To replace the balcony parapet, strengthen it, and insulate it, use foam block masonry. The installation of the parapet, partitions, and walls will be carried out by Window Systems specialists. We use certified materials in our work, follow installation technologies, and guarantee high quality structures.

Foam block is a type of cellular concrete. This is a durable material that provides insulation and increased sound insulation.

from 550 R/m2

How to lay out a parapet of foam blocks on a balcony or loggia yourself

I warmly welcome everyone.

Today I’ll tell you about how to lay out a parapet from foam blocks yourself. The parapet, in every sense, is a very necessary thing, and a number of important factors, such as glazing and further finishing of the balcony or loggia, largely depend on its strength and reliability. The parapet we are talking about and the loggia as a whole are located in a new building, so to speak. The loggia itself is small, its width is only 2.80.

The work on laying the parapet took only a couple of hours. So there is nothing particularly complicated about this, but some nuances are still present. Therefore, read everything carefully so you don’t miss anything.

What you need to know about a parapet made of foam blocks Required material for laying the parapet Laying the parapet itself from foam blocks Reinforcement of foam blocks Last row

Special offers and promotions!

Autumn discount 30%

Up to 30% discount on Rehau and KBE window profiles when concluding a contract on the day of measurement.

Drying as a gift!

When ordering glazing and finishing of a balcony or loggia from us, the Liana ceiling drying linen is free.

Discount for pensioners

We respect age and provide a 4.5% discount when completing a turnkey package of work. Blinds free

Blinds as a gift

Vertical blinds with installation as a gift to each client when ordering balcony glazing with plastic windows.

Repair and decoration of the balcony

| In our company you can also order turnkey insulation of the loggia |

| Own production | exact order fulfillment time | 100% Quality Guarantee | we employ professionals | 10 years of successful work |

I DID NOT BELIEVE THIS HAPPENED! EVERYTHING IS ON TIME, ON TIME, QUALITY AND AT A HIGH LEVEL, THIS IS A MOSBALCON. I'M GLAD THAT SUCH COMPANIES ARE IN OUR CITY.

Privacy Policy

By leaving data on the site, you agree to the Privacy and Information Protection Policy.

BASIC CONCEPTS

Site - a site located on the Internet at the address: www.mosbalkon.ru The Site Administration is located at the address: 115230, Moscow, Vernadsky Avenue, 93

User is a legal entity or individual who has posted his personal information using the Feedback Form on the pages of the site with subsequent transfer of data to the Site Administration.

Feedback form is a special form where the User places his personal information for the purpose of transferring data to the Site Administration.

GENERAL PROVISIONS

This Privacy Policy is an official standard document of the Site Administration and determines the procedure for processing and protecting information about legal entities and individuals using the Feedback Form on the Site.

The purpose of this Privacy Policy is to ensure the protection of information about the User, incl. his personal data from unauthorized access and disclosure to third parties.

What you need to know about a parapet made of foam blocks

First and foremost, you should know the maximum permissible load on the balcony ceiling. For different houses it differs in permissible load. This SNiP 2.01.07-85 says everything about this. In the article “Balcony parapet, an important part of glazing”, based on this SNiP, acceptable standards are written for old and new houses. Check out this article.

So the best solution for balconies and loggias is a parapet made of foam blocks. Lightweight, warm, reliable. But of course, each specific case must be considered and taken into account. Perhaps you first need to restore the balcony slab, and then think about how to lay out the parapet from foam blocks yourself.

Brick partition

This is the most reliable and wear-resistant, but at the same time heavy and expensive building material. Structures made from it are characterized by increased fire resistance, heat and sound insulation. To reduce the load on the slab, it is recommended to use silicate or ceramic hollow bricks. The laying technology is almost the same as for gas silicate blocks.

Before choosing this particular material for the construction of a balcony partition, you need to especially carefully assess the condition of the house. Compare: weight 1 sq.m. a wall made of the lightest hollow brick is more than 160 kg, and the weight of the same section made of foam blocks is up to 70 kg! Laying a fairly heavy and expensive brick wall makes sense in very rare situations. In most cases, the use of light gas silicate blocks is sufficient.

Required material for laying a parapet

For the laying of this parapet the following were purchased:

- foam blocks size 600x250x75 - 24 pcs.

- guide profile PN 75/40 for plasterboard – 1 piece

- glue for aerated concrete blocks - 1 bag

- and perforated metal mounting tape

Also, to secure the masonry to the side walls, you will need reinforcement or dowels. And to reinforce the blocks between each other, you can use masonry metal mesh. It comes in different varieties and is also available in convenient small rolls.

