Almost every person locks the door when leaving home. Therefore, sooner or later you encounter a problem when the front door lock for some reason has become unusable. This is quite natural, because every item deteriorates and breaks over time, which means the time comes to repair the lock or completely replace it. Usually it is enough to replace the lock core and the door will be locked again. How to remove the lock cylinder of the front door and replace it without calling a technician, read our article.

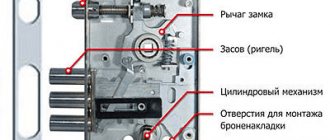

What is an entrance door lock cylinder?

The lock cylinder serves to transmit force from the key to the door mechanism.

The most popular are English locks, that is, those with a cylinder type of secret mechanism (cylinder). This element serves to transmit force from the key to the door mechanism. The cylinder can only activate the bolt when the corresponding key is inserted into the hole, which the secret system recognizes as “its own” and begins to rotate.

The cylinder mechanism has an elongated shape, so in simple terms it is also called a larva, secret, etc. The popularity of such locks is explained by the fact that they are easy to maintain; opening them does not require much effort and the key is small in size. If the cylinder fails, it can be quickly replaced, without requiring disassembly of the entire lock or its complete replacement.

Expert advice

If you have difficulties opening the door, you should not immediately change the secret; sometimes it is enough to lubricate the parts of the lock, and it will work normally again. To avoid problems with fixing the cylinder, it must be positioned perpendicular to the end of the door.

If the key in the lock is broken, then the situation is not as bad as it might seem. In this position, the cylinder is unlocked. It is unlikely that you will be able to get the fragment out, but you can turn it with a flat screwdriver, after which you can easily remove the cylinder and replace it.

Following the recommendations of specialists, you can independently dismantle and replace a failed cylinder mechanism. If you are not confident in your abilities or do not have the appropriate tool, then you should call a specialist.

Types of lock larvae

The cylinder is the core of the lock, consisting of a keyhole, several parallel code channels - springs with pins are inserted into them. Only at a certain position of each of them is the cylinder able to rotate and unlock the bolt. The notches and teeth on the key are responsible for lining up the pins in the desired position.

The larvae in modern locks are available in 2 types:

- double-sided - the core is unlocked with a key from both sides of the blade;

- one-way (with a turntable) - the door opens and closes from the inside without using a key (using a rotary handle).

Also, larvae are classified into 3 types according to the level of burglary resistance:

- Low - the pins allow for up to 10 thousand combinations, the pins are made of wear-resistant brass. Doors made in China are often equipped with such mechanisms.

- Medium - up to 50 thousand combinations are provided, but the material is still wearable and not durable.

- High - the number of combinations is over 100 thousand. The lock is made of high-quality materials - a brass body, hardened or magnetic pins. Protection against knocking out and drilling is provided.

Cylinder mechanisms are popular due to their ease of operation and maintenance. If the cylinder fails, there is no need to disassemble the entire lock and replace it with a new one - just remove the old core and install a working one.

Is it worth changing the core yourself?

The main criterion when choosing a cylinder security mechanism is the degree of burglary resistance. To ensure the secrecy of the cylinder mechanism, spring-loaded or floating steel pins are used. Conventionally, according to the degree of burglary resistance, they are divided into:

- Simple. They have a low level of privacy, all pins are located in the same plane in one or two rows. Such larvae can be opened with a bump key in a couple of minutes. The door can be opened with a key from any side.

- Combined. The presence of secret elements in the form of holes significantly complicates a hacking attempt. In common parlance, the combined devices are called “spinner keys.” This is due to the fact that the door can only be opened from the outside with a key. From the inside - with a rotary turntable.

- Semi-cylindrical. The keyhole is located only on the outside, so such locks are practically not used in private households.

In order to replace the core yourself, you need to have certain practical skills. It is important to determine the type and size of the core. Having dismantled the old lock core, measure the dimensions of the mechanism: L, B, Ø. A cylinder of suitable size is inserted into the door, turning the cam to the “closed” position. Next, fix it with a special fastening bolt. Despite the apparent simplicity of the operation, it is better to entrust core replacement to specialists. Unprofessional installation leads to jamming of the lock, and the lack of specialized tools and replacement skills significantly increases the labor intensity of the process.

Reasons for replacement

It is necessary to replace the locking mechanism cylinder if:

- The lock is worn out and it becomes difficult to unlock. The shelf life of cores from Turkish or Chinese manufacturers is 3-5 years, from European ones – up to 10 years.

- The mechanism is broken or damaged - for example, due to burglary attempts or careless use of the key.

- The lock on the premises was opened.

- The locking mechanism jams, and the key has to be “swinged” when inserted.

- Keys were lost or stolen or were used by strangers.

- The owners and tenants of the premises have changed.

- It was decided to change the lock to a more reliable model.

Attention! It is recommended to replace the cylinder at the first sign of a malfunction. Even small errors in operation can cause the door to lock. In this case, it is often necessary to take drastic measures - especially if children or incapacitated citizens remain locked in the premises.

Emergency call

Any of the listed methods can be applied either independently or with the assistance of specialists. In this case, the required method will be selected depending on the time during which the door must be opened.

If the lock definitely needs to be left undamaged, then there are organizations that will undertake to open any lock for a reasonable fee. But it’s advisable to find their contacts in advance, so that when something is wrong with the door, you don’t have to run around your neighbors asking to see their addresses and phone numbers.

Features of removing the cylinder on a damaged lock

It’s easy to remove the larva with your own hands:

- At the end of the lock, unscrew and completely pull out the screw holding the secret mechanism in the lock.

- The key is inserted into the hole and turned so that the pin is aligned with the body, that is, the secret is open and does not interfere with removing the cylinder; you need to turn the key 10-15%.

