Whatever the condition of your balcony, with the right approach you can easily turn it from a dovecote into a fairly comfortable place to relax, a dressing room and even a personal office. To do this, in addition to glazing, you just need to properly insulate the balcony roof and ensure its complete sealing.

Our tips and step-by-step master classes will help you figure out exactly what materials you will need, how to install them, and what is important to take into account. In fact, everything is quite simple, and you can handle this task yourself.

Roof repair on the top floor

On upper floors, the roof can be supported on consoles or on consoles and posts.

The cantilever roof is an independent structure, its frame is fixed only to the wall, not attached to the balcony, it is easier to install, and its repair will cost less.

It has low thermal insulation and transmits heat well. Insulation measures are carried out using lightweight materials. For information about balcony roof installation errors that lead to leaks, watch this video:

The cantilever-rack roof is attached to the balcony frame and forms an integral structure with it, retains heat better, and can withstand significant loads. To seal such a roof, you can use any materials.

If your balcony is leaking, you can do the work to fix the leak yourself. Sometimes minimal costs are enough to eliminate water leaks on the ceiling or balcony wall. To avoid situations with unexpected leaks on the balcony, it is necessary to regularly carry out preventive repairs.

The best posts

- How to make a plasterboard box in the bathroom - step-by-step instructions

- Painting drywall - step-by-step instructions

- Drywall figures or how to make the interior stylish and fashionable

- Socket boxes for drywall: correct selection and installation

- Wiring under drywall: lay it out correctly

- Grouting drywall joints: materials and techniques for performing the work

- How to join drywall in corners and the process of building a decorative niche

- Installing spotlights in drywall: advice from experienced specialists

Doing the work yourself

A number of works, of course, can be done with your own hands, even if you are not a professional builder.

A number of works, of course, can be done with your own hands, even if you are not a professional builder. It is enough to study the technology of their implementation and select compatible materials that can be used in a given climate zone. Work that you can do yourself when it comes to insulating a balcony:

- Insulating the balcony floor with your own hands, read more about floor insulation here.

- Waterproofing of balcony roof and canopy

- Insulation of balcony walls from the inside

- Bringing light to the balcony

- Installing an infrared heater

- Soundproofing the balcony canopy

- Waterproofing the floor on the balcony

Do-it-yourself insulation of the balcony roof

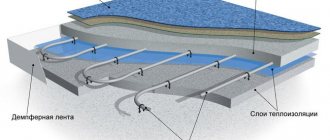

To insulate a balcony roof, you need to make successive layers in its structure. The roof of the balcony implies the presence of:

- Sprayed sound insulation or adhesive film on the balcony canopy

- Film waterproofing based on PVC or polyester

- Good vapor barrier made of anti-condensation film with a fleecy part

- Clearance for ventilation of the roof space

- Wooden log for good strengthening of the balcony roof

- Wind protection membranes with vapor permeability function

- Thermal insulation of the ceiling over the entire roof surface

- Sealing seams with foam

- Good vapor barrier insulation for balcony ceiling

- Fixings for false ceilings on the balcony

Do-it-yourself insulation of the balcony floor

As a rule, the floor on the balcony, made on your own, is made of wood.

As a rule, the floor on the balcony, made on your own, is made of wood. The boards are laid on the joists. Insulation for the floor on the balcony is installed between the joists. We must not forget about waterproofing the floor on the balcony. The surfaces between the floor and the insulation and between the base slab and the insulation need to be waterproofed to avoid the insulation getting wet and the spread of mold and mildew. When laying soft insulation, floor joists need to be done more often. This is not required when using solid floor insulation.

Do-it-yourself insulation of a balcony parapet

The parapet must be strong enough, but at the same time light. Usually, when it comes to heavy winter glazing, lightweight foam blocks or gas silicate bricks are used to build the parapet. These materials have a reduced thermal conductivity, which is a plus for their use, but at the same time they absorb moisture very well, and this should not be allowed. Therefore, the parapet on the balcony must be reliably protected from moisture and dampness. On the street side, it is logical to install siding or plastic panels. Do not neglect the installation of ebb tides. Flashings are needed above the installed glazing, under the glazing structure and above the base slab on the balcony. If lightweight summer glazing is acceptable on the balcony, then the parapet can be made on the basis of a metal frame. Usually, in this case, the enclosing structure of the balcony is left, only strengthening it.

