Each mechanism has its own service life. Castles are no exception. Therefore, you need to understand how to change the cylinder in the front door lock yourself, because the process itself is not as complicated as it might seem at first glance. Read the article to the end to understand when the core is replaced, how to remove it and install a new one. It also talks about several nuances that are useful to know when replacing the larva.

Common lock with English grub Source www.dea5.net

Types of lock larvae

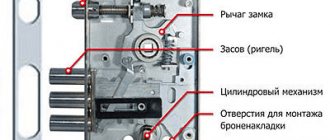

The cylinder is the core of the lock, consisting of a keyhole, several parallel code channels - springs with pins are inserted into them. Only at a certain position of each of them is the cylinder able to rotate and unlock the bolt. The notches and teeth on the key are responsible for lining up the pins in the desired position.

The larvae in modern locks are available in 2 types:

- double-sided - the core is unlocked with a key from both sides of the blade;

- one-way (with a turntable) - the door opens and closes from the inside without using a key (using a rotary handle).

Also, larvae are classified into 3 types according to the level of burglary resistance:

- Low - the pins allow for up to 10 thousand combinations, the pins are made of wear-resistant brass. Doors made in China are often equipped with such mechanisms.

- Medium - up to 50 thousand combinations are provided, but the material is still wearable and not durable.

- High - the number of combinations is over 100 thousand. The lock is made of high-quality materials - a brass body, hardened or magnetic pins. Protection against knocking out and drilling is provided.

Cylinder mechanisms are popular due to their ease of operation and maintenance. If the cylinder fails, there is no need to disassemble the entire lock and replace it with a new one - just remove the old core and install a working one.

Possible errors and unexpected situations

If the lock is replaced on the front door of a private house, then one problem may arise. The fact is that due to environmental influences, the mounting screw becomes corroded, making it almost impossible to tighten it. The only way out of this situation is to break out the larva. To do this, you need to remove the armor plate, grab the protruding edge of the cylinder with pliers or a wrench, and turn it sharply with force. Most often, due to the impact of physical force, the narrow neck breaks or cracks, which allows the core to be pulled out.

Reasons for replacement

It is necessary to replace the locking mechanism cylinder if:

- The lock is worn out and it becomes difficult to unlock. The shelf life of cores from Turkish or Chinese manufacturers is 3-5 years, from European ones – up to 10 years.

- The mechanism is broken or damaged - for example, due to burglary attempts or careless use of the key.

- The lock on the premises was opened.

- The locking mechanism jams, and the key has to be “swinged” when inserted.

- Keys were lost or stolen or were used by strangers.

- The owners and tenants of the premises have changed.

- It was decided to change the lock to a more reliable model.

Attention! It is recommended to replace the cylinder at the first sign of a malfunction. Even small errors in operation can cause the door to lock. In this case, it is often necessary to take drastic measures - especially if children or incapacitated citizens remain locked in the premises.

Types of faults

Plastic doors are a reliable design with high thermal insulation characteristics, but sometimes troubles happen with them.

Types of breakdowns:

- the lock or handle is broken;

- the handle is difficult to turn or, conversely, dangles;

- the sash does not fit, the fittings require adjustment;

- the awnings were loose.

Many of these problems can be fixed yourself.

If the design is under warranty, call a repairman; if the owner tries to repair the metal-plastic product himself, the warranty will be canceled.

Replacing the working larva

Before replacing the core, you need to buy a new larva - it must be the same size as the old one. It is recommended to purchase the item from the same brand. If you buy at random, there is a high probability that the cylinder will not fit.

Step-by-step instruction:

- Remove the armor plate from the door and unlock the lock with the key.

- Remove the screw from the end of the door and remove the plate.

- Insert the key into the hole and turn in the closing direction to release the bolts.

- Remove the screw in the center of the mechanism.

- Pull out and install a new larva - to fix it, carry out the steps in the reverse order.

Check the success of the manipulations with the door open to avoid blocking. The movement of the new core should be smooth, without extraneous vibrations or rattles.