The number of cinder blocks for a house is 8 by 8

To calculate the number of cinder concrete products per house, we determine the thickness of the walls to be 39 centimeters and their height to be 3 meters. In addition, the building has five windows and one entrance door, with a total area of 10 square meters.

First, let's look at a building with overall dimensions of 8 × 8 meters and calculate the area of load-bearing walls without taking into account window and door openings - (8 + 8) × 2 × 3 = 96-10 = 86 m2. Now let’s determine the total volume of building structures: 86 × 0.39 = 33.54 m3. After determining the volume of one block 0.39 × 0.19 × 0.19 = 0.014 m3 per product, you can calculate their total number for the entire house 33.54/0.014 = 2395 pieces.

Laying the parapet itself from foam blocks

Actually the process itself. We determined where the new block parapet would be and made appropriate markings on the floor and adjacent walls using a level. Next, a guide profile was mounted on the floor using dowels and self-tapping screws. The essence of its installation is to set the most even direction of the first row of the new parapet. Plus, it’s convenient, and you can safely add a couple of points to the strength of the entire masonry.

So. Blocks were inserted into the profile along with glue, rubbing them tightly against each other. The last foam block was sawn to size and also inserted into a row along with glue. Due to their porosity, the blocks themselves are easily sawn with a hacksaw. If you have an old unnecessary hacksaw, then feel free to use it. There are, however, also special hacksaws for concrete, but they are also expensive for other volumes.

To do this, you can use a wide brush or simply immerse the block in a wide container with one side and the other. Nothing bad will happen if you wet it completely. This will not affect the quality of the parapet masonry. Although someone will say that you don’t have to get it wet, but everything will be fine. Who knows, who knows...

The next and subsequent rows are placed in a running pattern. At the same time, they did not forget to rub the foam blocks well against each other. The second row of parapet was laid out. The vertical was checked using a level, marks made on the wall and a string stretched from wall to wall along the top edge of the foam block.

Properties of aerated concrete

Aerated concrete is a modification of traditional concrete, first produced about 100 years ago. The goal of the developers was to create an optimal material for building housing, with low weight and low thermal conductivity. Simply put, an attempt was made to get rid of the disadvantages of conventional concrete. The problem was solved in a very elegant way - they changed the structure of the material, adding a lot of air bubbles to it. To do this, lime and aluminum powder were added to the usual concrete composition, which react in the presence of water and release large amounts of carbon dioxide. A porous lightweight material is formed that has all the specified properties - it is much lighter than ordinary concrete and retains thermal energy very well.

However, along with the positive qualities of aerated concrete, the developers also had disadvantages. The material is not able to withstand significant loads and does not have the high load-bearing capacity characteristic of dense concrete. The reason for this was the pores, which simply collapse under pressure, and the material sags and decreases in volume. This property initially caused the rejection of builders, for whom the most important quality of building materials has always been strength.

Over time, the technology for producing aerated concrete was developed and the limits of permissible loads were determined. It turned out to be unsuitable for the construction of important and large structures, but for the construction of private houses it is one of the best options. The opportunity to save on building a foundation and heating a house is highly valued by developers. Aerated concrete today has found its niche and is in high demand.

Reinforcement of foam blocks

Now you need to make reinforcement for rigidity and strength. A parapet made of foam blocks requires mandatory reinforcement. This reinforcement can be done in different ways, but it is necessary:

- make a hollow inside the blocks and put reinforcement there

- lay a so-called masonry metal mesh between the foam blocks, and apply the solution for the next row on it

- or, as in our case, perforated metal mounting tape was used, laid and screwed with screws on top of the foam blocks

Plus, in the side walls for structural rigidity, reinforcement is fixed between the rows or you can use long anchors or something else. In our particular case, the parapet made of foam blocks does not bear any heavy load. Since the window frame stands on a metal parapet, we limited ourselves to fixing the punched tape into the foam blocks and walls. And also connected with the original metal parapet. It is smooth and strong, but it was possible not to tie them together.

Alternatively, you can screw the tape from the inside onto each row of blocks, thereby also tying them together. But since it was planned to decorate it with decorative brick tiles, this option was abandoned. The tiles were glued onto blocks and they would simply get in the way, so they removed them inside.

In our case, the loggia itself is small, only 2.80, there is no strong and excessive detonation when closing the doors, as for example on 6-meter loggias. There, of course, it is not worth connecting a parapet made of foam blocks with the original one, and also if the original parapet is wobbly and generally not reliable. This can have a detrimental effect on the newly laid block parapet.

For those interested, here are articles on the topic of finishing with decorative gypsum and flexible tiles:

Laying foam blocks with your own hands

The procedure itself is very simple. If you need to cut the material (for example, to lay it beautifully on the side), you can take a regular hacksaw for wood. Step-by-step instruction:

- Material calculation. It is important to clearly know the dimensions of the foam blocks, as well as the area of the loggia over which you or hired workers are going to work magic. The room parameters are divided by the dimensions of the foam block.