- By pulling the key, which cannot come out of the cylinder, it is removed along with the cylinder from the lock.

There is an armor plate on the outside of the door, so it is easier to pull out the cylinder from the inside.

How to avoid door problems

To prevent this from happening, it is worth taking periodic preventive measures:

- Lubricate the part with special oil several times a year;

- To make the mechanism last longer, you should not slam doors;

- Outdoor external locks should be regularly cleaned of debris, dust and dirt that fall inside from wind and rain.

If you were unable to open the door yourself, there is no need to break it. Call customer service and they will help you quickly.

What to do if the key breaks and gets stuck in the cylinder

Another problem with locks is broken keys inside the keyhole. It’s good if the plastic head breaks off - pliers solve all the problems. If the hole is flush with the keyhole, you will have to try hard to get the fragment out. The first thing to do is return the key position to its original position. You can do this in several ways:

- a narrow thin metal object, such as a screwdriver (the pins are locked with a key and the lock must open or close);

- the remaining part of the key, glued to the fragment with Moment glue.

But first you need to pour WD-40 into the keyhole to remove rust and oxides and leave for 20 minutes.

If the above methods do not help, you need to remove burrs from the key that are blocking the movement of the keyhole. This can be done with any tool with a thin and durable tip. The rest of the key, moved to the neutral position, can be removed using:

- sharp scissors, an awl or a large needle - wound on the side of the key. By moving towards yourself while simultaneously twitching parallel to the keyhole, the fragment is removed;

- contact glue - the key is glued together and taken out;

- a narrow blade from a jigsaw - the operating procedure is clearly visible in the photo below;

- tweezers.

If the above methods do not help, the last, more complex remedy remains - drilling a groove next to the key, through which the hook with a piece of the key of any sharp object has a greater angle and, therefore, greater adhesion force.

If all attempts to return the key fragment to its original position or remove it from the keyhole have failed, you will have to drill out the cylinder and remove it along with the stuck key.

How to remove

If there is a key and it opens the lock on at least one side, then the process of replacing the cylinder is simple and quick. When the key is lost or broken in the cylinder and its pin holds the bolt in the closed position, it is much more difficult to pull it out without a key, but it is possible.

Knocking out the larva

This method leads to damage to the lock, so it is recommended to resort to it only in the most extreme situations. To do this, use a chisel, the width of which is slightly less than the core of the lock, and a hammer; with their help, blows are applied to the core until it is mechanically destroyed, until it can be knocked out. When access to the lock bolt appears, it is moved aside and entered into the room. In this case, not only the locking mechanism is often damaged, but also part of the door leaf.

Breaking out the larva

The principle of this method is that, using an adjustable wrench, the larva is securely fixed and then sharply turned. The core fastening is damaged and it can be removed from the lock. This leads not only to its damage, but also to breakage of the lock, but the door leaf remains unharmed.

Reaming the larva

Compared to previous options, this one is more humane, but it also damages the secret mechanism, which can no longer be used once removed.

The drill is inserted into the key hole, after which the secret is drilled out at least half the length to damage the pin. When it loses contact with the bolt, the lock can be unlocked and the doors can be opened.

Using a master key or bumper key

Although this method is the safest, it requires appropriate skills to use it.

Using a master key requires not only free time, since the process is lengthy, but also knowledge of the structure of the larva.

It has several pins that are spring-loaded, and in order to rotate the mechanism they must be raised to a given height. The better the quality of the lock, the more such pins it contains and the more difficult it is to open it with a master key.

Curved and straight wire is used. The first one tries to set the pins in the desired position, and the second one tries to rotate the cylinder. Instead of wire, you can use a sharpened metal file.

The bumper key has a large number of grooves and allows you to place the pins in the desired position. First, such a key is inserted into the keyhole, then pulled out one pin and sharply hit on the key, after which it is immediately turned.

Preliminary preparation

Inspect the locking mechanism

Determine what?

- Presence/absence of armor plate.

- The degree of protection of the larva, including from unauthorized removal. Many models of cylinder locks provide for this, and therefore special inclusions made of hard alloys are placed in the borehole. When you try to open the door in this way, the drill quickly breaks.

Based on visual diagnostics, you can understand:

- how to drill out the lock cylinder correctly and what needs to be prepared;

- is it worth doing? This statement may seem strange to some, and therefore something needs to be clarified. To remove the core in some models of locks installed in doors, it is not necessary to drill it; the larva can simply be knocked out with a hammer and a fairly strong screwdriver (or a piece of metal rod).

- And this will take much less time, and the technology itself is so primitive that even a teenager can handle this work.

Prepare everything you need

- electric/drill. It is desirable that it has a speed control function, and that the tool runs on mains power rather than battery power. In the absence of one, a screwdriver will also help;

- extension cord (carrying);

- drill. There is a rule - its diameter should slightly exceed the width of the slot into which the key is inserted (for most cylinder lock cylinders it should be 3 mm); quite enough for accurate drilling. But this is the main working tool. For primary drilling, smaller analogues will be needed. For example, at 0.5 and 1.2.

- punch, hammer, screwdriver with a narrow blade;

- machine oil.

Tool for drilling the cylinder

Before work, it is better to prepare everything in advance so that during the process you do not have to interrupt and look for missing equipment. The main tool is an electric drill with a sufficient level of power and adjustable rotation speed. It is better to take a tool that operates from the mains, so that the battery does not unexpectedly run out during operation.

A thin metal drill is selected for the drill, slightly thicker than the bore hole, usually 3-5 mm is enough. For convenience, it is also recommended to take a center punch, with which you can mark the entry point of the drill; in this case, the drill will not jump off the relief surface of the core and will not damage the lock body or the surface of the door leaf. Instead of a punch, you can use a thin awl.

