Every person strives to make their home better. One of the options for improving your space is glazing balconies. And glazing balconies with wooden frames is the most environmentally friendly and aesthetic design of the interior of loggias and balconies. By glazing with wooden frames, goals such as the functionality of the balcony area, protecting the apartment from outside noise, preventing the penetration of cold air into the room, insects, and so on are achieved.

Of course, glazing a loggia or balcony with modern PVC windows is the most acceptable for most consumers, but some still choose a natural product - wooden frames, for a number of reasons.

Wooden balcony glazing is an excellent alternative to aluminum and metal-plastic windows. From the moment PVC windows came into fashion and everyone turned to this type of glazing, wooden frames were immediately forgotten. Today, construction markets offer excellent quality windows with wooden frames, which are not inferior in quality and functionality to aluminum and plastic windows.

We also recommend that you familiarize yourself with the material - wooden windows with double-glazed windows.

Balcony wooden frames - pros and cons, selection, production and repair

If the idea of glazing a balcony came up and, as a result of your choice, you decided to install wooden frames on it, then only because of their low cost and inexpensive installation. Therefore, today the article will be devoted to precisely this design, which is still considered the most popular among consumers. Our task is to find out the features of wooden balcony glazing, understand its pros and cons, and find out how to choose and install the material correctly.

Frames on the balcony can be double or single glass

It should be said that today the price of wooden frames made using metal-plastic technology is higher, so not everyone can afford them, preferring cheaper designs. The article will talk about two types of products, one of which can be made exclusively in a factory, but the second one is at home on a carpentry machine.

Selection of wood material

Since a wooden window can only be made from dry or laminated wood (laminated veneer lumber), these materials are chosen for the manufacture of window frames.

It is better to make a window frame from oak, larch or pine. If you compare wood with each other, then oak has a high cost. It is quite possible to make windows from wood with your own hands, efficiently and inexpensively; for this you need to choose the right material.

- Glued laminated timber. This is a lightweight and durable material that does not deform and has moisture-resistant properties. It acquired such characteristics due to its multi-layer nature and maximum drying. This material is the most suitable for making wooden windows. In this case, the most rational size of the timber is 5x5 cm.

- Solid timber. Sometimes the material has cracks and knots, so when purchasing it, it is carefully inspected for their presence. In addition, the board can be moved and it will change its shape. There is also a danger that during operation the frame may crack. Despite its shortcomings, solid timber is good value for money.

- Plywood sheets. This is the cheapest material of poor quality. Plywood tends to quickly absorb moisture and collapse. Therefore, the material is used only for those windows that are planned to be installed indoors.

What do manufacturers offer?

Consumers can choose:

| Traditional carpentry |

|

Products must be protected from the negative effects of the atmosphere. But before you coat the wooden frames on the balcony with an antiseptic, you should remove possible mold and mildew from them.

In the photo - the side part of the lower balcony glazing has movable sashes

Purpose

The design of balcony frames is developed without taking into account the protection of the room from penetration; it has a completely different task:

- Let in as much light as possible so that in the room behind the balcony there is no need to turn on the lighting during the day.

- Allow ventilation, for which often the side frames, and not just the front ones, have doors that can open to a certain angle or completely. The first option is usually found in products made using plastic window technology.

- It is good to protect the balcony from rain and snow.

The upper part of the balcony frame usually does not open

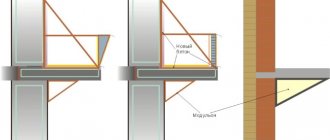

The design can be schematically represented as follows, although everyone is free to choose their own options:

- the upper third of a wooden balcony frame is usually solid;

- the lower part consists of fixed and movable doors installed in turn;

- the height usually coincides with the balcony opening;

- width – with the width of the balcony or loggia.

Tip: if the length of the loggia is 4-6 m, this will allow you to sequentially install several standard frames 2 m wide.

Installation of wooden Euro-windows on a balcony - in this case there is no blind part at the top

Product characteristics

The advantages include:

- the environmental friendliness of the material, there will be no harm from its operation;

- The products have a long service life, although traditional carpentry will have to be tidied up from time to time. At the same time, they guarantee that with proper installation and operation, their products can last for almost half a century without repair;

- the material is easy to process even not on a professional machine;

- a wooden window can be painted in any color or varnished;

- wood allows you to create a cozy interior in the room.

Advice: it is not difficult to install glass in carpentry yourself, which will save on the work of a craftsman.

- Over time, the material dries out;

- often wooden frames increase in size due to humidity;

- Almost every year, ordinary woodwork has to be varnished or painted.

