Of course, the work in this area of the façade does not end with the installation of window frames. Ahead lies a rather complex and responsible operation of finishing window slopes. And this is not only to give the appearance of the building a finished look, the intended design. There are also more important, from a practical point of view, reasons.

Finishing window slopes outside

Finishing of window slopes from the outside can be done using several technologies and using different materials. To decide on their choice, you need to consider the most affordable options for doing it yourself.

Material properties

Plastic slopes made of sandwich panels

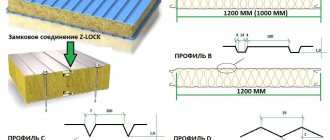

The structure of standard panels looks like a sheet, the outer side of which is solid-sheet PVC, the inner side is sheet polystyrene, and there is insulation in the middle. That is why this finishing option was called the American word - sandwich panel. They differ only in the material of the facing side, and the installation remains the same for any type.

Important! People call sandwich slopes – warm slopes. This is due to the insulation that is present in the panel

Once you have already imagined what they are, I will tell you about their advantages:

- Despite their popularity, they remain accessible to everyone due to their reasonable price.

- This is not just a building element, it is also an independent device that has its own set of components.

- The interior is filled with mineral wool or foamed polystyrene - this indicates the non-flammability of the structure.

- Excellent thermal insulation performance, as well as additional sound insulation, is achieved with their help.

- This finishing method is durable and strong.

- If you do the installation yourself, you must strictly follow the installation technology. In this case, resistance to moisture and mold will be at a high level.

Sandwich panels for finishing slopes

For those who have decided to change the windows in their house or apartment and install the slopes with their own hands, I will give you advice: you need to wait at least 24 hours after installing the windows and only then finish the slopes with sandwich panels. The advantage of installing a sandwich over plastering is that installation by hand does not require painting skills and is a clean method.

It is important not only to correctly install the slopes, but also how to cut the panels. It is better to cut plastic elements with a circular saw on plastic or aluminum. At the same time, a fine tooth pitch can cope with the task perfectly. In addition, the material must be cut at a temperature of +5 degrees Celsius - if the temperature regime is not observed, then due to a decrease in impact strength, chips may appear on the cut line. If the slopes are finished with PVC sandwich panels, then you can cut them with many tools. But the most optimal one is a hacksaw for metal; it can also be used for wood. You need to cut face up and with a slight angular inclination. At your own peril and risk, you can cut with a grinder, but if you apply a little too much pressure, the panel may break.

Advantages and disadvantages

Positive technical characteristics of the material:

- Thanks to the surface structure of sandwich panels, which is similar in appearance to the structure of plastic windows and window sills, the material does not require additional decoration or processing.

- If we compare the panels with drywall, the latter clearly loses, as it is susceptible to cracking and getting wet as a result of the influence of condensation. Sandwich panels are reliably protected from this effect, thanks to the plastic coating.

- The panels provide better thermal insulation. Although the product itself does not allow cold to pass through, most often the structure is additionally insulated, but this is done more in order to immobilize the panel and obtain a reinforced bond of the material with the window block using polyurethane foam.

- Cleaning the surface of the panels is not difficult. Any stains can be easily removed from the plastic coating using a cloth soaked in soapy water.

- The panels are easy to install. which does not require any special skills.

- Long service life - according to the indicators specified by the manufacturer, it is 15-20 years.

The presence of shortcomings in sandwich panels is mainly due to the quality of the material itself:

- Poor quality panels, as a result of the influence of high temperatures, usually formed due to direct sunlight, can become deformed and acquire a yellow tint.

- In addition, poor quality also affects the durability of products, which, if manufactured unscrupulously, leaves much to be desired.

When purchasing, it would be a good idea to pay attention to the manufacturer and make sure that the seller has certification of the product

Installation instructions

After installing new windows, you need to wait a day for the final polymerization of the polyurethane foam and after that you can begin finishing. Installation of window slopes made of sandwich panels is done according to the following principle.

- Initially, you need to take the dimensions of the window openings. All parameters of the places where finishing will be carried out are measured (parameters may sometimes differ even with a fairly large scatter).

- Window openings are prepared for installation. All weak parts of old plaster and masonry are removed and replaced. All surfaces must be treated with antiseptic agents to protect against the formation of mold and mildew. Excess polyurethane foam is trimmed from the windows.

