Sandwich panels for slopes: type of window opening finishing

In one of the articles on the site, we talked about how to finish external slopes on windows. In this article we will talk about slopes made of sandwich panels . External window finishing: photo examples and step-by-step instructions (read more)

Installation of a metal-plastic system is not the final stage of the window replacement process. To prevent freezing and condensation, the walls of the window opening are finished. Today, sandwich panels for slopes have proven themselves to be the best, characterized by excellent technical and performance qualities and ease of installation. You can learn more about this building material from the article.

Slopes on windows protect against condensation and resist freezing.

What are window slopes: the purpose of the structural element

The first step is to understand what slopes are and what their main purpose is. This structural element of a window opening is the inner wall of a niche surrounding the window frame on both sides. Installing a window profile is not the final stage. For a presentable appearance of the window system, it is necessary to install good fittings for PVC windows. It includes not only handles, mechanisms and hinges. The range of elements also includes window slopes, which are used to design the profile.

Slopes made of sandwich panels provide additional protection of the room from atmospheric influences.

Note! It is imperative to finish the slopes to eliminate the occurrence of many negative factors that will negatively affect the appearance, service life of the window system and the microclimate of the room.

Finishing the niche will prevent the accumulation of condensation and freezing of the window frame. It can protect the seams between the frame and the window opening from destruction, so it is important to carry out both internal and external cladding of slopes. Protecting niches can improve the thermal insulation properties of a room, preventing cold outdoor masses from penetrating inside and thermal energy from escaping outside.

Note! Window slopes are also a decorative design of a window system.

To finish the slopes, you can perform plastering, covering the surface with plasterboard, plastic panels. The most popular and least labor-intensive method today is the use of sandwich panels for slopes. This material not only gives the window a finished appearance, but also, thanks to the presence of internal insulation, provides a warm temperature regime in the room.

In addition, window slopes perform a decorative function.

When covering slopes with plasterboard, a large consumption of material will be required, which is associated with its fragility. Plastering the side elements is a labor-intensive and time-consuming process that requires certain skills to ultimately achieve a smooth surface. In addition, such work is associated with significant pollution of the surrounding space.

On a note! The combination of windows and slopes made of the same material looks most harmonious.

What requirements must the slope material meet?

Regardless of the technology for protective and decorative finishing of a window opening, finished slopes must meet certain requirements. The design must withstand various mechanical impacts without loss of operational and aesthetic characteristics. It is necessary that the slopes are moisture resistant. This especially applies to outdoor structures. The material must be characterized by wear resistance, immunity to ultraviolet rays and high humidity, and temperature changes.

Note! To waterproof the frame, a PVC window ebb is attached to its outer side.

Slopes must be moisture-resistant, wear-resistant, and have low thermal conductivity.

The protective structure of the window should not deform over time. It must be distinguished by a long period of operation without loss of original properties. Due to the fact that the slope panel closes the installation gap, this is the main source of heat loss. It is necessary that the material has low thermal conductivity, which will provide a good level of heat and sound insulation in the room.

The chosen finish for the slopes should be aesthetically appealing. High-quality cladding is characterized by a neat appearance. It is necessary that the finish is in harmony with the window profile and fits into the interior design of the room. Maco window fittings have proven themselves to be the best in this regard.

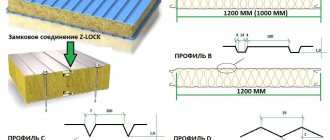

Sandwich panels: a modern universal material

Plastic sandwich panels are sheets of extruded polystyrene foam. The thickness of the products is 9 mm. The canvases can be finished on both sides with polyvinyl chloride film 1-1.5 mm thick. The internal structure of sandwich panels is represented by the following elements: a J- and C-shaped profile for fixing the internal edge of the slope, a guiding wooden beam, insulating material and an upper decorative panel.

Polyurethane foam, free-foam plastic, and extruded polystyrene are used as insulation in sandwich panels, which fills all cavities. The latter option is characterized by the best thermal resistance indicators. The insulation blocks the flow of cold air masses from the street into the room.

Sandwich panels are a universal product, widely used in repair and construction work.

The top decorative panel can be made of laminated plastic, rigid or foamed PVC sheet. The first type of coating is made by impregnating multilayer material with resins in the form of pressed decorative or kraft paper.