The height and width of the balcony frame corresponds to the light opening on the balcony or loggia

How to choose

You can invite your friend who knows about carpentry to the store or market, or use the tips below:

- The first step is to pay attention to the type of wood from which the frame is made. The best option is larch, oak, pine, but this is a last resort. They almost do not rot due to their structure and have sufficient strength.

Advice: you should not purchase products made from spruce, fir, hornbeam or beech.

- The frames must already be treated with an antiseptic.

- The optimal size of a wooden block for the product is 45 by 45 mm.

Ventilation is carried out only from the front of the balcony

If you decide to use a “Eurowindow”:

- Take it seriously, otherwise you'll just be wasting your money. The structure will not be able to last for the stated period if it is defective.

- The product must initially be coated with a special substance that will protect it from crumbling and losing its shape.

- It is best when the frame is made of larch, ash or oak.

- Pay attention to the appearance of the product.

Requirements for wood glazing

It doesn’t matter what material the glazing frames are made of, all work is carried out using the same scheme. True, there are certain differences.

When installing, you must adhere to the following rules:

Important! The use of wedges and spacers is not permitted.

In the economical version, the folding mode of the frames is not provided. In this case, the windows are opened using the usual turning method. The biggest disadvantage of using a wooden frame is the fragility of the structure and its significant weight. Sometimes for this reason it is simply impossible to install a modern double-glazed window.

If you install a double frame containing simple glass, it is unlikely that you will be able to achieve complete tightness, avoiding the penetration of cold air and noise. If someone decides to purchase factory-made frames, then this requires a meaningful and competent approach.

Euro-windows have virtually no disadvantages. But such constructive models are very expensive. Many users simply cannot afford such pleasure.

Modern wooden structures are produced using professional equipment by experienced specialists. This circumstance allows us to say that such products will be made with the highest quality. Mostly coniferous trees are used for production. They have sufficient strength, are easy to process and are little susceptible to decay. They are also resistant to fungal attack.

To extend their service life, wooden frames are impregnated with special compounds. This must be done without fail. Without this, their useful life is significantly reduced. Over time, they will begin to rot and lose their presentable appearance. After all, the frame from the outside will be in constant contact with unfavorable environmental factors.

The use of modern antiseptics allows you to protect the tree from putrefactive processes. Regular treatment of frames with protective compounds allows them to be used without problems for 10 years. You can often observe a longer service life.

When glazing a loggia with wooden frames, transoms can be installed. Solid sashes can be installed along the entire height of the frame. Glass with a thickness of 4 mm is inserted into the structure.

How to make a wooden frame yourself

Prepare a tool - a chisel, hammer, hand saw, electric router or carpentry machine.

The instructions involve several steps:

- Make a box - take a board with a section of 50x150 mm and make a groove in it. This is necessary for the tightness of the future structure.

- Saw the boards according to the calculated dimensions and connect them together with a tongue-and-groove system. Make grooves on the vertical parts, tenons on the horizontal ones.

- Lubricate them with wood glue and connect them with a metal square at 90°, checking the accuracy.

- Take window angles and strengthen the ends of the frame with them so that it becomes rigid. You can buy them at the market or at a hardware store.

- After the glue has dried, begin making a frame for the movable part of the product. Take a beam of smaller cross-section than the main box; you should have a gap of 1-2 mm with it.

- Make a moving part, where you also use a tongue-and-groove connection.

- Attach the inside to the window frame with hinges, and then install the glass, securing it with glazing beads.

Advice: before you decide to make a wooden frame for your balcony with your own hands, we recommend practicing on less complex and critical structures.

Installation of double-glazed windows

Gaskets must be placed in the lower and side internal parts of the frame installed in the opening. It is necessary to lay it so that the weight of the glass unit is evenly distributed over the frame. One of the edges of the gasket should extend slightly beyond the boundaries of the frame, so that after hammering in the bead, cracks do not form on the glass. After this, take two suction cups, press them to the surface of the glass and carefully place it in the window frame. At the end, the glazing beads are hammered in with a wooden mallet, and at this point, do-it-yourself glazing can be considered complete.

To fix the glass unit in the frame, you need to hammer in the glazing beads using a mallet

Installing frames and glass is a rather complex process that requires experience and certain skills, so if you are not completely confident in your abilities, it is better to immediately call specialists.

How to repair a wooden balcony frame

Even if they are dried out in places, but not rotten and strong frames can be restored, the main thing is that their internal structure is not damaged. Before starting restoration, the old paint must be removed from the product.

