This article reveals in detail all the intricacies of replacing different types of door lock cylinders.

Today, mortise and rim cylindrical locks have become an integral part of our daily lives. Such locks can be found almost everywhere - on the entrance doors of our houses, apartments and offices, on interior doors. Moreover, such locks are installed on wooden, metal, and metal-plastic doors. That is, everywhere. That is why the issue of lock repair, in particular replacing the lock core or cylinder, is relevant and important in our time.

The main distinctive feature of a lock with a cylinder is that if such a lock breaks, it is enough to replace only part of it - the cylinder - and at the same time, do not change the entire lock. By changing the cylinder, the set of keys that open the lock also changes. That is why cylindrical locks are used to increase the reliability and security of all types of doors.

Nowadays, replacing the lock cylinder occurs quite often. For example: if one or more keys are lost or stolen, if there are difficulties in opening the lock with the key (it won’t turn, it’s difficult to turn, it’s jammed), if you turn the key in the lock without opening the door, if you move or buy a new apartment or office, when you need to change a set of keys opening the door. In such situations, the entrance lock cylinder needs to be replaced.

Why do you need to change the larva?

The core of the lock bears the entire load during operation, including mechanical damage and manipulation by burglars. The need to replace the cylinder, even if it is working, arises in the following situations:

– Lost key. The loss of even one key from the set is a reason to urgently change the lock cylinder. There is a high probability that the key is not just lost, but stolen. If you hesitate to replace it, you may find that property is missing due to the entry of an unwanted guest.

– Temporary transfer of the key to other people. If the key was handed over to hired workers for repairs or cleaning, it is recommended to replace the lock cylinder upon completion of the work, even if the key has been returned. The reason here is that they could make a duplicate of the key while it was in the wrong hands.

– Doubts about reliability. Entrance metal panels are sold with locks, the reliability of which is questionable. Many owners change the core immediately after installing a new door leaf.

– Burglary or attempted burglary. After rough intervention, even if opening the entrance group fails, the lock is damaged and does not function as before.

A faulty cylinder must be replaced. It is worth paying attention to the slightest problems, for example, the need to use more force when turning the key than before. If such changes are ignored, the problems will increase until the door is locked with the key inside, and it will be impossible to enter or leave the apartment.

Method 1. Lockpick from hairpins

The mechanism of such a lock is based on a set of levers - special plates with shaped slots. On a proper key, the ridges on the bit line up with these slots.

When the key is rotated, the levers rise to the desired height, forming a path along which the locking pin moves.

To open the lever lock, you need to lift all the plates, line them up in the correct way and move the bolt. It sounds easy, but in reality everything is much more complicated. Especially for those who are doing this for the first time.

What types are there

Before changing the cylinder, you need to decide what type it is. A wide range is represented by the following types:

Cylinder. One of the popular types that are installed on many doors. Cylinder systems, in turn, differ into such subtypes as “key-key” and “key-spinner”, “gear” and “half-cylinder”. They differ in the complexity of dismantling and installation, but each of them, if you have sufficient knowledge, can be changed independently.

Pin. This type is also called English. It is inferior to cylinder in burglary resistance, so it is used less often.

Disk. A characteristic feature of the locking design is the rotary discs that secure the lock in the locked position. It is difficult to replace this type, since it is difficult to find a related cylinder. Therefore, it is more advisable to replace the entire lock.

Cross-shaped. There are pins inside the mechanism that can be easily turned using a Phillips screwdriver. Due to such a low level of burglary resistance, this type is in low demand.

Particularly difficult. The more complex the locking mechanism, the more reliable protection against burglary it provides. But this comes with another difficulty: it is almost impossible to replace the larva yourself. There is a risk of damaging a complex and expensive device, so it is advisable to seek the help of a professional.

Preparing to repair the castle

Replacing the front door lock cylinder begins with determining its type.

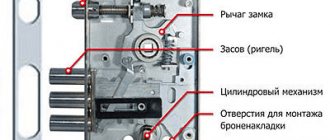

The locking mechanism consists of pins, washers, rotating blocks or movable probes. After turning the key in the core, they line up in a given order, and the structure opens. Their number depends on the complexity of the secret mechanism. Incorrectly aligned core elements prevent the locking bolt from moving, so the lock remains closed. The complexity of the secrecy mechanism depends on the quantity and quality of its parts.

