Materials for interior cladding of balconies. Advantages and disadvantages

A balcony covered with plastic panels at one of our facilities.

PVC plastic panels, or as they are also called plastic lining, are one of the most common finishing materials used today. This finishing option is most often used for budget repairs of non-insulated balconies or loggias. Sometimes insulated balconies are also sheathed with them.

The main advantages of plastic panels are their cost, which in relation to other finishing materials, such as good-class wooden lining, is much lower, and also one of the advantages is that you can cover a balcony with PVC plastic panels much faster. That is, the speed of installation. And the high speed of work is associated with the ease of attaching the panels to each other and the accompanying fittings. These are internal and external corners, various types of junctions and connectors. Another significant advantage of this material is that PVC panels are absolutely not afraid of water, moisture and temperature changes. Another plus is a large number of varieties of colors and shades. Starting from a simple white color to a complex pattern like marble or flowers

The disadvantages include the following points: it is plastic - an artificial material. Since very often, the walls of the balcony on the inside are not protected by curtains or blinds. That is, the sun hits the panels. When sunlight hits plastic panels, they can emit a specific odor. At least at the beginning of operation. So, these panels are characterized by a change in color. Over time, again, under the influence of sunlight, the plastic lining turns yellow. Not strong enough

Plastic panels are mounted on a pre-installed wooden frame made of lathing (wooden blocks measuring 20*40 mm). The distance between the bars is most often about 40 -50 cm. Of course, you can make the distance between the bars larger, about 60 centimeters, but this risks the fact that the plastic lining will sag and your walls will be less strong. The panels are attached to the wooden frame using a construction stapler and staples. It is also possible to use special fasteners called clamps.

Installation methods

Before sheathing a balcony or loggia, it is necessary to completely complete all other work: leveling and finishing floors, installing windows and doors.

Finishing a balcony with MDF panels begins with preparing the surface. There are two options for mounting panels:

- on glue;

- on the sheathing.

Covering an MDF balcony with glue has only one advantage - the thin thickness of the coating. This requires labor-intensive and dirty work to level the surface.

Installation on the lathing can be easily done even by low-skilled specialists, with their own hands and practically without dust and dirt. The lathing allows for additional thermal insulation of the surfaces being finished, which is especially important on balconies with their thin walls. The greatest advantage of the frame is the ability to level and hide any unevenness of the load-bearing surface.

Performing lathing

When making lathing for fastening MDF with your own hands, craftsmen are not limited in the choice of material. You can use wooden slats and metal profiles. Which of these materials is best to use when covering loggias with panels? The profile frame has less weight compared to a wooden frame, greater resistance to moisture, but is more labor-intensive when attaching panels.

A wooden frame has slightly more weight and low moisture resistance. The last drawback is eliminated when using bars impregnated with drying oil. The lining can be fastened with a construction stapler.

To cover the balcony, wooden slats with a cross-section of at least 20x20mm are used.

You need to have the following tools:

- Hammer or impact drill. Drilling holes for dowels or anchor bolts to secure slats or profiles to a load-bearing wall;

- Plumb line and building level to control the position of the frame slats;

- Metal scissors for cutting profiles;

- A cutter, riveter or screwdriver for fastening profiles together;

- A wood saw or jigsaw to cut MDF panels.

To attach the panels, you need to sew several horizontal slats onto the wall. The slats are located at a distance of 50-60 cm from each other, and one of them must pass along the top of the sheathing, and the other along the bottom.

The slats or profiles are attached directly to the load-bearing surface or to intermediate vertical slats. In the second case, the distance between the wall and the coating increases, and it is possible to lay an additional layer of heat-insulating coating.

In order to attach slats or profiles to the wall, you can use special profile fastenings for walls and ceilings, the so-called butterflies. Butterflies allow you to vary the distance from the surface to the profile within a wide range.

If the wall unevenness is small, wooden slats can be mounted directly to the wall, using leveling pads made from pieces of plywood of the required thickness in the necessary places.

To achieve a perfectly flat surface, first install one of the slats, preferably the top one, then the bottom one, controlling the vertical using a plumb line. By stretching several cords between the outer slats, it is easy to control the correct installation of the intermediate ones.

