SlavagodM

16134 0 4

SlavagodM September 14, 2016Specialization: master of interior and exterior finishing (plaster, putty, tiles, drywall, lining, laminate, etc.). In addition, plumbing, heating, electrical, conventional cladding and balcony extensions. That is, the renovation of an apartment or house was done on a turnkey basis with all the necessary types of work.

Beautiful interior decoration of the balcony with panels

In order to choose external or internal wall panels for a balcony, at a minimum you need to know what they can be like. Personally, I recommend using seven types that are best suited in certain conditions. Therefore, I will tell you more about the range, installation methods, and also demonstrate a video in this article.

What is the advantage of plastic panels?

In this matter, it is immediately worth dividing the panels into two types - for decorating walls and others for ceilings. Consider PVC panels for a balcony:

- Wall panels are very durable, they have practically no flexibility, which is why they are not afraid of loads, this allows plastic panels to withstand the weight of shelves and small cabinets.

- Ceiling panels cannot boast of high strength, however, their main purpose is to support their weight.

Advantages and possible disadvantages

Of course, in addition to the positive aspects, as with any material, there are disadvantages.

Undeniable advantages:

- Easy installation. It’s easy to finish finishing your balcony with plastic panels yourself, following our photos (visual instructions). The panels themselves are connected using the tongue-and-groove method; no special skills are required (except to use a screwdriver).

- Long service life. Manufacturers claim a service life of 25 years. PVC panels are an unattractive breeding ground for microorganisms, therefore, unlike wood and other materials, they are not subject to decomposition.

- Design. These are two waterproof surfaces connected by perpendicular partitions. They, in turn, form air cells. This structure provides increased sound and heat insulation. PVC is not installed close to the wall, but on the sheathing. That is, there is an air gap between the wall and the plastic and there is minimal play at the joints, which allows air to circulate and prevents the appearance of mold.

- Variety of textures and colors. You can choose the covering to suit any balcony interior.

- Light weight.

Obvious disadvantages include:

- Instability to mechanical stress.

- Toxicity. In the event of a fire, toxic substances are released that are harmful to health. It is for this reason that plastic is not recommended for a nursery, kitchen, living room, but in a dressing room, bathroom, corridor or balcony such cladding would be quite appropriate. When purchasing, it would be a good idea to ask the seller to present an environmental safety certificate. Low-quality plastic can release toxic substances even without any heating (you may have noticed the smell in new, renovated rooms). You shouldn’t think that everything will disappear; most likely, volatile polyphenols will continue to enter the air, and this is not very good for the health of residents.

- Budgeting. One of the main advantages can also be considered as a disadvantage. Many people perceive plastic as something very cheap, and it is no longer used for repairs slightly above average. But here, as in the saying, you need to stretch your legs over the blanket.

Why are plastic panels popular?

The material has a huge list of merits and privileges based on which consumers choose it. What is this?

It is easy to install. To work with PVC you do not need to have any special skills or abilities.

Light weight, another plus in installation. Due to the lightness and mobility of plastic sheets, they are easy to install, and a person without special physical training can handle them.

The financial component or simply the price. The material is cheap.

Durability. Plastic is a profitable investment; not only is it a cheap material, but it will last at least ten years, and this is a doubly profitable investment.

Attractive appearance - a well-kept balcony is always beautiful.

Environmental friendliness is an important component of today.

The variety of colors and textures also encourages people to choose plastic panels. You can choose any option at the customer’s request; it can ideally match the overall style of the apartment or ideally complement the design solution of the balcony itself.

It is easy to replace. At the same time, you can change local areas, this is profitable and practical. Families with small children or pets, where the risk of damage to the wall covering is quite high, will especially like this option.

Plastic panels can perfectly hide the necessary communications.

Ease of cleaning is another important point. Plastic panels can be cleaned by wet cleaning using detergents.

Plastic panels can improve the performance of a room in two ways at once - sound insulation and improvement of the thermal conditions in the room.

Wall work

The first thing you need to start with is the glazing of the balcony. The frames can be made of wood and installed in place yourself, but it is best to entrust this to organizations that deal with such issues. Moreover, after installing the frames, they will provide high-quality sealing of window openings.

- The next stage will be the insulation of the walls, special attention should be paid to the partitions facing the street.

- Foam plastic, mineral wool or penoplex can be used as insulation.

- After this process is over, you can begin finishing work.

The wall, which is a partition between the apartment and the balcony, does not need to be insulated, but only leveled with plaster, and then finished.

How to calculate the required number of panels?

The calculation should be made based on the size of the balcony and the desired finishing option. When making calculations, we must not forget about several details that play a big role when covering PVC balconies:

The panels are different, and their width is also varied. The standard option that will suit every balcony is 25 centimeters. If the walls have a complex architecture, you can use narrower specimens up to 10 centimeters wide;

The longest panel is 6 meters. For a standard balcony, options up to two and a half meters long are most often used.

To accurately hit the required size and number of panels, it is worth understanding the perimeter of the balcony. Multiply the perimeter by the height and divide by the width of the panel.

In this situation, it is better not to exclude the opening of doors and windows from the calculations; this will allow you to create a strategic reserve that can save you in the event of an error in the calculation or a defect in any gap.