- A starting “P” profile is installed around the perimeter. It is attached to the surface of the opening with self-tapping screws, in the corner formed by the cut of the wall and the window frame. The fastening pitch is 150-200 millimeters. From above and below, sections are inserted into the installed profile to the entire depth of the opening.

- Panel blanks are prepared to the required size. The cutting of individual elements is done using a stationery knife. In this case, the protective PVC layer with part of the polystyrene foam located inside is cut through on both sides. The resulting cut ends can be trimmed with sandpaper on a grater.

- First, the upper sandwich panels for the slopes are installed, followed by the side elements. At the same time, insulation is placed in the resulting space (if the slope is “warm”). Installation without insulation occurs with the application of liquid nails to the surface of the workpiece and additional gluing to the wall.

- The corners of the window opening are completed by mounting the corners in the form of an “F” profile. To do this, measure and cut individual profile elements with a length greater than 50 millimeters on each side. They secure the free ends of the panels, and the edges are overlapped. Using a linear line, the joints are marked diagonally from the corner to the opening. Both ends are cut along the mark. The result should be a beautiful joint with an angle of 45 degrees.

- All joints must be carefully sealed with sealant.

Before installing the “F” profile, you need to fill the space between the panels and the wall well. The corner near the window is carefully foamed, the main cavity is filled with insulation. Or, as an option, completely fill all the voids with foam.

The construction of slopes from sandwich panels is a good alternative to the more labor-intensive plastering option. Their installation does not require a whole list of “dirty” work on applying plaster with further leveling and finishing painting.

To some extent, sandwich panels for window slopes and plasterboard are inferior, structures made of which are more sensitive to moisture and also require finishing plaster.

The only competitor for quick and easy installation may be plastic panels, but they do not have their own insulation. If you choose between sandwich panels and ordinary plastic, then the former win in terms of heat and sound insulation.

Finishing process

Before you begin directly fixing the sandwich panels, you need to prepare the sheathing for them. In some cases, it is possible to install sandwich panels directly on the wall, but this is only possible if it is perfectly level and can support the weight of one or more panels. This applies to a greater extent to loggias, so you will have to construct a sheathing for the balcony. The latter can be made from a special metal profile, which is also used when installing siding on building facades. The use of wooden blocks is also suitable. The size of the elements for installation is indicated by the manufacturer himself.

On the balcony it is easier to create a metal frame that will withstand wind and other loads well. It is necessary to place vertical elements in increments of up to 50 cm. If other parameters are required for a particular type of sandwich panels, the manufacturer indicates them in the product data sheet. The metal frame on the balcony is fixed to the main slab, as well as to the one that acts as a roof, if present. Additionally, the elements are fixed to the load-bearing walls of the building to give them the required rigidity. When choosing this installation option, you can enlarge the balcony along the window sill. When fixing each slats under the sandwich panels, it is necessary to constantly monitor the vertical level.

The first step before installation is to install a starting strip, which can be the edge of the slab itself or a specially installed metal element. The sandwich panel is inspected for damage. After this, the protective film, which is located on the inside, is removed from it. In accordance with the manufacturer's instructions, holes are drilled through which the sandwich panels will be attached to the sheathing. When everything is ready, a sealing tape is glued around the perimeter of the sandwich panel, which will ensure a better fit to the metal sheathing. The panel is placed closely against the sheathing and fixed to the racks with self-tapping screws. The next element is installed in the locking part of the previous one until complete joining, after which the sandwich panels are fixed. The method of internal cladding with sandwich panels is shown in the video below.

Let's start installation

Finishing window slopes with sandwich panels

It will be quite easy to make slopes with sandwich panels if you follow the rules and sequence of actions. Even if you don’t have experience finishing slopes with your own hands, you don’t need to be afraid of this work. Before starting installation, you need to prepare tools and materials, you will need:

- Sandwich panel – you choose what material to buy from yourself

- Start profile

- F profile

- Liquid plastic – used as desired

- Tape measure and knife

- A screwdriver with self-tapping screws, a screwdriver and a drill - probably every home has the latter.

Slopes made of sandwich panels in a panel house

I have already said that installation should be done at least 24 hours after installing new windows. Using a tape measure, you need to take measurements and cut out panels for the side and top slopes. Use a knife to remove unnecessary pieces of polyurethane foam and begin installing the starting U profile using self-tapping screws for fastening. They need to be screwed in with a gap of 10-15 cm. Do not forget that the top profile is attached first, and only then the side ones should fit tightly with the top one. Next, we proceed to install the slopes using a sandwich panel; it is inserted into the grooves of the profile. Using the same scheme, we start from the upper slope.

