In modern construction industry, thermal insulation materials are widely used. Their use allows you to significantly reduce the estimated cost of the facility without losing quality. One of the most popular materials on the insulation market is polyurethane foam.

Polyurethane foam belongs to the group of artificial gas-filled plastics. It consists of polyurethane, between which there are air bubbles. The thermal conductivity of polyurethane foam is almost zero, which makes it an indispensable material at construction sites and in everyday life. There are several types of it:

- Rigid polyurethane foam is a new and promising material that has not yet stood the test of time. To date, scientists have only yet to study the behavior of this material after 30-40 years of operation. It is produced directly on the construction site. It is applied to the surface by spraying. Rigid polyurethane foam is used for insulation and sound insulation of ground and basement floors and foundations.

- Soft polyurethane foam - widely used as padded insulation and for the manufacture of various household items. Its density is 5-35 kg/m/.

Analysis of technical characteristics of polyurethane foam

This article will look at rigid polyurethane foam. It is increasingly being used on construction sites. It has low thermal conductivity and hydrophobicity. PU foam does not allow water vapor to pass through and does not rot. Fungus and mold do not form on its surface. It does not react with most reagents.

For a comprehensive study of this thermal insulation material, its main properties are considered:

- Thermal insulating properties.

- Soundproofing properties.

- Moisture resistance.

- Vapor permeability.

- Behavior in various chemical environments.

- Resistance to open fire.

- Density.

- Lifetime.

- Environmentally friendly.

Summary table of average parameters of the main thermal insulation and finishing materials

On the issue of determining the quality of the composition

When working, it is very important to use the correct product components manufactured by trusted companies. There are many fakes and not all manufacturers follow the recipe. This is why it is so important to work with one contractor and establish serious incoming controls.

The statistics are disappointing - in Russia, about 80% of supplied polyurethane foam is not adapted to the climatic conditions of the country. This suggests that the required insulation values will never be achieved, and the rate of erosion will greatly increase.

When working with polyurethane foam, you must not only be guided by the listed documents and requirements, but also request an additional set of papers from the contractor. Among them are the following:

- Data from "cup tests" to determine apparent foam density.

- Apparent density parameters for already sprayed polyurethane foam.

- A protocol drawn up based on the results of testing for the level of thermal conductivity.

- Recorded adhesion test data.

- Protocol indicating water absorption level testing data. Information about the level of vapor permeability established during the inspection and included in the officially certified protocol.

- The package of documents is supplemented with certificates - fire, hygiene, and compliance. A quality certificate is also requested.

We recommend requesting a price list indicating the cost of the mixture components in rubles, and not in conventional units, as unscrupulous contractors do.

Thermal insulation properties

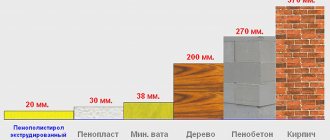

This parameter directly depends on the cell size and ranges from 0.019-0.035 W/mºC. The thermal conductivity of cellular polyurethane foam is worse than that of expanded polystyrene, expanded clay gravel and mineral wool. With the same thickness of the insulation layer, polyurethane foam retains heat much more effectively than the above materials.

Scheme for comparing the thermal insulation properties of various building materials

Soundproofing properties

Its porous and cellular structure provides satisfactory sound insulation, but not from all types of noise.

Important! There is no universal type of noise. Therefore, one material can effectively protect against impact noise, but not at all resist other types.

Polyurethane foam effectively protects interior spaces from various impact noises. This means that it will muffle the sounds of loud footsteps or dancing from neighbors upstairs. On the other hand, according to numerous consumer reviews, polyurethane foam practically does not protect the interior space from sounds from the street, loud conversations or music.

There is a simple explanation for this. Due to their structure, cellular materials (polyurethane foam, polystyrene foam) do not dampen sound waves well. For these purposes, it is better to use insulation with a fibrous structure (mineral wool). Their waves are damped due to vibrations of internal fibers.

Moisture resistance

To properly use thermal insulation materials, you need to know what percentage of moisture it can absorb. For polyurethane foam, this figure is 1-3 percent of the volume of material per day. This figure is significantly higher than that of foam plastic and mineral wool. To improve protection against moisture, additives are added to the PU foam composition. For example, regular castor oil reduces its hydrophobicity by 4 times.

Example of PPU foundation protection below ground level (in a humid environment)

Vapor permeability

In terms of this parameter, cellular polyurethane foam has high performance. Its vapor permeability coefficient is µ=50. For comparison, for heavy concrete this figure is 40-50 times lower. PPU is suitable for treating external surfaces of walls and foundations. It can completely stop concrete from absorbing moisture. On the other hand, it is not recommended for use in water. There is a possibility of a chemical hydration reaction occurring.

