The window sill is an integral part of the window opening. And since PVC windows are now a big priority, this part should also be made of plastic. Without this element, the interior of the room looks unfinished and uncomfortable.

But with prolonged and improper use of window sills on a variety of surfaces, this part of the window may require restoration. And we don’t always know how to update and how to repair a plastic window sill if cracks and chips appear, not to mention the change in color and deformation.

When is window sill repair necessary?

Despite the strength, durability and resistance of plastic to external influences, there are situations when the material deteriorates over time. Window sill repair is necessary in the following cases:

- chips, severe scratches, and cracks appeared on the surface;

- the plastic has turned yellow, which affects the appearance of the entire window structure;

- the seal is broken, causing cold air, dust or moisture to enter the room;

- There is a desire to replace the window sill with a wider and more functional one.

It is not always necessary to replace the window sill; often the problem can be solved by repair work using liquid plastic, chemical cleaners, putty or decorative film.

Materials for work

The market offers a wide range of materials and products for restoring aged or damaged window sills. Among these repair mixtures, the following compositions are most often used :

- Paint thinner or acetone to remove old paint.

- Putty for wood or plastic, if necessary, to seal cracks.

- Polymer elastic sealants that can elongate and not lose elasticity over time - for sealing and sealing seams.

- Fire-resistant penetrating liquid mixtures to protect wooden and chipboard structures from fire.

- Antibacterial compounds.

- Water-repellent chemicals are especially relevant for chipboard and MDF materials.

- Polishing compounds for stone and glass window sill boards, which are used in conjunction with special soft abrasives.

Advice. It is recommended to purchase materials and protective coatings from well-known manufacturers that have gained popularity in the consumer market, and their products have many reviews on online forums from satisfied customers.

Reasons for restoration

Plastic is a practical material and easy to care for. PVC products are easy to install. There is a wide range of colors, and the cost of PVC windows is affordable. But sometimes, after long-term use, it is necessary to restore a plastic window sill.

This element may require restoration in the following cases:

- Chips and scratches;

- Cracks;

- Traces from dishes and other objects;

- Spots and swellings;

- Color changes.

For your information! The main disadvantage of plastic is its susceptibility to mechanical damage.

Repair of a PVC window sill is carried out depending on the type of damage. Sometimes it is enough to use restorative agents, in other cases minor repairs will be required. If the damage is significant, you may need to replace the element or use special pads.

We also recommend updating the paint on the window sill.

Use of plastic pads

Onlays – prompt assistance in restoration. This product allows you to quickly eliminate defects without leaving a trace. They come in white or imitate different types of wood. The most famous manufacturer of linings is Werzalit. Price from 50 rub./piece. The cover is attached with mounting adhesive (Acrifix, Weiss, Cosmofen). Before attaching it, you need to level the surface with putty, additionally clean and degrease.

Rice. 4. Overlays for plastic windows

Common damage

Most often, the surface suffers from household damage. Such as:

- sunburn, resulting in yellow spots;

- cracks, chips, and scratches;

- chemical damage;

- traces from hot objects;

- flower pots leave traces and stains of various types;

- pet claw marks;

- surface subsidence in the center.

Plastic window sills are susceptible to similar troubles.

There are scratches on the window sill

Scratches on the windowsill can be caused by animal claws. Mechanical damage from any object will leave a mark. Careless movement of indoor plants is also dangerous for plastic. If the window sill is laminated, then shallow scratches can be easily removed. Use a marker that matches the color of the surface. Either white or neutral. Obvious scratches can be smoothed out with white sandpaper. Then apply Cosmofen polish to the surface. It contains acetone. Cosmofen dissolves surface film. You need to distribute the product evenly over the entire area of the scratch. After drying, you need to wipe the surface with a dry cloth. For deeper scratches, it is better to take solvent 646 (from 80 rubles). To level the surface, you should polish the treated area.

The appearance of cracks in the window sill

Cracks in plastic window sills appear infrequently, but it is possible. The reasons for their occurrence are due to violations of installation techniques, temperature changes or strong mechanical stress. Small scratches can be easily removed, for example, with Cosmofen polishing compound. Or sand the surface. You can also treat it with plastic putty:

- COSMOFEN RM-MINI – 620 RUR;

- Found Elisilk PP37 W - from 450 rubles;

- Knauf Fugen – from 400 rub.