- Materials are laid from bottom to top. Using a spatula with teeth, glue is applied to the surface. Foam blocks should be laid in a checkerboard pattern; if necessary, they can be cut with a hacksaw. To give greater reliability, thin metal wire is placed in the seams. Please note that the thickness of the seams should be small, otherwise all the heat will “fly out into the chimney” through them.

- Final interior finishing. It can be carried out in several variations.

Before you begin to lovingly insulate your balcony, turning it into a cozy place, you need to complete the markings. To do this, the surface is leveled, this is especially important if there are even small irregularities and roughnesses on it. If there is a flat base, simply cleaning the surface from construction husk will suffice. The markup should be done this way:

- On the cleaned floor slab we draw an extremely large diagonal of the balcony.

- From distant points we mark the thickness of the future wall, using a level or plumb line we draw vertical lines.

- You need to install a guide line on the marked lines at the top and bottom points (dowels will help with this).

- We tie a horizontal sliding line to the vertical lines, along which the blocks will be evenly lined up.

- This simple device will help control the smoothness of the surface.

Block manufacturers made sure that they had perfectly smooth edges. Therefore, with good and correctly executed masonry, you will get a smooth surface that will not need to be leveled additionally.

NOTE! To perform the masonry evenly, use a plumb line made of strong thread and a 300 gram weight.

An equally important stage of work is preparing the solution for laying out the blocks. The adhesive solution will help you dissolve the dry mixture in water (carefully follow the instructions and maintain the proportions, do not take the initiative!). If you take a simple cement mortar, it must be dissolved in water in a ratio of 1:3 with sand. Remember that foam blocks are a material that absorbs some moisture, so the solution should not be too thick.

Installation of blocks

Do not forget that it is prohibited to carry out work if there is frost outside (temperature below zero). The process of laying blocks is not complicated, but it is important to do everything clearly and without haste. Lay out the blocks according to the principle of classic brickwork (in a checkerboard pattern). Make sure that the laying is done along the threads that you previously stretched vertically and horizontally. Using a hacksaw and a grater, you can eliminate defects on blocks, adjusting them to the desired size. The inside of the blocks is finished with putty or sheathed with other material.

Advice! Insulating a balcony using foam blocks is a process that you can do yourself. But if you have never done anything like this before, it is better to hire outside experts who will do everything quickly and in the best possible way.

To summarize, we can say that foam blocks are a good option for insulating a loggia.

IMPORTANT! To ensure that the partition made of foam blocks does not collapse after the glue dries, it must be connected to the surface of the load-bearing wall.

It is important to follow a number of rules:

- Reinforcement is used for the connection. But it’s impossible to work with it without additional tools! This means you will need a wall chaser and other heavy tools.

- One end of the reinforcement is inserted into the load-bearing wall, the other into the structure made of foam blocks (in the process of its creation, in the 1st and every 3rd row of blocks).

- The advantage of foam block is its structure. The block is extremely easy to adjust to the required dimensions. You just need to take a regular hacksaw and work hard.

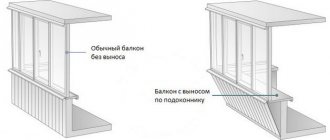

We recommend: 2 ways to make a balcony with an extension - along the window sill and the base of the slab

The last row

Two more rows were laid out using the same pattern. The second and fourth rows were reinforced. The last row of foam blocks for the parapet was first sawed to size, everything was adjusted, tried on in place, and then glued. The size was adjusted taking into account 2 cm of foam. The resulting gap between the foam blocks of the new parapet and the window sill was foamed at the end.

The last foam block was foamed on three sides, since it was not possible to securely fix it with an adhesive solution due to the window sill. The foam holds very securely.

By the way, do you know how beautiful wooden window sills are made? I think no, you don't know. And I’ll tell you about this in the article “Wooden window sills. What they are like inside." Study it so that you are not deceived when choosing window sills for yourself.

Well, in the end, it was necessary to rub all the seams between the blocks, but we decided to do this afterwards and with tile adhesive, while gluing the tiles themselves.

Cinder block building block calculator

When planning to build a private house, vehicle storage room or outbuilding from cinder blocks, developers are faced with the problem of determining the need for the material. A calculator for block walls will allow you to quickly calculate a slag concrete composite after entering the initial data, taking into account the characteristics of the material used and the thickness of the masonry composition.