Here is a video about how balconies and loggias are insulated with polystyrene foam, wooden slats, penofol and moisture-resistant plasterboard:

https://youtube.com/watch?v=H1se6Fl6Nms

Aluminum: universal option

Such popular sliding aluminum systems today are good for their ease of installation, price and lightness of design. Today they are only gaining popularity and delight balcony owners with durability, strength, environmental friendliness and lightness.

It is aluminum structures that are produced in the widest range of colors, which cannot but please the design soul of our compatriots. In fact, such windows can be painted in any color according to the RAL catalog, or they can be glued with a protective film to resemble antique bronze, gold or silver.

But in winter, ice often forms on the balconies of the upper floors in aluminum runners. In addition, this design is not the safest, and usually does not protect against the cold well enough. There is also an opinion that aluminum balconies are bad because they “leak”.

Although in fact, specifically when working with metal, you simply need to take into account the laws of physics and build at least a simple type of drainage system - then the balcony will turn out dry and warm. Due to the light weight of the aluminum system, it is especially convenient to install it “on the floor”, attaching it directly to the parapet on metal racks.

There is another important point that is often forgotten when talking about the balconies of the top floors: they are also not protected from burglary, like the balconies of the first floors. It is usually not difficult for criminals to get down from the roof canopy to the balcony.

So, the aluminum structure is the weakest in terms of burglary protection. It opens quite easily. Therefore, we advise you to install a grille on both aluminum glazing and PVC at once. After all, do not forget that the runs were originally designed for fire safety and the possibility of evacuation.

The fact that aluminum profiles are lightweight gives an advantage in the implementation of complex projects. For example, when a balcony is extended along a wall or a rather complex roof is made, which needs reliable but not heavy support.

Wood: for special comfort and closeness to nature Wooden glazing is made from pine or spruce frames of small cross-section. Usually there is one glass 4 mm thick, and the doors are hinged. With additional interior decoration of the balcony, such glazing helps to increase the temperature by 70°C compared to the street temperature, and reduces noise by 7-10 decibels.

On the plus side, we note that the doors themselves are small and elegant due to the high rigidity of the frames. But periodically these wooden frames need to be tinted to protect them from rotting.

Here are detailed instructions on how to install wooden glazing on the top floor:

- Step 1. Attach welded brackets to the parapet in order to slightly remove the glazing.

- Step 2. Fix a wide shelf on them and level it. Now attach a wooden shelf to it, and fix it to the wall of the house using three facade dowels.

- Step 3. Now place the frames, starting from the blank wall, one after another, first screwing them to the window sill, and then just connecting them together. Apply sealant to all seams and joints.

- Step 4: Once you're done with the side frame, begin installing the roof. To do this, you will need to attach a structure made of 50x50 mm timber to the wall of the house, which should be located slightly above the abutment line.

- Step 5. Now place the assembled roof structure under the canopy. Align along the short side of the balcony and press firmly against the wall.

- Step 6. Lay the roofing sheets overlapping each other. Secure them and foam the seams.

- Step 7. Place flashings around the perimeter of the glazing, seal the seam between the roof and the wall of the house. After this, glaze the frames, seal them with sealant and press them with glazing beads. The glazing is ready.

Wooden frames last less time than PVC or aluminum, but in their own way they are popular among connoisseurs of ecology in everything. Frameless glazing: a tribute to French fashion And about new products. As you know, the top floor has the best view of the city, and therefore frameless glazing is becoming increasingly popular.

At the same time, keep in mind that frameless glazing of the top floor balcony has some disadvantages. After all, here the glass does not travel along the lower guides, but only along the upper ones, and at the same time they weigh a lot. In order to securely fasten them, you will have to transfer the entire load to the roof of the balcony.

And finally, keep in mind that frameless glazing is, in essence, more decorative. It does not protect very well from slanting rain, cold or dust, since there are many gaps in this design. For a balcony on the top floor, this is not the best option, but such a balcony, of course, is well ventilated, there is no condensation inside, the sashes do not freeze, and the glass does not freeze. Therefore, if you are quite happy with this summer option, why not?

Tips for using profiled sheets

If the loggia is located on the top floor of the building, then using corrugated sheeting you can immediately make a roof, only it should have more stiffening ribs than the material that was used for the cladding.

For the roof, it is better to choose a profiled sheet with a larger number of stiffeners

Is it possible to prevent the loud noise that the material makes when it rains? Can. If you mount it on a thick layer of insulation. However, there is no way to completely get rid of the “drum roll”: this is the peculiarity of the profiled sheet. However, if the balcony is reliably sealed, then the sound in the apartment itself will not be particularly audible.