It is better to fix medium-depth cracks with white silicone sealant. First you need to clean the work area with water and degrease. To remove the crack between the wall and the window sill, you will need foam. After it hardens, you need to cut off the excess. A special sealant is applied over the foam. A suitable option is acrylic-based for white plastic.

The appearance of traces from flower pots on the windowsill

Plastic is resistant to stress and moisture. But over time, it can turn yellow where houseplants are. Systematic watering may leave residual water under the pot. This will cause the window sill to turn yellow. To remove these marks, you need to treat the surface with a soap solution. Wipe dry. Or use another way:

- alcohol;

- acetone;

- hydrogen peroxide;

- ammonia.

After treatment, be sure to wipe the area with a dry cloth. There is a good recipe for bleaching yellowness from plastic. Prepare a mixture of peroxide and powdered bleach. For 500 ml of cold water, 1 tbsp is enough. l. peroxide and 1 tbsp. l. bleach. Wipe the pot mark well. If necessary, repeat several times.

Window sill damaged by hot objects

An unextinguished cigarette or a hot mug can melt the plastic. Eliminating this defect is more difficult. You need to use pads. They are quite easy to install; you will need acetone or alcohol for degreasing and any acrylic-based glue. Removing the window sill is advisable in case of deep marks from hot objects. In this case, the surface cannot be restored.

Deformation of the window sill surface

In case of deformation, it is also worth using pads. When plastic is deformed due to gravity or temperature changes, it cannot always be restored. In this case, the strength of the plastic changes. The trim will give the window sill an attractive look. But its re-deformation is a matter of time. You will still need to replace the old window sill with a new one.

What products can be used to fill screw holes in a plastic window frame?

To seal holes from self-tapping screws, any sealant, putty or glue that has the following characteristics is perfect:

- combined with PVC;

- moisture resistance;

- resistance to temperature changes;

- does not change color over time.

Liquid plastic Cosmofen 345 is a sealing agent used for sealing the seams of window structures and gluing elements made of solid PVC.

Features of Cosmofen 345 sealant are resistance to aging, sunlight and other natural influences.

- color – white and transparent (can be tinted if necessary);

- when hardening, it takes on a visco-elastic structure;

- pre-hardening time – 8-10 minutes;

- complete hardening time – 24 hours at room temperature;

- The minimum temperature of use is +50 degrees.

Ultra-F façade putty is a product for exterior finishing work. Its features are excellent adhesion (adhesion) to concrete, brick, wood and PVC, the product is resistant to mechanical stress and natural influences.

Technical characteristics of Ultra-F:

- color – gray;

- drying time – 3 hours;

- complete drying time – 12 hours;

- The minimum temperature of use is +50 degrees.

Liquid nails of any brand are an adhesive for construction and installation work. They contain rubber and polymer substances. The bonding is so strong that it appears as if the surfaces being glued are nailed down with real nails.

To use liquid nails to repair a metal-plastic window frame, you need to select the color of the substance to match the frame and follow further instructions for use.

Whatever method you choose, the main thing is not to forget about safety precautions and use personal protective equipment (gloves and a long-sleeve shirt), and also do not inhale the fumes of adhesives. If you are persistent and careful, you can achieve an ideal result - the hole from the screw will be difficult to see even with a detailed examination of the surface of the frame.

Window sill upgrade options

There are many ways to restore plastic window sills, and repairing these elements has a number of advantages over complete replacement. It's simple and doesn't cost much work. In any case, PVC remains the most affordable material. Laminated surfaces are especially loved by customers. They look aesthetically pleasing, last a long time, are wear-resistant and reliable.

Restoration using putty

You can restore a damaged surface using a special material - a mixture of Reparaturset or Fenoplast, popularly called putty. It can be used if the damage is minor. It is sold in construction stores, the instructions for use are simple.

The consistency of the material resembles liquid plastic, therefore it is actively used in restoration work. It fills gaps and cracks, due to the fact that the mixture penetrates deep into the damaged area. For the best effect, the dry mixture is diluted not with water, but with a primer.