Use the online calculator and start purchasing materials for the construction of your future housing

To get the result, enter the following data:

- type and size of cinder block used. Wall products have dimensions of 39x19x18.8 cm, and partitions have dimensions of 39x9x18.8 cm;

- perimeter of the building walls. It is determined by summing the length of all main walls and partitions;

- height and thickness of walls. The thickness for wall materials is 19 or 39 cm, and for partitions 9 cm;

- thickness of the binder solution layer. The laying of cinder blocks is carried out on a cement mortar laid 1 or 1.5 cm thick.

Strengthening and installation of a metal parapet

Hello! It's time to touch on an important nuance, without which most glazing work cannot be done.

The parapet is a necessary element that ensures the safety of using the balcony. In addition, it performs aesthetic and practical functions.

The parapet can be made in different ways. During my practice I have seen quite a few of them. The rarest and most ineffective method is fencing a balcony made of wood. Some make it from brick or block masonry, but this applies more to loggias. The most common and reliable type of fencing today is the metal balcony parapet. In 90% of cases, metal structures are used to create or strengthen a parapet.

Advice from builders on calculating aerated concrete blocks

Common tips on this issue include:

- The need to use a calculator.

- Entering all required information.

- Using the design of the future structure as a source of basic information.

- Indication of the presence of windows and doors, their sizes.

Modern programs significantly simplify the work of calculating various parameters.

In conclusion, we note that online calculators are freely available. That is why they should definitely be used when designing a structure, as this will only bring benefits.

Main settings

Any fence must first of all meet two main characteristics - lightness and strength. The purpose of the parapet is to create safe conditions for people, while it is important not to overload the extension slab.

The minimum height of the balcony fencing is 90 cm. For comfortable operation of the balcony, it is possible to create a parapet of greater height, since when finishing the floor on the balcony, as a rule, logs and plywood are used, which means that the floor will rise 60-120 mm, and it will not be very comfortable to go out to the balcony, especially if this happens above the 2nd floor.

Parapet parameters are regulated by current state standards and SNiP. The height of the balcony fencing GOST 25772 -83 is 100 cm (for building heights up to 30 m) and 110 cm (for building heights above 30 m).

The material used during installation determines the thickness of the parapet. Metal parapets have the smallest thickness, while fences made of aerated concrete blocks have the maximum thickness.

Which blocks are best to lay out a balcony?

To determine which material is better for arranging a balcony - aerated concrete or foam concrete, you need to familiarize yourself with the characteristics of both.

Aerated blocks provide a more comfortable microclimate on the balcony. They have high frost resistance, and therefore do not require additional insulation. The surface of this material is easier to cover with plaster.

Foam concrete blocks are characterized by more pronounced moisture-resistant properties. However, it is a little heavier in weight. Therefore, it is best to select the material based on climatic conditions.

What to make a parapet on the balcony from?

As we said earlier, fences can be made of different materials: wood, metal, brick, aerated concrete block, etc. Let's consider each of the possible options.

Tree

For those who are interested in wooden fences for balconies, they are much easier to buy and install (of course, if you do not have experience in welding), but you should know that wood is unreliable. When exposed to the atmosphere, the material loses strength. Therefore, wooden parapets cannot be used for subsequent glazing.

Metal

Metal structures for fencing balconies are the most reliable material.

If you are planning to install a balcony fence without subsequent glazing, then you can choose a forged metal structure as a parapet. This option will give the balcony individuality. Can be sold in any size for different designs.

It is worth noting that the forged parapet is mounted to the wall of the house and the external slab using anchors.

If you plan to glaze the balcony, you should choose a welded metal fence. The structure is assembled from several elements and secured with anchors. From the outside, such a parapet can be covered with siding, corrugated sheets or other material for external work.

Brick or foam blocks

Heavy fencing made of bricks or aerated concrete blocks is not suitable for remote balcony slabs, although there are craftsmen who want to insulate a balcony and load the slab to its fullest. The material is used only when installing parapets on loggias.

Glazing of the loggia

When work with concrete, blocks and other heavy elements is completed, your balcony will be transformed before your eyes. It will already look like a mini-room, but the final effect is still far away. The “dessert” awaits you ahead - interior decoration of the room and installation of the window itself.

Many buyers, when choosing a window, are looking for cheapness, so they are inclined to favor aluminum and wooden options. This is a fundamentally wrong decision, since the main indicator on the balcony is heat capacity. This can only be guaranteed by high-quality PVC windows.

When the window installation is completed and the seams are sealed, you can begin internal insulation. It is important to understand the region with what climatic features you live in. If frost is severe in winter, insulation is mandatory. For example, you can install a “warm floor”.

Balcony railing repair

Even the strongest structures deteriorate over time and require repair. In some of the most advanced cases, the best solution is to dismantle the balcony railing and completely replace the parapet on the balcony.