Not all locking mechanisms can be partially replaced. For example, in lever-type structures, the core is integrated into its body, so in case of any malfunction, the entire constipation is replaced.

Designs with a cylinder mechanism have a replaceable core: disk, cross-shaped, pin, complex. Since disc cylinders suitable for an existing lock are not easy to find, locks of this type are completely replaced. To replace the inside of the cross-shaped mechanism, you will need to completely disassemble it. In a pin lock, you can easily replace the core if it is made with an English key. Pin locking mechanisms with a perforated key can be opened by drilling or knocking out the cylinder, which is technically difficult, but doable.

High-quality cylinder locks with a titanium body have more than a million code combinations, keys with floating elements and other additional security systems. In such designs, it is almost impossible to replace the cylinder yourself; it is better to entrust this to professionals or replace the constipation completely.

The standard of the mechanism must be taken into account. The cylinders produced according to the DIN standard for one type of core are interchangeable regardless of the manufacturer. The only things that matter are the thickness of the door leaf and the location of the fastening screw. RIM standard cylinders are produced for rim locks and are used quite rarely.

To replace the larva you will need:

- hammer;

- drill;

- screwdriver;

- crosshead screwdriver;

- roulette;

- center punch;

- replacement part

How to determine the possibility of self-replacement

Each type of cylinder requires certain actions to be replaced. There are types that cannot be replaced at all: in this case, the entire locking device is replaced. To determine the possibility of dismantling the old separate cylinder and installing a new one, you should pay attention to the following factors:

– Key shape. If it is flat with cutouts, cross-shaped or semicircular, complemented by notches, then the core can be replaced. If the key is round and there are two blades with notches on its shaft, then the lock it serves is not a cylinder, but a lever lock. This is a different type, based not on a cylinder, but on levers.

– The design of the lock at the end of the door leaf. If the head of a screw for a screwdriver (Phillips or flathead) is visible on the metal strip under the hole from where the locking tabs extend, then the lock cylinder can be changed. This screw holds the core and will have to be removed to remove it.

The cores in most cylinder mortise mechanisms can be replaced, but the overlay types are much more difficult. Only some types, including SHO-25, allow spot replacement of one element. Often, in order to protect entrance doors from burglary, you have to either change the entire rim lock, or purchase a mortise lock and install it in the door leaf.

General concept of the castle face

Surely many people imagine what the lock cylinder looks like - a mechanism that looks like a metal cylinder. Most locks are designed according to this principle. To replace the cylinder, you don’t have to purchase expensive parts or spend money on a new lock. It is also easy to remove and replace yourself. This is a huge advantage, since there is no need to spend money on the services of a specialist. Replacing the cylinder does not affect the condition of the lock; it remains just as strong and reliable.

How to choose a replacement secret

To choose the right replacement model from the wide variety available on the construction market, you need to pay attention to the following parameters:

Size . It is necessary that the new part fits freely into the prepared hole on the existing lock and fits tightly there.

Safety . It is advisable to install a new cylinder, the level of protection of which will be higher than the existing one.

Convenience . For home use, the “key-spinner” modification is more convenient, but it all depends on individual preferences. It is important to take this parameter into account when choosing.

Color . Models differ not only in level of complexity, but also in color. The construction market offers glossy and matte options, as well as those imitating silver or gold. It is important that the shade of the new cylinder matches the locking device. This way the door structure will look harmonious.

Method 1. Tin master key

Such locks are locked using pins assembled in a single block - the cylinder. It has a rotating core with a series of spring-loaded rods cut into two parts.

When there is no key in the hole or it is incorrect, the pins enter the core and block it.

A key with the correct profile raises the pins to such a height that the upper one is hidden in the body of the cylinder, and the lower one in the core, allowing it to rotate freely and open the lock.

It turns out that you need to recess all the pins to release the core of the larva, and then turn it. For mechanisms with several revolutions, the procedure will have to be repeated.

