Choosing a finish for such a specific place as a balcony or loggia is an important step towards creating a beautiful and practical space. According to my observations, few owners think about such an option as a terrace board on the balcony, the installation of which is carried out with some special features. I propose to take a closer look at this promising material, get acquainted with its varieties and installation principles.

Source hzcdn.com

Advantages and disadvantages of finishing

The term decking refers to several types of materials; All of them can be used both outdoors and indoors. The practicality of finishing for a balcony is confirmed by its following advantages:

- Resistance to high humidity in combination with temperature fluctuations.

- Water resistance: the surface is not afraid of direct contact with water.

- Strength, resistance to mechanical loads, including abrasion.

- Decorative value, allowing you to discreetly but stylishly decorate the space in the chosen style.

- The terrace board creates a comfortable environment; it is pleasant to walk on it barefoot, which cannot be said, for example, about ceramic tiles.

- Versatility: the material is used to decorate not only the floor, but also walls and parapets.

- The sheathing is environmentally friendly, does not rot, and does not harbor wood-boring beetles.

- The service life of different types of material is 20-50 years, and careful operation extends it.

Source taldomstroika.ru

The only disadvantage of decking boards that I have heard about is its cost. This is the reason why many owners prefer to cover the balcony with plastic panels or budget wooden lining. However, the cost indicates the quality of the material and the fact that over time it will not become moldy, like lining, and will not crack, like plastic.

Floor finishing

Even beginners can install a decking board. The main thing is that the floor is level, and that the cracks and cracks are sealed with cement mortar. If it is clear that the old screed is collapsing and unstable areas have formed, then it is worth dismantling it by pouring a new cement layer (how to do this correctly, read the article: “How to pour a floor on a balcony”).

Further:

- rub over any irregularities or bumps that appear with a construction float after the screed has dried;

- wait 2-7 days until the solution completely sets;

- install wooden logs from timber with a section of 50x50 mm across the balcony slab, maintaining a step of 50 cm;

- soak the boards with an antiseptic or treat them with drying oil.

Reference! The bars need to be laid out so that they are in a single plane. For insulation, insulation (mineral wool) is laid between the joists. On top - a layer of film when attaching the board with screws or raising the floor to the level of the door frame. The logs are selected with the appropriate cross-section. The height of the terrace panel should not be higher than the bottom edge of the door.

Consecutive works:

- Laying the initial lamella along the wall. Fixation with self-tapping screws or invisible fasteners.

- Installation of subsequent boards so that the end sides at the joints are on the joists when joining. Fixation with mounting clips, and the last lamella to the joists with self-tapping screws.

- Installation of wooden plinth around the perimeter of the loggia.

The main thing is to leave gaps between the boards for thermal expansion, which is important when working with wood. Otherwise, the panels laid closely will begin to swell, interfere with each other, warp, and tear out the fasteners.

If the balcony is heated and a stable temperature is maintained, then you can fasten the boards with self-tapping screws with a beveled head at an angle of 60 degrees. The material must get used to the microclimate and accept the street temperature, so after installation it is left for 1-2 days.

First, logs are installed on the rough surface at intervals of 50 cm, from the wall - at 1 cm. Then boards are installed, leaving small gaps and fastening with self-tapping screws. Although it is better to attach the first decking plate to anchors.

Varieties

There are two types of decking boards available on the building materials market. The first is made from solid wood, the second has a complex, composite composition including wood products. The first type is more expensive (sometimes significantly), but it is more difficult to care for. The second is more practical, as it has an attractive price-performance ratio.

Source bcoutdoorflooring.com

Pros and cons of decking

The seam deck board has not only the advantages described in the first chapter, but also disadvantages. Along with moisture, dirt escapes into the cracks between the boards and accumulates under the terrace.

A bank card or other small item may fall through. Herbs and shrubs grow from bottom to top. The cracks between the decking boards become loopholes for them. As a result, the flooring begins to intersperse with vegetation.

Advantages of decking boards

If the seams remain clean, the fasteners and the flooring subsystem in general can be seen through them. Another thing is seamless decking. Water can stagnate on it in puddles, but there is no grass breaking through from under the flooring and there is no possibility of losing small objects.

This board is similar to parquet and has similar locks. There is no need to buy fasteners or clips. Due to this, the estimate for laying decking without seams is reduced by approximately 1/5.

Decking board fastening system

Girls wearing seamless flooring appreciate the ability to walk on them in heels. Therefore, in public places, flooring is made according to the principle of parquet. The choice was also determined by the ease of cleaning the seamless decking.