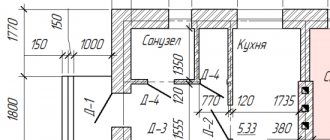

Diagram of how a wall “pie” works to remove moisture

Important! Not all polyurethane foam protects well. There are several types of cellular foam without a protective shell. They require additional vapor barrier.

Thermal resistance to heat transfer

To answer these questions, it is necessary to understand what the heat transfer resistance of enclosing structures is, which is defined as the thermal resistance coefficient R-value. Dimension m2•degS/W. Calculated using the formula: R-value = δ / λ, where δ is the layer thickness.

The wall or roof of a house consists of several layers of different materials. For example, the wall of a house: façade brick, insulation, foam concrete, rough plaster, fine plaster, wallpaper. Or layers of a flat roof: technoelast, screed, insulation, vapor barrier, floor slab.

And each layer individually resists heat transfer, i.e. prevents the building from cooling down when it is colder outside than inside or, conversely, from heating up when it is cooler inside than outside.

Each of these materials is characterized by its own thermal conductivity coefficient. And each layer has its own thickness. Foam concrete block 200mm, floor slab 220mm, technoelast with powder 4mm, etc. Therefore, for each of these layers, the heat transfer resistance Ri-value can be determined: the lambda and thickness of each layer are known. And, the higher the Ri-value, the better the layer works as thermal insulation.

The total heat transfer resistance Ro is calculated as the sum of the heat transfer resistance of each layer of the structure. Therefore, if the wall consists of 6 layers of different materials, then R1-value, R2-value, ..., R6-value should be determined, and then summed up.

From the formula R-value = δ / λ, it is clear that the smaller λ of the material used, the smaller the layer of this material, and, conversely, if the structure consists of layers of materials with large lambdas, then the layers should be thick.

Behavior in various chemical environments

| Reagents | Concentration, % | Durability |

| Tap water | – | St |

| Sea water | – | St |

| Hydrochloric acid | 36 | Nt |

| Sulfuric acid | 45 | St |

| Phosphoric acid | 40 | St |

| Sodium hydroxide | 40 | St |

| Ammonia water | 25 | St |

| Nitric acid | 68 | St |

| Acetone | – | Nt |

| Ketones | – | Nt |

| Carbon tetrachloride | – | Nt |

| Toluene | – | St |

| Gasoline, petroleum products | – | St |

| Soda | – | St |

| Ethyl acetate | – | Nt |

| Methyl alcohol | 96 | St |

| Ethanol | 96 | St |

| Ethers | – | Nt |

| Acetic acid | – | St |

| Mineral oils | – | St |

| Vegetable oil | – | St |

| Formic acid | – | Nt |

*St – resistant, Nt – unstable

Polyurethane foam has proven itself to be a material resistant to major chemical irritants. It resists evaporation of many chemical elements better than polystyrene foam, if their concentration does not exceed the norm. PU foam cannot be dissolved with gasoline, diesel fuel or various oils. Many concentrated acids are not able to destroy its structure.

Polyurethane foam can be used to protect metal surfaces. During its application to the metal, two layers of film are formed. The first fits tightly to the surface, and the second protects against chemical reagents.

Resistance to open fire

This is an important parameter when choosing insulation. It is no secret that in the event of a fire, the intensity of fire spread largely depends on the flammability of the insulating material. According to GOST 12.1.044-89, polyurethane foam belongs to the flammability groups G2 and G3. According to this classification, polyurethane foam is not an active source of combustion. It does not support the fire itself, but can only be ignited from other sources.

Important! Polyurethane foam will immediately go out if the fire is removed from it. Self-extinguishing is an important property that applies to all its types.

Density

An important parameter affecting the load-bearing capacity of insulation. For various purposes, material with its own density is provided. The range of density values for polyurethane foam is 8-80 kg/m3. Open cell material has a lower density than closed cell material.

Density of various types of polyurethane foam

Main responsibilities of the contractor

If you are working with polyurethane foam, you should consider several requirements:

- When performing work, you must strictly adhere to the rules of use for a specific recipe.

- All work processes must be recorded in a special journal.

- The thickness of the foam spraying is calculated based on the documentation provided by the manufacturer on the recipe and other parameters.

Those responsible for performing the work should provide a report of all processes used so that potentially dangerous deviations can be identified at an early stage.

Lifetime

Most manufacturers indicate a service life of 20-30 years. This is the warranty time during which the useful properties of the material are within acceptable limits. Recent studies by European scientists have shown surprising and encouraging results. When demolishing houses built 40-50 years ago using polyurethane foam, scientists found that its properties remained virtually unchanged. The structure and texture remained the same as originally. Further laboratory studies only confirmed the durability of this material.