How to change the cylinder in the front door lock

1. Unscrew the fastening screw holding the old cylinder.

2. Disconnect the cylinder.

3. Pull out the cylinder with a key.

4. Install a new one in place of the old core.

5. Secure it with a screw.

6. Check the functionality of the mechanism by locking and unlocking it.

This instruction is relevant for the cylinder mechanism of the “key-to-key” type (on both sides of the door there are keyholes that are unlocked with keys) and “key-turner” (there is a keyhole on the outside of the door, and a handle for unlocking the door on the inside). The second option is more convenient because it does not require the use of keys to open and lock the lock from the inside. The handle turns easily, which is why it is called a pinwheel.

Features of selecting a new door mechanism for replacement

- The new larva should match the old one in length and diameter. To do this, the cylinder must be removed and measured. The length depends on the thickness of the door and lock lining, and the diameter depends on the model and manufacturer.

- Rotary cam location: symmetrical or offset to the outside or inside.

- The distance from the end to the mounting hole may be equal or slightly greater, but not less. If you move or change the configuration, the insert will not be able to be secured.

- Choose the desired design: with a keyhole on both sides or with a turntable for opening the lock from the inside.

- You should choose a cylinder from the same manufacturer as the lock.

- Complete with the required number of keys so that you do not have to order additional production.

- The color of the coating on the cylinder should be in harmony with the color of the lock and escutcheon.

- The degree of protection is determined by the burglary resistance class. The reliability indicator should not be inferior to the previous mechanism.

- The ability to resist drilling is provided by the material of the body and the pins inside. For their manufacture, special hardened steel is used.

How to change the cylinder in a lock with overhead handles

If handles are built directly into the locking device, it is convenient to use such a mechanism. However, the presence of handles complicates the process of replacing the lock cylinder. You need to do the following:

1. Unscrew the fastening screw with a screwdriver. This screw is easy to find: it is located under the retractable tabs.

2. Remove the screw completely so that the cylinder dangles freely. It is not possible to remove the cylinder yet, since it is blocked by the overhead handle.

3. Remove the handles on both sides by unscrewing the fastening bolts holding them. Now access to the cylinder is completely open.

4. Insert the key into the keyhole and turn it slowly so that the cylinder is secured to it.

5. Pull out the key along with the cylinder.

6. In the new cylinder, use the key from its kit to combine the flag with the cylinder.

7. Insert the cylinder into the locking device.

8. Secure it with a screw.

9. Secure the handles in the same place.

10. Check the operation of the handles and locking with a new core.

Disassembly and removal of the larva

The method for removing the cylinder from the lock depends on whether the mortise or overlay mechanism needs to be disassembled.

To remove the lock cylinder of a mortise-type entrance door, you need to unscrew the middle screw securing the cylinder in its body. Then you need to insert the key into the hole and turn it so that it is possible to remove the cylinder from the body. If something does not work out, you need to turn the key clockwise with a minimum rotation angle of 10-15° until you can remove the flag - a part that prevents the removal of the larva. Then we press on it and remove it from the nest.

If the lock is overhead, you will first have to remove it from the door by unscrewing the screws that secure its body to the door leaf. Then unscrew the screws securing the core to the body of the mechanism.

It is necessary to drill out the lock cylinder if it cannot be removed any other way. If the procedure is carried out correctly, the structure will remain intact and function after replacing the core. The sequence of work is as follows:

- Using a punch and a hammer, mark the drilling point. It is located above the keyhole, under the line passing through the outer and inner cylinders.

- Using a drill with a diameter of 3 mm, drill the cylinder, destroying the pins.

- If this was not enough, the drill is replaced with a larger one (6.5 mm in diameter) and the cylinder mechanism is completely destroyed. If this is not enough, use a drill with a diameter of 19 mm or a specially tubular drill, but after this the constipation will have to be replaced completely.

- A flathead screwdriver or wire inserted into the core is turned like a key and the lock is opened.

In order not to destroy the structure, the drill must be held level, the drill should first be lubricated with machine oil. Overcoming each pin will be accompanied by a feeling of resistance. It is better to choose a low speed and do not put pressure on the drill, so as not to completely damage the mechanism. When removing the cylinder from the cross-shaped cylinder mechanism after drilling with a screwdriver, you need to lift the stopper and move the lock using the hook.