Instead of scooping dirt out of the cracks between the boards, it is simply washed off the surface of the flooring. Usually, the terrace is sprayed with a garden hose, or passed over the surface with a broom.

Made of wood

Natural wood on the floor will help turn the balcony into a terrace. The wooden board is made from particularly strong and hard wood that is resistant to moisture. Both classic wood (larch, cedar, oak, ash) and valuable exotic tree species (for example, from Indonesia) are used.

The durability of the natural material is achieved through painstaking preliminary preparation. The wood is thoroughly dried, and after thermal modification, the raw materials are treated with hydrophobic impregnations and antiseptics.

Heat treatment allows you to get a durable board, devoid of all the weaknesses of natural wood. Materials such as thermopine, thermobirch or thermoash are environmentally friendly raw materials that are fully recyclable.

Source ggexim.com

Material selection

As a floor covering for a glazed balcony, you can choose:

- terrace or deck board;

- linoleum;

- laminate;

- ceramic tiles.

Tiles are a good material for finishing a balcony, but insulating it will require the introduction of heated floors, which will lead to additional costs.

Laminate and linoleum are cheaper means for arranging floors on the balcony, but they are not resistant to moisture and mechanical damage. Any contact with water on the surface can cause it to rot or swell.

Made of polymer composite (WPC)

Polymer decking boards are a worthy alternative to solid wood. The reason for its popularity is explained by the material’s resistance to any external factors. WPC (wood-polymer composite) consists of the following components:

- Wood flour. Its content may vary, but in high-quality products it reaches up to 80%.

- Pigments. The desired shade is obtained by adding natural or synthetic dye.

- Plasticizers. Thanks to these chemically inert substances, the board is elastic and can withstand significant loads.

- Synthetic binders. These additives (polyethylene and other polymers) improve performance characteristics.

Source mapio.net

Composite decking is free from the disadvantages of wood, it does not cool your feet like tiles and is free from such nuisance as splinters. WPC is designed for long-term operation; with its help it is easy to recreate the feeling of a country terrace on a balcony or loggia. The material is presented on the market in the following versions:

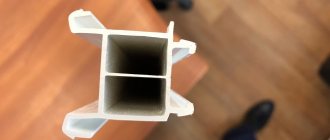

- Monolithic. Monolithic products weigh more, but at the same time demonstrate the highest strength. Externally, monolithic panels do not differ from hollow options.

- Hollow. Due to their light weight, the panels can be mounted on low-strength load-bearing structures. Hollow panels are more in demand: they are cheaper than monolithic ones, and their thermal conductivity is lower. Internal chambers (cavities) can be closed or open; in the latter case, dirt may accumulate in them.

- Modular (prefabricated) decking. It has the form of prefabricated modules, which in turn consist of several dies. Prefabricated decking made of wood-polymer composite can become an independent covering, or serve as protection for a more expensive floor.

Source pinimg.com

Main characteristics

The main properties and characteristics mean:

- density;

- compressive strength;

- bending strength;

- thermal conductivity;

- sound conductivity;

- possibility of mechanical processing;

- temperature regime;

- environmental Safety.

There are no general values for these parameters, because each of them can be changed when preparing the mixture. In most cases, manufacturers rely on these same values for the materials they want to replace.

Since in most cases products made from WPC replace the same products made from wood, the basic parameters of the material itself are identical to wood. One of the main advantages of this material is its suitability for processing with conventional tools.

Here's what you can do with this material:

- sawing with hand or circular saws;

- drill with drills on wood or metal;

- drive nails (to drive a thick nail, it is advisable to drill a hole first, otherwise the material may tear);

- screw in screws or self-tapping screws (regardless of the diameter, it is advisable to drill a hole);

- plan with a plane;

- to chop with an axe;

- cut with a knife, as well as with a hand or electric jigsaw with a wood saw.

The temperature regime, which for most products falls within the range from -50 to +50 degrees, is a very important parameter.

Some manufacturers expand the upper and lower limits of the temperature range, making the board more resistant to frost and heat, so before purchasing, you must carefully read the permissible temperature range indicated by the manufacturer.

Another important parameter is environmental safety.

Under normal conditions, none of the thermoplastic polymers used to produce WPC emit toxic substances, but during a fire toxic gases are released.

Therefore, WPC manufacturers add substances to the mixture that prevent the combustion of these polymers.