Rigid PVC sheet is represented by a white sheet covering, the thickness of which is in the range of 0.8-2 mm. The special coating can be glossy or matte. The density of such a panel reaches 1.4 g/m³. The internal structure of a foamed PVC sheet has a porous composition, so this coating is less dense and has good thermal insulation.

The outer layer can be painted in any color, which makes it possible to choose a shade that matches the window and the design of the room. The most popular is the white PVC sandwich panel for slopes. You can often find a yellow tint to the panels. Products made in a natural style, imitating wood, fit harmoniously into the interior.

Properties and structure: are there any disadvantages?

The outer layer of the structure can be made of different materials.

- Made from rigid PVC sheet. For the production of multilayer material, white sheet material is used. Thickness ranges from 0.8 to 2 mm. The coating of such a sheet can be glossy or matte. The leaf density is 1.4 g/cm3.

- Made from foamed PVC sheet. The internal part of the structure has a porous structure. Foamed sheets have a low material density (0.6 g/cm3) and good thermal insulation.

- Made from laminated plastic, which is created by impregnating a pack of decorative, overlay or craft paper with resins and then pressing it.

Multilayer panels can be supplied as ready-made systems that do not require preparatory work for assembling the material. Finished structures are attached to the facing material using glue. The second design variation is that such panels are assembled using self-tapping screws before installation technology.

Dimensions and design options of sandwich panels for windows

Sandwich panels are available in two variations: ready-made, where the material does not require assembly and is intended to be fixed using an adhesive, and disassembled, when it requires preliminary fixation of the component elements using self-tapping screws.

Sandwich panels are available for sale in finished form or disassembled.

Plastic window sandwich panels can be manufactured in single-sided and double-sided form. In the first case, one side of the product is rough, the other is the front side, which is thicker. For a double-sided product, both sides are front.

Note! Sandwich panels can be used for both plastic and wooden windows.

The dimensions of sandwich panels for slopes are determined by the equipment on which the material is produced. Despite this, standardized parameters exist. The products have a maximum length of 12-16 m. A larger value can lead to damage to the structure of the element under its own weight during the installation process. In addition, long products are difficult to transport. The width of the sandwich panels reaches 100, 115, 199 and 120 cm. The thickness is in the range of 5-35 cm. The most popular are white sandwich panels for slopes 3000x1500x10 mm.

Products are often made to individual sizes. Some versions of sandwich panels can be used to finish the slopes of not only windows, but also doors. In this case, their length is 3 m, width - 115, 130 and 150 cm. The thickness of the products is 10, 24, 32 and 40 mm. Sandwich panels 3000x1500x10 mm used for slopes are in great demand, the cost of which starts from 900 rubles/piece.

Sandwich panels of different thicknesses, lengths and widths are available for sale.

Average prices in the Russian Federation

There is a rating of the most popular sandwich panel manufacturers whose product quality meets all requirements:

- RUUKKI . The price depends on the thickness of the panel. For external slopes, a sheet with a thickness of 50 mm is suitable, its cost is 1090 rubles per 1 sq. meter.

- Kingspan . Panel thickness from 40 mm (for internal slopes) to 60 mm (external slope). Cost - 1800-1900 rubles per 1 sq. m.

- Bauset TPL . Panel thickness 9 mm - for internal slopes. price 1640 rubles per sheet of standard size.

You can also buy material at a price per linear meter. The cost depends on the width of the slope. Width from 5 cm to 16 cm - 650 rubles, from 16 cm to 25 cm - 700 rubles, from 35 cm to 50 cm - 1120 rubles.

Sandwich panels for slopes: advantages and disadvantages of the material

Sandwich panels for slopes have many advantages. This finish helps create good thermal and noise insulation. The sound absorption rate is 21 dB. The material has a high level of vapor permeability. This coating will not get wet from moisture, will not deform or crack. Sandwich panels exhibit increased resistance to mechanical damage, the negative effects of sunlight, and resistance to the formation of fungus and mold.

Note! To reliably connect the material to the slope, polyurethane foam is used, which at the same time serves as an additional insulation.

The design is characterized by its low weight, which is only 4 kg with a product thickness of 24 mm, so it does not have a significant impact on the elements of the window opening and does not require the use of reinforced fasteners.

Slopes finished with sandwich panels do not require constant maintenance. Any dirt can be easily removed with a sponge and soap solution, which will not damage the structure of the structure. The material is absolutely harmless to human health. During operation, no harmful components are released into the atmosphere.