Using corrugated sheets, you can also install a roof on balconies, but in this case it should have more stiffening ribs.

Here it is necessary to note one banal but important thing: corrugated sheets are a cheap material. And the disadvantage in the form of loudness is more than compensated by the cheapness. Moreover, with the help of corrugated sheets, you can design the external design of the loggia as you please: sometimes people install several pieces of corrugated sheets of different colors on one balcony. So it may even be gray-brown-crimson. And that's great!

Balcony roof design type

The first point of the construction plan is the type of balcony roof construction. Its choice depends on several nuances, which must be determined immediately, since it will be difficult to make structural changes to the finished roof.

What does the choice depend on:

- Desired roof size;

- Is it planned to further glaze the balcony?

- Load-bearing capacity of floors;

- Climatic features of the area.

By comparing each option on these points, you can easily choose the appropriate one in a particular case.

Independent frame

The independent roof frame is attached directly to the external wall of the building. The support is on the side members, and angles or I-beams act as stiffening ribs. This structure is reinforced with oblique supports, which are also attached to the wall.

It turns out that an independent roof does not exert any load on the balcony itself, but at the same time, due to the lack of reinforced support, it has weight restrictions.

Advantages of an independent frame:

- easy to assemble and install with your own hands;

- suitable for small balconies with low load-bearing capacity;

- will protect the balcony from rain and snow.

Despite the rather attractive appearance and ease of installation, such roofs are installed quite rarely. This is due to the disadvantages of an independent type of roof frame:

- there are restrictions on the weight of roofing materials;

- can only be installed on unglazed balconies;

- there is a danger of collapse due to the settling of heavy layers of snow;

- strong gusts of wind can blow away such a roof;

- not suitable for wide balconies.

So such a roof is not suitable for insulating and waterproofing a balcony.

Dependent frame

The second option is a dependent roof frame, resting not only on the load-bearing wall, but also on the frame of the balcony itself. In this case, most often, immediately after the roof is installed, glazing, waterproofing and insulation of the entire balcony begins.

Pros of a dependent frame:

- can be mounted on a balcony of any size;

- there are no restrictions in the choice of materials;

- able to withstand the load of snow settling on the roof;

- together with glazing it creates a balcony completely protected from weather conditions.

There are fewer disadvantages in this case:

- it is necessary to calculate the maximum load of the balcony itself and, if necessary, strengthen it;

- higher cost.

A balcony that is completely suitable for arranging a living room, dressing room or storing seams and vegetables will have to be thoroughly strengthened and insulated. At all stages you will have to spend not only money, but also time - but the result is definitely worth it.

Selection of roofing material

When planning how to make a roof on a balcony, it is very important to choose the optimal material in accordance with specific conditions. Today there is a fairly wide range of similar products on sale.

To install a balcony roof, you can use various types of roofing material:

- Various variations of steel sheets (in the form of corrugated sheets, including laminated, galvanized, corrugated sheets, etc.) These materials have a favorable quality-to-price ratio, as they are characterized by significant rigidity and resistance to deformation, strength and durability. The balcony roof made of corrugated sheets will not bend under the influence of wind and precipitation, and does not require repair. Metal sheets can be attached to various roof structures, both dependent and independent. In addition, by installing such a covering on top, you can significantly strengthen the roof canopy. The disadvantages of this roofing material include noise from gusts of wind, raindrops and hail - however, it can be easily eliminated by installing a layer of soundproofing material, which can be purchased at any hardware store.

- Soft roofing materials - for example, ondulin, flexible tiles, roofing bitumen and roofing felt. These roofing materials will cost slightly more than metal sheets. In addition, this design is less impact-resistant, but is characterized by excellent sound insulation properties. It is also worth considering that to install a soft roof covering, it is necessary to equip a strong supporting frame - more rigid than in the case of installing a metal roof.

