Plastic windows are now installed in every apartment or private house. They have firmly established their presence in the construction market and have become indispensable in the life of any person. For an impeccable appearance, you need not only to install the windows correctly, but also to properly process the slopes. At first glance, everything is quite simple, but when it came time to finish them, I encountered some subtleties. I decided to use the f profile for slopes and I want to tell you about the technology for using this plank. However, there are several more ways to finish window slopes.

F-profile for finishing the slope

Application of products

There are two types of slopes: one of them is located outside the building, the other is located on the inside. Both types require proper finishing. The slope is intended not only to give the windows an aesthetic appearance, it performs important protective functions.

Plastic windows are attached to the opening using mounting foam. It deteriorates under the influence of moisture and is gradually carried away by the wind, which is why it is important to install a slope profile that can protect the structure from adverse weather conditions. Otherwise, the foam may become deformed and damage the window frame.

Application of F-profile for finishing the external slope

Read more on our website about the types of platbands for metal-plastic window structures. How to finish the slopes of plastic windows with your own hands, see the link. We choose the most “correct” slopes for plastic windows. Prices for different types of slopes, consumer reviews

When replacing windows yourself, do not forget about installing sills for plastic windows.

DIY installation

If your plastic windows were recently installed, they may still be covered in protective film. Do not remove the film until the installation of the slopes is completed. For ease of understanding, we will divide the installation article into several points. Follow them consistently and you will not have any difficulties during installation. At the end of the article there is a video in which you can see the entire installation process. If you still have questions, please ask them in the comments.

Window opening sheathing

We install wooden sheathing around the perimeter of the window opening. We drill holes in the wall for the dowels; 9-centimeter screws are well suited for fixing the sheathing.

sheathing

Remember that the sheathing should not protrude beyond the plane of the wall. The slats must be strictly perpendicular or horizontal to the floor; leveling the surface can be done using a building level.

Installation of a U-shaped plastic profile

The U-shaped profile is mounted along the edge of the window frame. We will insert the plastic slope itself into the profile. To fasten the profile we use self-tapping screws.

Installation of U-profile

It is important to install the profile strictly perpendicular or parallel to the floor; for this we use a building level.

Installation of F-shaped plastic profile

This profile is also a kind of fastening for the slope; it is installed opposite the U-shaped plastic. The profile itself is mounted in such a way that the F-strip groove is opposite the U-shaped plastic. The F-profile is cut to a height slightly higher than the height of the window opening. On the protruding part of the profile we cut off the F-groove, since here the profiles will overlap and interfere with each other.

The final stage

At the corner of the junction of two F-shaped profiles, remove excess parts using construction scissors at an angle of 45 degrees.

The profile is attached to the wooden sheathing using a furniture stapler.

Installation of slopes

We are preparing to insert the slopes directly into the grooves of the F and U-shaped profile. Pay special attention to slope measurements. You won't get a second chance if you cut off more than you should! You'll have to buy a new plastic panel.

Don't be upset if you didn't get a perfectly straight cut and there are small defects. Small imperfections can be covered with special white silicone glue.

We do the final cleaning - we rub all the seams and joints with white silicone. The process has come to an end, we are enjoying the work done.

I hope you liked our article.

If you would like to learn how to adjust your vinyl windows and prepare them for winter, click here.

Finishing methods

There are several ways to tidy up your window. These may be the following options:

- Finishing with plaster. This method is quite old. Its main disadvantage is the complexity of the work. Plastering is time-consuming and requires careful cleaning of the area after finishing. When a house shrinks, it may crack.

- Application of drywall. This option is not bad, but it is only suitable for interior work. The room must be dry and warm, otherwise the sheet of drywall will begin to collapse.

- PVC profile for slopes is the best option. It is not afraid of moisture, temperature changes, is easy to install, and can be used both outside and indoors. This is an excellent solution for plastic windows, as it matches them perfectly in terms of material; the PVC F profile for slopes is very easy to install. It is quite possible to do this yourself. With other materials, for example, wood, the profile may not look so harmonious, although you can order wood lamination, and the differences will not be noticeable.

PVC profiles for slopes

Features of application

Finding out the desired profile is quite simple; it looks like the Latin letter “F”. The material is fixed using special plates that are fixed in its grooves. The starting profile for slopes has two important functions:

- Decorates the ends of windows, giving them a decorative look.