A few recommendations

Since lever locks are considered the most complex, it is recommended to purchase imported products. This will simplify the procedure for the necessary repairs. The reason lies in the fact that all the necessary parts are freely available in almost every retail store. The main advantage of foreign models is the ability to reconfigure the levers. In contrast, domestic manufacturers do not include such a feature in their locks.

It is worth lubricating the locks periodically. But this must be done carefully, because if you pour in an excess amount of motor oil, this will lead to further thickening, which will cause the mechanism to stop functioning normally. For lubrication, a syringe with a needle that is inserted into the well is suitable. Just a little oil is enough, after which you need to turn the mechanism all the way in both directions.

Replacing a damaged larva

The method of replacing a faulty core depends on the type of failure and the required urgency of action:

- The key cannot be inserted, it jams, it turns - initially it is recommended to clean the mechanism and lubricate it with special products (machine oil, grease, universal WD-40). If the action does not help, replace the larva using the method of drilling through a hole. The method will help to completely preserve the structure.

- The key broke in the lock, debris or foreign objects got into the hole, and they cannot be removed - replacing the core is also carried out by drilling, but the drill is not placed in the hole, but in the narrow part of the cylinder.

- The lock is locked and cannot be opened. If you need to quickly unlock the door, knocking or breaking is used. But later the lock will have to be completely changed.

- There is no key to unlock the door - you can try to open the door with master keys, this is a more gentle way. It is better to replace the larva by drilling it out.

Is it possible to change

Replacement is provided for any cylinder type locks. This is the type where the lock body is hidden in the door. You can tell that the core can be removed by looking at the fastening screw. It is located under the locking tabs. Most often, the screw has a cross-shaped shape, and less often - flat.

Castle SHO-25 Source krepost-zamok.com.ua

It is also possible to replace the core with parts of rim locks. This is the type where the body is attached to the door. Such models include the SHO-25, which was very popular in the nineties. Although most often this can only be done with the lock itself. To accurately determine the possibility of carrying out the procedure, you will need to completely remove the mechanism from the door.

The easiest way to determine the possibility of replacement is by the key. If it is flat or cross-shaped with texture, then the procedure can be performed. But if it is a stick with blades, then replacement is impossible.

If the model does not imply the ability to remove the core, then the only way to correct the problem is to purchase a new mechanism assembly. In this case, it is better to purchase a type of lock that will have a replaceable cylinder.

See also: Catalog of companies that specialize in the installation of doors and windows

Knockout

The method requires force on the mechanism - you will need a chisel and a hammer.

Place the chisel against the cylinder, then hit it vigorously with a hammer. Cheap locks are easily susceptible to this type of attack. Upon impact, the pins will bend the body of the device and the core will fall out from the back of the door. After this, you need to pry off the internal mechanism with a screwdriver and move the crossbars. The lock will open.

You should act carefully, since careless and excessive force can lead to damage not only to the locking mechanism, but also to the door leaf. The method is suitable for locks of burglary resistance classes 1 and 2; high-quality locks are protected from being knocked out.

It will not be possible to keep the larva in good condition using this method.

Installation of a new cylinder

In order for the installation of the larva to be successful, it is recommended to first compare the cores for identity. A new cylinder is inserted into the profile hole of the metal door, having previously removed the tongue inside.

When moving the core, you need to get the mounting screw into the groove and “bait” it. The operation is carried out “blind”, so patience is required. As soon as it is possible to make at least one turn, the larva fits tightly in the lock, without any play. After this, the screw is tightened until it stops.

Before using the new lock, a number of checks must be carried out. To begin with, they make a series of closings in the open position. If they went through satisfactorily, they try to close the door from the inside. After this, they check how easily the lock can be closed and opened from the outside.

You should know that there should be no extraneous sounds when the constipation is operating (creaks, crackling noises). The cylinder must move freely, without vibration. The key is inserted into the cylinder easily and at the same time tightly, without backlash.