If the condition of the fence is satisfactory, you can organize strengthening of the balcony parapet. To do this, fastening and reinforcing elements are welded to the finished structure. Rotten or cracked parts are partially dismantled.

To determine the condition of the fence, it is necessary to carefully inspect the entire structure. I strongly recommend entrusting this task to a specialist. The result of the inspection will allow:

- Identify visible damage.

- Determine the design features of this fence.

- Assess the deterioration of old fastenings.

Strengthening a balcony parapet is possible in several ways and depends on the materials used in the fencing.

Metal structures are strengthened by welding metal corners in certain places of the parapet. Worn sections of the fence are replaced with new metal elements. In addition, the old metal parapet can be strengthened by installing additional supporting parts (pipes and corners).

The use of foam blocks is considered a good solution for strengthening the fence. This material allows you not only to strengthen, but also to insulate the balcony.

Strengthening work is carried out not only when fencing repairs are necessary, but also if you plan to do glazing. Strengthening a balcony parapet under plastic glazing is practically no different from conventional strengthening of a fence.

It is important to note that installing a parapet on a balcony should not violate accepted building codes and safety requirements. When wondering how to make balcony railings for further glazing, remember that the main thing when installing a parapet is not beauty, but safety.

Thank you all for your attention. Vorotyntsev Andrey.

Preparation before starting work

With proper and high-quality masonry, a smooth surface is formed

Before you start insulating the balcony with foam blocks, you need to make markings. The entire surface must first be leveled, especially if it has significant unevenness and differences. If the base is fairly level, it is enough to simply clean it of construction debris. The markup is done like this:

- Using a plumb line and a level, we draw two vertical stripes, which are drawn on the adjacent lines.

- The distance from the line to the surface of the base on which the installation will be carried out must be equal to the thickness of the block.

- We connect the ends of the lines with horizontal stripes, which we draw on the floor and ceiling.

The blocks are made with perfectly smooth edges, so that with proper and high-quality masonry, a smooth surface is formed that does not require additional leveling.

Important detail : To ensure that the laying is done evenly, use a plumb line with a strong thread.

Let's consider how exactly with the help of threads you can control the verticality and horizontality of the laid surface:

- We measure a distance of 5 cm from the side walls.

- We carry out this procedure along the marking lines, both on the floor and on the ceiling.

- Next, we retreat 2-3 mm from the found points into the room and screw in the screws so that the caps stick out a few millimeters above the surface.

- A thread is attached to the caps so that two vertically stretched strings are formed. Make sure that the location of the tensioned thread strictly corresponds to the markings.

- Screw in the screws until the end.

- We tie a horizontal thread to the vertical threads so that it moves freely up and down and is slightly stretched.

- With the help of such a simple device, the evenness of the surface is controlled.

We recommend: Deflector for the chimney of a gas boiler - installation requirements and installation rules.

It is also important to correctly prepare the solution for installation. When using an adhesive solution, the dry mixture must be dissolved in water according to the proportions and instructions on the product packaging. When using ordinary cement mortar, we maintain the proportions so that for one portion of cement there are three portions of sand. It is important to remember that foam blocks have the ability to absorb a certain amount of moisture, so it is not recommended to make the solution very thick.

Strengthening the balcony parapet

Mikhail Kanaryka, 5th category installer

Our site’s questions were answered by an experienced person – 12 years of experience! - installer Mikhail Kanaryka :

— When do you need to strengthen the parapet on the balcony?

The professional method is simple - you need to shake the parapet by the railing in the “back and forth” direction. If it moves at least one centimeter, it means it’s time.

The parapet is popularly called a railing. In fact, the railing is the upper part of the parapet, the so-called handrails. This is just one of many components of the fence.

— For example, before glazing, we wanted to make masonry from foam blocks in place of the parapet...

Then before this it is important: firstly, that the balcony is not ancient and in good condition. Secondly, it is appropriate to place foam blocks on the balcony, where there is so-called cold glazing. Because double-glazed windows are heavy, and the weight of the balcony can become critical.