Vertical and horizontal slats are fastened together depending on the material. Wooden - using self-tapping screws, and metal - using special fasteners or by bending parts of the profile. The most common way to fasten profiles is with special self-tapping screws, which craftsmen call “bugs” or “fleas.” The end of the self-tapping screw has cutting edges, so no pre-drilling is required. In case of an error, the self-tapping screw can be easily unscrewed and installed in another location.

The cutter itself forms holes and fastens profiles by bending the metal at the junction. The undoubted advantage of this method is that it does not require any consumables, but it requires high accuracy of preliminary marking, since the connection is permanent.

Cladding balconies with plastic panels

Before starting work, you should know that the balcony is more susceptible to adverse conditions than rooms. Temperature changes and high humidity are factors that influence the possible deformation of walls, the appearance of fungus and mold.

Not every cosmetic renovation can withstand such pressure. It is worth paying more attention to the choice of consumables. When covering walls with plastic panels, experts advise giving preference to products from proven products from Vek.

PVC panels for balconies come in two types: laminated and regular. Each type is created using different technologies. The appearance of the finished finish also varies greatly.

Advantages of finishing

The most cost-effective repairs can be carried out using PVC wall panels. The material has ideal dimensions and does not leave behind a lot of debris and waste, which is especially important for a small space.

Plastic compares favorably with other materials. It is easy to clean, lightweight and practical. Covering loggias with PVC plastic panels has its advantages:

- Durability. PVC has a long service life. The characteristics of such panels are close to laminate. However, it is worth understanding that plastic does not last forever, so over time, small cracks and scratches will appear on the surface due to mechanical stress.

- Aesthetics. Panels can be of any shade and color and have different structures. Plastic is a malleable material, so sometimes you can see very unusual patterns that will help create a luxurious interior.

- Environmental friendliness. PVC is a safe material that does not contain toxic substances. Often, cladding made of plastic panels can be seen in children's and medical institutions. Also, during the installation of sheathing, polyurethane glue is usually used, which does not harm humans.

- Low installation complexity. A standard plastic panel has dimensions of 2700x250x90 cm. During the installation process, the sheathing is placed on the sheathing using a molding. The end result is free of gaps and crevices, so the panels look like a single unit.

- Resistance to adverse conditions. Of course, when exposed to sunlight, ordinary plastic panels will acquire an unpleasant tint, but if there are no curtains on the balcony, then it is better to choose a laminated option.

- Availability. The popularity of plastic panels is also due to their low cost. Even for the smallest budget you can choose good cladding.

- Versatility. They can be easily attached to any wall material and look great on concrete, brick and even plywood surfaces.

According to the production technology, all panels have reinforcement in the form of stiffening ribs, as well as external protection from thermal and chemical influences - a coating made of melamine resins. When choosing products with matte surfaces, you need to know that abrasives can be used to clean them. Glossy ones are easy to clean with a soap solution.

By repairing balcony walls with plastic laminated panels, you don’t have to worry about the service life of the coating - in some cases it can retain its original appearance for ten years.

Decorating the walls with PVC panels will increase the area of the apartment with minimal investment. But before repairing, it is always necessary to take into account the design features.

Selection of materials during installation

When choosing a material, you need to determine what the balcony or loggia will be used for. If there is no glazing, then you should choose products that are resistant to sub-zero temperatures: block house, lining, corrugated sheets, artificial stone, special plastic or plaster.

Sometimes apartment owners still heat the balcony. In this case, you can use any facing material that is most suitable for the design. More often, preference is given to plastic wall panels for balconies, lining, and MDF boards.

If you plan to make a full-fledged room in the room, then you should make the walls as practical and attractive as possible. Many designers advise using a combination of stone , brick and special decorative plaster.

Preparation for work

An important stage in the quality finishing of the premises will be the preparation process. It is necessary to eliminate all defects on the parapet and walls (cracks, gaps), as well as remove unnecessary things from the balcony and take out the trash. You should not leave, for example, pieces of concrete that are about to fall out of the wall. They can be beaten off with a hammer. Metal parts should be treated with an anti-corrosion agent.

If there is fungus, it must be removed using a blowtorch and copper sulfate. It is better to get rid of cracks with a solution of cement and sand. Also, before starting work, it is worth strengthening the parapet with special metal corners.

It is interesting that experts distinguish two types of balcony glazing - cold and warm. In the first case, it is necessary to make a frame from bars. In the second, it is better to cover the parapet with cellular concrete, and cover all surfaces with a layer of waterproofing composition. Special attention should be paid to insulation and vapor barrier. After all the preparatory work, it is necessary to install the sheathing.