It is not difficult to install a larva to replace the old one. The main thing is to choose the right one for your front door. It is necessary to know the thickness of the canvas and decide on the model according to the privacy criterion. Even a beginner can handle the replacement itself. You just need to strictly follow the instructions.

Bumper key or master key

The most gentle way to open a locked door is to use master keys, but the method is labor-intensive and requires certain skills and experience. You will need 2 wires - one straight to rotate the cylinder, the second with a curved end, which you need to tap on the pins. The goal is to build the right combination, then the lock will open.

An easier hacking method is to use a bump key. Its profile matches the original one and has a specific cutting of the heights of the secrets, which makes it possible to open the lock. After placing the key in the hole, it is struck (with a mallet, a screwdriver), the impact is transmitted to the support pins, pressed against the code springs. They repel and a space is formed between the pairs for a split second. The code pins remain in the core, and the support pins fly off into the body. At this time, you need to turn the key towards opening.

Attention! Opening the lock using the above methods is only permissible for the owner of the premises, his authorized representative or representatives of authorized departments. According to paragraph 1 of Art. 139 of the Criminal Code of the Russian Federation, criminal entry into someone else’s area is criminally punishable.

Drilling technology

Drilling out the larva

Everything you need is there. Now let’s look at how to properly drill out the lock cylinder using the available set of tools. The work order is as follows:

- the pin destruction point is located. For a cylinder lock, regardless of whether it is disk or plate, the center of the destructive channel should pass at a distance of ¼ of the length of the keyhole from its lower edge;

Attention: the channel is often drilled below the keyhole. In this case, you will need a drill with a larger diameter - 19 mm.

- in the place of drilling with a center punch (core) and a hammer, a recess (core) is knocked out so that the drill does not move to the side during operation (without a core, there is a high probability of damage to the cladding, insulation and door leaf);

Kerno (kerner).

- A drill with a diameter of 0.5 mm is inserted into the chuck of an electric drill or screwdriver. The tool is set to medium speed (with faster rotation, the drill may break, as well as with strong pressure). While drilling a channel, the drill must be regularly cooled with machine oil. If the drilling progress is stuck, the drill must be unscrewed in reverse to remove chips. After this, continue working. During operation, the drill must be kept level at all times so as not to damage the rest of the lock structure. Correctly performed drilling will be confirmed by periodically occurring resistance (5-6 times) when passing through the pins. Drilling depth 4.5-5.0 cm;

- the procedure is repeated alternately with 1.2 mm and then 3.6 mm drills;

- a screwdriver inserted into the keyhole opens the closed lock;

Attention: the cross-shaped cylinder lock, which can be determined by the key, is not flat, but round with 3 or 4 edges; it cannot be opened with a screwdriver. Here you need to lift the stopper with one wire, and use a hook made of another wire to move the bolt. It may not work right away, but after several attempts, the door will open. Practice shows that this will take a maximum of a couple of minutes.

- the cylinder is removed from the lock body;

- a new larva is installed.

Suvaldny castle

There is no cylinder in a lever-type lock, so the matter is complicated by finding the drilling point, which can be located in different places for different types of locks.

To find the correct drilling point, you need to understand the internal structure of the lever lock. Such structures consist of the following elements:

- Crossbar plate. Her job is to move the bolts.

- Level plates. This is the element responsible for secrecy.

- Shank. Applies pressure on the crossbars through levers.

- Leaf springs. They are designed to return the levers to their place. Each lever has its own spring.

- Code slot. Designed to enhance the secrecy of the locking mechanism. Developed individually to fit key grooves.

When working with a lever lock, the main part that you pay attention to is the shank that secures the bolt plate. The shank has a comb and a stand.

When the key enters the lock and turns, it acts on the comb, which, in turn, moves the bolt. The stand is designed to block the crossbar plate, working in conjunction with the levers.

To work you will need the following tools:

- electric drill;

- metal drills, diameter from 6 to 8 mm;

- a piece of rigid metal wire.