However, in the event of a strong fire, it is impossible to avoid the release of toxic gases, but even ordinary wood emits the same gases. Therefore, WPC is much safer than plywood, chipboard and other substances containing phenol and formaldehyde compounds.

Terrace board: variety of surfaces

Both monolithic and hollow products can have a smooth or corrugated surface, suitable for specific operating conditions:

- Corrugated (with longitudinal grooves) surface. This decking is suitable for balconies and loggias without glazing. It effectively drains water, and it is easier to move on a damp, corrugated surface than on a smooth one. The disadvantage of the material is the difficulty of maintaining cleanliness.

- A smooth deck board is laid on a glazed balcony. This surface is easier to care for; in a living space with furniture and decoration, it looks more harmonious than its corrugated counterpart.

Source pinimg.com

I would like to draw your attention to the fact that there is another classification of decking - according to the installation method. Seamless and seamless decking boards differ in the following characteristics:

- The seamless board has a tongue-and-groove fastening, so the gap between adjacent elements is visually closed. The floor looks monolithic, which is considered the main advantage: no one will break the heel, and you don’t have to wash dust out of the cracks. The downside is minimal ventilation of the coating, which is why it is only suitable for glazed rooms.

- A seam terrace board is suitable for an open balcony, loggia or used roof. During installation, a gap is maintained between adjacent planks, and the flooring is well ventilated. Disadvantage: a small object (jewelry, bank card) can slip through the gap, and it is not always possible to remove it.

Source zavoddpk.com

How to care for decking

The ribbed texture of the material suggests that the floor will be carefully maintained. For cleaning, use a soft bristle brush and non-aggressive detergents. If stains are found, they should be washed as quickly as possible so that grease and oil do not have time to be absorbed into the wood. During cleaning, the seams are inspected for contamination, ensuring that the grooves are not clogged with debris.

Advice. Furniture and flowerpots should be rearranged and replaced from time to time. This will help avoid structural deformation of the material, as well as its uneven aging.

Wood tends to wear out, so it will need to be renewed every 3-4 years. It is not recommended to use paints and varnishes that create a film on the surface. Since the floor will change parameters with changes in humidity and air temperature, the paint layer will begin to crack and peel off.

Impregnating compounds are suitable for painting First of all, it is drying oil - a natural material that preserves the wood grain and provides its protection. You can also use wood oils, which will highlight its texture and reduce slipping on a wet floor. Although the balcony is glazed, moisture still penetrates through the windows, so choose a sunny, not rainy day for painting.

Principles for installing decking boards on a loggia or balcony

Before starting work, the material must undergo acclimatization. It is unpacked and kept for at least two days in the place of future installation to equalize the humidity. Decorating a balcony or loggia with decking includes the following steps:

- First, prepare the base: seal the cracks and cracks, and, if necessary, make a leveling screed with a layer of waterproofing on top.

- Installation of logs (supporting elements). Logs made of wood, plastic or aluminum are suitable. They are laid in increments of half a meter and a technological distance from the walls of 5-10 mm.

Source supersklo.com.ua

- The deck board is laid with a mandatory compensation gap; for fixing, I recommend using only galvanized fasteners - self-tapping screws or hidden-mounted clamps.

Installation on walls is carried out in the same way. The surface is cleaned and dried well, a sheathing made of wood or metal is installed, wind insulation is laid, and then sheathed with boards.

Source stroy-okey.ru

Parapet and wall cladding

A balcony covered with terrace boards takes on a cozy, homely look. This finish harmonizes perfectly with wooden floors. Based on the characteristics of the balcony’s interior, the walls can be covered entirely or only the panels and the balcony parapet.

Wall cladding with decking:

- The old coating is removed from the walls and repairs are made: cracks are sealed, weak spots on the plastered surface are strengthened;

- External walls are covered with wind protection (you can use thick polyethylene film);

- The sheathing of bars is installed. If the decking panels are positioned horizontally, the sheathing slats are mounted in a vertical position, and vice versa, a horizontal sheathing is installed under the vertical arrangement of wooden panels. The bars are set according to level;

- Insulation can be laid between the sheathing bars. This applies mainly to the balcony parapet and side walls;

- The decking board is attached using self-tapping screws or nails without heads. Small gaps are left along the ceiling, floor and corner joints, up to 0.5 cm;

- The gap remaining between the ceiling, floor and board, as well as in the corners, is closed with a decorative wooden plinth.

Advice. To ensure that the panels do not differ in shades from each other, you should buy decking boards from the same batch. If material from different batches appears to be identical in color, the difference may become apparent after installation.