Panels for window slopes have many advantages.

Slopes made from sandwich panels do not require additional decoration, since they have a pleasant texture that is similar to the surface of a plastic window. The demand for the material is also associated with the reasonable price of sandwich panels for window slopes, which can be purchased at any hardware store.

However, such multilayer panels for finishing slopes have their drawbacks. The material is susceptible to high temperatures, which can lead to deformation changes and yellowing of the surface of the product. Finishing with sandwich panels is not performed if there is a small gap between the wall and the hinge. This will lead to the structure not fitting tightly to the niche. Incorrect installation may cause cracks and gaps to form.

Material properties

Plastic slopes made of sandwich panels

The structure of standard panels looks like a sheet, the outer side of which is solid-sheet PVC, the inner side is sheet polystyrene, and there is insulation in the middle. That is why this finishing option was called the American word - sandwich panel. They differ only in the material of the facing side, and the installation remains the same for any type.

Important! People call sandwich slopes – warm slopes. This is due to the insulation that is present in the panel

Once you have already imagined what they are, I will tell you about their advantages:

- Despite their popularity, they remain accessible to everyone due to their reasonable price.

- This is not just a building element, it is also an independent device that has its own set of components.

- The interior is filled with mineral wool or foamed polystyrene - this indicates the non-flammability of the structure.

- Excellent thermal insulation performance, as well as additional sound insulation, is achieved with their help.

- This finishing method is durable and strong.

- If you do the installation yourself, you must strictly follow the installation technology. In this case, resistance to moisture and mold will be at a high level.

Sandwich panels for finishing slopes

For those who have decided to change the windows in their house or apartment and install the slopes with their own hands, I will give you advice: you need to wait at least 24 hours after installing the windows and only then finish the slopes with sandwich panels. The advantage of installing a sandwich over plastering is that installation by hand does not require painting skills and is a clean method.

It is important not only to correctly install the slopes, but also how to cut the panels. It is better to cut plastic elements with a circular saw on plastic or aluminum. At the same time, a fine tooth pitch can cope with the task perfectly. In addition, the material must be cut at a temperature of +5 degrees Celsius - if the temperature regime is not observed, then due to a decrease in impact strength, chips may appear on the cut line. If the slopes are finished with PVC sandwich panels, then you can cut them with many tools. But the most optimal one is a hacksaw for metal; it can also be used for wood. You need to cut face up and with a slight angular inclination. At your own peril and risk, you can cut with a grinder, but if you apply a little too much pressure, the panel may break.

Comparison of sandwich panels and double-glazed windows: which is better

The design of a balcony or loggia is often accompanied by the joint installation of metal-plastic glazing and plastic sandwich panels. The latter are often used for covering blind sections, which can be located at the bottom of the balcony door frame that reaches the floor, or for finishing side sections. This is done to limit light transmission in specific areas. In addition, due to their good strength properties, sandwich panels are considered the best option in comparison with double-glazed windows in terms of safety.

Installing sandwich panels instead of double-glazed windows allows you to make the side sections of a balcony or loggia blank, which is necessary for installing cabinets or other items that should not be visible from the outside. This design can subsequently be used as a ventilation outlet, since a number of holes can be made in it.

Sandwich panels, unlike double-glazed windows, are resistant to moisture, ultraviolet radiation and mechanical stress.

However, using panels instead of double-glazed windows has other advantages. The material is resistant to various negative influences. It is impervious to ultraviolet radiation, moisture, chemicals, and tolerates mechanical and shock loads. The panels are strong, reliable and durable. They do not require special care, which cannot be said about traditional glazing. You can also choose different colors of the material, which is clearly shown in the photo of sandwich panels.

Note! The Salamander window profile is very popular today, and it is possible to order sandwich panels with a protective film, which not only improves the decorative qualities of the material, but also increases its strength characteristics.

Since the plastic sandwich panel is represented by a multilayer material, inside of which there is a layer of insulation, such cladding is characterized by good heat-insulating and sound-absorbing properties.

How to install slopes from sandwich panels

The process of finishing window slopes with sandwich panels consists of several stages. To carry out the work you will need the following tools and materials: PVC profile, edging and starting profiles, liquid nails, sealant, primer for concrete, plaster, antifungal agent, building level, tape measure, assembly knife, screwdriver, self-tapping screws, brush, spatula, sandpaper .

Installation of panel slopes can be done in three ways.