It is easy to restore a plastic window sill with this material; you should work with it immediately after preparation. The putty is applied to the surface and leveled. The composition dries in 15-20 minutes. After drying, the treated area is sanded with fine sandpaper and polished.

Advice! Before repairing major damage, it is worth practicing working with the material in an inconspicuous place.

Liquid plastic or acrylic

You can repair a plastic window sill using liquid plastic. The flowing substance perfectly seals all scratches, including deep ones, cracks and dents. This is an excellent option to cope with even significant damage. To eliminate deformation, you should use a ready-made composition.

All recesses are sealed with liquid plastic until the surface becomes even and smooth. The only caveat is that when restoring an old window sill, such patches may differ in shade from the rest of the surface. In this case, you can cover the product with a completely decorative film.

Liquid acrylic has a similar effect. This material is expensive, but it not only improves the decorative properties of the product, hides all defects, but also strengthens the surface. Liquid acrylic allows you to change the color and texture of the surface. The question remains that it is difficult to work with this material without special training.

Restoration using onlays

What to do if the plastic window sill is cracked? PVC plates will come to the rescue. Overlays are created for sheets no more than 6 cm in thickness. This is the simplest and most economical method of restoration, since it does not require any special skills. The problem area is hidden under a cover made of pure polyvinyl chloride. It is resistant to negative factors.

The overlays are installed as follows:

- The damaged area is filled with glue.

- A part equal in size to the surface of the window sill is cut off.

- The plastic is degreased and coated with an adhesive.

- The pad is installed in place and pressed down with a heavy object.

- To dry completely, leave the structure for 6-8 hours.

- The joints and cracks are filled with colorless sealant.

Some linings are simply released after drying from the protective film. Others need to be bent to the shape of the structure using a hair dryer.

Important! High temperatures should not be used when working with laminated and glossy overlays. They quickly lose their aesthetics.

Using overlays is the best way to repair a plastic window sill with your own hands.

If restoration work does not make sense, the window sill is dismantled and replaced with a new one. It is worth knowing that some companies working with PVC windows provide a guarantee under which damaged elements can be replaced at the expense of the manufacturer. Proper operation and proper maintenance will allow you to extend the service life of the structure.

Chemicals

How to remove scratches from a plastic window sill? Plastic is a durable material. But it is not immune to the appearance of traces of improper use and yellowing.

There is a special coating on the plastic surface of windows or window sills - film. You can tidy it up using special cleaners based on solvent.

If there are only a few problem areas on the surface, the product should be applied locally. If the entire window sill has lost its appearance, you can apply the composition to the entire area.

Chemicals will dissolve the yellow layer, and the surface will sparkle white again.

Laminated Film

You can repair the window sill of a plastic window with your own hands using laminated PVC film. Before you start gluing, you need to level the entire slab using putty or liquid glue.

Step-by-step instructions for gluing PVC film:

- A precise pattern is made on the back side.

- The edge is bent on one side and the film is fixed.

- Using a spatula or towel, smooth the coating over the entire area.

- When gluing the corners, cuts are made so that the material lies evenly on the surface.

- If there are still bubbles under the coating, you can pierce them with a needle and release the air.

In difficult places, you can use a hairdryer, which will make it elastic.

This type of work is easier to do with a partner.

There is a wide range of film designs available on the market. It is important to remember that this method of repairing a plastic window sill is only suitable for subsequent careful use.

Temperature changes and animal claws can quickly render the film unusable.

Using liquid acrylic

Liquid acrylic perfectly hides all defects of a plastic window sill. It is difficult to carry out restoration using this method on your own. Installation requires skill in working with the material, but the effect is excellent. The window sill looks like new. For restoration, you can use bulk acrylic (price is per liter):

- Art-eco – 2400 rub.;

- Art-Array - from 3900 rubles;

- Plastol – from 800 rub.

Rice. 5. Liquid acrylic on a plastic window sill

The material additionally strengthens the surface of the window sill. Acrylic can be used to change the color and texture of the window sill. Perfectly hides cracks, scratches and chips.