- Transparent roofing materials:

- in the form of sheets of cellular polycarbonate (transparent or translucent tinted plastic). This balcony roof looks very attractive and original. Polycarbonate sheets are distinguished by flexibility and special strength (no less than that of metal or concrete, and much higher than that of glass), as well as light weight, resistance to temperature changes and exposure to ultraviolet rays. The roof is made of transparent plastic and allows light to pass through perfectly; in addition, a special coating is applied to the outer side of the sheets to protect against ultraviolet radiation. These panels do not fade over time and are safe to use, as they do not crack or crumble upon impact. Due to the presence of air layers between the layers of material, polycarbonate panels are characterized by high thermal insulation properties, so it is advisable to use them for insulating a balcony room. This roofing material can be used for arranging roofs of various types;

- roofing double-glazed windows for the roof are made of special tempered glass or triplex (multilayer safety glass with polyvinyl butyral film of various shades, which increases its strength and protects it from crumbling during household impacts). Such a roof on a balcony looks very aesthetically pleasing, and is distinguished by high heat-saving properties, reliability and durability, as well as strength (it is not afraid of various mechanical influences). Installing such a roof on a balcony does not require much labor or time - usually the installation of double-glazed windows is carried out by the manufacturer. The disadvantage of this coating is its relatively high cost.

Currently, glazing of balconies with roofs in Khrushchev-era buildings is in great demand. In old houses, as an economical option, such a roof is built on the basis of wooden support trusses with a roof made of widely used roofing material - corrugated sheeting or ondulin. It is more expensive to equip a frame made of metal closed trusses. The most comfortable to use roof options are those with a roof made of corrugated sheets (with additional sound insulation of the entire roof surface and its insulation), as well as those made of cellular polycarbonate.

Why insulate the balcony roof at all?

It is necessary to insulate the roof of a balcony, and first of all, to protect against freezing and the formation of condensation inside. But there are other bonuses that you will receive if you decide to carry out such local repairs.

Let’s make a reservation right away that only roofs of a dependent type are insulated, i.e. with glazing, but an unglazed balcony does not need this, because the temperature on it is the street temperature, and there is no difference on both sides of the roof. In addition, such a roof also does not need sound insulation, because the sounds of rain will no longer be in a confined space, but will mix with street sounds.

Reason #1. Heat preservation

If you have installed glazing, then you must also insulate the roof. Keep in mind that this heat will still not be enough to comfortably spend time on the balcony in the Russian winter.

After all, the outer walls of a house cannot be insulated enough to reach room temperature. But it will be possible to create a pleasant microclimate in spring, summer and autumn. And for a home workshop or a place of relaxation and fitness, this will be enough.

In addition, the roof, especially a metal one, is always cold, and vapors easily accumulate on it in the form of drops, which then flow down and create unpleasant dampness. And steam gets onto the balcony quickly enough, just open the doors from the living room. And owners of an uninsulated balcony have to immediately open the window sash to the street to prevent condensation from forming.

Reason #2. Avoiding ice on the roof

Unfortunately, there have even been cases when the owner of an apartment is judged from whose balcony something fell on someone’s head, even if it was icicles. And they just grow where the room under an uninsulated roof has a higher air temperature than the outside one.

As a result, the snow cap constantly melts, accumulates in the form of ice and hangs from the eaves. And it is you, as the owner of the apartment, who must take care that icicles do not form on your roof. In extreme cases, you will have to constantly knock them down or come up with something as a catcher instead of a florist. Although everything can really be solved by simply insulating the balcony roof.

Reason #3. Heat protection

Few people know that roof insulation is also necessary to maintain a healthy microclimate on the balcony on hot summer days, when the roof heats up to +60-70°C in the summer, and unpleasant hot air is formed inside.

And the essence of any insulation is to create a layer between two spaces with different temperatures, and not allow it to equalize through heat transfer, or at least slow down this process as much as possible.

Those. In winter, an insulated roof will protect the interior of the balcony from the cold, and in summer – from the heat. Believe me, if you have never insulated your roof before, then in the very first summer you will feel the difference and will be grateful to yourself for the idea.

Reason #4. Noise insulation

A roof that is also insulated is more soundproofed, and in the rain the roar will not be the same as before. And it is at the insulation stage that additional materials are used to achieve 100% sound insulation - more on that later.

Reason #5. Possibility of full finishing

And finally, without insulation it is impossible to fully finish the balcony. The fact is that even a wooden lining will freeze if there is no additional layer between it and the metal roof. And the air here is not the best insulation.

In addition, if the balcony roof was damaged by hail or an object accidentally falling on it, then the waterproofing above the insulation will absorb the first flows of water. And it will be enough to disassemble the roof, replace damaged elements and return the finishing to its place.

In a word, at the very first problems, the moisture protection and insulation will suffer, and not immediately the walls and floor of the balcony. Economically, this is much more profitable.