Installation of slopes from sandwich panels is carried out in three ways: liquid nails, polyurethane foam or a frame made of wooden blocks can be used. The panels, in turn, are two- and three-layer. The last option is covered with PVC on both sides. Such panels are installed exclusively on a wooden frame, since they are characterized by increased rigidity. There is no point in attaching them to the wall using liquid nails, since the PVC back side has a low adhesion rate.

Installation of sandwich panels in a window on wooden slats consists of the following algorithm of actions. First, slope measurements are taken. The obtained data is transferred to the panels, after which blanks are made using a sharp knife. Panels can also be cut using a circular saw with a small pitch of teeth, which will eliminate the possibility of delamination or cracking of the product.

Note! The sandwich panel can be cut at a temperature not lower than 5 ºC; lower values lead to brittleness of the material.

Installation

Installation work of window slopes is carried out quite quickly. You can install the panels in just one day. Finishing slopes with sandwich panels is not a difficult task and you can do all the installation work yourself without much experience.

List of tools required for installation:

If necessary, you can further insulate the slopes by installing thermal insulation material on them. They can also be used as polyurethane foam. Liquid plastic can serve as a sealant between the slopes and the window - it is PVC-based glue. Its advantage is that over time it does not darken and does not spoil the appearance of the window. It is necessary that at least 24 hours pass after installing the window - this is the time for the polyurethane foam to dry.

Seven times measure cut once. So, we begin the installation work by measuring the slopes in order to accurately adjust the material to the size of the window. Taking into account the measurements, it is necessary to cut three strips, the top one parallel to the window sill and two side strips.

First we attach the starting profile, which in its shape resembles the letter “P”. Initially, the top one is fixed. There should be no gaps between the profiles. We fasten them using self-tapping screws 8-8.5 mm long, the distance between them should be no more than 15 cm.

Using polyurethane foam, we fill cracks and voids in the slopes. After the foam has dried, carefully trim and level it using a cutter. We insert the panel into the already installed upper profile. The side profiles are attached to the top board using self-tapping screws. Also, these profiles are fixed to the wall in increments of 150 mm. And we attach the last P-profiles to the window sill. We fill the gaps between the starting strips with liquid plastic. It is not recommended to use ordinary sealant, as it turns black over time, and this spoils the appearance of the window. After the liquid plastic in the gaps has dried, install two side panels.

The next final stage is the installation of finishing profiles. We take measurements and cut off the three necessary strips: one top and two side ones. It is recommended to cut the finishing strips with a margin of approximately 2-3 cm, and subsequently shorten them to the required size.

Then we snap the profiles onto the sandwich panel. In the corners the strips will overlap and need to be trimmed. On the profiles at the junction we mark the edges with a pencil and carefully cut them at an angle of 45 degrees. The void between the wall and the structure is filled with mounting foam. This will increase the degree of thermal insulation of the window. The junction of the finishing strips can also be covered with PVC glue for a more durable fixation.

Further installation of slopes from sandwich panels into the window

On the outside of the window frame along the edge, mounting strips should be secured to form a complete contour. The correct installation is controlled by the building level. Wooden elements must be made from dry wood. Otherwise, if they contain excess moisture, the slats will dry out, which will lead to deformation of the structure. Before fastening, they must be treated with special moisture-repellent compounds.

The gap between the frame and the panel can be filled with mineral wool or polyurethane foam.

The next step is to attach the starting profile to the plastic frame. The gap that has formed must be filled with polyurethane foam or mineral wool. Sandwich panels used for finishing slopes are inserted into the grooves of the profile. They are not glued using liquid nails or foam, but are nailed with a construction stapler. Staples can penetrate the outer side of products, so with this installation option, only three-layer products are used.

On a note! It is necessary to purchase a starting profile from the same manufacturer that produced the sandwich panels.

If the starting element is not used, the slopes are finished with sandwich panels by attaching the material with an adhesive composition. In this case, the inner corner is treated with sealant in order to hide possible defects.

Recommendations for use

Finishing with sandwich panels is possible in any conditions, but installation during rain is not recommended. Mineral wool insulation can get wet, and this will reduce the quality characteristics of the products.

When using sandwich panels, periodic inspection of the appearance of the products is necessary. Shaped parts and fastenings must be sealed. If this is not the case, then the inside of the panels can be additionally glued. It is better to clean dirty external surfaces with a soft brush. If the top coating of the panels is lamination, the use of abrasive cleaning agents is prohibited.