Polyvinyl chloride to the rescue

PVC panels have been rapidly gaining popularity since their inception. And all thanks to its qualities, which allow you to forget about most of the worries associated with caring for this material. Just look at the photo to find the positive aspects of PVC panels without words. And the main one is the speed of installation, achieved due to the large width of the material.

Finishing with PVC panels What attracts lining and PVC panels? The fact that anyone can do the work with their own hands and get an excellent result. If the walls of the balcony are fairly smooth, then even a frame is not required for cladding. And the surface is of high quality. In addition, polyvinyl chloride is not afraid of humidity and temperature changes, which allows it to maintain an impeccable appearance even after several decades.

PVC panels are available in two versions:

- seamless;

- with embossed edge.

Each option has its positive sides, but in terms of characteristics they are practically no different from each other. The main difference lies only in the design that the balcony walls acquire. With this material you can achieve any interior, which is what most owners require.

Materials for interior cladding: we make it stylish and modern

The first step is to properly consider your financial capabilities. Currently, the price range of building materials is so wide that it is possible to select cheaper analogues that, in many respects, are not inferior to expensive imported finishing materials.

So, how can you decorate the inside of a balcony?

The most common materials used for interior cladding:

1. Drywall + decorative finishing

The traditional, inexpensive finishing option has become popular due to its perfectly smooth surface of any configuration. The biggest disadvantage of drywall is that you will have to touch up the walls regularly. The paint may fade, resulting in a dull, uneven color on the walls.

Drywall also allows you to use various decorative design elements, for example, imitation of a brick wall in a loft style.

There are different ways to care for walls finished with plasterboard. It all depends on the coverage. We recommend using paint that can be washed, because open balcony windows constantly let in a lot of dust and dirt from the street.

The average resident does not think much about what to cover the balcony with, and therefore chooses the budget option. Drywall is especially good for temporary finishing, when redevelopment of the apartment space and major renovations are planned. The material is also used when housing is rented out. Expensive finishing materials are usually not chosen for unfamiliar residents.

However, with the right approach, you can create quite an interesting design or a neutral surface. There are many design options for drywall. As for maintainability, this is perhaps the most problematic material, which is easier to completely replace than to repair.

Manufacturers offer exotic finishing options for wealthy homeowners. The balcony can be covered with cork, bamboo or wicker. For these types of finishing, you will have to perfectly level all surfaces and plaster them. Then the materials sit on the glue. The biggest disadvantage is the high cost, but the design is non-standard and amazingly beautiful.

2. Wood: lining

The most popular wooden material is considered to be eurolining, but it happens that to decorate a balcony they use an imitation of a block house, timber, or ordinary planed or terrace boards. It is important to consider the mounting method here. Varieties of lining, like timber and block house, have a lock or tongue and groove. Thanks to this connection, the elements fit tightly together without gaps.

The advantage of wood should primarily be environmental friendliness. The tree does not emit dangerous toxic substances at elevated temperatures and does not become brittle in frost. Eurolining is more advanced, its connecting elements are more reliable than those of conventional lining. Ventilation grooves provide air exchange inside the structure.

What type of lining do you prefer, what is better to cover the inside of the balcony? Both materials are mounted according to an identical scheme. It should be noted the speed of installation, high sound and heat insulation, long service life. If one element is damaged, you will not have to change the entire upholstery. Wooden lining for balconies is in high demand and is available in areas where this material is not considered expensive. Otherwise, use cheaper analogues. For example, pressed sawdust. Compared to natural lining, such panels have a shorter service life, but they look good and are perfect for decorating a modest budget home.

Wooden lining can be used to decorate anything you like, not only walls, but ceilings and floors. Using different variations and colors, you can create a unique balcony style.

3. Plastic panels

Like its wooden counterpart, PVC lining is mounted on the sheathing. Installation cannot be called difficult if professionals do the work. Plastic is a good material for lining the inside of a balcony, but not the most environmentally friendly. PVC panels are available in a wide range, including sizes and colors. The finishing material consists of strips of various widths. After assembly on the wall they look like a homogeneous surface with seams. When laid correctly with a tongue-and-groove connection, the surface is uniform. The seams are very difficult to notice with the naked eye.