Work tool

Foam gun

Before you insulate a balcony roof or carry out its reconstruction, you need to have the following basic tools on hand:

- Hammer.

- Gun for polyurethane foam.

- Screwdriver.

- Wood saw.

- Tape measure, pencil.

- Construction knife.

- Level.

- Stapler with staples of the required length.

Glass roof on the balcony

The top floor is often distinguished by the presence of loggias with a roof. To create a roof, you will need the following materials:

- metal tiles;

- polycranate sheets;

- corrugated sheeting;

- the required shade of Euro slate.

The glass type of roofing is quite rare, because this material is highly expensive. A more acceptable option is to use corrugated sheeting; it is durable, practical, but requires additional sound insulation, because it makes a lot of noise when it rains.

Metal tiles are better in this sense, however, they are also more expensive. In addition, it has an attractive appearance. It needs to be laid in several layers to increase its service life and create a stylish design.

Euroslate has a lot of positive qualities:

- saving money;

- tightness;

- soundproofing;

- light weight;

- thermal insulation.

Its only drawback is its high level of flammability.

A good analogue of glass coating is polycarbonate. The material is durable, but it is not heavy at all, so the reinforced concrete slab receives the minimum possible load. Among the disadvantages of the raw material are low levels of protection from external noise, heat retention, and, moreover, it practically does not prevent the penetration of the sun's rays.

Advantages and disadvantages

Metal profiles as a material with which a balcony can be finished has not lost its relevance for many years, and the demand for it is constantly increasing. It is worth noting a number of advantages and disadvantages of such a product. Advantages of using metal profiles:

- Simplicity and ease of installation;

- Product resistance to atmospheric influences;

- Not subject to corrosion and combustion;

- Sheathing a balcony with a metal profile has a service life of more than 50 years;

- Easy to maintain;

- Completely sealed;

- Presentable appearance.

In addition to this list of advantages, the presented finish also has some disadvantages. For example, during rain there will be a loud noise from drops hitting its surface, since the metal base of the product has low noise insulation properties. It is also worth paying attention to the high level of thermal conductivity, which leads to the formation of condensation on both sides of the sheet when a temperature difference occurs.

What insulation materials are suitable for a balcony roof?

Perhaps the main and basic requirements for balcony insulation are environmental friendliness and the least hygroscopicity. Please note that in summer the roof of the balcony, especially the top floor, will heat up.

Based on their shape, insulation materials are divided into three categories: shapeless, sheet and roll.

Sheet materials: polystyrene foam and polyurethane foam.

Let's consider insulating the loggia with sheet materials, specifically polystyrene foam and expanded polystyrene. You can find a huge variety of types in the store, but Penoplex polystyrene foam is considered the best. In appearance it resembles Soviet foam plastic, although it is made using a completely different technology.

A balcony in which such insulation was used turns out noticeably warm and silent. It can even be connected to the living room.

To insulate the roof of your loggia with polystyrene foam, adhere to the following rules:

- Take measurements of the ceiling, purchase the required number of sheets.

- If there is sheathing, cut the sheets to size so that they fit between the beams.

- Secure the sheets with dowel umbrellas.

- Fill all seams with polyurethane foam.

- Cover with foam foam and seal the seams with foil tape.

Regarding foam plastic at a lower price, of course, it can also be sheathed with it, but subsequent finishing is mandatory, as is ensuring complete tightness. This material will come into contact with the roof of the balcony, and in the summer, when it’s hot, it will be hot, as a result of which toxins can penetrate into the room.

Shapeless materials, use of ecowool and polyurethane foam.

Shapeless materials can be a good competitor to polystyrene foam; we include blown-in ecowool, polyurethane foam and even mineral wool. Despite the fact that it is sold in roll form, it can easily be divided into pieces and placed in the right places.

We would like to remind you that polyurethane foam is also suitable for insulating a metal roof. When it is sprayed, oxygen reacts with the components of the insulation, and the result is a quickly hardening foam.

We can confidently call polyurethane foam a reliable assistant in insulating a loggia; it is in no way inferior to its analogues. Even though it is made from non-natural materials, it is considered safe for use.

Positive aspects also include resistance to mold, rot, and microorganisms. Can be used even in constant damp conditions. And polyurethane foam can withstand temperature changes well; the quality will not change even with fluctuations from -50 to + 180 degrees Celsius. It has a good thermal conductivity coefficient (0.022 W/m*K) and relatively low weight.

Roll materials: penofol and mineral wool.