Possible damage can be cut off and replaced with new ones, or can be restored using suitable repair paint if the type of polymer coating on the panel is known. Paint coating options include alkyd enamel or latex acrylate paint.

Sequence of installation of PVC sandwich panels on liquid nails

Let's consider the technology of installing slopes from sandwich panels using liquid nails. The first step is to thoroughly clean the slopes, removing old coating, dirt, and remnants of polyurethane foam. The base must be perfectly flat, so all defects should be eliminated using a plaster mixture. This material is used to seal all cracks and crevices and level the surface. The process is controlled by the construction level.

First of all, it is necessary to install the side slopes.

After the plastered surface has completely set, it should be treated with a primer intended for porous coatings. The procedure is carried out to ensure further reliable adhesion of the panels to the base. After drying, the surface is treated with a special antifungal compound. The dried base is ready for finishing with sandwich panels.

Before installing sandwich panels, measurements of each slope are taken to prepare products of appropriate dimensions. The sheathing is cut using a cutting object in the form of a mounting knife. The panel should be laid on the floor, then marked using a tape measure and pencil. Use a sharp knife blade to follow the marks several times. After trimming, the edges of the finished workpiece are processed with sandpaper to remove burrs.

The first step is to install the side slopes from sandwich panels with your own hands. The starting profile is attached to the wall near the window using self-tapping screws at 15 cm intervals. A strip of liquid nails is applied to the prepared panel in a zigzag design in the center and in straight stripes along the perimeter of the product. The workpiece is inserted with one edge into the starting profile and pressed firmly against the slope. The second side and top panels are installed in a similar manner. Components must be installed with minimal gaps between them.

Note! If the starting profile is not used when finishing slopes made of PVC panels, the sandwich element is mounted close to the window. It is inserted 1 cm deep, fixing it with polyurethane foam.

To complete this, you can putty the panel slopes.

To make the window opening look more aesthetically pleasing, it can be trimmed with an edging profile along its entire perimeter. To achieve a neat appearance, the joints in the corners must be cut at an angle of 45°. To mask butt joints, you can use liquid plastic or white sealant.

Installation instructions

After installing new windows, you need to wait a day for the final polymerization of the polyurethane foam and after that you can begin finishing. Installation of window slopes made of sandwich panels is done according to the following principle.

- Initially, you need to take the dimensions of the window openings. All parameters of the places where finishing will be carried out are measured (parameters may sometimes differ even with a fairly large scatter).

- Window openings are prepared for installation. All weak parts of old plaster and masonry are removed and replaced. All surfaces must be treated with antiseptic agents to protect against the formation of mold and mildew. Excess polyurethane foam is trimmed from the windows.

- A starting “P” profile is installed around the perimeter. It is attached to the surface of the opening with self-tapping screws, in the corner formed by the cut of the wall and the window frame. The fastening pitch is 150-200 millimeters. From above and below, sections are inserted into the installed profile to the entire depth of the opening.

- Panel blanks are prepared to the required size. The cutting of individual elements is done using a stationery knife. In this case, the protective PVC layer with part of the polystyrene foam located inside is cut through on both sides. The resulting cut ends can be trimmed with sandpaper on a grater.

- First, the upper sandwich panels for the slopes are installed, followed by the side elements. At the same time, insulation is placed in the resulting space (if the slope is “warm”). Installation without insulation occurs with the application of liquid nails to the surface of the workpiece and additional gluing to the wall.

- The corners of the window opening are completed by mounting the corners in the form of an “F” profile. To do this, measure and cut individual profile elements with a length greater than 50 millimeters on each side. They secure the free ends of the panels, and the edges are overlapped. Using a linear line, the joints are marked diagonally from the corner to the opening. Both ends are cut along the mark. The result should be a beautiful joint with an angle of 45 degrees.

- All joints must be carefully sealed with sealant.

Before installing the “F” profile, you need to fill the space between the panels and the wall well. The corner near the window is carefully foamed, the main cavity is filled with insulation. Or, as an option, completely fill all the voids with foam.

The construction of slopes from sandwich panels is a good alternative to the more labor-intensive plastering option. Their installation does not require a whole list of “dirty” work on applying plaster with further leveling and finishing painting.

To some extent, sandwich panels for window slopes and plasterboard are inferior, structures made of which are more sensitive to moisture and also require finishing plaster.