In some cases, 6 and 19 mm drills are selected for greater effect. The first drill is used for additional boring of the hole in order to accurately drill all the pins and pick up the lock. A thick drill corresponds to the diameter of the entire cylinder and is used if it is impossible to pick up the stopper through a small recess. But you need to understand that after such a hack it will not be possible to replace only the core, since the entire lock is damaged, so you will have to buy a new one.

To open a broken lock, you will also need a thin flat-head screwdriver, which will tighten the stopper, hook, or bent wire to latch the lock.

Preparation of the work area

Before you start directly drilling the lock, you must prevent the possibility of the tip of the tool sliding on the metal. Therefore, the “entry point” is marked with a center punch, otherwise there is a high probability of damage to the cladding, insulation and door leaf material.

Definition of the "working" point

Everything is clear about how to drill out the larva - with an electric drill. But where exactly to install the drill is an important question. Regardless of the modification of the cylinder lock (pin, plate, disk), the “channel” must pass near the installation of the security elements. Then the larva will come out quite easily.

There is one more rule for this - the optimal drilling point is ¼ of the length of the slot above its lower edge. That is, the well is conventionally divided in half, twice; there will be no error.

When to change the lock

The time to replace the cylinder in a door lock comes not only after noticeable structural faults or loss of the key. There are other reasons that make you think about the need for a quick procedure.

First you need to assess the condition of the locking mechanism core using a number of signs. If you don’t see the problem in time, then one day the door will simply be blocked. The situation will be fatal, since a breakdown may occur at the wrong time.

Cylinder types of locks have fine mechanics. Even minor wear of one of the parts can cause a malfunction of the locking mechanism. The pins will not rise to the desired height, preventing the cylinder from opening. Pay attention to the key. It is usually made from a material similar in hardness to parts of the larva. It is easier to understand the wear and tear of the structure if the door can only be unlocked with one key. When there are several of them in the house, this factor should be taken into account.

To determine the degree of wear of a key, compare it with an unused set. Please pay attention to the following parameters:

- Form.

- Sharpness of edges.

- The height of the indents.

- Coating.

In Chinese models, according to statistics, the lock cylinder is replaced every 5 years. European analogues have a longer shelf life - up to 10 years.

| Advice! The new cylinder should have the same dimensions as the old one. This concerns the length of the element, the distance from the edge of the cylinder to the rotating mechanism. Write down these parameters, and then select a new part. |

The English larva is a mechanism that does not stop working at a specific moment. Signs of failure may appear even before the product fails completely. So, the cylinder can jam half a turn. To tighten the key all the way, you need to wiggle it. You should be wary if extraneous sounds appear when opening the door leaf - creaking, clanging, grinding, crunching. Most often, in such a mechanism, the cam of the larva breaks, which takes on the main load.

Drilling technology

Drilling out the larva

Everything you need is there. Now let’s look at how to properly drill out the lock cylinder using the available set of tools. The work order is as follows:

- the pin destruction point is located. For a cylinder lock, regardless of whether it is disk or plate, the center of the destructive channel should pass at a distance of ¼ of the length of the keyhole from its lower edge;

Attention: the channel is often drilled below the keyhole. In this case, you will need a drill with a larger diameter - 19 mm.

- in the place of drilling with a center punch (core) and a hammer, a recess (core) is knocked out so that the drill does not move to the side during operation (without a core, there is a high probability of damage to the cladding, insulation and door leaf);

Kerno (kerner).

- A drill with a diameter of 0.5 mm is inserted into the chuck of an electric drill or screwdriver. The tool is set to medium speed (with faster rotation, the drill may break, as well as with strong pressure). While drilling a channel, the drill must be regularly cooled with machine oil. If the drilling progress is stuck, the drill must be unscrewed in reverse to remove chips. After this, continue working. During operation, the drill must be kept level at all times so as not to damage the rest of the lock structure. Correctly performed drilling will be confirmed by periodically occurring resistance (5-6 times) when passing through the pins. Drilling depth 4.5-5.0 cm;

- the procedure is repeated alternately with 1.2 mm and then 3.6 mm drills;

- a screwdriver inserted into the keyhole opens the closed lock;

Attention: the cross-shaped cylinder lock, which can be determined by the key, is not flat, but round with 3 or 4 edges; it cannot be opened with a screwdriver. Here you need to lift the stopper with one wire, and use a hook made of another wire to move the bolt. It may not work right away, but after several attempts, the door will open. Practice shows that this will take a maximum of a couple of minutes.

- the cylinder is removed from the lock body;

- a new larva is installed.

Suvaldny castle

There is no cylinder in a lever-type lock, so the matter is complicated by finding the drilling point, which can be located in different places for different types of locks.

To find the correct drilling point, you need to understand the internal structure of the lever lock. Such structures consist of the following elements:

- Crossbar plate. Her job is to move the bolts.

- Level plates. This is the element responsible for secrecy.

- Shank. Applies pressure on the crossbars through levers.

- Leaf springs. They are designed to return the levers to their place. Each lever has its own spring.

- Code slot. Designed to enhance the secrecy of the locking mechanism. Developed individually to fit key grooves.

When working with a lever lock, the main part that you pay attention to is the shank that secures the bolt plate. The shank has a comb and a stand.

When the key enters the lock and turns, it acts on the comb, which, in turn, moves the bolt. The stand is designed to block the crossbar plate, working in conjunction with the levers.

To work you will need the following tools:

- electric drill;

- metal drills, diameter from 6 to 8 mm;

- a piece of rigid metal wire.

Step-by-step instructions on how to drill a lock in an apartment door:

- The first step is to find the location of the shank. To do this, you need to know exactly the lock model. It is better to find instructions or search for information in open sources on the Internet.