Tips for choosing a new one

Before replacing the cylinder in the lock, you will need to purchase another one. Before purchasing, you need to measure the thickness of the door, taking into account all the linings, including insulation, so that the core does not sink into it. Then the cylinder is removed.

It is necessary to measure its length, width and diameter. Despite the fact that most manufacturers produce universal cylinders, it is better to purchase a cylinder of the same brand as the old lock. It is necessary to consider whether the locking mechanism is closed on both sides with a key or has a turntable on one side. The color of the core also plays a role so that it does not stand out against the background of the constipation body.

Another factor influencing the choice of cylinder is the material from which it is made. The most unreliable are silumin cores. It is better to prefer products made of aluminum, steel, zinc or an alloy of aluminum and zinc. You shouldn't skimp on the larva. A high-quality product from a trusted manufacturer will not be cheap, but it will not have to be replaced too quickly.

How to change the cylinder of a rim lock

The process of dismantling the old core and installing a new one in an overhead mechanism differs little from a mortise one. This also allows access to the cylinder and replacement is performed. The difference is that in order to get inside the overhead lock, it must be removed from the door. The stages of work are as follows:

- Unscrew the fastening screws holding the lock to the door leaf.

- Remove the lock.

- Remove its back cover by unscrewing the fasteners.

- Remove the old cylinder by unscrewing the screws holding it in place.

- Install a new cylinder.

- Screw the fasteners.

- Return the lock to its place.

- Screw in the fasteners.

- Check the quality of the lock.

Is it worth repairing the castle?

Repairing bolts in a metal door is possible only in the event of a minor breakdown, and only on condition that the manufacturer has taken care to produce spare parts. Unfortunately, not all manufacturers do this.

But if you calculate how much it can cost to dismantle, diagnose the lock, reassemble it, purchase spare parts, repair and installation, then in most cases it turns out that it is cheaper to immediately buy a new locking device. But this applies for the most part to domestically produced deadbolts.

If your metal door has an expensive imported deadbolt model, under which the entire structure was mounted, sometimes it is simply impossible to insert another lock.

You have to replace the entire door or try to repair the locks on the metal frames. Of course, if you have no experience in such matters, and you are not familiar with the design of the deadbolt, you will need a good specialist.

Helpful Tips:

The following recommendations will help you replace the cylinder without errors.

– Difficulties may arise when connecting the fastener to the cylinder. When tightening the mounting screw, you need to keep it perpendicular to the end surface. Insert into the hole slowly and until it stops.

– If the purchased larva turns out to be slightly larger than the existing hole, then it can be expanded using a drill and chisel.

– When placing a new core in the lock, you need to be careful that it does not fall inside the door. It will be difficult to find and remove it; you will need to remove the entire lock.

– The mounting screw must hold the cylinder securely, but excessive tightening force may strip the thread. When the head of the fastener is already level with the metal strip, you need to turn it 1.5 turns - this is enough.

– A common mistake when installing a cylinder yourself is its misalignment. Because of this, the lock will not function properly, so it is important to ensure that the cylinder is positioned correctly.

Planned replacement

This refers to a situation where, for some reason, the door lock cylinder in relatively working condition changes. That is, if there is a key that opens the lock on at least one side. This happens, for example, if one of the keys is lost, or the inside of the mechanism is rusted (clogged).

In the normal state - closed or open - a pin protrudes from the cylinder, which pushes the lock bolt. Therefore, to replace the mechanism, it is necessary to have a key - only when you turn it a quarter (or half) turn, the pin will hide in the lock cylinder and it can be pulled out.

In this case, the sequence of actions is as follows:

- You need to remove the armor plate and handles from the door lock (in some models, the handles are combined with external panels that also secure the cylinder)

- At the end of the door, near the bolt (tongue) of the lock, there is usually a fastening screw that holds the cylinder. It needs to be unscrewed.

- A key is inserted into the working part of the lock. It must be turned little by little and at the same time pull (or push) the larva. When the pin stops clinging to the inside of the lock, its cylinder will simply come out - it can be easily pulled out.

