that the dangerous technology of insulating loggias with isolon has been promoted online.

10 mm thick. A video review from Instagram about the sad consequences of this technology was the last straw that pushed us to figure it out. We studied the theory and standards, performed thermal calculations, studied the recommendations of thermal insulation manufacturers and specialists in building thermal physics. Doctor of Technical Sciences Anatoly Vitalievich Zhuchkov helped us find out the causes of problems with the insulation of balconies and loggias. We express our special gratitude to him for his informative consultations.

The purpose of this article: to give good advice and protect you from mistakes that lead not only to loss of money, but also to loss of health

.

Argument No. 1. Insulating a loggia with isolon: review from Instagram

You can get into a lot of problems if you ignore the laws of heating engineering and the instructions of building materials manufacturers. See for yourself:

This thermal protection is similar to walking in the cold in light clothing. Will it keep you warm? Same with walls. If they have too thin insulation, the room will be cold. In addition, condensation will accumulate on and under the finish. Due to constant dampness, rot and mold will appear over time, which can cause dangerous diseases. We’ll talk about them a little later, but for now let’s look at where the insulation technology shown on Instagram came from.

Use of polystyrene foam

Polystyrene foam is a plastic material with a cellular structure. All internal voids are filled with gas, which ensures low thermal conductivity of the foam. Polystyrene foam is produced in the form of square sheets with a side size of 1 m and a thickness of 2, 3, 4, 5 and 10 cm. The material can have different densities, but the greatest demand is for foam with a density of 15-25 kg/sq.cm.

Foam plastic will certainly be of interest to those who are looking for ideas for quick, effective, and most importantly, not too expensive insulation of a balcony. What is the attractiveness of this thermal insulation material?

- Insulating a balcony with polystyrene foam will cost you little, since the prices for the material are quite affordable;

- Polystyrene foam is characterized by a low level of thermal conductivity;

- Foam plastic is non-toxic, therefore it does not require mandatory insulation during installation and operation;

- Polystyrene foam is easy to transport and install;

- Foam plastic is suitable for both external and internal insulation work;

- The polystyrene foam is practically not inhabited by pathogenic microorganisms.

What should you pay attention to when using polystyrene foam?

- Foam is loved by rodents, so you should protect the loggia from mouse attacks;

- It is not recommended to insulate with foam plastic in windy weather due to its high windage;

- Caution should be exercised when working with paints and solvents;

- Installing polystyrene foam inside the balcony will reduce the free space by 2-10 cm.

The difference between foamed polystyrenes

As mentioned above, the use of liquid and powder gas-forming agents is better, so products obtained using this technology have stable thermal insulation characteristics. Although, this cannot be called the only reason why Technoplex and Penoplex do not contain freon. There are two more:

- Sealed cells of new material that have not yet been used have remnants of freon. Formally, it is called safe, but in reality it is better not to deal with it. It can cause lung problems in children.

- Over time, the gas will be forced out of the cells by air and humidity. And if dirty raw materials containing styrene were used in the manufacture of the material, then the contents will penetrate into the external environment.

And if technical grades of EPS, such as Penofol, are used to treat foundations, highways, and plinths, then the presence of freon in the composition does not affect the material in any way. But to insulate your home, it is better to use safe products. Therefore, the answer to the question: Penoplex or Penofol, which is better, can be answered - the first option.

How do you know which is better Penoplex or expanded polystyrene? After all, many recommend insulating with foam plastic, because it has a low price and excellent characteristics. To answer this question, you need to know how penoplex differs from expanded polystyrene. Let's start with production technology.

Technoplex, Penoplex and even Penofol are created during the extrusion process. This allows you to obtain a very dense linear structure, which affects the material’s resistance to water and humidity, as well as strength. Therefore, foam plastic is somewhat worse than materials created by extrusion methods.

Using isolon

Another material with very attractive characteristics is isolon. Such a heat insulator will be an effective solution to the problem for those who are planning to insulate a loggia and at the same time want to save as much usable space as possible. Izolon is called foamed polyethylene. During its production, foaming of polymer raw materials is carried out in the presence of a special catalyst and under high pressure conditions. As a result, isolon takes the form of a rolled material consisting of thousands of sealed bubbles filled with air. Thanks to this structure, the thermal conductivity of isolon is very low, and sound absorption, on the contrary, is very high.