- Use an electric drill or a powerful screwdriver to drill a hole in the desired location. The stand should completely collapse.

- A wire is inserted into the core of the lock, with the help of which the bolt plate is pushed away from the inside of the door frame. The door is open.

Once the closed door has been opened, you will have to completely change the internal mechanism of the lock. In some cases, it is also necessary to replace the door trim.

Cylinder lock

Now let’s figure out how to properly drill out a lock cylinder with a cylinder device. In this case, it is also important to understand where the hole should be made so that the lock can be opened.

Consider the design of a cylinder lock. It consists of the following elements:

- frame;

- crossbar;

- larva.

The main element is considered to be the larva - this is the core of the castle. Inside the cylinder there are pins, which, when turning the key, act on the locking bolt (cam), opening or locking the device.

The key, turning in the lock, presses on the cam, which, in turn, pushes the bolt. It turns out that in order to open a locked lock, you need to remove the pin lock, which prevents the cam from turning inside. After drilling the cylinder, the lock can be easily opened with a simple screwdriver.

Cam.

What you will need to work with the cylinder cylinder:

- electric drill (optionally, a powerful screwdriver);

- if you have to drill from the outside of the door, you will most likely need an extension cord;

- metal drills, diameter 0.5 mm, 1.2 mm, 3.6 mm. If you have to drill out the cylinder from the outside, you will have to go through an iron armored plate. In this case, simple metal drills are not enough; you will need to buy drills with pobedit tips;

- mark. Needed to prepare the drilling point. By hitting the core with a hammer on the surface of the larva in the right place, a small dent is obtained, which helps the drill not to go beyond the limits;

- hammer;

- a screwdriver with a thin straight blade;

- machine oil to lower the temperature of the drill.

How to drill out the front door lock cylinder:

- The point for drilling is determined. To find it, you should visually divide the height of the larva into four parts. The lower quarter will be the right place to apply effort. This approach to finding the drilling point is valid for both disk and plate types of locks. If you have to make a hole below the keyhole, you need to use a metal drill with a diameter of 19 mm.

- The drilling point has been found, now it needs to be marked on the surface of the larva. To do this, take a hammer and a core. With a gentle blow, the point is applied to the surface. Now the drill will not slip and damage the outer finish of the door leaf.

- At the first stage of drilling, a drill with a diameter of 0.5 mm is used. To avoid overheating the drill, set the screwdriver or drill to medium speed. It is also important not to use excessive force when drilling, because... thin drills break very quickly when heated and pressed. While working with an electric drill, you need to periodically cool the hot drill in machine oil. It happens that the drill gets stuck inside the larva. In this case, select the reverse mode on a screwdriver or electric drill and twist the drill outward. When drilling, it is important not to deviate the drill, maintaining a right angle in relation to the door leaf. If the master does everything correctly, several dips are felt during drilling, thus the pins go through. Usually it is enough to drill the cylinder to a depth of 50 mm.

- After passing the hole with a 0.5 mm drill, it is alternately expanded with 1.2 mm and 3.6 mm drills.

- If everything is done correctly, push a screwdriver into the hole and turn it. The lock should open. There are locks with cross-shaped cylinder cylinders. They can be identified by the appearance of the key, which has three or four edges. In this case, a screwdriver will not help; you will have to use two wire rods: one to lift the stopper, and the other to press on the bolt. Usually a couple of minutes is enough to get used to the structure of the lock and working with wire.

- After opening the door, the larva is removed.

- A new larva is purchased and installed.

Sometimes, after widening the hole with a 3.6 mm drill, it is not possible to move the cam. If such a problem occurs, you have to continue drilling. Usually a 6.5 mm drill is enough, but in some cases you can use a hollow type drill with a diameter of 19 mm, however, you need to understand that in this case you will have to change the entire lock.

Constipation-type technology

It is recommended to install a lock with a cross-shaped cylinder in interior doors and doors leading to offices, retail or utility rooms, in other words, in those rooms that are additionally protected by more durable doors or alarms.

To open such a lock, you will need to drill a hole just above the keyhole to the pins, and then tighten the lock with an awl or a thin screwdriver. Simultaneously with raising the stopper, the bolt is pulled back using a hook made of thin wire, which will cause the bolt to move inward and open the door.

The cylinder with pins is drilled in a similar way, and then rotated inside using a thin tool, such as a screwdriver.

The keyhole is drilled using a 3 mm drill. To prevent the drill from breaking, it is recommended to place it strictly perpendicular to the borehole hole. If drilling does not help, you will need to make another hole above the hole, and then use a hook to move the bolt.

An overhead lever lock is drilled where the post is attached to the edge of the bolt, usually just above the center of the bore hole. After drilling the rack, the lever lock is opened with a non-original key of a similar type or its blank for a future duplicate. But you should understand that drilling will only help if the product is not equipped with additional protective devices.

Locking mechanisms made of hardened steel or armored with linings are drilled using a heavy-duty carbide-tipped drill. Finding such a drill is problematic; in addition, it is quite expensive, and you will have to work hard to drill it.

Therefore, it is easier to leave this matter to a specialist, whose call will cost approximately the same amount as a heavy-duty metal drill.

Drilling an iron lock

The instructions on how to drill a lock in a lever-type apartment door are very simple and consist of only 3 points:

- The location of the shank strut is determined. It is located in different places in different castles. The instructions will help if the autopsy is carried out from the inside or the Internet if from the outside;

- a channel is drilled, completely destroying the stand;

- Using a hook made of wire (knitting needles), the bolt plate is moved to the back side of the lock body, opening the doors.

Note that, unlike a cylinder lock, here you will have to completely change the locking mechanism and restore the damaged lining of the front door.