The only competitor for quick and easy installation may be plastic panels, but they do not have their own insulation. If you choose between sandwich panels and ordinary plastic, then the former win in terms of heat and sound insulation.

Do-it-yourself installation of sandwich panels on polyurethane foam

Slopes made of sandwich panels for plastic windows can be mounted using polyurethane foam. For this, a multilayer type of material with two stiffeners is selected. At the first stage, measurements are taken. The final type of finishing of the window opening depends on the accuracy of this process. Based on the results obtained, the products are marked, according to which the panels are trimmed with a sharp object.

A starting profile is mounted to the joining area between the wall and the window frame using self-tapping screws in increments of 10-15 cm. Finishing the slopes with sandwich panels begins from the top strip. It is inserted into the groove of the starting profile. The resulting gap between the wall and the PVC element is filled with polyurethane foam. The material should be applied very carefully, since during the drying process the foam can double in size.

On a note! It is better to choose a professional type of polyurethane foam, applied to the surface in a small layer.

Panels with two stiffeners are suitable for mounting on polyurethane foam.

A plastic sandwich panel is being installed, which is done using masking tape. Next, the side slopes are sheathed in the same way. After the mounting foam has completely dried, the excess material is cut off, and the structure is ready for further use.

Fastener "P" profile

A starting profile is cut according to the dimensions of the slopes, resembling the letter P in cross-section. It is attached using self-tapping screws exactly along the edge of the window profile.

The distance between the screws is approximately 10-15 cm. In this case, first of all, the profile should be installed at the top, while the side elements are brought close to the top, leaving no gaps.

A nuance: it is possible to install slopes using a sandwich panel without using a starting profile. In this case, strips of sandwich panels are placed closely behind the window profile 1 cm deep, with step-by-step foaming of the niche to fix the slope. This process is more labor-intensive than using a “P” profile, but the result is more aesthetically pleasing.

How to choose slopes: the best finishing option

There are several options for finishing slopes. Materials such as plaster, plasterboard, gypsum fiber, plastic panels and sandwich panels can be used for this. The price for window slopes of the latter type of material is the highest compared to other options.

The traditional way to finish slopes is to plaster the side and top niches of the window frame. The technology consists of leveling the surface by applying several layers of plaster, followed by priming and painting the surface. This method is characterized by a number of distinctive advantages. First of all, it is distinguished by its versatility. You can plaster the slope in a room with any humidity and temperature conditions. The mixture itself is an inexpensive material.

Plaster slopes are characterized by resistance to mechanical stress, ultraviolet radiation and moisture. This finish does not contain seams or joints. The surface is perfectly flat and smooth. In the event of a decrease in aesthetics, such slopes can easily be updated or repaired.

For slopes, plasterboard, plastic and sandwich panels, as well as gypsum fiber are used.

Despite its many advantages, this method of finishing slopes has its drawbacks. Plastering side niches is a long and labor-intensive process that requires breaks in work to dry each new layer. In addition, to get a good result you need to have the appropriate skills. Plaster slopes are characterized by low thermal insulation properties. They are prone to freezing and condensation.

Note! To perform plastering work, you will need to trim the mounting foam inward by 1-2 cm, which will weaken the thermal insulation seam.

The plaster and plastic frame do not interact well enough with each other, which will soon lead to the formation of cracks. They can be filled using sealant. However, there is no universal composition that equally exhibits good adhesion to plaster and PVC window block.

Plaster slopes

The construction of these slopes takes place in several stages.

To increase adhesion, the surface is first treated with a primer. Then several layers of plaster are applied, each of which must be allowed to dry.

Plaster is the cheapest, but ineffective way to finish slopes, since the lack of heat-insulating properties of this finish leads to hypothermia and further fogging of the windows.

The plaster is applied using a mesh, and the gap between the window and the plaster must be sealed with silicone.

Features of plasterboard slopes for window openings

Many people prefer plasterboard slopes. The method is based on gluing or screwing sheets of material of the required size to the side niches, followed by priming, puttying and painting. This option attracts with its simple and quick installation, which even a novice master can handle. The material is also characterized by an acceptable cost.

Installation of plasterboard slopes is a quick and easy finishing option.

Using strips of plasterboard, you can create perfectly smooth sides of the window. The space between the drywall and the wall is filled with mounting foam, which serves as a seal for the window. This surface is suitable for numerous paintings.