Typically, plastic panels are chosen for exterior decoration. However, as an inexpensive and attractive finishing material for balconies, plastic lining is also attached to the inner surface of the walls. If you are looking for the answer to the question of how to inexpensively decorate a balcony, you can consider that you have already found it. The combination of colors and shades will create an exclusive and neat room. Do not use more than three colors, otherwise the room may look vulgar.

Basic requirements when choosing plastic panels:

— durability; — practicality; - attractiveness; — ease of installation; — maintainability.

How to cover a balcony outside

Exterior finishing of a balcony places slightly different requirements on materials. In addition, it must be strong and reliable, wear-resistant. To understand the best way to cover the outside of a balcony, let’s look at the main options.

Vinyl siding

It is available in two versions - traditional in the form of long boards with a tongue and groove fastening, which is often used to sheathe houses, and facade in the form of slabs with uneven edges, imitating stone or masonry. Both materials are mounted on the sheathing using self-tapping screws, but the frame is assembled slightly differently, adapting to the geometry of each material.

You can cover the balcony with siding. Regular or base (right)

Metal siding or corrugated sheet

Although vinyl is considered durable among plastics, it cannot compete with metal. If for high-lying balconies how durable the material is is not critical, then for lower floors it is very important. That’s why the balconies below are often sheathed on the outside with metal siding or corrugated sheets.

Whether it is better to cover a balcony with siding or corrugated sheets is a matter of personal preference. Both have a high degree of reliability. Siding is made of aluminum or galvanized iron, on the front surface of which a polymer film is applied. Profiled sheet is a shaped sheet of roofing iron coated with polymer or paint. The service life is stated to be from 15 to 25 years.

You can inexpensively cover the outside of a balcony with metal siding or corrugated sheets

The main difference is the installation method. A part of the desired shape is cut out of the corrugated sheet and a large piece is attached to the sheathing with special self-tapping screws with a painted head. Siding is also assembled like lining: there is a tenon on one side and a groove on the other. Along the edge of the strip there is perforation for fasteners. Self-tapping screws are screwed into it (in the middle of the hole, slightly short of the cap - leaving the ability to move with temperature changes in the materials).

How to decorate a house with siding is written in the article “How to cover a house with siding with your own hands.” If you choose this material, you will need to know the features and installation rules...

Wood paneling

Houses are built from wood, so why not cover the outside of the balcony with it? Not a bad option, but the wood requires maintenance. Therefore, special attention should be paid to the impregnation of the material used. Take antiseptic and protective compounds for outdoor work. The treatment is carried out before installation begins - then it will be problematic. When finishing, do not forget to process the ends of the boards cut to size. Otherwise, the entire installation is the same.

You can sheathe the outside of the balcony with wood - clapboard, for example

Just keep in mind that without proper care, attractive cladding will turn into something unattractive. A fragment of a tree left without care can be seen in the photo below on the right.

Materials for rough finishing of the balcony

As we know, the frame of a glass-transparent structure is installed on a concrete parapet of a balcony (if its load-bearing capacity allows) or on a specially constructed wall made of foam concrete blocks.

Then, if the balcony is supposed to be insulated, thermal insulation is laid. For these purposes, the following materials are most often used:

- polystyrene foam (a cheap, lightweight material, characterized by very low thermal conductivity, but is destroyed by sunlight, due to technological pores it picks up moisture, although it can be moisture-resistant and crumbles when frozen, and when exposed to fire it smolders with the release of toxic substances);

- extruded polystyrene foam - has almost no disadvantages and is excellent for insulating a balcony;

- foil penofol (also an ideal option, since it has a minimum thickness and prevents contact of warm air with external structures, preventing moisture from condensing at the dew point).

Insulation materials based on mineral wool accumulate moisture and require hydro- and vapor barrier, so it is better not to use them on the balcony.

For rough cladding you can use:

- moisture-resistant or aviation plywood (required density - from 0.8 kg/m2 with a thickness of 3 mm) with high heat resistance (from +30 to -40°C) and water absorption up to 12%;

- moisture-resistant drywall;

- gypsum plaster (for structures without insulation).

Sheathing made of plywood or plasterboard is attached to a sheathing made of wooden blocks or metal profiles. This rough finish, like the plaster layer, is excellent for painting, gluing with decorative stone and tiles.

Features of external decoration

The choice of materials for finishing and insulating a balcony or loggia can be influenced by many factors, but some of them simply need to be taken into account. Knowledge of such nuances will make it possible to more confidently navigate the variety of materials for finishing and insulation, choosing those that will perform best in each specific case.