Main types of locks

The weakest point in a metal door is the lock, because by breaking it you can easily get inside the room, despite all the protection. Therefore, it is necessary not only to select the right models, but also to replace them on time. But it is not always necessary to purchase a new lock assembly. Some versions allow you to replace only the cylinder.

Even the owner of the premises can perform the procedure. But to be completely sure that all stages will be carried out in accordance with the rules, it is best to invite a master. He not only knows how to change the larva correctly, but will also independently select a replacement that will ideally fit the existing base.

There are four main types of lock:

- Electronic. The design contains a microcircuit, so it can only operate on power.

- Electromechanical. It is a combination of mechanical and electronic locks.

- Electromagnetic. The design of the mechanism includes a powerful magnet.

- Mechanical. Standard locks. There are cylinder and lever ones.

An example of an electronic lock for an entrance door Source sun9-65.userapi.com

All mechanisms can be further divided into thrust and non-expanded. They, in turn, have several subtypes. Each person decides for himself what type of lock to choose for his front door.

What to do if drilling does not help

If it is not possible to turn the cam after a drill with a diameter of 3.6 mm, drilling is continued, but with a 6.5 mm drill, which completely destroys the keyhole. You can also use a 19mm diameter tubular drill. But these are extreme measures, since the castle itself is destroyed along with the larva.

Reaming

The method is quite delicate - it allows you to avoid completely replacing the lock; you can remove the faulty cylinder and install a new one.

Step-by-step instruction:

- Prepare a drill with a diameter of 6 mm. Attach it to the well.

- Drill the cylinder at least to the middle. It is important to ensure that the drill does not go sideways.

- Remove the damaged larva and install a working one.

How to drill

A drill of the smallest thickness is installed at the entry point indicated by the center punch, after which the drill is turned on. The first millimeters are passed at minimum speed without excessive pressure on the drill, then you can add speed. A minimum of effort and speed will allow the drill to move slightly into the metal without breaking. During the entire drilling process, it is not recommended to rush and work at maximum speed, as this can lead to breakage of the drill, after which you will have to look for a new one, which takes a lot of time.

The drill is installed perpendicular to the borehole, gradually tilting at an angle, which makes it possible to quickly get to the pins and damage them. Experts recommend soaking the drill in mineral oil every couple of minutes to make work easier.

If you notice that the cylinder has become harder to drill, and the drill itself is biting or sticking, reduce the speed, reverse and remove the drill from the recess. It would be a good idea to blow out any metal shavings that would interfere with the interior view.

As soon as you feel that you have reached the last pin, change the drill to a thicker one. This will allow you to drill out the lock cylinder until the pins are completely destroyed. How to do this using the front door as an example is shown in the video below.

Pick-gun

Pick-gun hacking is the use of a special tool to install pins in a line and rotate the cylinder.

To counter the pick-gun, there are several constructive solutions:

- use of other elements in the cylinder design (for example, disks, frame cylinders)

- combination of cylinder mechanisms with other security elements (frames + pins)

- additional recognition elements in the cylinder mechanism and key (for example, a wheel)

- protective pads blocking access to the end part of the cylinder mechanism, magnetic and code pads

Hull rupture

The purpose of the method is to break the body of the cylinder mechanism into 2 halves. The housing is destroyed along the hole for the mounting screw.

The following is used as protection:

- armor pads

- minimizing the protrusion of the profile mechanism no more than 3 mm

- the use of metal plates (rods) in the design to impart rigidity to the mechanism body

Pick-hook

A pin or paperclip can replace it. To make a master key from a paper clip, straighten it and bend one of the ends 90 degrees. You can also bend one end into a small loop. Pliers will help you quickly cope with the task. The object must be made of strong metal that does not bend when pressure is applied to the pins.

Picks made from a hacksaw blade work best. Hair bobby pins are also a good material for a lockpick. Cut off the rounded ends of the bobby pin and make a right angle out of it, and then bend the edge 3-5 mm at an angle of 90 degrees.

If you correctly and consistently open the larva, the method using master keys allows you to avoid damaging the locking mechanism and ensure opening within 2-5 minutes. But if there is a strong tension on the cylinder or a lot of pressure on the pins, there is a risk of damage to the cylinder.

Trace method

The key blank is rotated all the way, adjustments are made according to the marks on it, and so on until the key fits.

To complicate the use of this method:

- protective pads are used that block access to the end part of the mechanism (magnetic and code pads)

- mechanisms with a perforated key are used

- mechanisms are used with a combination of different types of mechanism security elements (frames and pins)

- mechanisms with “telescopic” pins are used

Svyortysh

A strong blank is used to mechanically roll up the cylinder, destroying the secrecy of the mechanism.

To complicate the use of this method:

- protective pads are used that block access to the end part of the mechanism (magnetic and code pads)

- do not install profile cylinders of poor quality and low cost

- mechanisms with stronger steel pins are used in the design

- mechanisms with a complex key channel profile are used

Manipulation

Using a master key, the pins are installed and the cylinder is rotated with a special tool.

To complicate the use of this method:

- elements of the cylinder mechanism are manufactured with high precision

- to create interference during manipulation, a complex key channel profile is used

- the design of the mechanism uses pins of a certain shape, which complicate the breaking of the mechanism (“mushroom-shaped” or “reel” pins)

- mechanisms with several separate independent pin rows are used

- mechanisms are used with a combination of different types of mechanism security elements (frames and pins)

- mechanisms with “telescopic” pins are used

- protective pads are used that block access to the end part of the mechanism (magnetic and code pads)

Chemical hack

The return springs of the pins are dissolved using a liquid poured into the mechanism. After this, the cylinder is turned using a screwdriver.