Environmental friendliness

An important parameter that modern builders are paying more and more attention to. During the production process, polyurethane foam goes from liquid to solid in 30 seconds. After this, harmful fumes from its surface stop. If it is heated to 450 Cº, carbon dioxide and carbon monoxide will begin to be released. However, the same thing can be observed when wood is heated.

Polyurethane foam does not emit compounds harmful to the human body

Spray layer thickness

Most experts agree that the thickness of the spray layer for one pass should be about 25 mm. In fact, the optimal layer thickness should not be 15 mm. Then, in the standard recommended insulation for many regions of the country - 50 mm, several layers can be placed at once. This further increases the level of impermeability by increasing the degree of protection.

It is important to understand that if work is carried out in difficult conditions and the employee does not have the proper level of qualifications, a large error in application may occur. Then the design vapor permeability of the composition will be violated.

Much attention should be paid to the working conditions. All specialists must be equipped with personal protective equipment. Access to the site by strangers during the spraying process is prohibited - this can lead to poisoning and other health problems.

Positive and negative properties of polyurethane foam

For a more convenient understanding of the essence, properties and scope of the material, you need to have an idea not only of the physical and chemical properties, but also know its positive and negative sides.

Positive

- Polyurethane foam has good adhesion. It adheres to wood, metal, and concrete surfaces without any problems. It does not require additional fasteners. Due to its elastic structure and method of application, polyurethane foam fits well on uneven substrates. Before applying it, the surface does not require additional treatment with primer or paint.

- PPU has a low cost. It is produced directly on the construction site by mixing two components. There are no costs for additional transportation and manufacturing.

- Polyurethane foam is a lightweight material that does not load building structures.

- In addition to heat and sound insulation, polyurethane foam strengthens load-bearing walls, making the structure stronger and more durable.

- It is practically unaffected by extremely low and high temperatures. PU foam is not destroyed by cyclic freezing and thawing.

- The polyurethane foam coating has a monolithic structure. There are no gaps for the appearance of cold bridges. The wind doesn't blow through it.

Negative

- Polyurethane foam quickly degrades under the influence of ultraviolet rays. Therefore, it does not remain open, but requires protection. It can be covered with a layer of paint or plastered. The use of various cladding panels is also suitable.

- Polyurethane foam is a non-flammable material. Still, it is not recommended to use it in places of possible contact with open fire. If this is technically impossible, then the polyurethane foam is covered with fire-resistant plasterboard.

Application area

Liquid two-component polyurethane foam serves as an excellent insulation material for any structural elements of frame, brick, block and panel buildings, since its low weight does not create serious mechanical loads on house structures, including lightweight ones.

Good adhesion of polyurethane foam with all building materials allows you to spray insulation on vertical and inclined surfaces: facades, roofing, walls inside the house, ceiling. Excellent thermal insulation properties coupled with fairly high moisture resistance make this type of insulation attractive for thermal insulation of country houses, attics, balconies, floors (along joists). Low level of moisture absorption - foundation.

Attention: the use of the material under compressive loads reduces the thermal insulation effect to zero, and therefore polyurethane foam is not sprayed under the screed and “wet facade”.

Polyurethane foam insulation is also used in other industries. It is used to insulate freezers and is sprayed onto pipes of heating systems. Recently, in industrial construction they have begun to use ready-made sheet material for sandwich panels, when liquid polyurethane foam is poured into molds at the factory.

Application technology

The two components are fed into the mixing tank. There they are mixed under pressure and sprayed onto the surface to be treated using a gun. After a few seconds, the mixture sharply increases in volume and quickly hardens.

Method of applying polyurethane foam

Important! To apply polyurethane foam, special equipment and personal protective equipment are required. Therefore, it is better to entrust this process to professional construction organizations.

Polyurethane foam is a quality material in all respects. Savings of time and money can be 50-70% compared to using traditional insulation. Work can be carried out all year round. Technologies do not stand still, so insulating building structures using polyurethane foam will become cheaper and more reliable.

About catalytic mixtures

When carrying out spraying work, it is important to select the correct catalytic mixtures. Tertiary amines with high levels of activity are common. They are mixed with other amine catalysts. This helps greatly increase reactivity.

The specialist should pay attention to the degree of catalyst concentration. If it is too low, then the entire sprayed layer will gradually flow down the surface. This creates sagging and problems with leveling the coating.

How to install

One of the most common methods is spraying. Using this method, the material holds well and is used economically; it is suitable for structures with complex geometry, protrusions and recesses. For the process to be successful, you need to:

- • Make sure that the wall or other surface is dry.

- • No high humidity, rain, hail or snow.