- Levels the surface without the use of complex structures and plaster.

Installation of the starting profile

For high-quality façade cladding, a starter profile for PVC panels should be used. The starting profile is installed along the contour of the building. And the upper edge of such a profile should be installed along the bottom line of the building cladding.

Vinyl flashings should also be installed. They will help create beautiful joints and also protect the base. Vinyl ebbs are attached strictly under the starting profile.

After this, internal and external corners and frames for door and window openings are attached. Lastly, the finishing profile is used. You can also replace the finishing profile with molding.

Ready solution

The F-shaped profile for slopes is a convenient solution for cladding. It creates a perfectly flat surface, free of imperfections, protects the opening from moisture and sunlight, as well as wind, dust, and other mechanical influences.

The starting profile is attached to a plastic window without the use of glue. The design not only helps to make the slopes visually attractive, but is also perfect for places where different materials meet. The starting profile is most often mounted in this way: one side of it touches the wall, the other touches the plastic structure. If the size of the material does not correspond to the required parameter, it can be cut using a stationery knife; for the same purpose, a grinder or a metal file is sometimes used.

How to make slopes on plastic windows from sandwich panels - photo + instructions

The article discusses one of the most common and today one of the latest methods of finishing window slopes - finishing with sandwich panels. During the description, attention will be paid to the methods of attaching the panel base to the frame profile, the advantages and disadvantages of each method.

Currently, when choosing windows for their home or apartment, many people are guided not only by the parameters of their energy efficiency and heat conservation, but also by the issue of aesthetics.

It is necessary that the window unit fits clearly into the design of the room, while slopes on plastic windows require appropriate design. To ensure that a beautiful window and the walls in the room are a single whole, the window slopes can be finished with sandwich panels using the technology described below.

Tools and materials

To install slopes made of sandwich panels, you must have the following tools:

- screwdriver;

- Bulgarian;

- metal scissors;

- stationery knife;

- roulette;

- level;

- goniometer (small);

- marker (pencil);

- gun with polyurethane foam;

- liquid plastic;

- masking tape.

Material to be used:

- Sandwich panels according to the dimensions of the slopes.

- “P” and “F” shaped plastic profile.

- Bracket for fastening slopes.

- Self-tapping screws.

Preparatory work

Before installing slopes on windows, it is necessary to carry out preparatory work related to the preparation of walls. This work is not long, but it is necessary. After dismantling the old window, a lot of dust and dirt remains, which must be swept away with a broom, or better yet, removed with a vacuum cleaner. In some cases, it is necessary to knock down old plastered slopes, because they can interfere with the correct installation of new ones. It may be necessary to plaster the cracks between the bricks with a thin layer, because in old houses cold air from the street blows very strongly from these cracks! After this, the surface must be treated with a primer or plain water.

The most common methods of installing plastic sandwich panels for slopes is mounting on a U-shaped (starting) profile.

Photo of a “U” shaped (starting) plastic profile for installing slopes on windows.

And fastening to special brackets for slopes.

Photo of brackets for installing sandwich panels on plastic windows.

Fastening plastic sandwich panels with a “U” shaped profile

To implement the first method, at the beginning of installation it is necessary to take the dimensions of the window frame - its height and width. In accordance with the size of the frame width, use scissors to cut a U-shaped profile. Then, using a screwdriver and so-called “bug” self-tapping screws, screw this profile end-to-end along the upper contour of the front part of the frame.

Self-tapping screws used to attach a plastic “U” shaped profile to the frame.

The fastening step with self-tapping screws is 10-15 cm.

After this, in accordance with the height of the frame (minus 1 cm - this is a profile that is already attached horizontally), cut 2 more “U” shaped profile strips. The upper part of each segment must be cut at an angle to the horizontal upper profile, because the upper slope is attached with a slight slope relative to the lintel of the window opening. The finished sections of the profile are attached end-to-end along the left and right contours of the front part of the frame.

Attention: when attaching the starting profile, it is necessary that its short side be turned towards the frame, and its long side, respectively, towards the wall opening.

Having installed the profile, you can begin measuring the upper sandwich panel. In order to measure correctly, it is necessary (in accordance with the notes in the photo below) to measure the length “A” and the length “B”.

Installation of slopes from sandwich panels.