What to consider when choosing materials for exterior finishing:

Modern industry offers dozens of types of finishing materials for balconies

- The balcony is often exposed to sunlight, so the material for finishing its walls should be chosen in a way that will not be subject to fading, maintaining its original characteristics and presentable appearance under the sun for as long as possible;

- The thermal insulation properties of materials also play an important role. If it is necessary to ensure insulation of the loggia, experts recommend using finishing building materials with a thermal conductivity value less than 0.3 W/mK;

- Materials for interior decoration of the loggia, characterized by high density and thermal conductivity, can be used as a source of passive heating/cooling of the loggia;

- What the loggia will look like from the inside depends on what it is planned to be used for. Finishing the walls and ceiling of the loggia with light-colored materials will ensure that sunlight is reflected onto the floor. If the floor on the balcony, on the contrary, is finished with dark-colored building materials, the floor covering will act as a passive heat source.

Decorating the outside of the balcony will always come first for those who decide to turn the balcony into a more or less comfortable living space. What material to choose for finishing and insulating the loggia from the outside must be decided based on its properties.

Scheme for finishing a standard balcony with clapboard

The external decoration of the balcony walls must be airtight, reliable, and also resistant to temperature changes, precipitation, and gusts of wind.

Experts recommend choosing the following materials for finishing the balcony outside:

- plastic lining;

- metal profile sheets;

- vinyl siding.

The profiled metal sheet meets the above requirements in all respects. The only serious drawback of this finishing building material is that it is susceptible to corrosion. But treatment with anti-corrosion paint will help you easily cope with this problem.

Vinyl siding is less durable, but is resistant to changes in weather conditions, and is also able to ensure the tightness of the balcony skin. This material is resistant to temperature changes, precipitation, and gusts of wind.

With all the advantages of siding, it also has a disadvantage - it is a mobile, plastic material that has low mechanical stability.

It is used only for cladding walls from the outside. Siding for internal work is not produced, so even the most unscrupulous seller will not be able to “confuse” siding for external work with a less durable one intended for insulating premises from the inside, as is the case with lining.

The design of siding panels is designed for installation by touch. Frequent sheathing of walls for installation of siding is not required, and all profile recesses will be turned downwards, which will prevent moisture from leaking.

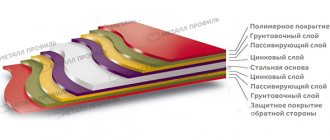

Structure of a corrugated sheet for finishing a balcony

An additional advantage of this material is that it can last up to 50 years without losing its original properties and presentable appearance. Caring for it is quite simple - just periodically rinse the casing with plain water.

Plastic lining is made from polyvinyl chloride, like vinyl siding. It is just as easy to care for, but it is less durable, and moisture can accumulate in the tongue-and-groove lock of the clapboard cladding due to the surface tension of water, even if the clapboard is mounted with the ridge up. Therefore, it is better not to use plastic lining for cladding and insulating the loggia from the outside.

Features of the use of PVC and MDF panels for finishing balconies/loggias

Finishing options made from PVC panels fully meet these requirements. Finishing a loggia with panels based on polyvinyl chloride is popular due to their affordable cost and wide range.

The main advantages of cladding with PVC wall panels are the following factors:

- a rich palette of colors for the front surface, allowing you to imitate the finishing cladding of natural building and finishing materials;

- chemical inertness to atmospheric moisture, decay and aggression of detergents;

- resistance to solar ultraviolet radiation;

- increased heat, - and insulating qualities due to the cellular structure of the material;

- excellent moisture resistance – the panels do not lose their physical properties in a humid environment;

- durability in operation exceeding 15-20 years;

- The material is antistatic, as a result of which dust penetrating from the street does not settle on the surface of the cladding.

In Fig. Below are examples of PVC lamellas.

The disadvantages of finishing a balcony with PVC panels include low mechanical resistance to impacts and possible damage from sharp objects.

No less popular is facing the loggia from the inside with MDF panels. In terms of decorative and aesthetic properties, this finishing material is close to natural wood, since MDF sheets are formed from pressed wood pulp.

In comparison with cladding a loggia with PVC panels, MDF cladding is inferior to it in the following quality indicators:

- poor moisture resistance;

- shorter service life.