Perhaps the main advantage of mineral wool today is ease of use. It is easily divided into pieces and compressed, it is convenient to use for hard-to-reach places.

To secure the insulation, you can use thin wooden slats directly along the sheathing. You can also use nylon thread and a stapler, which will be more convenient and quick.

Laying penofol will not take much time and effort. The material itself is a silver roll insulation with a reflective coating.

It has four properties at once: vapor barrier, waterproofing, sound insulation and thermal insulation, which makes it ideal for a balcony. It is well suited for installation; it is convenient to cut and attach to the ceiling, and in addition it is completely safe for use.

It is quite easy to attach penofol to the roof of the loggia. To do this, you just need to use a construction stapler and use it to attach the insulation (reflective layer down) to the sheathing. A balcony made in this way will have all the necessary properties.

Advanced editing

Insulating the ceiling on the balcony with mineral wool, polystyrene foam / polystyrene foam requires a lot of time and labor, because you will have to work on a stepladder, constantly lifting your neck and arms up.

Tools: stepladder, hacksaw, hammer drill with concrete drill, metal profiles and hangers, dowels, foam in a gun, spirit level, ruler with pencil, glue.

Fixation points are marked on the ceiling for the suspensions to which the profiles will be attached. A layer of foil polyethylene is glued. Polyfoam / penoplex sheets are mounted in the same way, which are fixed with dowels. Profiles are mounted, onto which drywall/panels are then attached.

It is possible to insulate the ceiling on the loggia with mineral wool after the isonol layer has been laid. Then the slats are installed. Cotton wool is placed between them. The slats will serve as the basis for heavy finishing materials.

Insulating a loggia ceiling with your own hands will cost less than hiring workers, but you should still trust the professionals if you are not entirely confident in your abilities.

Post-and-beam design

In this case, the roof does not rest on the glazing, but directly on the racks connected in some way to the slab of the balcony structure. A hole is drilled in the slab and a fastening element is inserted there. A wooden block or metal profile is attached to this element. And the profile already holds profiles and trusses for installing the roof.

Such a roof is not dependent on other structures, because it rests directly on the slab. The bars or metal profile rest directly on it. This can be done using anchors, or pour a layer of cement mortar onto the slab and strengthen the posts in it.

This construction technology is acceptable if the slab is new and strong enough.

How is the ceiling finished?

It’s time to start finishing when the insulation and waterproofing work has been completed.

Before you start finishing, you need to decide on the following questions:

- How will you use the balcony? Basic goals.

- The structure should not be heavy.

- Safety. The material must be environmentally friendly and not emit toxic substances.

- Moisture resistance.

- The decoration should correspond to the overall design of the balcony and look harmonious with the floor and walls.

Popular materials for cladding balcony ceilings are:

- Wooden lining. In order for this finish to serve you longer, impregnate it with an antiseptic and moisture-repellent composition.

- Plastic panels. Installation is simple, cheap and has good properties during operation.

Stretch ceiling. The relatively low price will provide another air insulation layer. A big plus is its resistance to moisture.

The ceiling can be finished with plasterboard or other construction. A well-insulated and finished balcony will open up new possibilities for using this area; it will be suitable not only for storing things, but even for tea drinking.External sound insulation technology

The work has to be done outside, with all the difficulties that arise. Before starting the operation, it is better to consult with the service organization. If you don’t need permission to change the facade of the building, then you can start. The work order is as follows:

- inspection of the roof’s load-bearing structure and identification of possible deficiencies;

- strengthening or repairing rafters or other roofing bases, if necessary;

- installation of sound-absorbing materials.

As the main material you can use euroroofing felt, soft roofing, bitumen shingles, vibration-absorbing mastics, roofing tapes. If the work on soundproofing a balcony is done correctly, then the inhabitants of the home and their neighbors will be free from noise for many years.

Might be interesting

A soft roof will completely eliminate the noise of rain

Waterproofing when arranging a balcony roof

After laying the wooden sheathing slats into the roof frame, you will need to lay the top layer of rolled waterproofing. The panels are cut out and glued to the wooden base of the balcony roof using ready-made bitumen mastic or glue. The waterproofing sheets are laid with an overlap of 10-15 cm, the seams must be glued and rolled with a rubber roller.