Step-by-step instruction

Overlays for Werzalit window sills

You can update a plastic window sill without removing it using PVC overlays. The product is designed to quickly eliminate defects of any complexity. In stores, the product is presented in white or with imitation wood species. A well-known manufacturer of linings is Werzalit. The element is attached with mounting adhesive, for example, Acrifix or Cosmofen.

Advantages of overlays:

- budget solution;

- easy installation;

- reliability;

- water-repellent effect and protection against UV radiation;

- different textures.

To repair a plastic window sill, use the instructions:

- Treat the surface with cleaning products to remove dust, grease and stains. Level the surface with putty or fill the deformed areas with glue.

- Measure the depth of the window and cut off the excess from the lining.

- Treat the product with alcohol.

- Apply a thin layer of mounting adhesive. Install the pad and place a heavy press on top. Leave for 6-8 hours for the materials to adhere and the assembly adhesive to dry.

- Fill the groove between the window sill and the trim with silicone.

- Before installing the plugs, measure the length of the product and cut off the excess with a saw. Apply glue and secure the parts at the ends. Remove the protective film after the composition has completely dried.

- After gluing the overlay to the old base, heat the edge of the plate with a hair dryer and bend it. Do not heat treat laminated or glossy parts as this will ruin their appearance.

You can repair the window sill in other ways - the choice of technology depends on the type and degree of damage to the surface.

It is recommended to change the structural element of the window if its integrity is compromised.

Proper and timely care preserves the appearance of the product for a long time.

Removing the plate

If all of the above methods for restoring window sills are not suitable or the plastic is very swollen, and you no longer know how to seal the plastic window sill, you can try to radically get rid of the problem by completely replacing the part.

Dismantling the element requires some effort:

- Cut off the mounting foam and carefully pull the element towards you, holding the slopes.

- We remove the vacated space from garbage.

- We place the new plate according to the dimensions of the old window sill.

- We supply support rails.

- Lubricate the side of the connection between the plate and the window with silicone sealant.

- We install the new window sill into the slot, checking it with a level.

- We fill the voids with polyurethane foam, and place a weight on top of the part.

- Remove the protective film after the foam has dried.

Important! Before giving preference to PVC windows, you should pay attention to the fact that some companies provide a guarantee for replacing the window sill if it is damaged. .

If the window sill is severely damaged, it is recommended to replace it

Installing a PVC window sill is not such a complicated process, but it requires attention and perseverance. If you choose between replacing a plastic window sill and restoring it, then the second option, of course, is more attractive in terms of saving money, the absence of waste and the variety of color palettes. And if you use a plastic cover, then the list of materials from which the window sill can be made is not limited to plastic. It can be concrete, wood, brick and metal.

It turns out that dismantling and restoring window sills with your own hands generally depends on the deformation of structures, the availability of funds and free time. And in order for this interior detail to serve for many years, you should use it for its intended purpose and properly care for the plastic texture using products specifically intended for it.

Window sill repair: restoration of wooden products

Wood is a very soft and pliable material that can be restored in almost 100% of cases. The only exceptions are those wooden window sills that have rotted and turned into dust. In all other cases, there is only one obstacle in the process of window sill restoration - a large number of layers of paint that will definitely have to be removed. This is the first stage of work related to solving the question of how to repair a wooden window sill with your own hands? There are several ways to remove old paint from a wooden surface.

- Chemically - here you will need a remover for old paint. It is applied to the surface of the window sill and after a few minutes the paint bubbles, after which it can be removed with a spatula. This option has a lot of disadvantages. Firstly, the remover is very toxic. Secondly, each layer of paint will have to be processed separately.

- Temperature. The paint is heated to a high temperature using a hair dryer, after which it becomes soft and pliable for removal with a spatula. This option has only one drawback - the length of the process.

- Mechanical method, which involves the use of a grinding machine. Just like the previous option, it has several disadvantages. Firstly, the machine is not able to remove the paint in the corners and along the window - here you will have to peel it off with your hands. Secondly, you can go broke on abrasive material. Thirdly, this is a very dirty process.

Wooden window sill repair photo

Alternatively, if the wooden window sill can be carefully dismantled, the old paint can be burned using a blowtorch or autogen - naturally, this should not be done in an apartment, since the volatile remains of burnt paint are very toxic.