To complicate the use of this method:

- protective pads are used that block access to the end part of the mechanism (magnetic and code pads)

- mechanisms are used in which the total length of the body pin and the core pin is greater than the length of the code channel to the parting line

- mechanisms with pins in the upper part of the body are used

- mechanisms are used with a combination of different types of mechanism security elements (frames and pins)

Pick-tensioner

A master key tensioner is a thin object 15-20 cm that does not break when the cylinder is pulled and easily fits into the keyhole

This is a thin object 15-20 cm, which does not break when the cylinder is pulled and easily fits into the keyhole without falling through it completely. A hex wrench or flathead screwdriver may be suitable for this purpose. You should use the master key carefully: the slightest force and it will break and remain in the lock cylinder.

Knockout

The method requires force on the mechanism - you will need a chisel and a hammer.

Place the chisel against the cylinder, then hit it vigorously with a hammer. Cheap locks are easily susceptible to this type of attack. Upon impact, the pins will bend the body of the device and the core will fall out from the back of the door. After this, you need to pry off the internal mechanism with a screwdriver and move the crossbars. The lock will open.

You should act carefully, since careless and excessive force can lead to damage not only to the locking mechanism, but also to the door leaf. The method is suitable for locks of burglary resistance classes 1 and 2; high-quality locks are protected from being knocked out.

It will not be possible to keep the larva in good condition using this method.

Breaking out

The method is more delicate than the previous one and does not pose a threat to the canvas. To open the door, use an adjustable wrench or similar device to grab part of the core and forcefully shake it from side to side. Carry out manipulations until the fastenings of the larva break.

The method only works for older lock models. Modern cylinders do not have protruding parts to grab onto.

Calling a specialist from the emergency service

If you need to quickly open a lock without a key, it is advisable to contact specialized organizations for opening, repairing and installing locks. Masters of such services mainly work around the clock and arrive at the scene of an incident from 20 minutes to 1 hour.

The advantage of contacting the special services is the ability to delicately remove the cylinder and install a new one without damaging the lock, handle, or door leaf. The master already has samples of locking mechanisms with him, and he himself will choose the appropriate one.

As a last resort, you can contact the police or the Ministry of Emergency Situations, but then you cannot count on a delicate approach.

Video description

To see how to replace the lock cylinder of the front door, watch the following video:

You need to not only install the lock cylinder, but also check its functionality. To do this, you need to close the door from the inside, and then open it from the outside. The mechanism should operate smoothly and silently. Any vibrations, noises or difficulties in operation are an indication that the cylinder was not installed correctly or is already faulty. All new mechanisms operate smoothly and without backlash.

Seven tips for choosing a new larva

Tip #1. Deciding on the package

According to the configuration, cylinder cylinders come in 2 types:

- Key plus key - an option where keys are inserted on both sides, the good thing is that if you insert the key from the inside, you can’t open the lock from the outside;

- Key plus a screw - if a screw is installed on the inside instead of a key, then in the event of a fire or some other emergency, it will not be difficult to quickly unlock the lock.

The configuration and type of lock cylinder is determined depending on the specific situation

Tip #2. Selecting the privacy level

Pins are responsible for encoding the larvae; they are also called pins; they are located at the bottom of the mechanism. The pins, by means of springs, fit into the cutouts on the key, each pin corresponds to a given position, thus setting the level of secrecy.

- In budget models, 5 pins are installed and secrecy is limited to ten thousand options;

- In the middle price category, 6 pins are installed and the number of options increases to fifty thousand;

- Expensive locks have 6 or more pins, plus additional secrets, such as magnetic inserts. The number of options here starts from one hundred thousand, but usually manufacturers indicate several million.

The more pins are installed on the lock cylinder, the higher the level of secrecy of the mechanism

Tip #3. Lock cylinder weight

If the larva weighs around 100 grams, then you are dealing with a cheap model, the insides of which are made of aluminum or silumin. It won't last long. A high-quality product with a steel or bronze mechanism cannot weigh less than 180 grams, and the weight of some models reaches 250 grams.

You can determine the quality of the larva by weight; the weight of a normal model starts from 180 g

Tip #4. Drill protection

It is impossible to visually see the protection against drilling of the lock cylinder. The fact is that such protection is provided by the internal insert and pins made of high-strength steel. The only advice that can be given in this case is to carefully study the accompanying documentation and choose a reliable manufacturer.

Protection against drilling is provided by steel inserts in the lock cylinder

There are cylinders with vertical milling into which the key is inserted horizontally. Advertising claims that this is a sign of high security, but in reality their resistance to hacking is no different from traditional larvae with a vertical key arrangement.

Larvae with a horizontal keyhole have the same resistance to burglary as their relatives with a vertical key.

Tip #5. Bump protection

Bumping is the name given to knocking out a keyhole with a heavy tool. The robbers place some kind of superstructure on the keyhole and hit it with a heavy hammer or sledgehammer, after which the larva flies inside the home, and without it you can open the lock with any screwdriver.

Anti-bumping cylinders can be recognized by the presence of a special steel bracket on the side of the mechanism. According to the manufacturers, this bracket can withstand heavy loads and will not allow the lock to be knocked out.

The steel bracket serves to protect against knocking out the cylinder with a heavy tool

Tip #6. Magnetic protection

It is not possible to open a cylinder with magnetic protection using ordinary master keys. The fact is that one of the pins of such a cylinder is magnetized and it reacts to a reciprocal magnetic insert that is built into the key, and the insert and pin have their own potential and the first magnet you come across cannot open such a lock.

Larvae with magnetic inserts are found in the middle and upper price categories

Tip #7. Product cost

Determining the quality of a product by its cost is a risky business; a high price may be the result of transportation costs or the banal greed of a businessman, but it is still worth paying attention to this point.