The length of the waterproofing panels is cut so that the upper edge of the sheet rests 10-15 cm on the wall, in the area where the roof adjoins the concrete facade of the building. The opposite edge of the waterproofing sheet must completely cover the space between the double-glazed window frame and the roof. From the inside, a thick polyethylene film is stretched over the sheathing and moisture-resistant plywood is stuffed.

To avoid the formation of cracks, a niche is cut with a hammer drill to a depth of 0.5-0.8 cm between the edge of the waterproofing sheet and the vertical surface of the wall on brick or concrete along the entire length of the balcony roof. The height of the niche is 8-10 cm. The cut surface is cleaned of dust and coated with primer, after which the edges of the roll waterproofing panels are glued into the niche.

A groove 5-7 mm wide and 15-20 mm deep is cut above the niche using a grinder. When assembling the balcony roof, the edge of the corner strip is inserted into the groove, protecting the joint between the roof and the wall.

Laying sheets of metal tiles or metal profiles is carried out in the usual manner; the roofing material must be glued at the overlaps of the waves with mastic or other liquid waterproofing. The heads of the screws must be sealed with silicone washers. The wavy profile of ondulin, metal tiles or corrugated sheets in the junction area must be covered with a profiled wavy seal, similar to what is used for waterproofing a slate roof at the junction with a ridge beam. Otherwise, powerful winds can easily drive the flow of rainwater in the abutment area into the holes between the waves of the roofing.

The inner surface of the roof is often insulated with foamed thin-sheet polyethylene foam, polystyrene foam or extruded polystyrene foam; mineral fibers are very rarely used. Experts recommend, if the situation allows, not to rush to lay insulation under the waterproofing layer. According to their recommendation, before installation, you need to test the roof waterproofing in two or three heavy rainfalls. Only after this, if there are no comments, can you glue the foam and the inner lining of the balcony.

How to insulate a loggia ceiling or balcony roof

If the roof is leaking, then all efforts to improve the balcony will be in vain. Leaks occur for various reasons, but most often the roof becomes unusable due to the fact that the coating becomes thinner during use. Repairing and insulating the balcony roof protects against these troubles.

Why is insulation work needed?

If the material used for the roof is laid correctly, it will provide good protection from precipitation. If the material is installed incorrectly, even small loads from wind and precipitation lead to the appearance of microcracks and, as a result, depressurization of the roof occurs.

Don’t put off the issue of insulating your balcony roof. In the future, minor damage to the canopy turns into serious defects and dampness from the outside of your apartment will spread to the neighboring ones. But no one wants to quarrel with their neighbors about this.

If the roof is leaking, it needs urgent repairs. If the roof seal is compromised, the balcony cladding materials will begin to deteriorate. Restoration costs are a direct loss for you.

Varieties of visor designs

The correct approach to repair will allow you to get a practical and lightweight visor. The most popular type of roof over balconies is a lean-to canopy with a downward slope from the wall of the house. The slope varies from 15 to 75 degrees. When arranging the roof, you need to consider the following:

— a slope closer to 15 degrees will help save roofing and all other materials;

— a slope closer to 75 degrees guarantees a complete absence of moisture on the canopy. Moisture simply will not linger on it.

Required Tools

To repair the roof, prepare the following tools:

- screwdriver and hammer drill;

— a gun for applying mounting foam;

- construction stapler and level;

- knife for foam plastic;

Balcony roof repair process

Work begins with dismantling the old coating. Assess the condition of the frame. If necessary, expand it and strengthen it with additional metal corners. Further work proceeds in the following sequence:

— installation of supports. To support the new roof, you need to purchase hollow metal pipes in the shape of a triangle. Their number depends on the length of the balcony, and the angle between the tubes depends on the slope of the canopy. The pipes must be welded together. The finished supports are attached with anchor dowels to the wall of the house with a short part. The length of the dowels is 7-8 cm, at least;

- installation of sheathing. For the sheathing, take a wooden beam 40 by 40 mm. It is advisable to treat it with an antiseptic in advance. Attach the sheathing elements to the metal trusses with bolts or self-tapping screws. Cover the sheathing with plastic film or other waterproofing membrane;

— installation of roofing material. After installing the sheathing, you can begin installing the roofing material. It is not always possible to cover the canopy with one large sheet. For a large balcony, you cannot do without joints in the roof covering. For coverings made of metal tiles or corrugated sheets, galvanized screws are best suited. In this case, in the places where the material is attached to the sheathing, the risk of corrosion will be minimal;

— processing of joints. Take a good look at all the joints on the roofing carpet. If they are not tight, seal them from the inside with foam. Fill the outside with caulk and cement. Hermobutyl is ideal for these purposes. After hardening, it becomes plastic and will not crack for a long time. The joints formed between the wall and the canopy must be covered with an apron. Cover the areas where it adjoins the wall and roof with polymer mastic.

