preparation, they insert a plastic window into a wooden house with their own hands.

Fastening the window structure into the prepared opening

We install the window sill first; it will be the base for the double-glazed windows, so it needs to be placed strictly level (horizontally). For fastening strength, notches are made on the sides of the box approximately 8 mm deep. Adjustment is carried out using plastic plates or boards. Fastening occurs with self-tapping screws to the bottom of the box. When screwing in, you should place washers under the screw head; this will prevent damage to the surface.

The window sill is installed strictly horizontally

The next step is to properly install the handle. The film that protects the structures should not be removed; it protects them from damage when the windows are installed. When attaching, the handle must be placed horizontally. When all the fittings have been assembled, the installation of metal-plastic windows begins.

First you need to level the PVC frame. A frame is placed on two-centimeter bars and leveled horizontally, using a water level. After this, they move on to vertical alignment.

Having obtained ideal parameters at the water level, they fix the frame with self-tapping screws to the frame, using mounting fasteners that were specially purchased in the store. It is important not to get the self-tapping screw into the crest of the log where the socket is installed .

Secure the frame with self-tapping screws

After attaching the window element, we get 2-centimeter gaps around it for the mounting foam.

Before using polyurethane foam, you need to hang the shutters so that after foaming the frame profile does not bend and damage the window. It is important to remember that foam can only be used when the sash is closed.

Control and foaming of the structure

After hanging the sashes, you need to check how the double-glazed window opens and closes. If a window that is half open does not close or move further, then the frame is considered to be installed correctly and the alignment is correct. After closing the sash, foam it with installation foam and leave it for complete fixation for a day.

Why is casing made for plastic windows in a timber house?

To get high-quality PVC windows in a wooden house, you need to strictly follow the installation specifications, that is, install them on a special frame (base). The need for such a design is due to the characteristics of wooden buildings. Unlike a building made of stone (concrete or brick), a wooden panel house is unstable over a long period.

The casing prevents frame deformation when the house shrinks

The building will be completed within the first five years after its construction. In this case, the walls dry out up to 6 cm. This important nuance must be taken into account when installing a plastic window in a frame house. It is clear that you cannot simply insert a plastic window into a wooden house; you need to create a structure for the opening, which is called a casing, or they also say a window frame. Its direct purpose is to prevent the frame from being affected by wall shrinkage, so the socket:

- strengthens the opening;

- bears the load;

- prevents the effects of shrinkage.

The pigtail looks like a box made from thick boards. The structure is attached to the side rack on a groove, no fasteners are used. There is a gap left above the jamb to compensate for shrinkage for a wooden house . There are several options for installing it:

- A groove is cut in the log into which the block is placed. Self-tapping screws are screwed into the last element of the embedded beam;

- a groove is cut out in the racks on the sides of the structure, a tenon is cut out from the end of the log in the opening;

- A groove is made at the end of the logs, and a tenon is placed on the side posts of the box.

Options for installing casing

To get a high-quality design, you need to follow the technology for installing plastic windows in a wooden house. To begin with, cover the ridges of the logs with insulation and secure it with staples or small nails. This stage is necessary to insulate the house and eliminate creaks. Then the lower crossbar of the casing is mounted, and carriages (side posts of the frame) are stuffed onto the ridges, and the upper jumper is placed in the upper groove of the posts. After assembling the box, carefully connect it with self-tapping screws, it is important that they do not get into the logs.

The gaps that are visible in the opening after installing the casing must be filled with tow or insulation. Then the standard installation of plastic windows in a frame house or log house takes place.

The cracks are sealed with insulation or tow.

The compensation gap is filled with flat boards pre-wrapped with tow. As the walls shrink, they are gradually knocked out. To do this, remove the top casing and, having knocked out the board, put it back.

Relevance of wooden windows

In recent years, plastic windows have almost completely replaced wooden windows. This happened due to the low cost of PVC products, as well as their practicality. However, not all characteristics of plastic were positive. The peculiarity of such windows is that the material quickly loses its factory characteristics.

While PVC windows gradually change color, wooden structures can serve for decades in the best condition. In order to understand the relevance of wood products, it is worth considering the pros and cons of both types.