Transfer these dimensions to the sandwich panel. Most often, the length of “A” is shorter than the length of “B”, so the figure obtained on the panel sheet will have the shape of a trapezoid. Sometimes these lengths are equal, then the figure will have the shape of a rectangle. It is possible to transfer length “B” to the plastic, but it is easier to do this in a way that will be described below.

After dimensions “A” and “B” are transferred to the panel, using a grinder you need to cut off the resulting figure. At the same time, we do not pay attention to the width of the panel. Next, the resulting segment is inserted with one side into the starting profile, previously attached to the frame profile, and with the other side it leans against the top of the window opening. In the part where the opening ends, a line is drawn with a pencil, along which the excess part of the panel is subsequently cut off.

When the panel is adjusted, it is necessary to remove the protective film from it and reinsert it into the starting profile. The side of the panel farthest from the window is attached to the wall with masking tape in at least 3 places so that the gap between the panel and the wall is 2-3 cm. When attaching, you must maintain a level in the horizontal area. Then this gap along the edge is filled with polyurethane foam. The upper slope is ready.

We make slopes on the windows with our own hands.

After this, you can begin measuring the side slopes. First, the length “D” is measured, after which the angle formed between the upper slope and the vertical profile of the frame is measured using a protractor. A straight line equal to the length “D” is drawn on the sandwich panel, and an inclined line is drawn using a protractor placed at the desired angle at the end of the straight line.

Thus, the height dimensions of the side slope are transferred to the panel. The slope can be cut, but with a margin of width.

As in the case of the upper slope, the width of the side slope should be marked with a pencil along the wall when the slope is installed in the side starting profile, and then cut it off. The left and right side slopes must be the same in size and angle of elevation. The only difference is the front side of the panel. Like the top one, the side slopes are installed on one side into the starting profile. The other side is attached to the wall using masking tape. It is necessary to maintain a level in the vertical area. The gap between the panel and the wall along the edge is filled with foam. To maintain symmetry, the angle of rotation of the side slopes must be the same. It is set using a protractor.

We make plastic slopes for windows.

When all the slopes are in place, you can start measuring and cutting out the “F” shaped profiles that will cover the foam seam between the slope and the wall.

"F" profile photo.

First, the side profiles are attached, and then the top profile. To do this, you need to measure the length “E” and transfer it to the profile. From the end of the resulting segment, using a square, a line is drawn upward on the profile at an angle of 45 degrees. Along this line, using metal scissors, you need to cut the profile.

The resulting segment is applied to the end of the sandwich panel.

We make slopes of plastic windows with our own hands.

In the same way, the profile is installed on the second slope. To prepare the profile of the upper slope, it is necessary to measure the distance from the upper edge of the left profile to the upper edge of the right and transfer it to the profile. After this, on both sides of the resulting segment, draw a line from top to bottom at an angle of 45 degrees and cut it off. Place the resulting profile on the end of the top panel. Attention: the pieces of masking tape that held the panels are also glued on top of the “F” shaped profile. They must be completely removed after 24 hours from the moment of installation of the slopes.

Installation of slopes of plastic windows.

The final stage of installation of slopes is finishing with liquid plastic the joints between the top and side panels, between the panels and the frame profile, between the panels and the window sill.

The finishing of the slopes with sandwich panels is completed.

Photo of slopes on plastic windows made of sandwich panels.

Fastening sandwich panels to special brackets for slopes

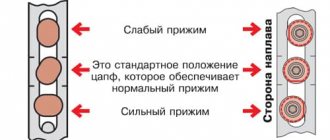

The difference between this method is that to fasten the panels, brackets are attached to the end of the window frame, which, instead of a “U” shaped profile, hold the base of the panel to the frame.

Installation of slopes made of sandwich panels with fastening to special brackets.

Positive features of this fastening method:

- The slopes look aesthetically pleasing and beautiful.

- Installation time is reduced.

A negative feature of this method is that if there is strong pressure on the base of the slope in a place where there is no bracket, the slope may come off the frame.

Despite this nuance, preference is given to mounting slopes on brackets, because the desire to improve the appearance exceeds the desire for reliability!

rems-info.ru

Advantages

The starting profile for PVC windows has several obvious advantages:

- Ability to resist ultraviolet radiation. The profile does not fade even for ten years.

- The material is durable, looks good, and can fit into any interior without standing out.

- Suitable for use both indoors and from the facade.

- Moisture resistant.

- The chalk content in the composition is minimal.