Details

Insulation tools

In order to create reliable insulation, you will need the following materials and devices:

- Hammer or screwdriver-drill.

- High quality construction level.

- A construction knife or a regular hacksaw for wood.

- Tape measure or stapler.

- Gun for polyurethane foam.

Next, we will consider the insulation process.

How to make insulation yourself

If we look at the stages, then the roof for the balcony inside is insulated in this way:

- First, you need to assess the condition of the roof and, if necessary, insulate the roof frame.

- Next, you need to fix the roofing material, lay it in one sheet, and the joints must be treated with construction sealant.

Install the soundproofing layer, and for this you should use a simple adhesive tape and apply it in such a way that it fits tightly to the roof.

Below are three methods of insulating the roof on a balcony.

How to insulate a balcony with foam plastic

The easiest way is to insulate with foam plastic using construction adhesive. A more reliable method would be to install a protective layer on the roof - self-tapping screws. The basic rule will be to carefully follow the sequence during repairs - first insulate the surface of the ceiling, and then the floor and walls. When laying polystyrene foam layers, cut out slabs of the required length and coat the surface with an adhesive layer using a spatula. Then fix it on the surface and leave until dry. All joints must be sealed as best as possible using construction foam. Next, along the overall height of the loggia or balcony, install a reinforced metal mesh, place a new layer of glue on top of the foam surface, and sink the mesh into it. After drying, clean the surface with sandpaper. Fix the selected finishing material on the foam.

Insulation of a balcony roof using mineral wool

The installation of mineral wool on a balcony roof occurs in several stages, which must be followed for a long and high-quality service of the work performed. The initial stage will be to create waterproofing for each surface of the balcony. To do this, professionals use roll coatings, for example, polyethylene film, roofing felt or pargamite. Next will be the installation of wood sheathing, and the distance between the crossbars should be at least 1 cm of mineral wool thickness. To form an additional protective layer of air, the thickness of the sheathing block must be 1 cm greater than the thickness of the insulation layer. The third stage of insulating the loggia will be the installation of mineral wool slabs.

Dense slabs can be used for ceiling finishing. Insulation instructions for insulation look like this:

- It is necessary to apply glue to the slab, which has a consistency similar to sour cream, since otherwise it will not be securely fixed.

- Afterwards, the slab goes into the prepared cell of the sheathing; first, it is bent in the middle, and then gently pressed over the total area.

- If you come across a small piece of insulation, then their total length may be a couple of cm longer than the cell.

- When finished, all gaps that appear are filled with glue.

At the end of the process, attach everything with dowels and plywood sheets, and thin slats are placed on top. Also, instead of large dowels, you can use a construction stapler or self-tapping screws.

Roof insulation with polystyrene foam

Before insulating the roof using polystyrene foam, install the balcony frame and also prepare the surfaces. The preparatory process looks like this:

- Carry out a careful inspection of the surface for smudges, as well as unsightly brown spots.

- Remove the swollen layer of building materials.

- Treat the entire surface with a special composition against fungal colonies, treat the surface with a primer for stability.

- If the loggia is leaking, fill the microscopic cracks with a special polyurethane type sealant.

- It is important to widen large gaps with a grinder; evaluate the condition of the reinforcement and cover everything with a stable anti-corrosion compound. Moisten the cracks and fill them with polyurethane foam, and after drying, cover everything with sealant.

- If necessary, continue leveling the wall surfaces and ceiling, and the finishing will help hide all flaws.

Sheathing begins from the ceiling, and a convenient thickness of an expanded polystyrene sheet will be 5 cm. Under the putty layer there is insulation with a density of 25 kg/cm 2.

The stages of insulating a balcony roof from the inside look like this:

- Mark the location of fixation, secure hangers for metal profiles.

- Carefully treat the surface with a special adhesive composition, pressing firmly and fixing for a couple of minutes, installing with self-tapping screws.

- If plaster is to be applied on top, after the glue has hardened, glue a construction reinforcing mesh onto it.

- If you plan to decorate with wooden materials or MDF panels, install a layer of vapor insulation on the foam plastic.

Sheets with a foil surface are suitable as an ideal raw material for vapor insulation for insulation.