At the same time, with regard to the possibility of using for cladding a loggia, both types of finishing materials combine the following properties:

- decorative versatility, allowing adaptation to various design styles;

- elasticity and flexibility of the panels, allowing you to finish walls, hiding unevenness and inaccuracies in the manufacture of the sheathing;

- It is recommended to fasten the panels on special frames-battens.

In Fig. Below are examples of MDF plates.

Wood

Decorating a loggia or balcony with wood products is common. These include: imitation timber, block house, terrace or simple planed board. Lining and its varieties are in great demand. This product involves a tongue-and-groove design, which creates a continuous surface without gaps, and installation is hassle-free.

A significant difference between a simple wooden lining and its euro prototype is that the first option is represented by a planed board of natural moisture, and the second - dried. Eurolining is of higher quality and has a more complex type of profile. It is equipped with special ventilation ducts.

Internal lining of balconies with such material has many advantages:

- environmental friendliness,

- durability,

- ease of installation,

- high quality connection,

- excellent sound and moisture insulation.

For installation, it is enough to prepare the surface and install the lathing for fastening the lining elements. Then the planks are firmly connected to each other and secured to the surface with screws or nails. The edges are hidden with corners.

What are MDF panels

In our country, the exact name Medium Density Fiberboard appeared relatively recently. They are made by pressing finely dispersed chips at high temperatures, the binding element is lignin.

Brief properties and classification:

- The density of the MDF panel is 650–850 kg/m³ (depending on the specific brand).

- In appearance, the front side can be flat or embossed. On flat panels, the front side is covered with natural veneer or polymer film (laminated panels). On embossed ones, the design is covered with paints and varnishes.

- They come in slatted, panel and tile sizes. Lath tiles are similar in linear dimensions to lining, tiled tiles resemble square facing tiles, sheet tiles are large in size and are used for covering large surfaces.

Table of finishing materials

The materials for finishing the loggia and balcony are absolutely identical. These are wooden lining, PVC and MDF panels, cork, textured plaster, artificial stone, tiles, drywall, laminate, etc. Knowing how to decorate a balcony, feel free to use the same panels or tiles on the loggia. With the difference that for a spacious remote structure you need to use larger elements.

| Wooden lining | Price | from 1,400 rub/sq.m. |

| pros | Environmentally friendly material, frost-resistant, warm, easy to care for. Durable if handled correctly. | |

| Minuses | Any wood needs to be treated with several compounds to prevent rot, woodworms and fire. | |

| Ease of installation | Relatively simple installation, but time-consuming, since each panel must be screwed with several screws. | |

| Appearance | It looks “more expensive” than plastic and acquires a noble hue over time. The appearance also depends on the class of wood. | |

| Possible placements | Walls. | |

| Plastic | from 1,300 rub/sq.m. | |

| Environmental safety, resistance to high humidity (PVC can be washed), durability. Incombustible. Easy. Easy care. | ||

| It cracks at low temperatures and is “afraid” of punctures. | ||

| Very easy installation | ||

| Looks aesthetically pleasing. Variety of colors, textures, patterns. | ||

| Ceiling, walls | ||

| MDF lining | from 900 rub/sq.m. | |

| Moisture resistance, stronger than chipboard, low thermal conductivity, resistance to temperature changes, rotting, mold. The material is dense and does not “interest” insects. | ||

| Heavy weight (heavier than wood of the same size). Increased dust formation during cutting and drilling. Glue and synthetic resins in MDF boards may contain toxic substances (formaldehyde, etc.) | ||

| Installation can be carried out without special skills. But a respirator is required. You first need to drill holes for fastenings, but the walls do not need to be prepared. | ||

| Large selection of colors and textures (veneer, relief, polymer film) | ||

| Walls | ||

| Wood boards | from 650 rub/sq.m. | |

| Can be cut in any direction. | ||

| Suitable only for heated balconies. They are afraid of moisture. | ||

| Simple installation on the lathing. | ||

| All types of boards, except OSB, have a decorative coating. | ||

| Walls, floor | ||

| Cork panels | from 1,250 rub/sq.m. | |

| Environmentally friendly, waterproof coating, does not burn, easy to cut, antistatic. | ||

| A prerequisite for installation is a leveled surface. Only for balconies with warm glazing. | ||

| Installation is carried out on plaster and drywall. Special glue is used. Installation requires skills. | ||