Step-by-step instructions on how to drill a lock in an apartment door:

- The first step is to find the location of the shank. To do this, you need to know exactly the lock model. It is better to find instructions or search for information in open sources on the Internet.

- Use an electric drill or a powerful screwdriver to drill a hole in the desired location. The stand should completely collapse.

- A wire is inserted into the core of the lock, with the help of which the bolt plate is pushed away from the inside of the door frame. The door is open.

Once the closed door has been opened, you will have to completely change the internal mechanism of the lock. In some cases, it is also necessary to replace the door trim.

Cylinder lock

Now let’s figure out how to properly drill out a lock cylinder with a cylinder device. In this case, it is also important to understand where the hole should be made so that the lock can be opened.

Consider the design of a cylinder lock. It consists of the following elements:

- frame;

- crossbar;

- larva.

The main element is considered to be the larva - this is the core of the castle. Inside the cylinder there are pins, which, when turning the key, act on the locking bolt (cam), opening or locking the device.

The key, turning in the lock, presses on the cam, which, in turn, pushes the bolt. It turns out that in order to open a locked lock, you need to remove the pin lock, which prevents the cam from turning inside. After drilling the cylinder, the lock can be easily opened with a simple screwdriver.

Cam.

What you will need to work with the cylinder cylinder:

- electric drill (optionally, a powerful screwdriver);

- if you have to drill from the outside of the door, you will most likely need an extension cord;

- metal drills, diameter 0.5 mm, 1.2 mm, 3.6 mm. If you have to drill out the cylinder from the outside, you will have to go through an iron armored plate. In this case, simple metal drills are not enough; you will need to buy drills with pobedit tips;

- mark. Needed to prepare the drilling point. By hitting the core with a hammer on the surface of the larva in the right place, a small dent is obtained, which helps the drill not to go beyond the limits;

- hammer;

- a screwdriver with a thin straight blade;

- machine oil to lower the temperature of the drill.

How to drill out the front door lock cylinder:

- The point for drilling is determined. To find it, you should visually divide the height of the larva into four parts. The lower quarter will be the right place to apply effort. This approach to finding the drilling point is valid for both disk and plate types of locks. If you have to make a hole below the keyhole, you need to use a metal drill with a diameter of 19 mm.

- The drilling point has been found, now it needs to be marked on the surface of the larva. To do this, take a hammer and a core. With a gentle blow, the point is applied to the surface. Now the drill will not slip and damage the outer finish of the door leaf.

- At the first stage of drilling, a drill with a diameter of 0.5 mm is used. To avoid overheating the drill, set the screwdriver or drill to medium speed. It is also important not to use excessive force when drilling, because... thin drills break very quickly when heated and pressed. While working with an electric drill, you need to periodically cool the hot drill in machine oil. It happens that the drill gets stuck inside the larva. In this case, select the reverse mode on a screwdriver or electric drill and twist the drill outward. When drilling, it is important not to deviate the drill, maintaining a right angle in relation to the door leaf. If the master does everything correctly, several dips are felt during drilling, thus the pins go through. Usually it is enough to drill the cylinder to a depth of 50 mm.

- After passing the hole with a 0.5 mm drill, it is alternately expanded with 1.2 mm and 3.6 mm drills.

- If everything is done correctly, push a screwdriver into the hole and turn it. The lock should open. There are locks with cross-shaped cylinder cylinders. They can be identified by the appearance of the key, which has three or four edges. In this case, a screwdriver will not help; you will have to use two wire rods: one to lift the stopper, and the other to press on the bolt. Usually a couple of minutes is enough to get used to the structure of the lock and working with wire.

- After opening the door, the larva is removed.

- A new larva is purchased and installed.

Sometimes, after widening the hole with a 3.6 mm drill, it is not possible to move the cam. If such a problem occurs, you have to continue drilling. Usually a 6.5 mm drill is enough, but in some cases you can use a hollow type drill with a diameter of 19 mm, however, you need to understand that in this case you will have to change the entire lock.