Briefly about the main thing

Terrace boards are successfully used for covering floors and walls on any type of balcony (open or glazed). The material is environmentally friendly and can withstand outdoor use with fluctuations in temperature and humidity.

Products on the market are made from wood or polymer composite. The surface of both can be smooth or corrugated, and according to the installation method - suture or seamless. Sheathing a balcony or loggia is carried out with preliminary leveling of the floor and walls. Then logs or lathing (for walls) are installed, and the selected decking is laid on top.

Question

Write in the comments which flooring (wood or composite) you think will be easier to maintain in the future?

Advantages of WPC for finishing a balcony

In Moscow, fencing balconies and loggias with larch or decking is not uncommon. Residents of the capital have long understood the advantages of these materials.

1 Which brand to choose?

One of the most popular manufacturers of decking boards is TeraGrand (Russia, Belarus). Prices from 1799 RUR/m². The range includes both solid and hollow boards, as well as fencing, steps and facades made of WPC. WPC fencing has the following advantages:

- Easy to install - installation of decking does not take much time and is carried out with household tools. More attention needs to be paid to preparing the base.

- Resistance to changes in temperature and humidity. Polymer and natural materials retain their characteristics in summer heat and winter cold.

- Environmental Safety. Terrace boards on the loggia do not emit harmful substances into the environment. WPC balcony railings do not cause allergic reactions upon contact with skin.

- Larch floors do not deteriorate from exposure to chemicals and organic compounds. Insects do not live in wood and do not spoil it.

- Strength. The decking board on the balcony can withstand strong pressure and impacts from hard objects without damage.

- Low thermal conductivity. The material is used to insulate a glazed object without the use of additional layers.

- Presentable appearance. Slats made of polymer, thermo-ash, teak, and analogues look beautiful and luxurious. Products can be painted in one of the colors or imitate valuable wood species.

- Durability. The estimated service life of WPC fencing for a balcony is 50 years.

- UV resistance. The material retains its characteristics, does not fade or become stained

No special conditions are required for transportation and storage of goods. It can be kept in a cold barn and even in the open air.

What subtleties should you consider when choosing decking?

A deck board of proper quality has the following characteristics:

- homogeneous structure without areas of different sizes;

- all edges are well defined, processed in a straight line without waves;

- cells are identical in size and thickness;

- surfaces without pits, potholes, clots;

- the grooves and tongues coincide, and the distance between them is equal;

- cut without peeling;

- the material does not deform if you apply effort.

You can check the reliability of the manufacturer by asking him to show all the shades in stock. If only dark colors are present, it means that bark and wood waste were used in production, and not high-quality wood. This will significantly reduce the performance properties of the product.

Peculiarities

The coating, which has the second name “decking,” can be a natural material or a solution made of composites and polymers.

Externally, both varieties are very reminiscent of a corrugated parquet board or a stacked floor made of wooden planks. At the same time, natural decking can be made from valuable wood or ordinary larch, and composite planks can have voids inside or be solid. The difference will be in the lower weight of hollow planks and the greater strength of solid ones. In terms of cost, both solutions will not be economical - such design will cost a considerable amount. But the positive qualities of coatings of this type will be a factor justifying the high price. In addition to the high cost, it should be noted that such materials were specially designed for use outside residential spaces, which makes them one of the best solutions for finishing balconies.

Pros and cons of decking

The seam deck board has not only the advantages described in the first chapter, but also disadvantages. Along with moisture, dirt escapes into the cracks between the boards and accumulates under the terrace.

A bank card or other small item may fall through. Herbs and shrubs grow from bottom to top. The cracks between the decking boards become loopholes for them. As a result, the flooring begins to intersperse with vegetation.

Advantages of decking boards

If the seams remain clean, the fasteners and the flooring subsystem in general can be seen through them. Another thing is seamless decking. Water can stagnate on it in puddles, but there is no grass breaking through from under the flooring and there is no possibility of losing small objects.

This board is similar to parquet and has similar locks. There is no need to buy fasteners or clips. Due to this, the estimate for laying decking without seams is reduced by approximately 1/5.

Decking board fastening system

Girls wearing seamless flooring appreciate the ability to walk on them in heels. Therefore, in public places, flooring is made according to the principle of parquet. The choice was also determined by the ease of cleaning the seamless decking.

Instead of scooping dirt out of the cracks between the boards, it is simply washed off the surface of the flooring. Usually, the terrace is sprayed with a garden hose, or passed over the surface with a broom.