How many pieces of foam block are in a cube?

| Block size, mm | volume, m3 | Quantity per 1 m3, pcs. |

| 600x200x200 | 0.024 | 41.7 |

| 600x250x200 | 0.03 | 33.3 |

| 600x300x200 | 0.036 | 27.8 |

| 600x350x200 | 0.042 | 23.8 |

| 600x375x200 | 0.045 | 22.2 |

| 600x400x200 | 0.048 | 20.8 |

| 600x450x200 | 0.054 | 18.5 |

| 600x500x200 | 0.06 | 16.7 |

| 600x250x250 | 0.0375 | 26.7 |

| 600x250x250 | 0.0375 | 26.7 |

| 600x300x250 | 0.045 | 22.2 |

| 600x350x250 | 0.0525 | 19.0 |

| 600x375x250 | 0.05625 | 17.8 |

| 600x400x250 | 0.06 | 16.7 |

| 600x450x250 | 0.0675 | 14.8 |

| 600x500x250 | 0.075 | 13.3 |

| Block size, mm | volume, m3 | Quantity per 1 m3, pcs. |

| 625x500x75 | 0.023 | 42.7 |

| 625x500x100 | 0.031 | 32.0 |

| 625x500x125 | 0.039 | 25.6 |

| 625x500x150 | 0.047 | 21.3 |

| 625x500x175 | 0.055 | 18.3 |

| 625x250x100 | 0.016 | 64.0 |

| 625x250x125 | 0.020 | 51.2 |

| 625x250x150 | 0.023 | 42.7 |

| 625x250x175 | 0.027 | 36.6 |

| 625x250x200 | 0.031 | 32.0 |

| 625x250x250 | 0.039 | 25.6 |

| 625x250x300 | 0.047 | 21.3 |

| 625x250x375 | 0.059 | 17.1 |

| 625x250x400 | 0.063 | 16.0 |

| 625x250x500 | 0.078 | 12.8 |

Replacing the parapet on the balcony

Someone pulls out the parapet, tying it to the car

Repairing a new parapet on a balcony always begins with removing the old one. The parapet can be removed using the most unexpected methods. For example, one daredevil “towed” it with a Zhiguli car on a cable. The dismantling took place on the first floor, so it ended without incident. If the customer lives higher up, then the old parapet is lowered down on a cable.

A new parapet is erected in place of the old one in almost the same way as during strengthening. You can install foam blocks or a metal parapet, which you order according to an individual sketch.

Someone will ask: why replace the parapet at all? It’s enough just to strengthen the old one... We answer: if you remove the old parapet, for example, on a 4-meter loggia and put foam blocks in its place, you will get a square meter of usable area.

How to make a calculation?

To carry out the most accurate calculations, quite a lot of input data is required

First, let's pay attention to the possibility of using formulas and online calculators

Both options carry out calculations based on derived dependencies and mathematical formulas, but in the first case you will have to do the calculations yourself, in the other you just need to enter the required data.

Calculation formulas

Formulas for calculating the required number of blocks for construction work:

Where:

- L is the length of the walls that will be erected using the calculated material.

- H is the height of the walls, in this case the average is taken, which determines the error.

- Spr – area of window and door openings, measured in sq.m.

- 05 is the coefficient that was adopted taking into account the work of cutting blocks.

- B – thickness of the created wall.

The result obtained determines how much material is required to complete the work. If the masonry is carried out in one row, then the value of B can be eliminated from the formula, which will allow us to obtain an indicator in square meters.

To calculate the number of blocks when calculating the required volume, you should divide the result obtained by the volume of one block; if the area indicator was obtained, then by the area of the front surface.

Calculating the parameters of the block is quite simple, since almost all manufacturers indicate its overall dimensions.

Online calculator

You can significantly simplify your calculations by using an online calculator, for example, https://stroy-calc.ru/raschet-gazoblokov. Its calculation accuracy is very high, and you only need to enter the required information.

The features of using this calculator include the following points:

- It is required to enter the overall dimensions of the block that is planned to be used during construction. When opening the page, these values are already filled with the parameters of the most common gas block. It is worth considering that the linear parameters are indicated in millimeters. If the dimensions were measured in centimeters, then the result should be multiplied by 10.

- There is also a field in which you should enter a density indicator. This parameter can be left unchanged if it is not known. Density is entered to calculate the load on the foundation and the total weight of all necessary blocks - the latter parameter will be needed when choosing the transport on which delivery will be carried out.

- Specify the parameters for the perimeter, height and thickness of the walls. In this case, the height is taken into account at the corners.

- You can also enter the thickness of the mortar that will be used for laying.

- If you need to calculate the final cost, then the price per square meter of material is also indicated.

There are also additional parameters that open when you check the boxes “Gables” and “Take into account windows and doors”. The pediment is different in that it often has solid masonry with a wedge-shaped elevation, that is, the amount of building material used increases.

In the gables tab that opens, their number, width and height are indicated. It is believed that the thickness of the pediment is the same as the rest of the walls.

A common mistake is that windows and doors are not taken into account in the calculations. The calculator in question allows you to enter the dimensions of windows and doors to calculate their area, as well as the number of these elements.

Balcony parapet cladding

Once the new parapet is ready, it's time to give it a finished look. To do this, we sheathe it inside and out.