When calculating the required amount for the ceiling, measure by dividing the area of the ceiling by the width of the panel. Round the resulting number up to the nearest whole number.

For reserve, it is worth purchasing two or three more panels. This will avoid unnecessary fuss when performing work. In addition, if panels are purchased in advance, before repairs, then you may encounter another problem.

The store may run out of panels or their production may be suspended. That is why it is better not to buy materials in advance or to buy them with a reserve sufficient for force majeure situations.

Ceiling work

Here, first of all, it is necessary to do waterproofing, and only after that proceed with laying electrical wiring, if required. At the final stage, plasterboard, lining, MDF panels, and siding can be used as materials.

- At one time, the Armstrong type ceiling was in demand because it was quite easy to install.

- It is still relevant now, and instead of the usual plasterboard tiles, in this version you can use plastic or stained glass.

Recently, stretch ceilings have become very popular. Since the balcony area is small, little material is required, and the work will be completed quickly and efficiently by professionals.

What to buy from accessories?

Unfortunately, plastic panels alone will not be enough to decorate a balcony with PVC panels. To successfully complete the repair, it is necessary to provide a number of necessary elements:

- External corner;

- Internal type corner;

- Profile F;

- Start profile;

- Ceiling plinth;

- Profile for docking;

- Skirting for the floor.

Instructions

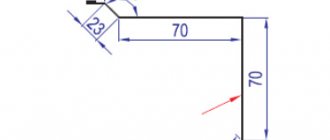

First you need to install the sheathing. Measure 5 cm from the floor and install the timber. This is necessary if lighting is sewn into the ceiling; in a simpler version, it can be attached directly to the ceiling without the gap necessary for working with electricity and installing lamps.

Fastening must be done using nails. It is ideal to treat everything with an antiseptic to prevent the appearance of mold and mildew. During prolonged rains, this is possible.

Next, we place the beams and make a gap between them of 50 cm. On the other side, at the same level, we place exactly the same beam. The remaining beams on the other side are set according to the same principle with a gap of 50 cm. All work must be checked using a building level.

The timber that covers the window is cut off. We also attach the timber to the window sill using self-tapping screws. In parallel, another beam is attached to it, but this time to the floor.

Next, we attach a new beam between the slats at a right angle with a gap of 50 centimeters between them.

Afterwards, a rail is installed parallel to the finished frame.

Important: if the balcony is large and wide, then the structure must be strengthened and additional slats added depending on the length and width of the balcony.

We fix the rail with a self-tapping screw at an angle. The first profile is made in the form of a U-bar, which is attached to the finished structure. Such strips should also be obtained at the window sill and at the junction of the side and internal walls.

The plastic panel is checked with a level for evenness and then attached using self-tapping screws, and then subsequent panels are installed in the lock of the previous one.

Don't be afraid of having to trim the last panel, this is a classic practice.

Under the window, the panels are fastened after changing the size of the panels to fit the window sill space according to the same principle.

Balconies covered with PVC are durable and attractive. Sheathing a balcony with PVC panels is easy and simple even for the average person.

And what a variety of activities can be arranged on a balcony decorated in exactly this way. You can easily place a relaxation area there or a great place to practice yoga in the morning.

Such a balcony is suitable for home meals in the warm season, just like there is beautiful greenery outside the window. Plastic panels will look great both in an impromptu gym and in a home workshop.

In this case, plastic panels will also be as practical as possible, because even with a small defect they will be easy to replace locally, in the damaged area!

It is worth choosing light shades, however, you should not choose a pure white shade. As you know, plastic is proven to absorb toxic elements from the air, and the balcony is an area where the amount of dust and dirt from the street is colossal.

That is why a pure white balcony can quickly lose its festive and clean appearance. In such a situation, it is better to choose warm pastel colors or go for rich dark shades. They are the ones that will serve as long as possible.

It is also worth taking a closer look at complex patterns based on stains and abrasions. This effect will be as convenient and practical as possible for any balcony.

Good balconies and easy repairs, so that the new balcony will delight you for a long time and bring many happy minutes spent on it!

About the material

Although the consumer became acquainted with plastic relatively recently, the material was invented at the beginning of the last century. Moreover, the chemist who received the coveted formula did not at all strive to invent something similar. At that time he was working on a completely different project. PVC, like many other inventions that have become famous and have benefited man (take penicillin, for example), can be called the result of a random experiment.

Initially, plastic was heavy and had a porous surface. Such material was not suitable for finishing premises and could not compete with boards based on wood waste (chipboard, MDF). It required improvement, which is what the manufacturers rushed to do, having realized earlier than others that PVC was the future. They persistently strived for perfection, and finally, a fundamentally new technology was invented in Germany (the method of free foaming of PVC), which made polyvinyl chloride a leader in the finishing materials market (and not only). PVC panels have become lightweight, and their surface is smooth. The range of colors and textures began to quickly expand with new designs that imitate a variety of materials: elegant wood patterns, “speckles” and “stains” characteristic of stone, and the rough surface of brick. Panels made of polyvinyl chloride began to replace paint and wallpaper, lining, chipboard and fiberboard, and drywall. Competitors gradually lost ground, and PVC, due to its availability, won the market.

Photo of PVC balcony finishing

Please repost