- Now the price for a normal larva starts from 500 rubles. If you are offered an item with fabulous protection at a bargain price, then it is either a fake or a stolen item;

- Larvae with a price ranging from 500 to 1000 rubles are of quite decent quality, in this case it is the average price category;

- Anything that is more expensive than a thousand rubles is already closer to an elite product; often the quality of such products is really high.

What are the lock options?

Cylinder locks are universal in terms of use. Installed on different types of doors. Very simple and easy to use. In addition, they meet strict safety requirements. Depending on the modification, the devices can accommodate different types of secrets. Based on this feature, locks are divided into the following types:

- With pin. The larva is represented by a set of spring-loaded pins, which are arranged in 1-3 rows. The cylinder is rotated only if the key is used to move the pins to the required position. After the key is removed, the pins return to their original position.

- With frame cylinder. This lock contains a cylinder of five plates with a central groove. The key passes through this groove. Thanks to the side springs, the frames take the required position.

- Disk type. The secret part is represented by small washers with holes. When the holes match, the locking device opens. The disk mechanism has a high level of secrecy. Rarely breaks.

Replacing a damaged larva

The method of replacing a faulty core depends on the type of failure and the required urgency of action:

- The key cannot be inserted, it jams, it turns - initially it is recommended to clean the mechanism and lubricate it with special products (machine oil, grease, universal WD-40). If the action does not help, replace the larva using the method of drilling through a hole. The method will help to completely preserve the structure.

- The key broke in the lock, debris or foreign objects got into the hole, and they cannot be removed - replacing the core is also carried out by drilling, but the drill is not placed in the hole, but in the narrow part of the cylinder.

- The lock is locked and cannot be opened. If you need to quickly unlock the door, knocking or breaking is used. But later the lock will have to be completely changed.

- There is no key to unlock the door - you can try to open the door with master keys, this is a more gentle way. It is better to replace the larva by drilling it out.

Methods for opening locks

Today there are a whole host of different ways to break locks - it all depends on the set of tools and experience of the burglar. At the same time, there are intellectual methods (the “safeguards” work), in which the door and locking devices remain unharmed, and forceful ones, the representatives of which are burglars - here one cannot do without mechanical damage to the lock.

Security guards use various types of master keys, improvised means in the form of pins and wires, and special keys (“bumping” for cylinder locks and self-dialing for lever locks).

Burglars also have several ways to open the door:

- knocking out - this method is only suitable for cylinder locks. It consists of knocking out the larva from the lock body using an iron insert and a hammer. There are two negative points here: you always need to change the lock completely and there is a high probability of damage to the door leaf, even if the door is metal;

- breaking out is carried out using a special device - a “roll” made of high-strength steel, which, when inserted into the keyhole, when rotated 360°, destroys the locking mechanism. Here it is also necessary to change the lock completely;

- Drilling out the lock is the most gentle method of all forceful methods of breaking locking devices - only the cylinder of a cylinder lock is changed.

How to knock out a lock - a striking blow to the cylinder or a drill as a panacea

One of the main methods of opening is mechanical force, which cylinder locks do not tolerate well, especially if special protective armored linings are not installed, and the internal mechanism of the device does not have special pins made of hardened steel. How to knock out a lock ? At first glance, it is relatively simple - take a hammer and a chisel, place the latter on the cylinder and apply strong blows with the hammer.

The second method of mechanical force is to drill out the cylinder, after getting rid of it, access to the inside of the locking mechanism will open. There is another method using a drill. It will be effective if you personally installed the lock and know exactly where the sockets with pins are located. Drill them out, after which the locking device can be opened with a regular screwdriver by turning the cylinder.

Preparing to repair the castle

Replacing the front door lock cylinder begins with determining its type.

The locking mechanism consists of pins, washers, rotating blocks or movable probes. After turning the key in the core, they line up in a given order, and the structure opens. Their number depends on the complexity of the secret mechanism. Incorrectly aligned core elements prevent the locking bolt from moving, so the lock remains closed. The complexity of the secrecy mechanism depends on the quantity and quality of its parts.

Not all locking mechanisms can be partially replaced. For example, in lever-type structures, the core is integrated into its body, so in case of any malfunction, the entire constipation is replaced.

Designs with a cylinder mechanism have a replaceable core: disk, cross-shaped, pin, complex. Since disc cylinders suitable for an existing lock are not easy to find, locks of this type are completely replaced. To replace the inside of the cross-shaped mechanism, you will need to completely disassemble it. In a pin lock, you can easily replace the core if it is made with an English key. Pin locking mechanisms with a perforated key can be opened by drilling or knocking out the cylinder, which is technically difficult, but doable.

Article on the topic: Interior doors: how to choose which ones there are

High-quality cylinder locks with a titanium body have more than a million code combinations, keys with floating elements and other additional security systems. In such designs, it is almost impossible to replace the cylinder yourself; it is better to entrust this to professionals or replace the constipation completely.

The standard of the mechanism must be taken into account. The cylinders produced according to the DIN standard for one type of core are interchangeable regardless of the manufacturer. The only things that matter are the thickness of the door leaf and the location of the fastening screw. RIM standard cylinders are produced for rim locks and are used quite rarely.

To replace the larva you will need:

- hammer;

- drill;

- screwdriver;

- crosshead screwdriver;

- roulette;

- center punch;

- replacement part

Preventive measures

In order for a door lock to serve for a long time, it must be used correctly.

To ensure the maximum service life of the door lock and its cylinder, it is not enough just to purchase a high-quality mechanism and install it correctly, you must also operate it correctly.

In order not to wait until the cylinder is completely out of order, but to replace it in time, you must take into account that the key and the cylinders have almost the same hardness, so you need to look at the condition of the key.

Remember that a lock uses multiple keys, so they wear out less than the pins of a security mechanism.

