When installing door and balcony blocks along the entire perimeter of the opening, PSUL tape must be used, which allows structures to “breathe properly” and effectively protects polyurethane foam seams from external influences and moisture. The effectiveness of this material is confirmed by the fact that it is successfully used in other problem areas, ensuring tightness of joints on the roof, gutters, ventilation ducts and even seams between individual concrete blocks. The need to create ventilated butt joints when installing window structures is regulated by GOST 30971-2012. Compliance with this requirement allows you to significantly extend the service life of the installation joints themselves and helps create a favorable microclimate in the interior.

An unprotected assembly seam actively absorbs water, so when the humidity level increases by only 5%, its heat transfer resistance coefficient is reduced exactly by half. That is, the outer perimeter of window or door blocks automatically turns into a “cold bridge”.

Specifications

The sealing tape is made of special polyurethane foam (foam rubber), which is impregnated with vapor-permeable modified acrylic to give the seal the necessary properties. Some time after gluing, the PSUL expands, completely filling the installation joints. Unlike other types of seals, pre-compressed tape seals even seams with slight unevenness. The size of the tape remains unchanged until it is unwound and the protective coating is removed from the adhesive layer.

Tape expansion over time

The types of PSULs common on the modern market have the following characteristics:

- Thickness in a compressed state (in a roll) from 2 to 8 mm in increments of 1 mm; expanding, the tape is capable of filling a gap of up to 80 mm.

- The minimum width is 1 cm, the maximum is 40 (5 mm increments). There are thicker and wider types of PSULs, but they are less available.

- The tape is quite plastic and is characterized by resistance to mechanical deformation of 12% -15%, depending on the brand and thickness.

- The material used for PSUL allows the tape to be used at temperatures from -50°C to 90°C without loss of functional properties.

- The seal is fireproof (characterized as flame retardant).

- Resistant to ultraviolet radiation (does not deteriorate from sunlight, such as polyurethane foam).

- The vapor-permeable structure of the PSUL eliminates the accumulation of moisture in it, which prevents the appearance of mold formations and subsequent rotting of the insulated surfaces.

- The raw materials used to make the tape are chemically neutral and do not interact with household solvents, building mixtures and paints and varnishes.

- It is possible to work with PSUL regardless of the season and ambient temperature.

- Subject to compliance with operational standards and installation rules, the service life is at least 20 years.

The tape is supplied in rolls. Its quantity depends on the thickness when rolled up and averages from 4 to 15 meters.

Short description

The self-expanding sealing tape is coated on one side with a special glue, with which you can firmly fix the product so that it does not move during operation. The material ideally fills all the unevenness between the installed parts. Due to this, the master manages to achieve complete protection and tightness.

If you use PSUL as a sealant, you can achieve a number of advantages. The tape has a high vapor permeability rate, which means that hot steam will freely escape, and the walls of the house themselves will breathe. But at the same time, the product remains waterproof; even heavy rain will not cause leaks. The seal can expand several times, and this is very important during operation.

Negative weather conditions have virtually no effect on the PSUL, due to which the product has a long service life. In addition, the tape interacts well with other building materials.

How to choose?

What to pay attention to:

- First of all, pay attention to the size of the adhesive part of the tape , that is, its width. This parameter is determined by the distance from the top of the quarter of the opening to the seam filled with polyurethane foam (ideally, the PSUL should evenly fill all free space). A quarter, as a rule, is not made very deep - its size is on average 20-30 mm.

- An equally important property of the tape is the expansion coefficient (measured as a percentage). Optimal efficiency of the PSUL is possible when it increases relative to the compressed size by no more than 30% . Seals with a coefficient of 50% or more are characterized by low mechanical density and are not able to provide the required level of insulation for a long time.

Construction of wooden houses

Since the appearance of PSUL tape on sale, it has been actively used in the construction of private real estate from solid wood as a reliable inter-crown sealant. The material is especially effective if the house is built from glued profiled timber. This technology came to Russia from foreign builders, and in a short period of time it gained trust due to its simplicity and reliability.

Today, the popularity of wooden houses remains quite high, due to which the seal continues to be in great demand. When laying timber, builders use this sealing material in two rows. Builders also glue PSUL to those areas where the array is connected to each other. Due to this, the joints can boast of high tightness.

There are several varieties of tape on sale, each model differs in its thickness, length, and degree of expansion. Of course, denser material, the size of which is 40 mm, has the highest reliability indicators. But about the degree of expansion, it is better to consult with specialists, since this parameter is always selected individually (it all depends on the distance between the parts). The impregnation used in production affects the final quality of the tape.

Application area

The installation seam, for the protection of which PSUL was not used, accumulates moisture over time, which leads to its rapid destruction. In addition, increased dampness in the seam area significantly reduces its resistance to heat leakage from the room, for example, if the humidity is only 5% higher than normal, the heat loss at the installation gap will double.

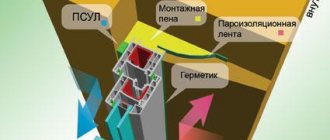

Pre-compressed tape is required for use when installing according to GOST (installation using the triple seam principle).

Scheme for using mounting tapes on windows

View from above

This significantly extends the service life of the installation gap, the adjacent opening and the window as a whole. The seal protects the seam from sunlight (destructive for polyurethane foam), absorbs noise, helps retain heat, and also prevents the foam from leaking out, making the appearance of the installed structure more aesthetically pleasing.

In addition to filling joints when installing windows and balcony glazing, PSUL is used in the following situations:

- Sealing joints in concrete structures.

- Sealing of roof elements.

- When assembling ventilation systems.

- Filling longitudinal joints between logs in wooden log houses.