Now you can replace it with another one, reassemble the lock in the reverse order, and it is ready for use again.

Recourse

Replacing the cylinder lock cylinder is a simple job, but errors are possible here too. It is important to choose the right replacement model and install it correctly. Upon completion of the work, you need to carefully check its results. How easily the key turns in the keyhole. Do the door handles respond or are they blocked? How smoothly do the locking tabs change their position? Do you hear any extraneous sounds when unlocking and locking the door?

If you don’t want to search for and install a core, the right decision is to turn to specialists. Our lock service performs this work on a turnkey basis: the locksmith will come to you immediately with a set of several cylinders, select the one you need and install it. We work in Moscow and the Moscow region. If you live in this region and want to change your lock, call us and schedule an appointment. Our technicians are proven professionals who are never late.

Removing the old lock core

To change the cylinder in the door, you need to release the mechanism from the drive. When it comes to a rim lock, all you need is a screwdriver to remove the screws. Mortise models can also be removed, but from the door end, where two screws are also located. But if in the first option the core is removed along with the other components, then in the latter you need to act differently, because the larva “pierces” the lock body through and through.

Step-by-step instructions consist of three stages:

- At the end of the door, unscrew the fastening bolts. In most cases there are two, perhaps three. The bolts are removed.

- Insert the key and turn it 10-15 degrees until the tongue is flush with the core.

- They take it out of the seat right by the key, since it will no longer be possible to free it.

First remove the decorative trims from both sides of the door leaf. Otherwise, changing the larva will not work. But now you can take it with you and go to the store. Attach it to the new one, making sure that the dimensions and position of the tongue match. This is the best way to select the core. At a minimum, you need to take measurements, and even better, make a sketch with dimensions.

Other security cylinder standards

If the cylinders described above fit certain standards and can be installed in any cylinder lock body, then the following considered security mechanisms have different sizes and are strictly individually suitable for one specific lock (or for some models of one manufacturer). For example, the Turkish cross cylinder mechanism.

Suitable only for locks of this type (can be installed in locks from other Turkish manufacturers (for example, FAYN), or with minor modifications, for locks made in China (for example, 3M)).

And here is the domestic cross-key secrecy mechanism:

Suitable only for locks made in Kirov. And as you probably already understood, the Kirov mechanism cannot be inserted into the KALE KILIT case and vice versa.

For some domestic rim locks, it is possible to purchase a cylinder separately. For example, the frequently broken “FORT” mechanism, which is only suitable for locks manufactured in the city of Petrozavodsk.

The locks are of terrible quality, the security mechanism and lock components are made mostly of silumin (a very fragile alloy), hence frequent breakdowns and, of course, the opportunity to purchase a new cylinder! In the next photo, from left to right, you can see the cylinder mechanisms for the Glazov and Iset rim locks.

Their problem is the same - soft materials and poor workmanship. Often such specific cylinders (there is no choice of a better quality cylinder) are ordered and manufactured in China.

If you need to replace a lock cylinder in Nizhny Novgorod, our service specialists are always at your service by calling +7-987-110-30-43.

We will first find out what will suit you, advise you on prices and, after agreement, we will send a specialist to you for a replacement.

Our company's assortment includes a huge selection of CMS. We sell both cheap Turkish and Chinese-made larvae, as well as highly secret CMS from renowned European manufacturers. If, after reading the material, the lock cylinder still raises questions, we are always happy to advise you in the comments under this material.

Repairing the door cylinder

There are cases when the larva does not need to be replaced with a new one, but can be repaired. To do this, first of all you need to find a plate secured with “claws” and move them a little so that you can move the plate. This will allow you to see the core of the castle, where the problem often lies.

But repairing an old cylinder is only possible if the part must be disassembled. During work, you must be extremely careful and pay special attention to removing the pins, because if they are assembled incorrectly, the lock can be thrown away, because the key that was previously used may not fit at all.

The cause of a door cylinder malfunction may be rust. To fix the problem, it is best to use graphite. Lubrication oils are already becoming obsolete, because their frequent use leads to complete failure of the part. This happens because oil tends to thicken over time.