Finishing of plastic slopes

Then there are two options:

- The first is to insert pieces of the starting profile into the vertical bar from above and below, and then the side panels fit into these grooves.

- The second is to simply attach the panel end-to-end with the window sill and the upper slope, after which the gaps are closed using liquid plastic.

When this stage is completed, all that remains is to give the slopes a finished look. To do this, use the f profile; it needs to be secured to the edges of the sandwich fabric. For additional thermal insulation, the voids between the sandwich sheet and the wall are filled with polyurethane foam - this process does not bring any inconvenience, since it is very easy to dismantle the profile. After filling the voids, the bar is returned to its place.

Plastic slopes made of sandwich panels for a balcony block

One more tip! It is better to trim the f profile after installation - to do this, it is attached with an overlap and then a cutting line is outlined using a pencil. In this way, maximum joining of the planks can be achieved.

We also recommend reading:

Convenient finishing of slopes with a PVC profile Beautiful and convenient do-it-yourself slopes made of PVC panels, wood or simply plastered Practical and easy installation of plastic slopes on windows Features of using plastic corners on slopes Arrangement and installation of metal slopes for windows

Technology for quick plastering of doorways

Doorways are an important part of the interior, and their appearance says a lot about the quality of the finish. The slopes must be smooth and neat, just like the walls themselves. In this article we will tell you how to plaster the slopes of entrance and interior doorways with your own hands.

Plaster performs the following tasks:

- the base plane of the slope is formed, preparations are made for finishing

- fills the gap between the wall and the door block

- additional sound and heat insulation is provided

If it is not planned to install a door block in the doorway, the slope provides an organic transition between the planes of the walls of adjacent rooms.

What comes first: installing doors or plastering?

First, the door block is installed, then the slope is formed. There is an explanation for this.

After installing the door, a technological gap inevitably forms, which the craftsmen fill with polyurethane foam. This gap is made in order to be able to adjust, achieving a vertical arrangement of the box posts.

Materials and tools

To carry out the work you will need a set of tools and materials:

- water containers;

- plaster, water and mixer for mixing;

- masking tape will help protect the surface of the door frame;

- plastering rule;

- metal profile for installing beacons;

- spatulas for working with plaster;

- level (bubble or laser) to control the verticality of the beacons;

- a tape measure, a pencil and a square will help with marking;

- a screwdriver (possibly a hammer drill) to secure the profile;

- deep penetration primer, brush and tray for applying the primer.

Selection of plaster mixture

For plastering work, two main types of mixtures are used:

Cement-sand .

In rooms with high humidity, unheated rooms, on slopes of entrance doors, external slopes and surfaces intended for finishing with ceramic tiles, cement-based solutions are used. Such materials do not suffer from significant changes in humidity and temperature and are highly durable. You can prepare a simple mixture yourself from sand and cement grade M400 in a ratio of 4:1. They are used for economic reasons when it is necessary to process large, rough surface defects.

It is more practical to use ready-made mixtures with a balanced composition, plasticizers and improved adhesion.

In areas where additional thermal insulation is needed, warm plaster filled with perlite or vermiculite is used. Plaster .

To form internal interior slopes, which are prepared for the application of paint, wallpaper or decorative plaster, gypsum starting mixtures are used. Gypsum-based solutions are more flexible and easier to process. Gypsum is much lighter and has lower thermal conductivity.

How to plaster with your own hands

The installation of door slopes begins after the plastering of the walls is completed. This makes it easier to install the beacon profile and maintain the “geometry” of the planes.

The work can be roughly divided into several stages:

- preparation of the base;

- marking;

- profile installation;

- applying a plaster layer;

- dismantling the profile and final finishing of the plane.

Let's take a closer look at how to plaster slopes after installing doors:

- The base is considered prepared when old coatings and crumbling areas are removed, the surface is free of greasy stains, and dust is removed.

- When plastering bricks, a reinforcing mesh is often attached.

- Next, a layer of deep penetration primer is applied. Be sure to let the primer dry.