| There are few colors, but the coating looks aesthetically pleasing. | ||

| Walls | ||

| Decorative rock | from 1,650 rub/sq.m. | |

| Durable frost-resistant material. Not afraid of either moisture or sun. | ||

| The material is cold to the touch. A stone that is too thin can crumble quickly. | ||

| You need to be able to lay decorative stone; the quality of the masonry also depends on the quality of the mortar. | ||

| It looks beautiful. | ||

| Walls, floor | ||

| Ceramic tile | from 1,000 rub/sq.m. | |

| Hygienic and durable material. | ||

| Cold, quite slippery if used on the floor. | ||

| The tiles must be laid by a specialist. | ||

| Wide range of colors and styles. It looks neat and aesthetically pleasing. | ||

| Walls, ceiling, maybe the floor (but it will be slippery). | ||

| Drywall | from 1,000 rub/sq.m. | |

| Perfectly levels walls; leaves room for imagination for finishing. Excellent sound insulator. Moisture resistant. | ||

| Suitable for base layer only. Fragile. Cannot be used on open and uninsulated balconies. | ||

| Installation is simple. | ||

| It looks neat, but in itself is not suitable as a finishing material. | ||

| Walls, ceiling | ||

| Laminate | from 1,400 rub/sq.m. | |

| Not afraid of cold, easy to clean. Durable, durable, moisture and heat resistant, does not attract dust. | ||

| High-quality laminate has no disadvantages. | ||

| Laminate flooring is easy to lay on your own. The balcony does not need to be insulated before installation. | ||

| Beautiful appearance, warm, pleasant to the touch (you can walk barefoot). The coating imitates any surface. | ||

| Floor. Sometimes walls. | ||

| Decorative plaster | from 1,200 rub/sq.m. | |

| It washes well, and after a while it can be renewed by simply applying a layer of paint over the plaster. | ||

| If the base is uneven, you must first level it using drywall. | ||

| Can be applied directly to the surface, since the material is not only decorative, but also a protective coating. | ||

| You can create any texture. Variety of colors. | ||

| Walls and ceiling |

Characteristics of PVC panels

The basis of any plastic panel is polyvinyl chloride. PVC has been produced on an industrial scale since 1912. This material is used in many industries, for example for the production of films, window profiles or plumbing pipes. The PVC panel profile consists of two walls separated by stiffening ribs. Stiffening ribs make the panel durable and improve heat and sound insulation. Similar in nature, panels may differ in the groove system and the method of applying texture to the front surface.

Groove system

There are two options for connecting PVC panels to each other:

- Hidden groove - a connection in which a flat plane is created, and the junction of the panels is almost invisible;

- Joint with groove - the place where the panels meet is marked by a small recess - a groove. The sheathed plane has alternating grooves, which makes the cladding more voluminous, and in some cases, finishing the balcony with panels with a groove visually increases the size of the room.

Method of applying texture to PVC panel

For finishing balconies and loggias, three types of plastic panels are usually used:

- Without texture, usually white with a matte or glossy, smooth surface. Such panels are used for covering ceilings or window slopes.

- Panels with a pattern applied using thermal printing. With this method, the texture is imprinted in the mass of panels, while the front surface remains smooth. Thermal printing makes it possible to apply almost any design to the surface of the panel; there are no restrictions in the color range.

- Lamination or gluing to a panel a special film with a three-dimensional texture that replicates the surface of natural materials. The laminating film has a high density, which significantly improves the performance characteristics of the plastic panel.

How to cover a balcony without glazing

Since the decoration of an unglazed balcony will be exposed to all atmospheric phenomena, you need to choose from materials for the exterior decoration of the house. Possible options:

- siding - vinyl, base, metal;

- decorative finishing stone;

- porcelain stoneware;

- plasters for external use;

- tree;

- ceramic frost-resistant tiles;

- polycarbonate

Most of the material is familiar to you. Questions may only arise regarding polycarbonate. They recently began sheathing the balcony with polycarbonate. And you can make not only a canopy on the upper floors (pictured on the left). This material looks very nice paired with a forged balcony fence. But on such a balcony the order should be perfect.

Polycarbonate for finishing the balcony

Thermal insulation device

A balcony decorated with MDF panels with your own hands needs thermal insulation. Its installation must begin even before the construction of the frame. First of all, a layer of waterproofing is attached to the wall, and on top of it is a layer of foamed foil polyethylene. This material reflects thermal radiation well and is an excellent flexible heat insulator. After this stage, the frame elements are attached.