You don’t have to worry about completely removing paint from a wooden window sill - this option is acceptable when the product will be painted again. In this case, the surface of the window sill will only need to be sanded to remove sagging old paint.

After such preliminary preparation, the old wooden window sill will need to be puttied to remove various kinds of cavities, potholes and large scratches, then remove dust from it and treat the surface with a degreasing compound (solvent) and only then apply a new coat of paint. It should be noted right away that this is best done with a roller and not in one layer - at a minimum, painting should be done in two layers, each of which should dry thoroughly within several days.

Blowing from under the windowsill - how and with what to seal the cracks for the winter

Winter, cold wind, as a result, drafts and blows from the window, neither the owners of new plastic nor the owners of old wooden windows are immune from this. Insulation of windows in an apartment or private house should extend to the spaces above and below the window sill, because there may be cracks into which it will blow.

What to do if it's blowing from under the windowsill? How to identify the cause and eliminate the gap?

If the window was recently installed, you should contact the company that performed the installation. If the warranty period has expired or you did the installation yourself, you need to consider ways to solve the problem yourself.

Blowing from under the window sill is possible if it is installed incorrectly, or if the mounting foam that foams the space between the window sill and the wall sag.

Methods for insulating a window sill depend on which unit is the source of the blowing.

Blowing between the window sill and the window - how to eliminate the gap

Laying a blanket over the windowsill The simplest, but not very aesthetically pleasing way to eliminate drafts is to place a barrier between the source of the draft and the room.

The method is good as a temporary measure until repair work is carried out to eliminate the blowing.

How to seal a gap between a window sill and a window

Seal the gap with sealant

Seal the gap between the window sill and the window with sealant To ensure tightness, it is enough to purchase a transparent sealant, clean the area where it is applied from dust, degrease and wipe dry, then cut off the tip of the tube nozzle and squeeze out the sealant in a thin layer.

Note that when decorating a sealed seam above a window sill, you need to do the work quickly, in one movement, so that the seam turns out beautiful and not intermittent. In this case, part of the sealant that will accumulate on the coin will be consumed in those places where there is not enough of it, and after the seam is formed, the excess sealant is removed from the coin.

During the process of forming the seam, it is possible that part of the sealant will accumulate behind the edges of the coin and harden on the frame and window sill. There is nothing wrong with this; after hardening, the sealant can be easily removed.

The advantage of this method is that the work can be completed in just a few minutes. However, the seam provides complete tightness for 1-2 years after application. This is due to the fact that the sealant gradually moves away from the plastic base or paint during cleaning, in particular washing the window sill. In addition, over time it becomes darker, and one gets the impression that the window sill where it meets the window frame is dirty.

Close the gap between the window sill and the window with a profile

The method consists of forming additional protection for the sealed seam with a plastic strip (profile).

Work order:

– prepare a plastic profile for the bathroom. Profile configuration – internal corner. Length equal to the length of the window plus 20-30 mm;

– cut off the perforated part. How to do this is shown in the picture;

How to cut an internal corner profile to seal the gap above the window sill Make holes in the corners of the slopes along the edges of the window sill - make holes 10-15 mm deep in the corners of the window sill. These are future seats for the inner corner;

– clean the junction of the frame and the window sill from debris, dust, grease and wipe dry;

– fill the gap with sealant. This will compact it;

– cleaning the seam. If the seam is not very large, you can skip this step. Otherwise, you need to remove excess sealant with a coin;

Insert the profile (reverse corner) into the recesses above the window sill - place one end of the inner corner blank into the hole filled with sealant at a distance of 10-15 mm; Press the profile along the entire length of the window sill - carefully pressing the profile against the sealant, secure it along the entire length of the window;

– insert the second end of the profile into the prepared bed.

The advantage of this method of window sill insulation is that, despite the labor intensity, after sealing the cracks and holes, you get a neat, moisture-resistant and durable corner.

Blows from under the sill of a plastic or wooden window

The reasons why it blows from below the window sill are due to an insufficient amount of mounting foam, which is used to fill the distance between the wall and the window sill after installation, or due to its subsidence.

How and with what to seal foam under the windowsill

There are two options for eliminating blowing.