You need to compare the key that is most often used with a spare one, you need to pay attention to the appearance of smoothed edges on it, a decrease in their height or erasing of the coating.

It is also impossible to lubricate the cylinder mechanism; it is permissible to apply a small amount of oil only to its cam. When opening a door, you should always inspect the key so that its grooves are not clogged with debris, as well as the keyhole for the presence of foreign objects.

If the lock is almost working

Such a replacement occurs if some malfunctions are discovered in the lock: for example, the key suddenly began to open it only on one side. Often such a planned replacement is planned when residents lose one or more of the keys. Often the secret mechanism rusts and becomes clogged, in which case changing the cylinder is also necessary.

For such an operation, a key is required, because only with one is the replacement process possible. The fact is that in the normal state the larva cannot be pulled out: the pin pushing the bolt of the mechanism is in the way. And only by turning the key a little in the lock, you can force this pin to hide, thereby freeing up space for vigorous activity.

Algorithm of actions:

- The first step is to disconnect the armor plate and door handles, since in some locks the cylinder is also secured using external panels combined with the handles.

- Then you need to find and unscrew the fastening screw that holds the lock. It is located at the end, near the tongue, called the crossbar.

- Now you need to insert the key into the lock, start turning it, while not forgetting to constantly try to push out (pull out) the cylinder. It will pop out freely when the pin is freed from the internal mechanism. This is where you need to quickly pull it out.

The operation to rescue the secretion larva has been completed. All that remains is to take a new one and place it in its rightful place. When assembling the lock, the reverse sequence of actions is followed.

Door hacking methods

It is believed that any door can be opened. A high-quality model will simply take more time. Burglary is influenced by various factors: the skill of the burglar, certain tools and the structural details of the door.

Knowing how the front door is opened allows you to understand how well manufacturers protect their products.

The hacking method is divided into forceful and intellectual. The force method uses physical force, which is used to destroy doors. Intelligent methods are carried out using a variety of master keys and relate to lock structures.

There are the following ways to break into a door:

- Bending or pressing the door plate is the most common method of opening inexpensive models. A crowbar is inserted between the door frame and the plate and wrung out. In this case, the lock bolts lose their function and do not prevent the door from opening.

- The box squeeze is different in that the crowbar is placed between the wall and the door frame. The end result should be the inversion of the entire door block structure. This hack is suitable for a structure where the door leaf was installed incorrectly. In this case, large gaps remain between the wall surface and the door structure, which are filled with polyurethane foam.

- Destruction of loops with squeezing of the fabric is carried out after cutting off the loops. The door opens in the opposite direction using a special device.

- When a door is broken through, the casing is broken in order to destroy the lock.

- Cutting the door leaf is done using a special knife or scissors cutting metal in the area of the lock structure. Then the lock is removed and the entrance to the apartment is cleared. Metal doors made in China are easily susceptible to such hacking.

- The cylinder is knocked down by strong blows. It breaks and access to the lock mechanism is provided. In this case, blows are delivered from different sides.

- The door structure can also be removed using a jack.

Lock damage

There are special methods to help you pick a lock on a door:

- Padlocks are dismantled using an autogen or grinder.

- Lockpicks are used for doors, which are considered a universal tool. There are simple types of master keys: hooks and metal rods. Criminals also use electromechanical products. Using picks you can identify and move each pin. The attackers benefit from the fact that the details are not executed with perfect precision. Opening is carried out even with the approximate position of the part necessary for opening the locking mechanism.

- You can break the lock by forcefully turning the “roll”. A screwdriver or a special plate is placed in the cylinder. Forces are applied to this part in the direction of turning the key. In this case, elements made of non-hard metals are trimmed with scissors. The first blade is set in a stationary position, and the second rotates and cuts the pins. And the castle gives way.

- Drilling is done to remove the larva. In this case, you can drill out a lever-type door lock or a lock cylinder:

- In cylinder-type structures, the cylinder is drilled out. Since the material used in its manufacture is quite soft, a drill is used to make a hole in the cylinder core and open access to the mechanism;

- Locks with a secret are processed with a thin drill. In this case, small holes are drilled into which the pins are removed. The secrecy of the locking mechanism disappears, and it can be opened with any key.

- The easiest way is to select keys. Criminals can have many different combinations in their arsenal.

- Locks can be hacked using an unusual method. A certain acid is added to the hole in the locking mechanism, which will destroy all the springs. After this, the structure is opened with an ordinary screwdriver.

- Criminals can knock out the lock. Standard cylinders are secured with a screw that passes through the core of the product. However, the cylinder design is not designed for significant loads. With a strong impact across the surface of the door leaf, the screw is sheared.

- Entrance doors are also opened using the cylinder breaking method. The cylinder is grabbed by the protruding part and is broken by rotation. A crack appears, dividing the structure into two parts. The mechanism is pulled out in the same way.

- You can break the door lock by sawing the bolt, which is the locking part of the locking mechanism.

- You can pick locks using impression. In this case, the prepared key blank is rotated in the lock and traces of contact between the bit and the lever remain. Then turning is carried out at the obtained points. The process is repeated until the desired key is created.

Related article: How to recode a combination lock on your front door

How to replace it yourself

After the old cylinder has been dismantled and a new one has been purchased, it must be installed correctly; this is done in the following sequence:

- Installation of the new cylinder in the designated place. The pin is removed, that is, hidden in the housing so that it does not interfere with installation.

- At the end of the door, insert a mounting screw into the hole in the lock. If it does not fit into the threads on the cylinder, they need to be slightly shaken, and then securely tighten the screw.

- Check the functionality of the lock; it should close/open smoothly and almost silently. First they do this with the door open and if everything is fine, they check it when it is closed.

- Install the linings if they have been dismantled.