Another remarkable feature that insulating a balcony with this material has is that the heat is not only not released into the environment, but is reflected back into the room. This is possible due to the fact that the walls are finished with isolon, covered with foil on the outside.

Other characteristics of isolon include complete moisture resistance, resistance to gasoline and other petroleum products, and complete safety for human health.

Very often, isolon is used not as an independent insulation, but as one of the layers of the “thermal insulation cake”. Thus, insulation with polystyrene foam with an additional top layer of isolon shows good results.

Izolon is supplied in rolls, so before installation it must be cut into pieces of suitable sizes. The joints between the pieces are glued with ordinary stationery or special construction tape.

Comparison of insulation materials. Thermal conductivity table

Comparison of foam block, mineral wool and polystyrene foam by thermal conductivity

The table above comparing thermal insulation by thermal conductivity gives a complete picture of which material is best to use. All that remains is to compare the data from the thermal conductivity table with the cost of thermal insulation from suppliers. In this case, it is necessary to accurately calculate the required thickness of insulation when using various materials in order to select the required amount of material.

How's it going with penoplex?

Penoplex is a more modern analogue of polystyrene foam. Accordingly, the insulation of the loggia using it is carried out using a similar technology. Penoplex is called extruded polystyrene foam. If you come across the abbreviations XPS or EPS, then know: we are talking specifically about penoplex. Its main difference from polystyrene foam is its higher density, which means greater rigidity and resistance to damage due to mechanical stress. For comparison: if foam plastic for thermal insulation work is chosen with a density of 10-25 kg/sq. cm, then penoplex – 35-45 kg/sq.cm. The increased rigidity of this material makes it an ideal heat insulator not only for walls, but also for balcony floors. Coverings made from OSB panels can be laid directly on polystyrene foam, without installing joists.

Other attractive characteristics of penoplex

- Ease of installation due to the presence of special grooves along the edges of the plates;

- Long service life - up to 40 years;

- Moderate level of combustion toxicity (T2).

Physics of heat transfer

The phenomenon of heat exchange as a method of energy transfer can only occur in the presence of a temperature difference. There are three types of heat exchange in nature:

- convection;

- radiation;

- thermal conductivity.

Convection occurs due to the movement of warm and cold currents in liquid and gaseous media. For example, room air, heated by contact with a hot radiator, due to expansion, becomes lighter and rises, giving way to cold air. This process will continue continuously as long as there is a temperature difference in the room. The observed column of smoke from a chimney is a good illustration of convective heat transfer.

Radiation is a method of propagating thermal energy in the form of electromagnetic waves. All bodies around us are sources of radiation, the degree and intensity of which depends on their temperature. Some of the radiation from bodies with high temperatures can be seen with the naked eye; some bodies emit heat so weakly that it can only be detected using a thermal imager.

Thermal conduction occurs due to the transfer of energy between adjacent solid particles. Heating or cooling one area of a solid body will cause heat distribution within the body until the temperature in it equalizes. A wooden tea spoon and a metal spoon immersed in boiling water will not heat up equally. This happens because different materials conduct heat differently. Some are intense, and some are so bad that they can serve as thermal barriers.

Mineral wool - a proven option

Mineral wool based on glass, slag or stone is one of the best sellers in the modern market of thermal insulation materials. Insulating a loggia with such material will also be relatively inexpensive, which, however, will not affect the quality in any way.

Mineral wool is supplied both in the form of rolls and in sheets packed in bales. Its internal structure can be layered (horizontally and vertically), as well as spatial or corrugated. It depends on the raw materials used in the manufacture of mineral wool.

The thickness of the mineral wool layers varies from 20 mm to 20 cm. For maximum effective insulation, wool is used, covered on one side with foil. This, firstly, facilitates installation, and secondly, helps to reflect heat back into the room.

In addition, mineral wool

- is resistant to temperature changes;

- does not collapse under the influence of chemical reagents;

- provides excellent sound insulation;

- does not require preliminary leveling of the walls.

However, please note that when working with mineral wool, you should be careful, namely, use special clothing and personal protective equipment (gloves, goggles, respirator). This is necessary to prevent the negative effects of dust and formaldehyde resins on your health.

Both the wall and the floor rejoice at a large piece

In addition to hidden characteristics, externally assessed parameters also play an important role. These include, for example, linear dimensions. Due to the presence of several qualifications in this category, we will consider them separately.

The width of both insulation materials is not very diverse and is fixed at 580 and 600 mm for technoplex and penoplex, respectively.