The insulation is placed in the cells of a fully assembled frame. Mineral wool or foamed polystyrene of the required thickness is used as insulation.

When using mineral wool, a layer of vapor barrier is laid on top of it. At this point, the preparatory stages are completed, and the panels can be installed. With high-quality thermal insulation, heat loss will be minimal, and PVC panels can also be used.

Which material to choose?

To correctly determine which type is best for use in a particular situation, you need to compare several factors.

Properties

High-quality products do not have a significant difference in the main parameters, but in some others there are significant differences:

- Fire safety. Both options refer to flammable materials that can support a fire. But PVC, when exposed to temperatures above 100 degrees, deforms and begins to release harmful substances, so it should not be placed near heating elements.

- Frost resistance. At subzero temperatures, polyvinyl chloride becomes brittle. Parts made from recycled materials will be particularly unstable.

- Availability. The cost of plastic products is somewhat lower, and they also have a larger decorative range.

The operational and aesthetic characteristics of MDF are somewhat higher, but plastic is much cheaper

Scope of use

When decorating the interior of a house or cottage, you should follow some recommendations:

- For showers and toilets, wall panels made of polyvinyl chloride would be an excellent solution.

- When decorating a bedroom, they give preference to MDF; this coating looks more noble.

- For a loggia or attic (if there is heating), plastic products are also a good option. They are combined with MDF parts, which are ideal for unheated balconies. The ceiling can be made of PVC.

- It is recommended to cover the corridor and hallway with fiberboards, as they are more durable.

- It is better to divide the kitchen into zones and use a combination of products.

- MDF coated with PVC film can be used for the manufacture of bathroom furniture and facades of interior items.

Thus, the choice of material should be based on the area of use and financial capabilities.

Fastening with glue

This is the fastest method if the balcony surfaces are perfectly flat. The panels are secured with glue or liquid nails. The main advantage of the method is that neither specific tools nor special skills are needed.

Procedure:

- Dismantling the previous finish, cleaning it from dirt.

- Leveling walls and eliminating cracks with cement-sand plaster.

- Applying primer.

- Wall putty.

- Gluing panels.

The panels are glued from the corner of the room and then moved along the wall. After applying the glue they are pressed tightly against the wall. Excess adhesive is removed with a knife. As a result of finishing the balcony with MDF panels, it looks like in the photo of construction magazines - natural and aesthetically pleasing.

In our company, you can select any MDF wall panels for finishing, and then order their installation on a balcony or loggia.

Sheathing with MDF boards

Interestingly, MDF panels were created by accident. They were first received by inventor William Mason due to his own forgetfulness and a malfunction of the steam press. The abbreviation stands for simply: medium translated from English - “average”, density - “density”, fiberboard - “slab”.

The panels have good resistance to high humidity conditions. When compared with a similar chipboard board, MDF is smoother, stronger and more durable due to the use of surface lamination technology. In the manufacture of panels, emphasis is placed on the characteristics of resistance to water, fire and biological factors.

For many years, “jack of all trades” have chosen MDF for interior decoration because of the best price-quality ratio. You can find very inexpensive types in stores.

You can sheathe MDF boards indoors using the same technology as when using lining. It is necessary to create wooden guides that will hide uneven walls, as well as lay materials for thermal insulation. For installation it is worth purchasing special brackets.

Advantages of the material

MDF panels are characterized by increased moisture resistance. They can be washed using soap solutions. The material is also as durable as solid wood. It has low thermal conductivity and is frost-resistant. Fungus and insects do not damage its surface.

MDF can be installed without any special preparation. The high density of the material provides a variety of created relief. In addition, they are significantly cheaper than vinyl and wood lining.

Disadvantages of MDF

To line the walls of a balcony with MDF panels, considerable strength will be required due to the heavy weight of the material. It is also worth understanding that more dust will accumulate on such a surface. And before creating the necessary fasteners, you should always drill holes for screws and nails. It is also important to know that the composition of the stove often contains harmful substances, for example, formaldehyde.

Before decorating a balcony or loggia with special panels, it is necessary to draw up an approximate list of the most significant factors. For some owners, the most important thing is the practicality of the material and its naturalness. For others, the main thing is the financial issue. Well, for still others, the decorative component comes first.

Source