For this use:

- Various washing solutions will dissolve it, after which it can be easily removed from the wood. The disadvantage is that everything around is dirty, and then the frame will have to dry for a long time.

- A sharp scraper or spatula that is used to simply scrape off paint. Disadvantage: the main structure can be damaged.

- A construction hairdryer that heats it up. We recommend using the latter in combination with a grinding machine or spatula. Even if something remains on the surface, it will become a protective layer for fungus and mold. Prepare a solvent and rags for work so that you can quickly remove paint from wood and tools.

Tip: do not use a gas can with a nozzle to remove old paint, it is dangerous.

Repair of wooden frames on the balcony must be carried out periodically

Preparing the frame for painting

- Take sandpaper and go over the product again. To make the work easier and faster, you can use a grinder.

- Carefully inspect the surface; it may have defects, in particular chips and cracks. If found, seal them with wood putty using a spatula, and after it dries, clean the area with emery cloth.

Advice: you should not apply putty in a thick layer at once; it is better to cover the defect layer by layer, allowing the previous one to dry.

- Install the glass and secure it with glazing beads, seal the cracks with window putty between them and the glass. Alternatively, use a construction gun with a silicone balloon.

- New frames from which the paint has been removed can be thoroughly cleaned down to the wood and varnished. Do not forget to first coat the window with special impregnations against rot, and a layer of primer will give the product the selected shade.

Tip: use varnish for exterior work, and use oil paints for old frames.

Option 1 - installing glass yourself - (old type windows)

A more economical option, in which you do not need to buy a ready-made double-glazed window, is slightly inferior in terms of heat and sound insulation.

To install glass in a window frame, you need to prepare the necessary tools and materials. Glass is a sharp material, and to avoid cutting yourself, protective gloves are used during the work. Tools and materials you will need:

Before you start cutting glass, you need to decide on the required dimensions. Using a tape measure, measure the distance between the grooves on the frame. Since wood tends to shrink and expand during temperature changes, the glass is cut 4 mm smaller than the resulting numbers. Otherwise, it may burst when compressed. Glass cutting and installation process:

- The material is placed on a table or other horizontal surface.

- Cover with a cloth and mark according to the sizes.

- First, make a cut from the short side of the glass, then from the long side.

- A ruler is applied to the marks, along which one cut is made with a glass cutter.

- The glass is placed in a cut line on the edge of the table and gently pressed onto it. It will break into two parts.

- Small sections of glass (from 0.5 to 0.20 cm) are bitten off with pliers.

To avoid cutting glass yourself, you can contact a special glass cutting service. Silicone sealant is applied to the edge of the frame, then the glass is inserted. Glazing beads are mounted on top and secured with nails.

How to glaze a balcony with wooden frames

Every person strives to make their home better. One of the options for improving your space is glazing balconies. And glazing balconies with wooden frames is the most environmentally friendly and aesthetic design of the interior of loggias and balconies. By glazing with wooden frames, goals such as the functionality of the balcony area, protecting the apartment from outside noise, preventing the penetration of cold air into the room, insects, and so on are achieved.

Of course, glazing a loggia or balcony with modern PVC windows is the most acceptable for most consumers, but some still choose a natural product - wooden frames, for a number of reasons.

Wooden balcony glazing is an excellent alternative to aluminum and metal-plastic windows. From the moment PVC windows came into fashion and everyone turned to this type of glazing, wooden frames were immediately forgotten. Today, construction markets offer excellent quality windows with wooden frames, which are not inferior in quality and functionality to aluminum and plastic windows.

Option 2 - install a ready-made double-glazed window - (windows of a new type)

You can buy double-glazed windows without a frame from manufacturers or window companies, although the choice of sizes is limited, so take this into account at the stage of drawing up window drawings.

To secure a finished double-glazed window into a wooden frame, a colorless sealant is required. It will be invisible and will not spoil the appearance of the window.

After the window is ready, it is installed in the window opening. This is not difficult to do, but during installation you need to take into account the type of opening and the material from which the house is built. Rules for installing Euro-windows in a brick and concrete room:

- The opening into which the glass unit is installed must be smooth and clean. Using a level, the geometry of the opening is checked, all uneven places are leveled.

- A double-glazed window made of wood is installed in the opening and secured with self-tapping screws. Fastenings are made at a distance of 70-80 cm from each other. Do not use foam or nails for fixation.

- If gaps appear between the double-glazed window and the frame, the window will lose its characteristics. To prevent this from happening, the window is treated with a sealant during installation.

- All cracks and holes are sealed with polyurethane foam. It will protect the room from dust, dirt and the penetration of cold air inside.