Sealing foam under the window sill The first one is suitable, if the window was installed recently and work on decorating the window opening has not yet been carried out, you can remove the window sill and blow foam over the junction of the wall and the window frame. After this, install the window sill in place.

Window sill repair process on video

Why does water accumulate on the windowsill of plastic windows?

Often, after the blowing has been eliminated, users are faced with the fact that complete tightness leads to water accumulating on the windows and sills of plastic windows. This is condensation that forms for various reasons, in particular:

- due to lack of ventilation,

- due to the significant width of the window sill. It protrudes beyond the heating radiator and the warm air does not have time to warm up the glass and prevent the appearance of moisture;

- high indoor humidity. The appearance of condensation is typical for the kitchen or for rooms in which renovation work is being carried out;

- low temperature in the rooms;

- defects in window installation and slope insulation.

How to get rid of condensation on a windowsill:

- install a convection valve;

- remove all unnecessary things from the windowsill, in particular potted indoor plants;

- replace the heating radiator or replace the window sill with a narrower one;

- Ventilate the room periodically.

How to eliminate condensation on PVC windows is shown in the video

Do-it-yourself window sill repair: restoration of the concrete surface

Now such window sills are practically no longer used - they were in use during the Soviet Union and we can say that since then they have already sunk into oblivion. Nevertheless, they are still found in old houses and apartments and attract people with their strength and durability. In a good way, such products need to be changed, but if there is such a need, then they can be restored. This is done in a very interesting way.

- To begin with, as in the case of a wooden window sill, it is necessary to carry out a series of preparatory work - that is, remove the paint that falls off over time in layers, sand the paint that adheres well and, of course, fill up all large potholes and cavities. You don’t have to bother too much with minor damage - they are not a hindrance. After the putty has dried, the old concrete window sill needs to be sanded again, then cleaned of dust and degreased with a solvent.

- The second stage of work related to solving the issue of restoration of a concrete window sill is the installation of some semblance of formwork - it is necessary in order to keep the paint from flowing off the window sill. It is best to use masking tape as formwork - for rigidity it is better to stick it in three or even four layers. You should not raise it too high above the plane of the window sill, as this will result in loss of rigidity. Five millimeters will be enough.

- Next comes the most interesting part. Take a can of paint (nitro enamel or oil), mix it well and simply pour it onto the windowsill. You will have to help a little with a spatula - the paint needs to be distributed in a more or less even layer. Do not smooth it, but simply push it in the right direction - in general, it should spread on its own. Only with this formulation of the question will its upper surface be perfectly smooth and, most importantly, glossy. Don't believe me? You can simply pour a large drop of paint onto the plywood and let it dry completely - you will be surprised how perfect and beautiful the stain will be.

Window sill repair photo

Causes of defects in plastic

It is difficult to call a plastic window sill the most durable option, since after installation a small amount of time may pass, and various defects may already form on its surface. Most of these problems can be repaired yourself, but some may be almost impossible to repair. Among the most common reasons why scratches and stains appear on the windowsill are the following:

Plastic window sills are highly susceptible to mechanical damage due to their rather soft texture.

- fairly strong mechanical actions, impacts with heavy objects, for example;

- pets can scratch the surface, in some cases very deeply;

- the formation of stains from flower pots and other objects that have been standing on the windowsill for quite a long time;

- discoloration from direct sunlight;

- chemicals or detergents containing caustic components may leave a trace;

- Cigarette butts can melt through the top layers of PVC.

Other publications in the “Windows” section. Translucent structures”

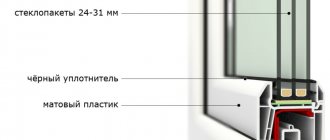

If your apartment has PVC windows with single-chamber double-glazed windows, this may be the reason why the windows blow cold. For our climatic region, it is necessary to install plastic windows with double-glazed windows. Another possible cause is cold air moving away from windows.

Requirements for the manufacture and installation of window blocks made of PVC profiles are set out in GOST 30674-99 “Window blocks made of polyvinyl chloride profiles”. “Appendix D” of this GOST provides general requirements for the installation of products (see below). It is indicated that the installation of window blocks made of PVC profiles should.