Another indicator, the length, is a little pleasing, especially for the technoplex. If penoplex has a slab length of 1200 mm (2400 mm only for the slab of maximum density), then its opponent has 1180, 2380, 3000, 4000 and even 4500 mm. What a scope!

The range of slab thicknesses allows you to save money when combining a thermal insulation layer without resorting to laying a large amount of excess material. According to this parameter, penoplex shows results from 20 to 150 mm, with a more modest 20-120 mm for technoplex.

Foiled polystyrene foam is the best solution

What is insulation of a balcony with such material? Expanded polystyrene is also called gas-filled polystyrene. To minimize heat loss, it is equipped with a backing made of aluminum foil.

Although the moisture absorption of polystyrene foam does not exceed 0.25 mm per year, it is not recommended to install it on a floor or wall that is subject to dampness, since the foil will not allow them to dry out properly. As a result, mold or mildew may develop under the polystyrene foam.

Expanded polystyrene is resistant to temperature changes in the range of 80°: from minus 40°C to plus 40°C. This heat insulator exhibits the same stability when interacting with alcohols. The integrity of expanded polystyrene can be damaged only by the action of solvents, but when insulating a balcony it is quite possible to do without the use of such means.

Expanded polystyrene is considered a very flammable material. Its ignition occurs already at 210-310 °C, so the most serious manufacturers add fire retardants to the raw materials, which significantly reduce the flammability of polystyrene foam. The presence of such components in the heat insulator can be recognized by the letter “C” in the material marking, for example, PSB-S.

As a rule, expanded polystyrene is supplied in the form of rolls 1 m wide. The thickness of the insulation is 10-50 mm.

When thickness matters

In practice, to assess the ability of a building structure to retain heat, one coefficient? few. For example, our experience suggests that of two brick walls, the thicker one is “warmer”. Therefore, the thermal efficiency of a particular structure is determined by the indicator of resistance to heat transfer - thermal resistance (denoted “R”). In thermal engineering calculations, this indicator helps to take into account both the thickness and the nature of the material used in the structure.

R, (m2°C)/W is the amount of heat in watts (W) passing through 1 m2 (square meter) of the surface of a structure if the temperature difference on its opposite surfaces is 1 °C (degree Celsius).

As you can see, the formulation of R resembles the formulation of ?. However, these are mutually inverse quantities - the more one, the less the other. They are connected by a simple formula:

R=S/?, where S (in meters) is the thickness of the material layer or the thickness of the structure made from it. If the wall is multi-layered, then the thermal resistance of all its layers is added up, obtaining the total thermal resistance.

Is the frying pan with the cast iron handle still on the fire? Then let us explain what thermal resistance is using its example. If you wrap a heated pen in a piece of newspaper, it will be of little use. Let's wrap more newspapers - now it's normal, not hot. In both cases, the material is the same – paper. Lambda has not changed, but the thickness of the thermal insulation has increased. Thermal resistance has increased, which means heat flows worse.

Let's repeat the experiment, but with a woolen rag. Wool itself retains heat better, since its thermal conductivity coefficient is lower than that of paper (? = 0.03 and 0.14, respectively). Therefore, in order not to burn your hand, you no longer need to wrap the rag too much. The same thermal resistance R as a potholder made from thick newspaper will be achieved by just 1-2 layers of woolen fabric.

In other words:

- By changing the thickness or changing the number of layers, selecting materials according to the coefficient ?, you can get the thermal resistance you need.

- The higher the thermal resistance R, the better the heat retention. And vice versa.

Applying the results of our frying pan experiments to insulating a balcony with a thin layer of isolon, we can conclude:

Walls and ceilings with low heat transfer resistance will cool down quickly - the apartment will be cold.

Argument No. 3. Standards and calculations

Let's return from academic terms and frying pans to Amateur technology. It is based on the “scientific” argument of its author: “ Believe me, I know what I’m saying.”

“, we are moving on to heat calculations.

LET'S SPECIFY. The calculations are voluminous and complex, so in this article we present only their results with explanations. If you are interested in the details of our calculations, read about them here.

1st result: You can’t do that!

In the Amateur technology of insulating a loggia with isolon, the wall in section has the following structure:

The diagram shows everything that is needed to calculate the total heat transfer resistance of the wall: names of materials in the layers and their thickness, thermal conductivity coefficients? (lambda) layers and their thermal resistance R. We find that the heat transfer resistance of the wall is 1.337 m2°C/W

.