Finishing the parapet inside the balcony

Parapet sheathing from the street side

Most often, siding, corrugated sheets (galvanized steel sheets) or plastic lining are used. All these materials will perfectly protect your new parapet from moisture.

The plastic lining on the outside is fixed in the same way as on the inside of the balcony.

Read how to cover a balcony with siding here.

Most likely, you will want to use the services of a professional. Find out how much it costs to finish a turnkey balcony, and what it includes, from this material.

Final finishing

If the attached loggia to the room is properly insulated, similar types of final coatings can be used on it as in the living room. As a rule, choose the same finishing materials that were used in the attached room.

The walls, sheathed with insulation and covered with a vapor barrier, are covered with plasterboard and then puttied. You can glue wallpaper or apply decorative plaster to drywall. You can use traditional “balcony” lining or plastic panels.

The flooring can be anything: wood, tile, laminate, linoleum or cork. Since the radiator cannot be taken out onto the loggia, a “warm floor” can be installed during the finishing process.

By insulating the loggia, you will reduce the amount of heat that escapes from your home by about a third.

Insulation of balcony parapet

When it comes to insulating the parapets of loggias and balconies, Mikhail Kanaryka is a real ace. And therefore he gave the necessary comment:

The parapet is usually insulated along with the rest of the balcony

— When should a metal parapet be insulated?

When we finished strengthening it and sheathed it on the outside (inside, of course, after insulation). By the way, insulating a balcony with a metal parapet is simply pointless. Although this will not be difficult to do.

— How is it now fashionable to insulate parapets?

Most often, polystyrene foam, penoplex or mineral wool. They are glued or inserted into the sheathing. From experience I can say that polystyrene foam is more often chosen, although penoplex is better. Polystyrene foam is cheaper. As for mineral wool: you need to be careful with it - it’s too loose.

Another material is penofol (foamed polyethylene foil). It is placed on glue or secured with a stapler on top of the foam, or under it. And always with the shiny side out. It is this side that reflects the heat back to the balcony.

Materials for additional insulation of foam blocks

It is imperative to put an additional layer of insulation, since blocks alone will not fully cope with frost.

Mineral wool

Mineral wool based on glass, slag or stone is a proven option, which not without reason occupies the first position in the market of thermal insulation materials. The cost of such material for insulating a balcony is relatively low, but the quality will be higher.

Mineral wool is produced both in the form of rolls and in the form of layers. Inside, this material can be layered (horizontally and vertically); a spatial or corrugated structure is also allowed. The secret lies in the raw materials that are used to create the insulation.

Layers of mineral wool can be of very different thicknesses - from 5 cm to 20 cm. To get maximum results when insulating, professionals advise using mineral wool, one side of which is covered with foil. Firstly, installation work will be easier, and secondly, the heat will ricochet back into the room.

Penofol

Penofol is a universal material for insulating rooms. With its help, you can turn not only a balcony, but also an attic and other basement space into a warm corner; it is also suitable for the roof and foundation. Penofol can be installed both outside and inside the building.

Diagnostics of the load-bearing slab, elimination of defects and selection of a method for strengthening the parapet

In preparation for high-quality glazing of a balcony, you should perform a number of actions:

- We carefully check the load-bearing slab and the parapet itself, identify their technical condition, and then eliminate minor defects on site.

On an open balcony, it is necessary to waterproof the surface of the floor and roof, protecting the balcony from the harmful effects of weather conditions.

- If you take on the slab thoroughly, it is advisable to completely dismantle the floor covering, but this is done only if in the future you plan to insulate it or install heating underneath it. Without dismantling, it is practically impossible to check the condition of the slab and strengthen it, and this in turn creates an additional risk of collapse.

Before starting work, we identify the degree of dilapidation and other features of this structure, after which we begin to select the necessary materials to strengthen it, without losing sight of their mass and the weight of the future glazing, which will create additional load on the balcony slab.

Important! Metal reinforcement of the parapet is an excellent option even for neglected balconies, but high-quality brickwork will help to properly strengthen the loggia.

Plasterboard partition

This is an average option that has good thermal conductivity and low weight. The construction of the structure takes literally several hours. The sheet material has an almost perfectly flat surface, which means leveling the finished partition is not required. Additional advantages of plasterboard are environmental friendliness and fire resistance.

Metal reinforcement

Metal reinforcement looks like this:

- If the technical condition of the parapet is acceptable (does not require radical measures), then it can be strengthened by welding metal corners to the areas of old reinforcement necessary for this.

- In case of severe wear and tear, the old metal parapet is carefully separated and then replaced with a new one.

What information can be obtained from the calculation results?

When using the usual formula, you can only get an approximate result of how many blocks will be needed. Therefore, recently calculations are carried out in this way extremely rarely.