Constipation-type technology

It is recommended to install a lock with a cross-shaped cylinder in interior doors and doors leading to offices, retail or utility rooms, in other words, in those rooms that are additionally protected by more durable doors or alarms.

To open such a lock, you will need to drill a hole just above the keyhole to the pins, and then tighten the lock with an awl or a thin screwdriver. Simultaneously with raising the stopper, the bolt is pulled back using a hook made of thin wire, which will cause the bolt to move inward and open the door.

The cylinder with pins is drilled in a similar way, and then rotated inside using a thin tool, such as a screwdriver.

The keyhole is drilled using a 3 mm drill. To prevent the drill from breaking, it is recommended to place it strictly perpendicular to the borehole hole. If drilling does not help, you will need to make another hole above the hole, and then use a hook to move the bolt.

An overhead lever lock is drilled where the post is attached to the edge of the bolt, usually just above the center of the bore hole. After drilling the rack, the lever lock is opened with a non-original key of a similar type or its blank for a future duplicate. But you should understand that drilling will only help if the product is not equipped with additional protective devices.

Locking mechanisms made of hardened steel or armored with linings are drilled using a heavy-duty carbide-tipped drill. Finding such a drill is problematic; in addition, it is quite expensive, and you will have to work hard to drill it.

Therefore, it is easier to leave this matter to a specialist, whose call will cost approximately the same amount as a heavy-duty metal drill.

Drilling an iron lock

The instructions on how to drill a lock in a lever-type apartment door are very simple and consist of only 3 points:

- The location of the shank strut is determined. It is located in different places in different castles. The instructions will help if the autopsy is carried out from the inside or the Internet if from the outside;

- a channel is drilled, completely destroying the stand;

- Using a hook made of wire (knitting needles), the bolt plate is moved to the back side of the lock body, opening the doors.

Note that, unlike a cylinder lock, here you will have to completely change the locking mechanism and restore the damaged lining of the front door.

Calling a specialist from the emergency service

If you need to quickly open a lock without a key, it is advisable to contact specialized organizations for opening, repairing and installing locks. Masters of such services mainly work around the clock and arrive at the scene of an incident from 20 minutes to 1 hour.

The advantage of contacting the special services is the ability to delicately remove the cylinder and install a new one without damaging the lock, handle, or door leaf. The master already has samples of locking mechanisms with him, and he himself will choose the appropriate one.

As a last resort, you can contact the police or the Ministry of Emergency Situations, but then you cannot count on a delicate approach.

How to avoid door problems

To prevent this from happening, it is worth taking periodic preventive measures:

- Lubricate the part with special oil several times a year;

- To make the mechanism last longer, you should not slam doors;

- Outdoor external locks should be regularly cleaned of debris, dust and dirt that fall inside from wind and rain.

If you were unable to open the door yourself, there is no need to break it. Call customer service and they will help you quickly.

The key is in the lock, but it doesn't work

A key that is stuck or broken off in the hole makes it difficult to break into the lock and replace the cylinder. If part of it protrudes from the cylinder, you can use lubricant to remove it. Inject the product into the well and leave for 20-30 minutes. Next, grab the key or fragment with pliers, slightly loosen it and try to pull it out.

The method works if the broken part can be clamped with a tool. It will also help if the key has not yet turned in the hole. In other cases, you will need to open the mechanism along with the key and replace the lock or cylinder with a new one.

Video description

To see how to replace the front door lock cylinder, see the following video:

It is necessary not only to install the lock cylinder, but to check its functionality. To do this, you need to close the door from the inside, and then open it from the outside. The mechanism should operate smoothly and silently. Any vibrations, noises or difficulties in operation are an indication that the cylinder was not installed correctly or is already faulty. All new mechanisms operate smoothly and without backlash.