- The semicircular end of the tail allows you to lay the profile on the most uneven wall.

- Hides wall imperfections, levels slopes without the use of other materials.

- The plank can be safely cut, no chips or cracks will appear on it.

- Installation is carried out independently; this does not require special skills.

- No glue is used.

fprofile and scope of its application

Installation of slopes on PVC windows

For complete cladding with PVC panels, various additional elements are used, which help to perform the installation efficiently and correctly. fprofile is one of

of these elements, which outwardly looks like a plank, the cut of which resembles the letter “F”. The ends of the plate are securely fixed in the grooves of the profile during installation. The F profile serves two functions:

- Decorative design of the ends of the trim

- Aligning the common plane

Ready plastic slope

The f-shaped profile is the finishing cladding of the window space, which ensures a good adhesion of PVC panels to the walls. It can also be used for doorways. The ease of use of the f strip is due to the fact that its installation does not require the use of an adhesive solution, as is the case with an eraser corner. That is, when I glue the wallpaper, I will just need to remove the f strip from the slope, and upon completion of the pasting, insert it into place. Using the f profile, not only PVC panels are joined, but also planes of dissimilar materials. If you use it as a starting profile, then one side of it will press against the wall, and the other against the slope. When finishing with your own hands, the f-shaped profile is easy to cut into the required strips. To do this, you can use a hacksaw, grinder or paper knife.

I have highlighted a sufficient number of advantages of the PVC profile:

- It does not turn yellow for about 10 years and is lightfast.

- Elastic and not fragile.

- Contains a minimal amount of chalk.

- It has a semicircular tail that fits perfectly even on curved walls.

- Chips and cracks do not appear after cutting the plank.

- Easy installation without glue.

Double-hung window with a window into a panel house made of 5 chamber profiles

I liked that the profile can be used for both PVC and sandwich panels. Being universal, it can last quite a long time.

Important! It happens that the plank is placed on glue - this is an unacceptable action, because after some time cracks may form through which cold can enter the house. In addition, the profile is known for the fact that it does not need to be secured with the help of auxiliary means.

PVC windows and slopes

The starting profile for a PVC window sill is ideal, but it can be used not only with it, but also if the walls are made of sandwich panels. The material will help protect the inside of the panel, easily attach to it and last a long time.

Do not put the profile on glue. This action will cause it to crack when exposed to low temperatures and begin to leak moisture.

PVC fabric that is too cheap may also be excessively soft. This will make it fragile. The soft fabric does not last long and is not suitable for outdoor use. It easily deforms from any touch.

You should not save on materials; once you save and purchase low-quality PVC panels, you risk not only spending extra money on replacing them, but also incurring more serious costs if the window frame is deformed.

Have you replaced your plastic windows, but decided to make the slopes yourself? Read our article “Finishing window slopes inside an apartment.” Read prices for different types of slopes, consumer reviews, and how to choose them correctly in our article “Choosing the most “correct” slopes for plastic windows.” When completing the finishing yourself, do not forget to insulate the slopes of plastic windows.

Finishing the facade with PVC profile

After installing the starting profiles, the internal and external corners are fixed. After this, door and window openings and connecting profiles are installed. performed using staples, screws and nails. You can also use special mixtures or an adhesive solution.

However, such mixtures should be used only at certain temperatures, and you also need to focus on air humidity and other unfavorable factors that can reduce the quality of profile fastening.

Installation starts from the bottom. The panels are attached to the starting profile. It is recommended to start cladding the facade from the left corner, gradually moving to the right. However, if the panels have the same color and shade, then you can start from any corner.

It is not recommended to use PVC profiles for cladding the facades of houses located in regions where the temperature often drops below -10C°. This temperature indicator negatively affects the durability of the material, because at low temperatures the panels become very fragile and can crack.

The starting profile for PVC panels is used for high-quality finishing of structures made of various materials. The use of PVC panels is not only an inexpensive and simple solution to the problem of facade insulation. The use of this material allows you to protect the structure from moisture and dampness, as well as other negative environmental influences.

In addition, PVC panels allow you to efficiently, quickly and inexpensively update the facade and hide any defects that may have arisen during operation or during the construction process.

With proper installation and the use of high-quality material, PVC panels for facade finishing can last for decades. However, for this it is necessary to strictly follow all recommendations when installing them and be sure to use a starting profile to protect the end faces of the panels from damage.