Similar calculations for the ceiling give even lower figures - 0.804 m2°C/W

. Section of the ceiling in the diagram below.

Let's look at the standards. Strange. Apparently there is some kind of typo in them, because they require that enclosing structures in Moscow (external walls and ceilings) have a thermal resistance of at least 2.99 m2°C/W

.

CONCLUSION: The statement that 10 mm thick isolon is sufficient for high-quality insulation of balconies and loggias is erroneous. This is too thin a layer, which is a gross violation of the rules of construction heating engineering.

2nd result: Cold and expensive

Let’s look at what such stupid thermal protection will lead to, using the example of the apartment shown on the plan:

Here the balcony is attached to the living area by dismantling the window and door unit. It is highlighted in red on the plan. They use the same amateurish technology for insulating balconies and loggias 1 cm isolon, which also provides for the installation of electric heating under the floor covering.

Heat calculations show that if the apartment before reconstruction was +20°C, then after:

• without additional heating, the temperature can drop to +15.8°C

;

• with constantly working electric heated floor – up to +17.6°C

, which is also far from a resort.

What about paying for electricity? With good thermal insulation, the heated floor turns on/off, working 30-50% of the time during the day. In the case under consideration, the insulation is weak, so the warm floor works constantly, trying to warm the room.

Let's figure it out. An electric floor with a power of 400-500 W will fit on such a balcony. In a day it will generate 9.6-12 kW, in a month 288-360 kW. If the price tag in Moscow in 2022 is 5.47 rubles/kW, then the payment will be 1575-1969 rubles

. And this is just for one small balcony three by a meter!

CONCLUSION: By insulating your balcony with 1 cm of isolon, you get invigorating freshness and overpay for electricity.

3rd result: Wet corners and mold

When we calculated the thermal resistance of walls and ceilings, we did not take into account the zones where such resistance would be even lower.

These are the so-called cold bridges passing through fasteners, sheathing of PVC panels and corners. In these places, the walls and ceilings cool especially intensely. Heat calculations show that in cold weather the temperature in the corners of a balcony insulated with a thin layer of isolon can drop to +5.9°C

!

And this is only on the PVC sheathing on the side of the warm room. Under the skin the temperature is even lower. For example, on the ceiling, isolon will freeze to -2.8?

C. In such places, condensation will form, and this is dampness, which will lead to damaged finishes, fungus or mold.

CONCLUSION: Proper calculations for insulation will save you from dampness and mold on your balcony or loggia.

ARGUMENT No. 4. HEALTH IS IN DANGER

If you carefully watched the video review from Instagram, you probably noticed a dark coating on the balcony railing. It's mold

or mold fungus, which causes much bigger problems than temperature discomfort or overpayment for light.

Even a small moldy area sprays millions of toxic spores. Once in the body, they can dramatically undermine health - cause the development of allergies, headaches, diseases of the skin, lungs, kidneys and liver. A person’s immunity decreases, the risk of cancer increases and, in general, the aging of the body accelerates.

Of the many types of mold, the most dangerous is black mold, which often grows in damp corners, on window slopes and window sills. It is the cause of the fatal disease aspergillosis.

.

More details about the dangers of mold fungi, as well as the signs of their impact on humans, are described in this video:

If the balcony or loggia is not insulated correctly, then you will have to constantly fight the fungus. But even by drying the air with a fan heater or electric heated floor and regularly washing off the mold, you will not remove it completely. It will still grow not on the trim, but under it or inside the wall. What's next? Diseases that become chronic and treatment without end.

REMINDER. According to GOST R ISO14 “Air of enclosed spaces”, all structures contaminated with mold must be cleaned, and if complete cleaning is not possible, removed. Therefore, Amateur technology in the future is a complete rework of balcony insulation and finishing. Have you already provided the asking price? Dismantling, purchasing new materials, renovating again. Add here the search for builders and payment for their services, as well as destruction and discomfort.

CONCLUSION: Amateurish insulation of a balcony or loggia using 1 cm of isolon is a way to make a person sick and poor.

Argument No. 5. Manufacturer's recommendations

Let's take a look at the website of the Izolon® trademark - JSC Izhevsk Plastics Plant. The manufacturer certainly knows all the nuances of using his material.