The calculator discussed in this article allows you to get a larger number of indicators; there are also links to other programs that allow you to calculate the required amount of insulation.

The main results from the calculations of this calculator:

- The perimeter of the building and the total area of the masonry.

- Number of blocks, their weight and volume. Cost of building material.

- Required amount of solution.

- Number of rows.

- Approximate weight of the wall and the pressure exerted on the base.

The above list determines that the online calculator allows you to obtain information that is used in many other calculations, for example, when choosing the type of foundation and the amount of its grounding.

Reinforcing the parapet with foam blocks

Foam block, thanks to its undeniable advantages, is in great demand in the building materials market. It does a good job of strengthening the balcony parapet, while the material has increased strength and sound insulation, and the composition of the building foam block allows high-quality heat retention in the room. It is often used not only for strengthening, but also for additional thermal insulation of loggias in multi-story buildings. Another distinctive feature of the material is reasonable prices.

- Long service life.

- Low thermal conductivity.

- Increased resistance to high temperature.

- Installation using the material can be successfully performed by non-professionals.

- Safe for health.

Construction foam blocks also have disadvantages, for example, poor resistance to high humidity and natural precipitation (therefore, when installing the material, steam and waterproofing material are used).

Important! In this case, the foam block is laid first, then the waterproofing layer is applied, after which the finishing is done with galvanized metal.

The nature of work with foam blocks is as follows:

Upon completion of work on the balcony parapet, we finish it with galvanized sheets.

Features of foam concrete

Foam blocks are products made from cellular concrete.

The composition of foam concrete includes:

- Cement;

- Sand;

- Water;

- Foaming agent.

In turn, foaming agents of organic or synthetic origin can be used.

Cellular concrete blocks

The porous structure of the material is obtained due to the formation of air bubbles in the concrete. This is achieved by simple mechanical mixing of the components. Then the mixture is poured into molds. Concrete hardens under natural conditions.

Advantages of the material

Thanks to their cellular structure, foam blocks have a number of remarkable qualities:

- Low thermal conductivity - it largely depends on the density of the products.

- The light weight of the foam block allows you to build any structure without the use of construction equipment, with your own hands.

- High degree of sound insulation - the material can be used as a sound insulator.

- The closed pores of concrete give the material a low water absorption coefficient.

- Foam blocks belong to the category of non-combustible materials . Buildings and structures made from them are fireproof.

- Despite the porosity, foam concrete products have sufficient strength.

- The ability to transmit steam makes it possible to create a favorable microclimate inside the house.

- Wall structures made of foam blocks give very little shrinkage . Therefore, they can be finished immediately after construction.

- At the same time, they look good enough from an aesthetic point of view , so the walls can be left without facade decoration.

The porous structure of the material gives it many positive qualities

Foam blocks can be used without additional finishing

Comparison of foam concrete parameters with other building materials

Unlike other popular building materials, products made from cellular concrete are not susceptible to rotting, damage by insects, rodents and mold. They have sufficient strength to be used as load-bearing structures. However, the price of foam blocks is much lower than that of brick, wood or other building products.

We insulate the structure

The standard insulation of a loggia (balcony) parapet is complete thermal insulation, where the interior of the structure is insulated together with the walls, floor and ceiling.

- foil polyethylene foam;

- construction foam;

- penoplex;

- mineral wool.

If insulation is combined with balcony heating, then the most practical material is roll insulation. It has excellent heat-reflecting qualities, resistance to moisture and at the same time is extremely convenient to install.

If you take foil polyethylene foam (penofol), then you can, even without professional skills, carefully and efficiently install the first thermal insulation layer, eliminating all possible cracks in the working surface. Repeating the operation provides additional heat protection. The material is not only very easily attached to the surface (both a stapler and special glue are suitable for this), but also does not require careful leveling.

In the case of using tile insulation (foam plastic, penoplex, etc.), lathing, thermal insulation and vapor barrier film are used for high-quality installation. The final stage is the decorative finishing of the parapet, after which the loggia or balcony will acquire the long-awaited appearance.

Selection of tools and materials

Hammer drill - you can’t do without it

The materials needed are: foam blocks, fasteners, cement (it is better to use special glue), 8 mm reinforcement.

To carry out the work you will also need a minimum set of tools:

- ruler - preferably 1 meter long;

- strong thread (nylon);

- solution container (bucket);

- Master OK;

- roulette;

- workwear;

- pencil;

- bar-rule;

- drill or hammer drill.

An important aspect is the choice of cementing material. Experts often advise that it is best to use a special glue that has centering abilities when dried. The advantage of this glue is that when used, the blocks fit closer to each other, which provides better thermal insulation.