Sip panels are used in the construction of buildings with a small number of floors and premises for domestic, public and residential purposes. For example, most often SIP panels are used to build...

- Ventilated panels came to us from Japanese craftsmen, famous for their quality, reliability and durability. The composition of the panels is cement and sand, which are held together with cellulose fibers (fiber)....

- In the mid-90s, the usual nails and screws were replaced by a new product - liquid nails. One drop of this product is enough to fix...

- I-profiles.

- F-profiles.

- L-profiles.

- P-profiles.

Installation of plastic windows or installation of a new entrance group is always accompanied by accompanying finishing work. First of all, this is sealing the joints between the window frame or door frame and the wall.

One of the simplest and most effective ways to decorate door and window openings is to decorate them with plastic slopes.

For this purpose, special kits were created from polyvinyl chloride, including various structural elements. One of the most important among them is the plastic profile for slopes.

Starting forms are classified depending on the cross-sectional shape

Structurally, the installation of plastic slopes is in many ways similar to the assembly of a construction set. This is achieved by maximum unification of all parts, as a result the entire structure becomes very technologically advanced and functional.

Each of its elements is intended for strictly defined purposes and performs a specific function. To attach plastic panels to the load-bearing base and to join them together, a starting profile for slopes is used.

Profiles are produced from both metal and PVC

Today there are several types of starting profiles, which significantly expands the scope of their use. Depending on their design, they can be used to fasten elements of decorative finishing in various ways in different places of the opening.

They are classified depending on the shape of their section. The profiles are designated by Latin and Russian letters, with which the pattern of their cross-section is similar. On the modern market of finishing materials there are the following types of PVC starting profiles:

This starting profile has a cross-section in the form of a capital English letter I: one wide central shelf and two short side ones. The I-shaped profile is installed directly on the wall and is intended for attaching plastic or plasterboard slopes to it.

The special shape of the part allows it to be attached to the opening in almost any position. The main condition is that it should be positioned with a long shelf perpendicular to the load-bearing surface, that is, “stand” on short shelves.

This model is used more often than others

One of the most popular types of plastic profiles. This PVC profile is made in the shape of the letter F - it has one long shelf and two short ones adjacent to the long one on one side. Using F-profiles, slopes can be installed from a wide variety of materials:

- Polyvinyl chloride.

- Sandwich panels.

- Wood-based composite materials (MDF, LDVP, laminate, etc.).

- Plasterboard sheet.

Thanks to its design, the F-shaped profile performs two functions at once - fastening and decorative. The presence of a second narrow shelf allows you to close the joint of the facing panel with the F-profile without the use of any additional elements in the form of decorative corners or putty.

Mount this profile perpendicular to the window

Using this starting profile, standard slopes made of plastic or plasterboard sheets 10 mm thick are installed. Its cross-section consists of three shelves: one wide and two narrow.

The L-shaped profile is attached perpendicular to the plane of the window: the wide shelf is adjacent to the wall of the opening, the narrow one adjacent to it is to the window frame, and the narrow shelf opposite the long one serves to mask the joining seam at the junction of the finishing panel.

In its design and scope of application, it is similar to the L-profile. The only difference is that this part has two wide shelves connected by one narrow one.

The installation scheme of the U-shaped element is similar to the installation of the L-profile, only the outer plastic plate, designed to hide the joint with the slope, is wider. This makes it possible to cover wider or uneven seams.

What is required for finishing

The starting profile is the main component. If the window is standard, you will need 6 meters (the fact is that the panels are sold in lengths of 3 and 6 m). In addition, you will need a drill or screwdriver, as well as metal cuts.

The F-profile is attached using liquid nails. Before its installation, a starting profile is attached. This is easy if the windows are level. Pay attention to the joints: they must be cut to fit exactly together. You need to start work from the side slopes. Insulation can be placed between the wall and the profile.

The most affordable and easy to install is the plastic profile for slopes. It will significantly reduce your costs, save time and money.

Preparatory work

Before installing the starting profile, preparatory work should be carried out. It is necessary to clean the surfaces from various contaminants and level them.

We begin preparing the surface of the facade.

- Thoroughly clean the walls of plants, branches and various fasteners.

- Remove all decorative elements, wind boards and trim, as well as other types of protruding parts from the surface of the walls.

- Use a level to check the evenness of the walls.

- Check the window openings and frames, and, if there are any errors, correct the defects.