How to use polyethylene foam

The installation of Izolon® products is described in detail by the company's engineers in the album of technical solutions. Let's see. Steam, hydro, and wind barriers are made from 5-10 mm isolon, but nowhere are there instructions to use it as full-fledged thermal insulation. Wherever reliable protection from frost is needed, the thickness of the main insulation made of foamed polyethylene should be 100-150 mm!

The manufacturer's recommendations coincide with our heat calculations. They also show that, taking into account corners and other cold places, the isolon layer when insulating balconies or loggias should be at least 10 cm.

CONCLUSION: The manufacturer confirms that reliable thermal insulation of building structures cannot be 1 cm thick.

Expanded clay

Expanded clay is produced by thermal transformation of low-melting clay. As a result, expanded clay takes the form of granules with a porous structure. During thermal insulation work, expanded clay is used only as backfill at the stage of floor insulation. Expanded clay is especially suitable for arranging wooden floors.

Expanded clay absorbs water well, but releases it slowly, so it is recommended to cover the backfill with plastic film before pouring the concrete screed. Please note that the thickness of the screed must be at least 5 cm, otherwise cracks may appear.

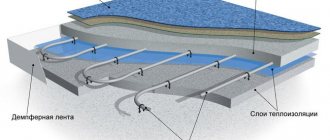

Thermal insulation of flat roofs

Flat roofs are usually insulated with polystyrene foam due to its resistance to mechanical stress.

The material is also applicable to pitched roof types, but for them experts often recommend the use of fiber insulation. Mineral wool and glass wool better fill the under-roof space, which eliminates the appearance of cold bridges.

Preparatory work and waterproofing

Before installing thermal insulation, it is necessary to prepare the insulated surface. It should be dry and clean. The old backfill is removed. Then the waterproofing film is laid.

This is necessary to ensure that moisture does not accumulate between the insulation and the roof, which can lead to mold, rotting of wooden structures and corrosion of metal elements.

It is important to install the film so that there is a gap of 2 cm between it and the sheathing to remove moisture

Installation of insulation

Foam boards are laid on top of the waterproofing. They can be secured using glue, liquid nails, anchors, dowels, or flooring. For additional reliability, mounting in several ways is possible.

When laying insulation, care must be taken to ensure that there are no voids and that the slabs are tightly adjacent to each other.

The resulting cracks must be filled with foam.

Covering with geotextile material and gravel

Geotextiles are laid on top of foam boards. It protects the roof from the negative effects of the sun and reduces the effect of mechanical loads. As a result, the service life of the roof is increased.

Following the geotextile is backfilling with gravel, the fraction of which is 16/32. The thickness of the layer should be at least 5 cm. A cement-sand screed is made on top of the gravel.

Penofol

Insulation of loggias, interfloor, basement and attic floors, foundations, roofs - all this work can be carried out with penofol. This material is suitable for both external and internal thermal insulation.

The most commonly used types of penofol:

type A – foil-coated on one side; type B – foil coated on both sides; type C – foiled on one side and covered with a self-adhesive backing on the other; types R and M – embossed (foiled on one side); ALP type – foil-coated on one side, laminated with polyethylene film on the other.

Density and thermal conductivity of thermal insulation in the form of plates and segments

The table shows the density values and temperature dependence of the thermal conductivity of thermal insulation molded in the form of slabs, segments, etc., as well as their maximum operating temperature.

Thermal insulation density, thermal conductivity and temperature are indicated for such thermal insulation as: diatom segments, sovelite segments and shells, newel shells, asbestos cement segments, vulcanite slabs, vermiculite shells, foam concrete segments, foam glass slabs, cork segments, peat segments, mineral wool segments, alfol smooth sheets (segments), corrugated aluminum foil (segments), ball insulation backfilled into segments, rod thermal insulation backfilled into segments (porcelain rods with a diameter of 0.5 mm).

The lightest thermal insulation is alfol; according to the table, it has a density of 200 kg/m3 and a maximum operating temperature of up to 500°C. High-temperature thermal insulation (up to 2000°C) includes ball and rod insulation. However, such thermal insulation has a high density and low thermal conductivity, equal to 0.23...0.39 W/(m deg). The thermal conductivity of thermal insulation depends on temperature. The table presents formulas for the temperature dependence of thermal conductivity of thermal insulation and its maximum operating temperature.

Note: to calculate the thermal conductivity coefficient from the dependencies in the table, it is necessary to enter the temperature in degrees Celsius.