However, this method is not without drawbacks. The material is susceptible to moisture, so it can be used exclusively for finishing internal slopes. Condensation forms on the surface, which will soon lead to swelling and destruction of the structure. Such defects can be eliminated by completely redoing the slopes.

Drywall, like plaster slopes, is not able to interact firmly with the plastic frame. This contributes to the formation of cracks at the joints. The material is quite fragile, which does not exclude the possibility of it being pressed through and bending during installation.

After installing drywall, you will need to prime, putty and paint the surface to give it a finished appearance, which is not required when using sandwich panels for window slopes. It will take a few more days to complete all the work.

Installation of such slopes is carried out in two ways: frameless and frame.

On a note! To avoid finishing, you can use laminated drywall, which is mounted using special corners covering the ends of the sheet.

Sequence of installation of plasterboard slopes

Installation of plasterboard slopes can be carried out in two ways: framed and frameless. With the frame installation method, at the initial stage you should screw the starting profile using self-tapping screws, as in the case of using sandwich panels for window slopes. It is fixed on the line of joining of the plasterboard sheet and the window frame in the groove. The original frame is ready, after which you can begin installation.

A feature of plasterboard slopes is that the strips of material do not fit tightly to the window frame. A gap is formed, which negatively affects the thermal insulation properties of the opening. This space should be filled with mounting foam or mineral wool.

Note! Filling the gap with polyurethane foam is done very carefully, since the material increases in volume, which can lead to damage to the drywall.

Fastening drywall can be done using liquid nails.

At the junction of plasterboard panels, perforated corners are installed. The finished surface is primed and puttied. After the composition has completely dried, the coating is rubbed with sandpaper to obtain a smooth base, which can be painted in any color with water-based paint.

The frameless method involves installing plasterboard panels to the window opening using liquid nails or other suitable composition. The surface is first thoroughly cleaned and primed. Each slope element with applied glue is pressed tightly against the niche. To fix the elements, you can either use a wooden beam, which will give the structure evenness, or install spacers to the window sill. After complete drying, the slopes are puttied and then painted.

Installation subtleties

You can install multilayer PVC panels yourself, the main thing is to follow all the rules and instructions for installing such materials. Using window slopes as an example, we will consider the technique of installing plastic panels at home.

Required tools for installation:

- self-tapping screws, liquid nails, sealant;

- mounting profiles;

- polyurethane foam;

- sandwich panels;

- mounting level;

- knife-cutter, electric jigsaw, scissors for cutting metal materials;

- electric drill;

- in some cases, experienced craftsmen use a grinder to cut panels.

Beginning builders need to use such a tool with caution, because if you apply too much pressure, the material will break. Before you start laying the sheets, you need to get rid of dirt (dust, paint, foam)

Sandwich materials are laid only on a clean base. If there is mold, it must be eliminated and the surface treated with a special impregnation.

Before you start laying the sheets, you need to get rid of dirt (dust, paint, foam). Sandwich materials are laid only on a clean base. If mold exists, it must be eliminated and the surface treated with a special impregnation.

- Preparation and measurement of slopes. Using a tape measure, measure the length and width of the slopes in order to cut the panels to fit the slope.

- Installation of profiles. The initial U-shaped profiles (starting profiles) are cut and fastened with self-tapping screws, which are installed along the edges of the profiles, leaving a gap of 15 cm between them.

- The side sections and the top PVC panel are installed in the plastic profile. The sections are fixed to the wall with liquid nails or foam.

- The areas adjacent to the walls are covered with cladding material made from an L-shaped profile. The border profile is installed using liquid nails.

- Finally, the junction areas are treated with white silicone sealant.

You need to use polyurethane foam with extreme caution, because when it comes out it doubles in volume. Otherwise, large gaps will form between the layered sheets and the wall, and the entire work will have to be redone

Slopes on balconies and loggias made of sandwich slabs are made similarly to the slopes of metal-plastic windows in an apartment.

Features of slopes for gypsum fiber windows

Gypsum fiber is often used to finish slopes. The technology for installing the material is similar to the principle of finishing niches with plasterboard. However, gypsum fiber has distinctive advantages over its analogue. The material has good strength and rigidity. There is a variety of products that are characterized by excellent moisture-proof properties. This feature makes it possible to use the material for finishing the external slopes of windows.