PVC:

- The perfect appearance soon gives way to scuffs, stains and a yellow surface color.

- When ignited, a large amount of toxic substances are released.

- The low cost is due to the fact that production is carried out in a conveyor production mode.

- The design includes only the frame, therefore, installation is quick.

- The service life of windows is about 20 years.

Tree:

- The level of environmental friendliness is much higher than that of plastic products.

- Externally, the windows look expensive.

- The profile can be painted.

- The high cost of most options is due to the production of products to order.

- The frame must be mounted in a box that is installed in the opening.

- Thanks to the breathable structure of the material, windows do not need to be ventilated too often.

- Wooden options are characterized by unique durability (the structure can be used without problems for 20–70 years).

The basic performance characteristics of the two materials are almost identical, but wood products are more reliable.

The final stage when glazing a wooden structure

The final finishing after installing PVC windows in a log house is done in the same way as wooden ones, that is, after installing the frame structure and insulation, wooden platbands are installed. When ordering PVC windows in a wooden structure, you should take a closer look at the option with a wood texture, this will allow them to look harmonious against the background of the felled structure .

Many manufacturers of PVC structures offer not only the classic white color option for frames. You can order any shade that the customer desires. Colored plastic frames will cost a little more, but will be a more suitable option for a home made of natural materials.

When ordering, it is important to take the correct measurements of the opening and not make a mistake in the width of the window sill. Self-installation of a PVC window in a wooden house if you know all the nuances is not such a difficult process. You can do it yourself, without resorting to the help of expensive installers.

GOSTs and requirements

When carrying out work, a necessary condition is the installation of wooden windows, taking into account national standards, the requirements of the state standard GOST 24700-99 (reflecting the description of mandatory technological work, the permissibility of the materials used and typical installation junction units). Installation must be carried out at a temperature of at least +15°C.

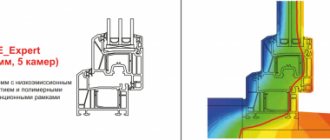

The width of the frame varies in regions with different climates and ranges from 120 to 220 mm, the main thing for these dimensions is the thickness of the wall, but the window sill must have a width of at least 170 mm, and the slope must be at least 100 mm.

Mounting blocks (slats or boards) are used from materials with a thickness of 50 to 150 mm (according to the size of the gap between the clean opening and the frame).

Deviations in vertical and horizontal planes should be no higher than 1.5 mm per meter and no higher than 3 mm across the width of the window.

The gaps in the side parts are calculated at 15-25 mm, at the top and bottom - up to 60 mm. The frame angles must be strictly 90°. It is important to ensure reliable sealing of the gaps between the frame and the ebb, the angle of inclination of which should be at least 10°.

When the difference in diagonals is no more than 10 mm per meter of length, the through installation method is used, for values larger - using metal plates. The anchor method involves increasing the dimensions of the frame so that they are greater than the maximum levels of the outer perimeter by 10-20 mm in height and up to 40 mm in width.

Fasteners must be installed taking into account a distance of 800 mm between them. Recommended dowel sizes are diameter 6 mm, length 80 mm + frame thickness + gap width. For example, if the frame is 40mm wide and the gap is 20mm, then the length of the construction nails should be 140mm.

The width of the casing parts should not be more than 250 mm, this is due to the possible appearance of cracks in larger boards.

The humidity of the solid wood materials used must be at least 12%. All natural elements of wooden window structures must be impregnated with antiseptic agents.

Insulating materials must meet the requirements of sanitary and epidemiological standards. When choosing materials, compliance with hygienic standards is checked: mineral wool, polyurethane foam, compressor belts, polyurethane foam cords. The use of high-quality materials for sealing seams increases noise and heat insulation, prevents the penetration of moisture into the gaps and the occurrence of fungal and mold defects. The tightness and quality of insulation work must comply with the State Standards:

- 30971-2002 — “Mounting seams of joints connecting window blocks to wall openings”;

- R 52749-2007 - “Window installation joints with self-expanding vapor-permeable tapes.”