Application of PSUL tape when installing plastic windows according to GOST:

What happens if you don't use PSUL tape?

Some installation teams, in order to save money allocated for the purchase of materials and time, ignore the requirement for the mandatory use of PSUL. Failure to use it leads to the fact that the hardened polyurethane foam absorbs and retains moisture in the internal pores for a long time. This triggers the process of destruction of the assembly seam, which entails quite a lot of unpleasant consequences:

- depressurization of window or door units;

- increased heat loss;

- the appearance of condensation;

- rapid development of fungus and mold;

- destruction of internal slopes.

Some unscrupulous installers argue for violation of installation technologies by the fact that anyway, the windows along the perimeter of the external slopes will be puttyed or covered with strips, so the seams will be protected in any case. This information is unreliable and misleads customers, since the specified slope cladding is not capable of providing effective protection against moisture.

Advantages and disadvantages

Sealing gaps with unevenness

Positive qualities of PSUL:

- The sealant does not require any subsequent treatment, such as plastering or painting;

- Takes the form of curvatures in a quarter of the opening, filling all the cracks and voids;

- Resistant to weather conditions common at any time of the year;

- Over time, it does not lose its qualities from ultraviolet radiation;

- Vapor permeable (promotes the passage of steam from the inside of the room, preventing the accumulation of moisture in the seams);

- The tape is made on a self-adhesive basis, which greatly simplifies installation;

- The service life, subject to installation rules, is at least 20 years;

- In polyurethane foam impregnated with modified acrylic, mold and other fungal formations do not appear;

- Compatible with all modern building materials;

- PSUL for filling external joints does not allow moisture to pass through from the outside;

- The sealant is not flammable.

The weaknesses of pre-compressed tape include, first of all, an increase in the installation time of the window structure, since the block cannot be foamed until the seal has completely expanded, finally filling the seams. Naturally, the use of PSUL requires additional costs, but the funds spent on high-quality installation are compensated by the long service life of the structure and its high energy-saving properties.

Recommendations from experts

When working with PSUL, it is necessary to remember that the final expansion of the tape depends on the ambient temperature. If work is carried out in the cold season, then you can use a regular construction hairdryer, which will speed up the expansion process of the material. Experts do not recommend purchasing a tape that is smaller than needed.

Otherwise, you may encounter very negative aspects:

- The polyurethane foam will simply squeeze out the tape.

- Leaks form.

- The installation seam may simply collapse.

- A gusty wind will blow out the PSUL.

Only the right choice of material can ensure high-quality and durable sealing so that the seam is maximally protected. If the master decides to use already expanded strips during work, this can seriously complicate the technology, which is why construction manipulations will be of poor quality.

For additional protection of the tape, you can use a self-adhesive plastic strip. The product will perfectly cover the outside assembly seam from the negative effects of ultraviolet radiation, and will also extend the final service life.

How to work with tape

The procedure for installing a window unit using a pre-compressed seal:

- The opening is cleaned of dirt and primed with a primer;

- It is necessary to remove the protective film from the street side of the window profile, then clean the surface of any adhesive residue and degrease it with a solvent. If the film is left on the profile, then after gluing the PSUL, it will not be possible to completely remove it.

- The edge of the tape in a skein (3-4 cm) is not suitable for use, so it is cut off before starting work.

- The gluing is carried out by gradually removing the protective film (with an advance of 5-10 cm), cutting it to size directly on the frame. First they are attached to the upper profile, then to the side ones (the lower part is insulated with other materials).

- Next, the window block is placed in the opening, secured to plates or anchors, and the gaps are filled.

After fixing it on the profile, the tape will begin to expand, so you should not hesitate to install the frame, otherwise it will be quite difficult to level it when the PSUL has fully expanded.

Note. Full expansion of the tape at a temperature of 20°C occurs in approximately 20-30 minutes. In cold weather, this process can increase 2-3 times. To speed it up, the tape, after gluing and installing the window in the opening, is heated with a hair dryer.

The principle of installing PVC windows

There is nothing difficult in installing a plastic structure. The installation process itself consists of several main stages. In order to prevent the most common mistakes, adhesive tape is initially glued to the front part of the window frame so that the product lies as flat as possible. When the master fills the seams with polyurethane foam, the PSUL must be open. This will minimize the chance of insulating material getting underneath the tape, which is simply not acceptable.

Keeping the product simply glued to the window frame is prohibited, since the PSUL will lose all its properties. The building material must be installed in the opening itself. The master needs to ensure that the tape is ideal in size and degree of expansion. If the product is too thin or thick, then after a short period of time the material will lose half of its valuable qualities.

Qualified builders recommend installing a multifunctional vapor-permeable waterproofing tape at low tide. This approach will avoid the negative impact of flowing rainwater on this problem area. Of course, you can additionally use universal liquid sealants, which are guaranteed to prevent the development of negative consequences.

Some tips when choosing

The principle of choosing PSUL is most easily illustrated with an example. So, for a gap with a width of 5 mm, a tape with a maximum expansion of 20 mm is optimal. For gaps of 6–10 mm – 30 mm, etc. Typically, as the thickness of the tape increases, the reliability of its seal increases.

If possible, it is better to choose a PSUL with a higher maximum expansion. For example, for a 17 mm seam, you can take a tape that expands to 20 mm, but a modification with a working thickness of 30 mm will prove more effective in such conditions.

A wider PSUL is more expensive, but when choosing, you cannot focus only on price. It is important to correctly match the width of the adhesive layer, the gap and the tape after expansion. It is better to purchase it with a reserve. If necessary, the material can be used to seal tiled roofs and free-flow pipes, for example, as part of a storm drain, or for another purpose.