Slopes made of gypsum fiber are characterized by ease of installation and high speed of work. The material has excellent technical and performance qualities. It withstands mechanical stress and adverse environmental factors. Due to the presence of fibers in the structure of the material, it is an additional insulation for the window, which increases its thermal insulation properties, which makes it similar to PVC sandwich panels for slopes.

Drywall is characterized by high strength and rigidity.

Due to the good strength and rigidity of the material, it is possible to obtain an ideal design geometry that will have a long period of operation. Such slopes are characterized by maintainability. The damaged area can be puttied and tinted.

The disadvantages of the material include its higher cost compared to conventional drywall. However, it is lower than the price of sandwich panels for slopes. Cutting such material is also much more difficult. The surface needs finishing, which is carried out by priming, puttying and painting.

On a note! When painting gypsum fiber slopes with high-quality latex paint, it is possible to obtain a durable, moisture-resistant surface that can be washed.

Plastic panels for window slopes: material features

You can create reliable and aesthetic slopes using plastic panels. They are characterized by a sufficient level of rigidity, wear resistance, and moisture resistance. As a result of using the material, it will be possible to create a flat, smooth surface that does not require finishing.

Plastic panels for slopes do not require additional finishing.

Note! For slopes, you should choose panels made of virgin plastic that are resistant to ultraviolet radiation, which will not lead to yellowing over time.

The panels are installed using liquid nails, which ensures reliable, strong and durable fixation. Installation of the material is easy and quick, with a minimum amount of dust and dirt during the work process. Due to the fact that the slope and the window frame are made of the same material, it is possible to ensure that there are no gaps in the places where the elements come into contact.

Note! For additional tightness, eliminating the negative effects of temperature changes, the butt joint is treated with a sealant.

Plastic panels are attached using liquid nails, and the joints are treated with sealant.

PVC panels for slopes are completely moisture-resistant, so they can also be used for exterior decoration. The presence of an edge profile allows you to give the window a more aesthetic appearance. The element is applied to the joint between the wall trim and the window opening. The cost of the material is an order of magnitude lower than the price of sandwich panels for slopes of plastic windows.

The disadvantages include the insufficient strength of the material, which is why it is prone to mechanical damage. If a defect occurs, the strip is completely replaced. Additional elements are often of low quality, as a result of which they turn yellow, standing out unattractively against the snow-white background of the slopes. In addition, unlike sandwich panels for slopes, plastic elements do not contain insulation, which reduces the thermal insulation properties of the window.

Sandwich panels are very popular today when finishing window slopes. This is due to strength, reliability, moisture resistance and good thermal insulation qualities. The material is installed easily and simply. We are also pleased with the affordable price per m2 of sandwich panels for slopes, which averages 150-200 rubles.

Peculiarities

Unlike old wooden frames, modern plastic windows are equipped with special ventilation equipment. For this purpose, the upper part of the window frame is tilted, forming a narrow opening for the flow of fresh air. As a result, air turbulence occurs with sharp changes in temperature conditions.

Drywall is often used for this purpose, but such building material can freeze in winter, and caring for it requires a lot of effort.

If the room is built of brick or reinforced concrete blocks, only sandwich panels can be used for maximum insulation of the slopes.

The advantages of using sandwich panels are as follows:

- additional noise and thermal insulation is performed. Additional insulation is carried out using polyurethane foam to better connect the material to the slope;

- does not require constant care and maintenance. Any type of contaminant can be easily washed off with a cleaning solution without damaging the structure;

- high vapor permeability. Unlike plasterboard material, sandwich panels do not get wet or crack when exposed to moisture;

- low weight of the structure (the weight of 1 m² with a product thickness of 24 mm is 3.9 kg);

- highly resistant to mechanical damage;

- resistance to ultraviolet radiation;

- stylish design appearance;

- resistance to mold and mildew;

- reasonable cost of the product;

- do not require additional registration. The surface of the panels has a structure similar to the surface of plastic windows;

- environmentally friendly material. It does not emit harmful substances, thereby causing no harm to living organisms during operation.

Despite the fact that multilayer panels have many advantages, some consumers have negative reviews about this building material, such as:

- under the influence of high temperatures the product turns yellow and becomes deformed;

- improper installation of the material can lead to the formation of gaps and cracks;

- Slopes cannot be finished using sandwich panels if the distance between the hinge and the wall is small. Otherwise, the structure will walk around the perimeter;

- Only low quality materials have such disadvantages.