- Marking the future slope is necessary for uniform distribution of the plaster layer. On the door frame, measure the width that will not be covered with plaster (do this on both sides and at the top). A corner is placed at this mark and a line for the future slope of plaster is drawn on the floor. The beacon profile is installed vertically using these marks.

Installation of sandwich panels for windows

The installation of such products has a number of specific and technical features, without taking into account which you may not get a positive result:

In areas with a hot climate, ordering window sandwich panels with renolit film is mandatory, since in the sun such a panel can heat up to 70°C - a temperature at which deformation of the plastic is quite likely. When installing panels, it is necessary to take into account the high value of the coefficient of linear expansion of sandwich panels, which reaches 7 * 10 -50 C. When cutting the panel to the required size, it is necessary to use a circular saw with a fine pitch of teeth, since otherwise the plastic may chip and delaminate . In this case, cutting cannot be performed at temperatures below +5°C, since in these cases the sandwich panel material becomes very brittle.

During installation, use only the starting profile recommended by the manufacturer. Profile replacement is not allowed. Immediately after installation, the protective film must be removed.

Installation of window sandwich panels is much faster and more convenient than plasterboard slopes, as evidenced by the video presented.

Performance characteristics of window sandwich panels

Despite their lightness, as well as a rich color finish (products are available with a matte and glossy plastic surface, as well as laminated), the considered window panels differ:

- high resistance to solar radiation;

- low moisture absorption;

- sufficient surface resistance against abrasive external influences;

- resistance against possible cyclic loads;

- significant operating temperature range (from –50 to + 60°C).

The appearance of the installed window sandwich panels can be seen in the photo.

An effective solution to the problem of the junction of a plastic structure and slopes

When sealing areas where the material adjoins the window, silicone is traditionally used as a sealant for sandwich panels. But this material is short-lived and quickly loses its sealing properties, gets dirty and spoils the appearance.

The ideal solution is offered by specialists. Our know-how lies in the use of liquid plastic for sealing joints, which is devoid of all the above-mentioned disadvantages of silicone. After curing, liquid plastic acquires the strength and gloss of ordinary plastic.

Window slope options

The traditional way of finishing is, of course, plaster. If such work is carried out by a qualified specialist, then you can forget about repairing slopes for many years. An important point when choosing this method is that there is no need to install a plastic corner at the border of the slopes and the wall.

The choice of this method is justified primarily if the wall in which the window is located is also leveled with plaster. But, given that when removing slopes, the layer of plaster reaches 5-7 cm or more, it is necessary to install a reinforcing mesh. Only a master can do this kind of work efficiently.

This option did not suit me because the wall framing the window was made of plasterboard and, in addition, a table top was already installed, which served as a window sill.

Three alternatives were considered. Finishing window slopes with plasterboard, followed by painting, plasterboard slopes with plastic glued to its surface and the use of sandwich panels.

Nowadays, the option of painting plasterboard slopes is used perhaps only for budget repairs of non-residential premises. Plastic glued to a plasterboard base is a variation of the same economical option.

Temperature changes, as well as high humidity, quickly destroy drywall. Carrying out restoration repairs every 2-3 years is not our method. Therefore, we chose PVC sandwich panels.

The sandwich panel is 10 mm. a sandwich consisting of two PVC sheets between which there is polystyrene foam insulation. The only inconvenience when purchasing is the need to purchase a whole sheet measuring 3000x1500 mm.

There are no difficulties in working with it - it can be easily cut with a grinder and even with an ordinary knife (if rough cutting into pieces is necessary for lifting into the apartment).

What is liquid plastic

Liquid plastic has recently appeared on the construction market. It has found application in many areas, including the installation of plastic slopes.

Liquid plastic is used for gluing plastic slopes

Liquid plastic is a type of modern sealant that can be used as glue when attaching plastic slopes. The content of liquid PVC in its base gives this material many positive qualities.

Mode of application

Using this glue, you can guarantee strong adhesion between the material and the surface.

Using liquid plastic when processing joints and seams, you can be sure that it will never turn yellow, as happens with silicone analogues. This ensures a neat appearance of the window opening.

When temperature changes indoors, plastic panels secured with silicone may lose their joint tightness. And the panels, placed on glue in the form of liquid plastic, will stay in place for many years.

When working with this material, it is important to consider that it hardens in one minute . This is the interval during which it is necessary to apply it and distribute it over the surface. You need to work quickly and efficiently the first time.