- • The wind does not exceed weak 5 m/s, and it is better to protect the work area from it.

- • Make sure that the coating area is warm - not lower than +10 degrees.

- • Heat the mixture - about +18-25 degrees at the time of application; cold is difficult to work with and does not hold well.

- • Apply a layer of no more than 3-5 cm, if thicker is required - in 2-3 steps after drying.

The room must be ventilated. The person should wear a special suit, mask and respirator. Start with difficult areas: pipes, convex or concave parts, ventilation hatches or electrical distribution boxes.

Helpful Tips:

- • It is recommended to apply the composition in several layers. This way the effect will be more significant and adhesion will be higher. It is important to ensure that the previous layer is completely dry. Especially significant on walls with signs of destruction. Here it will lie unevenly and will require 2-3 additional sprayings to even out the area.

- • Before purchasing, you should consult with a specialist to choose the right brand of polyurethane foam with the required impermeability. This will save money and time spent on repairs. You can purchase high-quality, high-strength material.

- • If you apply polyurethane foam taking into account all the requirements and advice, then a coating will appear on the surface that will last for many years and will perform its tasks until the end of its service.

This material is used to insulate the foundation and external walls if necessary. It is also used to treat main pipes to retain heat in them. Mounted on balconies and loggias, used inside toys and sponges for washing dishes. This is a large part of production, which is involved in various fields. It’s easy to purchase, and it’s easy to apply. The result is of high quality and retains its beneficial properties for many years if handled correctly.

Review of manufacturers

In order for the insulation of the house to go without problems, and for the polyurethane foam to be of high quality, you need to purchase it from well-known manufacturers. There are several most popular companies:

- SYNTHESIA ESPANOLA SA produces different types of polyurethane foam, the materials are of high quality and ease of use;

- Ecotermix produces various thermal insulation systems, sprayed types of polyurethane foam;

- Demilec produces environmentally friendly thermal insulation based on polyurethane foam;

- Bayer is the world's leading chemicals manufacturer.

Table of thermal conductivity of materials

| Material | Thermal conductivity of materials, W/m*⸰С | Density, kg/m³ |

| Polyurethane foam | 0,020 | 30 |

| 0,029 | 40 | |

| 0,035 | 60 | |

| 0,041 | 80 | |

| Expanded polystyrene | 0,037 | 10-11 |

| 0,035 | 15-16 | |

| 0,037 | 16-17 | |

| 0,033 | 25-27 | |

| 0,041 | 35-37 | |

| Expanded polystyrene (extruded) | 0,028-0,034 | 28-45 |

| Basalt wool | 0,039 | 30-35 |

| 0,036 | 34-38 | |

| 0,035 | 38-45 | |

| 0,035 | 40-50 | |

| 0,036 | 80-90 | |

| 0,038 | 145 | |

| 0,038 | 120-190 | |

| Ecowool | 0,032 | 35 |

| 0,038 | 50 | |

| 0,04 | 65 | |

| 0,041 | 70 | |

| Izolon | 0,031 | 33 |

| 0,033 | 50 | |

| 0,036 | 66 | |

| 0,039 | 100 | |

| Penofol | 0,037-0,051 | 45 |

| 0,038-0,052 | 54 | |

| 0,038-0,052 | 74 |

- Environmentally friendly.

This factor is significant, especially in the case of insulating a residential building, since many materials emit formaldehyde, which affects the growth of cancerous tumors. Therefore, it is necessary to make a choice towards non-toxic and biologically neutral materials. From an environmental point of view, stone wool is considered the best thermal insulation material.

- Fire safety.

The material must be non-flammable and safe. Any material can burn, the difference is at what temperature it ignites. It is important that the insulation is self-extinguishing.

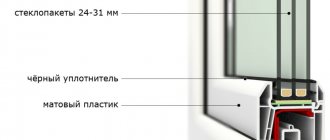

- Steam and waterproof.

Those materials that are waterproof have an advantage, since moisture absorption leads to the fact that the effectiveness of the material becomes low and the useful characteristics of the insulation after a year of use are reduced by 50% or more.

- Durability.

Content

- Comparison of polyurethane foam with other insulation materials

- Expert conclusions

- What does it look like?

- Price and forum reviews

- Video

First of all, I am interested in the question: in what situations, for the thermal insulation of what kind of structures is it advisable to use polyurethane foam spraying? Is this only effective for pipes? Or for the surfaces of houses too?

Using this technology, numerous structures are now successfully insulated:

- Facades and foundations of buildings;

- Floors (both attic and interfloor);

- Walls;

- Roofing structures (both outside and inside);

- Various types of containers;

- Industrial refrigerators (including automobiles) and refrigerators;

- Hangars, warehouses, workshops;