The tongue is jammed

The reasons why the tongue inside the lock jams are:

- latch deformation,

- breakdown of spring mechanisms - especially typical for English-type devices;

- violation of the seats of the spring or other elements inside the housing;

- If the tongue is broken (due to impact or slamming) - you will need to disassemble the lock to remove parts.

You can try to solve the problem using a flat and hard object - a plastic card, an aluminum ruler, a knife blade. It must be carefully placed in the gap between the door leaf and the frame and pulled back. This will provide access to the tongue - you need to hook it and press it into the lock, then the door will unlock.

You can also saw the tongue, but this method is labor-intensive and will not work if there is a small gap between the frame and the blade.

If the problem is related to the skewed door leaf, force will be required to align it. You will need a tool that acts as a lever - a screwdriver, a chisel, a wedge. The object must be driven into the problem area, installing the door in its original place. At the same time pull it by the handle to open it.

The handle is loose, the locking mechanism is faulty

During operation, the screws that secure the handle may become loose. Repairing a loose plastic door mechanism is very easy to do yourself. At the base of the handle there is a vertical decorative plate covering the fasteners. We turn it to a horizontal position, pry up the plate, pulling it slightly toward ourselves, and turn the plate to a horizontal position. Access to the fasteners is open, use a Phillips screwdriver to tighten the bolts, and return the trim to its place.

If the handle breaks, we purchase a new one from the window company. The square rod for the fitting groove is standard for all handles; pay attention to the material from which it is made. We unscrew the broken product from the balcony door, insert the square into the fitting groove, and fasten it with bolts.

If the handle is intact, but turns with difficulty, it is necessary to lubricate all moving elements of the fittings.

If the locking mechanism is broken, you need to figure out whether a separate element can be replaced or the entire mechanism needs to be replaced. To more accurately determine the extent of the damage, we call a specialist from a window company.

Aluminum reinforced handles cost 2-3 times more than plastic ones, but they will pay for themselves, since they are almost impossible to break.

Prevention of breakdowns

Preventative measures that prevent the occurrence of malfunctions and guarantee the longevity of the lock include:

- Carrying out maintenance measures - cleaning the lock from dust, dirt, and lubricating it if necessary.

- Regularly planned replacement of the cylinder - after the expiration date stated by the manufacturer, or at the first errors in operation.

- Correct operation of the lock - for example, you can turn the key only when it is completely placed in the hole.

- Do not allow the door leaf to skew, straighten it immediately - even if the locking mechanism is still functioning normally.

- Do not use keys of poor quality, scratched or broken.

- Open the door by the handle, do not pull the key.

- Avoid force (slamming doors, hitting).

The cylinder mechanism is easily repairable and in most cases does not require a complete replacement of the lock. If you have a key, you can install a new cylinder in a few minutes, but it is important that it matches the size of the old one. If the door is locked, drilling will help preserve the lock. If you need to urgently solve a problem, it is recommended to seek help from professionals.

How to select and replace with a new lock core

Based on the sample of the removed lock part, a new one of the same type and size is purchased. It is important that the length, width and diameter match the sample. It is also recommended to pay attention to the location of the rotating tongue on the cylinder mechanism: there are models where the tongue is located in the center or closer to one of the edges of the mechanism. If the larva had a “spinner-key” type of constipation, then it is better to purchase the same one for convenience. It is also worth paying attention to the manufacturer: a lock cylinder from a Chinese door cannot always be replaced with a mechanism from a European manufacturer. Don’t forget about aesthetic perception: the golden core will be dissonant with the silver lock and handle.

If you do not want to leave the house open while purchasing a new core, it is recommended to measure the mechanism and write down all the necessary parameters, and then assemble the lock.

The purchased cylinder is inserted into the lock socket in such a way that the square pin of the handle easily enters and exits through it. After which the cylinder mechanism is fixed at the end with a screw, protective linings and a handle are assembled.

Before slamming the door after replacing the cylinder, check several times how the lock closes and opens with the door open. There should be no extraneous sounds or vibrations when turning the lock, the key should easily enter and exit the hole.