It is also worth considering that liquid plastic is quite toxic due to the chemical reaction that occurs, so when working with it you must use a respirator and ensure a flow of fresh air into the room.

It should be noted that after liquid PVC-based glue dries, it will become absolutely harmless to the environment and people.

Positive qualities of liquid plastic

The appearance of this modern material did not go unnoticed by specialists involved in the installation of metal-plastic windows. For them, the question of how to glue plastic slopes has disappeared forever. Liquid plastic is characterized by the following positive qualities:

- When processing joints, the highest degree of sealing is achieved;

- It cannot be washed off with water, like its silicone counterpart;

- It does not turn yellow over time, does not emit or absorb foreign odors;

- The material does not change its qualities even after 10 years;

- It is moisture resistant;

- Does not rot or become moldy;

- Does not collapse or fade when exposed to sunlight;

- Resistant to mechanical stress;

- Has an affordable price.

Sandwich panels for windows price and quality

When choosing sandwich panels, pay attention to their quality and finish. The cost varies depending on the type, color, structure and thickness of the cladding board

The modern market of installation materials offers a different range of structures: both embossed and smooth. In addition, a wide range of colors allows you to choose a sandwich panel individually suited to the interior of the room. The use of denser materials will significantly raise the bar in price. Also, when purchasing imported sandwich panels, you will have to pay even more. However, the quality of the domestic coating produced is no longer inferior to a foreign product. Therefore, think twice about the need to purchase imported sandwich panels.

Features of the material

Unlike wooden window structures, modern plastic frames have ventilation equipment. It is for this purpose that the upper part of the sash is tilted, resulting in a narrow opening through which air masses flow. Because of this, air turbulences with sharp temperature changes are formed. To increase the service life of the window system, you need to responsibly approach the finishing of window slopes.

Drywall is often used for these purposes, but in winter this material can freeze. In addition, it needs to be carefully looked after. If the building is made of reinforced concrete blocks or bricks, a sandwich should be used for maximum thermal insulation of the slope panels. Main advantages of the material:

- does not require special care, any contamination can be removed with a soap solution;

- low weight of structures;

- resistance to sunlight;

- resistance to fungus;

- the material does not require additional decoration, the outer surface resembles window plastic;

- high rates of thermal and sound insulation; construction foam can be used to improve thermal insulation and adhesion of the panel to the slope;

- good vapor permeability, the panels do not get wet or deform under the influence of moisture;

- resistance to mechanical damage;

- stylish design;

- acceptable price;

- The material is environmentally friendly and does not emit substances harmful to humans during operation.

Despite a number of obvious advantages, sandwich, like any other building material, has a number of disadvantages. Some of them:

- improper installation of panels can cause gaps and cracks;

- under the influence of high temperatures, structures turn yellow and become deformed;

- Products cannot be installed if there is a small distance between the hinge and the wall (otherwise the panels will “walk” around the entire perimeter).

Varieties

Any type of material consists of insulating sheets made of polystyrene foam (extruded), polyurethane foam or free-foam plastic. The thickness of this sheet is 9 mm.

For production they are used:

- Rigid PVC sheet. Its thickness is 0.8-2.0 mm, density 1.4 g/m3, matte or glossy coating, white color.

- Foamed PVC sheet. This porous material has good thermal insulation, density 0.6 g/m3.

- Laminated plastic. Made by impregnating a multilayer material with resins and further pressing.

There are also two options for assembling a multilayer structure :

- Double layer or single sided. In this case, the panel consists of two layers - rough and front.

- Three-layer or double-sided. This option has both sides facing.

Important. Mineral wool is most often used as insulation. It is resistant to mold and fungi, and has high levels of sound and heat insulation. Therefore, it is best suited for designing slopes.

External

For external installation, it is recommended to use a three-layer type of panels. It is tougher, holds its shape better and resists external factors well. Another plus is its excellent appearance; the panels are in harmony with different styles of facades. Disadvantage - the surface may turn yellow under the rays of active sun.

Domestic

For interior decoration, you can use both two-layer and three-layer models . If the slopes are designed on both sides, then a two-layer panel will provide all the necessary parameters.

The panels compare favorably with other types of interior slope design in their ease of installation and maintenance, and attractive appearance. To carry out the work, you do not need to prepare special equipment or tools. If the products are made with high quality, then it will not be possible to highlight obvious shortcomings.