- When the foam hardens, it is cut with a knife. The outside of the replaced area is sealed with tape, and cashing is installed on top. This is to protect it from destruction.

To ensure high performance properties, windows are insulated using Swedish technology. The method got its name thanks to the EuroStrip material, which was chosen by the Swedes. In terms of heat saving, groove insulation of wooden windows is not inferior to PVC insulation packages. The manufacturer produces 3 types of seals: silicone and rubber, as well as thermoplastic elastomer.

Pros and cons of wooden frames

Innovative technologies have not passed by and wooden structures. The products are made from high-quality wood and models are presented treated with antifungal and fire-resistant compounds, and in their functional features the products are not inferior to aluminum and plastic windows. The frames have rubber gaskets that guarantee a complete fit, as well as rotating mechanisms that allow you to easily open the windows for ventilation.

Do-it-yourself balcony glazing with wooden frames

The use of paint and varnish coatings allows you to preserve the pristine beauty of wooden frames for a long time, protecting them from moisture and drying out. However, wood glazing is not cheap; moreover, it can be several times more expensive than installing metal-plastic windows. However, wooden window frames are the most environmentally friendly option.

Advantages of wooden glazing:

- natural material that does not emit harmful chemical fumes when exposed to sunlight;

- high quality workmanship allows wooden frames to last for at least 50 years;

- wooden frames lend themselves perfectly to processing;

- they can be painted with paint and varnish, thereby maintaining the products in proper form;

- creates unique comfort and coziness in the interior.

It is worth noting that glazing with wooden frames is also carried out using the ancient, so-called “handicraft” manufacturing option. But their independent installation presupposes the presence of special skills, abilities, and knowledge that allow high-quality manufacturing work to be carried out. Therefore, it is better to entrust production to professionals. However, sometimes it is possible to make windows from wood yourself. But as for installing frames, anyone can do this.

Keep in mind that wood glazing differs from factory-made window units, but they are not without their drawbacks.

High-quality glazing with wooden frames

Cons of glazing:

As for the disadvantages of wooden glazing, this is, first of all, drying or swelling of frames, depending on climatic conditions, wood needs annual maintenance, namely painting or varnishing, and wooden frames can warp over time.

To reduce all defects to a minimum, only thoroughly dried wood is used in the manufacturing process. During operation, wooden frames must be carefully processed and painted, especially on the street side, where the frames are exposed to climatic conditions.

Preparing the balcony for glazing

First you need to figure out that the base on which the wooden box is supposed to be installed will withstand the load. If the balcony has metal fences, it is better to get rid of them and install the parapet by laying out foam blocks on the parapet. Carrying out such types of work will make it an excellent support for the frame itself, and will also have an additional function - insulation.

If you have a balcony railing, you need to carefully examine it, preferably digest it, setting everything to the same level. A supporting wooden beam is attached to the metal corner, on which the frames will subsequently be installed. Spacers are installed from profiles under the timber; other auxiliary materials can be used; they can ensure a rigid position of the structure.

Also, the balcony slab should be strengthened so that it can withstand the load, and potholes and cracks should be sealed using mortar or an adhesive mixture.

Carrying out installation work

Before performing installation work, the sashes are removed from the frames. This measure will help you avoid troubles associated with accidentally breaking glass during installation. If the design involves blind windows, then the glass should be removed. When the installation work is completed, they are placed in their original place.

Frame installation

It is necessary to secure anchor plates along the entire perimeter of the frame. The pitch is 0.7 m. Installation of the wooden box is carried out using a building level. In this case, it is necessary to check the installation in the horizontal and vertical directions. If the sashes are skewed, they will not fit tightly. The window simply won't close. No wedges or spacers should be used during installation.

There are holes on the anchor plates. Through them, a recess is made in the concrete base for the dowel. To do this, use a hammer drill. An anchor is screwed to the dowel. Using the same scheme, the frame is attached to the lower base, joints in the wall, and ceiling.

You can attach the frame without plates. To do this, a hole is made in it. Fasteners are inserted into it, with the help of which they are fixed to the base. Before installation, locations for holes are marked on the frame.

Work at the finishing stage

When the frame is installed, the windows need to be insulated. All seams must be sealed with foam. After it hardens, the excess must be cut off with a knife. After this, putty work is carried out. Places where foam sealing is performed should not be left open for a long time. This is due to the fact that when the foam is exposed to direct sunlight, it is destroyed and loses its sealant properties.

After the foam has dried, the frame is installed in a permanent place. All seams are treated with silicone followed by installation of glazing beads. At this point, the work on glazing the balcony using wooden frames can be considered complete.